RU2648124C1 - Ceramic mixture for production of finish tiles and glazed tiles - Google Patents

Ceramic mixture for production of finish tiles and glazed tiles Download PDFInfo

- Publication number

- RU2648124C1 RU2648124C1 RU2017110343A RU2017110343A RU2648124C1 RU 2648124 C1 RU2648124 C1 RU 2648124C1 RU 2017110343 A RU2017110343 A RU 2017110343A RU 2017110343 A RU2017110343 A RU 2017110343A RU 2648124 C1 RU2648124 C1 RU 2648124C1

- Authority

- RU

- Russia

- Prior art keywords

- tiles

- ceramic

- production

- finish

- clay

- Prior art date

Links

- 239000000919 ceramic Substances 0.000 title claims abstract description 19

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 7

- 239000000203 mixture Substances 0.000 title abstract description 7

- 239000012141 concentrate Substances 0.000 claims abstract description 7

- 239000010434 nepheline Substances 0.000 claims abstract description 7

- 229910052664 nepheline Inorganic materials 0.000 claims abstract description 7

- 239000010451 perlite Substances 0.000 claims abstract description 7

- 235000019362 perlite Nutrition 0.000 claims abstract description 7

- 239000004927 clay Substances 0.000 claims description 12

- 239000010458 rotten stone Substances 0.000 claims description 6

- 239000002994 raw material Substances 0.000 claims description 5

- -1 chalk Substances 0.000 claims description 3

- 239000000126 substance Substances 0.000 abstract description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 abstract 1

- 238000010276 construction Methods 0.000 abstract 1

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 abstract 1

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229910010413 TiO 2 Inorganic materials 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/04—Clay; Kaolin

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/13—Compounding ingredients

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/13—Compounding ingredients

- C04B33/132—Waste materials; Refuse; Residues

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P40/00—Technologies relating to the processing of minerals

- Y02P40/60—Production of ceramic materials or ceramic elements, e.g. substitution of clay or shale by alternative raw materials, e.g. ashes

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Dispersion Chemistry (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Organic Chemistry (AREA)

- Environmental & Geological Engineering (AREA)

- Compositions Of Oxide Ceramics (AREA)

Abstract

Description

Изобретение относится к составам керамических масс, которые могут быть использованы в производстве облицовочной плитки, изразцов.The invention relates to compositions of ceramic masses that can be used in the manufacture of tiles, tiles.

Известна керамическая масса, включающая, мас. %: глинистое сырье 15,0-35,0; керамический бой 2,0-5,0; нефелиновый концентрат 15,0-20,0; перлит 15,0-20,0; мел 5,0-10,0; трепел 40,0-45,0 [1].Known ceramic mass, including, by weight. %: clay raw materials 15.0-35.0; ceramic battle 2.0-5.0; nepheline concentrate 15.0-20.0; perlite 15.0-20.0; chalk 5.0-10.0; Tripoli 40.0-45.0 [1].

Задача изобретения состоит в повышении термостойкости изделий, полученных из керамической массы.The objective of the invention is to increase the heat resistance of products obtained from ceramic mass.

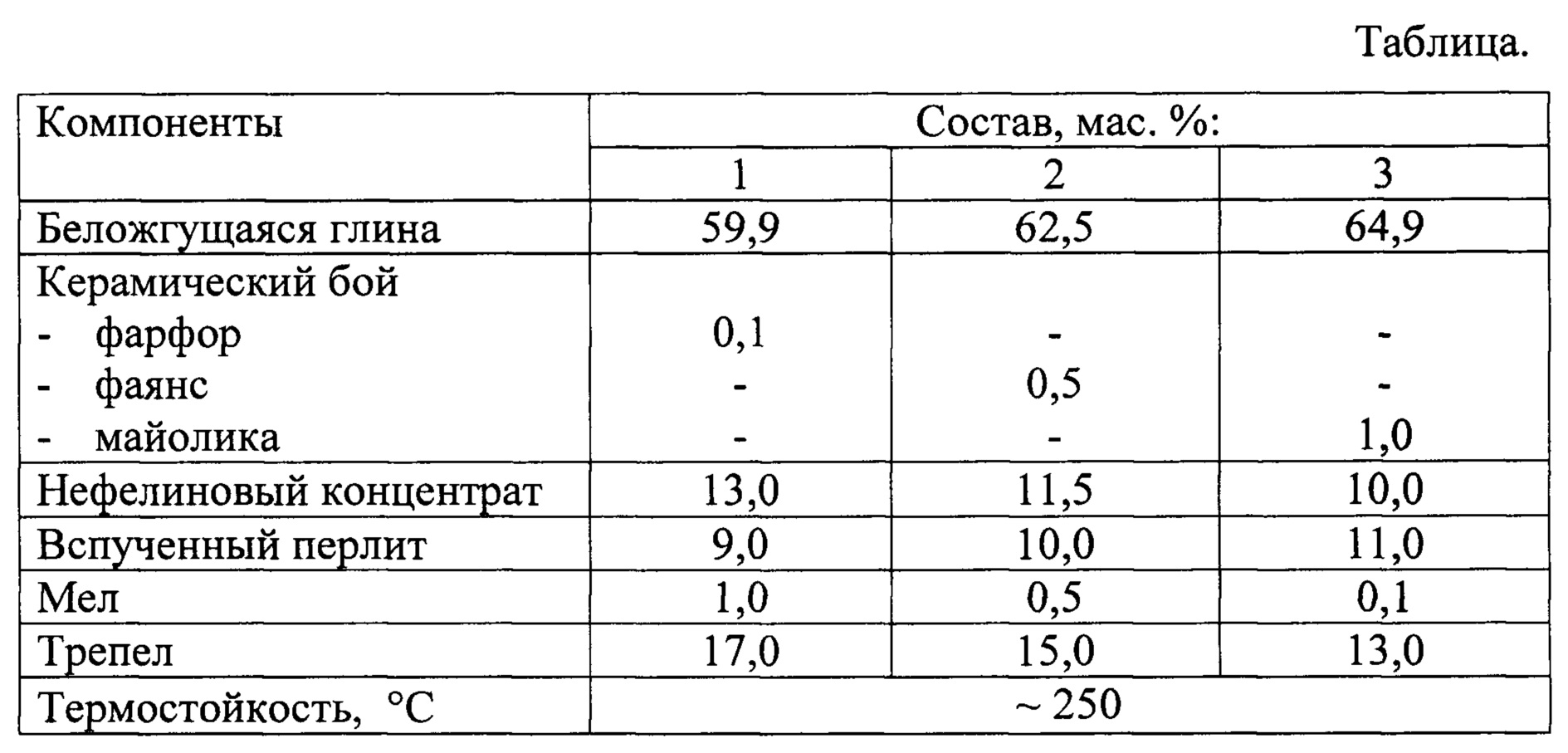

Технический результат достигается тем, что керамическая масса для изготовления облицовочной плитки, изразцов, включающая глинистое сырье, керамический бой, нефелиновый концентрат, вспученный перлит, мел, трепел, в качестве глинистого сырья содержит беложгущуюся глину, причем компоненты находятся при следующем соотношении, мас. %: беложгущаяся глина 59,9-64,9; керамический бой 0,1-1,0; нефелиновый концентрат 10,0-13,0; вспученный перлит 9,0-11,0; мел 0,1-1,0; трепел 13,0-17,0. В таблице приведены составы керамической массы для изготовления облицовочной плитки, изразцов.The technical result is achieved by the fact that the ceramic mass for the manufacture of facing tiles, tiles, including clay raw materials, ceramic bout, nepheline concentrate, expanded perlite, chalk, tripoli, as clay raw materials contains white clay, and the components are in the following ratio, wt. %: white-burning clay 59.9-64.9; ceramic battle 0.1-1.0; nepheline concentrate 10.0-13.0; expanded perlite 9.0-11.0; chalk 0.1-1.0; Tripoli 13.0-17.0. The table shows the compositions of the ceramic mass for the manufacture of tiles, tiles.

Для приготовления керамической массы используют любые качественные беложгущиеся глины, например глину Веселовского месторождения, характеризующуюся следующим химическим составом, мас. %: SiO2 47,6-55,5; TiO2 0,9-1,4; Al2O3 28,0-35,5; Fe2O3 0,6-0,9; CaO 0,6-1,5; MgO 0,2-0,7; K2O 1,7-2,3; Na2O 0,4-0,6; п.п.п. 8,5-10,1.To prepare the ceramic mass, any high-quality white-burning clay is used, for example, clay of the Veselovskoye deposit, characterized by the following chemical composition, wt. %: SiO 2 47.6-55.5; TiO 2 0.9-1.4; Al 2 O 3 28.0-35.5; Fe 2 O 3 0.6-0.9; CaO 0.6-1.5; MgO 0.2-0.7; K 2 O 1.7-2.3; Na 2 O, 0.4-0.6; p.p.p. 8.5-10.1.

Компоненты дозируют в требуемых количествах. Керамический бой, нефелиновый концентрат, вспученный перлит, мел, трепел по отдельности размалывают до порошкообразного состояния (остаток на сите №008 не более 10%), смешивают с беложгущейся глиной и готовят керамическую массу с влажностью 20-26%, из которой пластическим способом формуют облицовочные плитки или изразцы. Изделия сушат до влажности 1-6% и при температуре 1130-1180°С проводят обжиг. Поверхность обожженных изделий покрывают слоем цветной глазури и при температуре 900-930°С проводят второй обжиг. Возможно последующее декорирование поверхности изделий термостойкими керамическими красками.The components are dosed in the required amounts. Ceramic fight, nepheline concentrate, expanded perlite, chalk, tripoli separately grind to a powdery state (residue on sieve No. 008 no more than 10%), mixed with white clay and prepare a ceramic mass with a moisture content of 20-26%, from which they are molded in a plastic way facing tiles or tiles. Products are dried to a moisture content of 1-6% and fired at a temperature of 1130-1180 ° C. The surface of the calcined products is covered with a layer of colored glaze and a second firing is carried out at a temperature of 900-930 ° C. Subsequent decorating of the product surface with heat-resistant ceramic paints is possible.

Источники информацииInformation sources

1. SU 937416, 1982.1. SU 937416, 1982.

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2017110343A RU2648124C1 (en) | 2017-03-28 | 2017-03-28 | Ceramic mixture for production of finish tiles and glazed tiles |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2017110343A RU2648124C1 (en) | 2017-03-28 | 2017-03-28 | Ceramic mixture for production of finish tiles and glazed tiles |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| RU2648124C1 true RU2648124C1 (en) | 2018-03-22 |

Family

ID=61708090

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2017110343A RU2648124C1 (en) | 2017-03-28 | 2017-03-28 | Ceramic mixture for production of finish tiles and glazed tiles |

Country Status (1)

| Country | Link |

|---|---|

| RU (1) | RU2648124C1 (en) |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU937416A1 (en) * | 1980-11-14 | 1982-06-23 | Государственный научно-исследовательский институт строительной керамики | Ceramic composition for making tiles |

| SU1071601A1 (en) * | 1982-06-17 | 1984-02-07 | Государственный научно-исследовательский институт строительной керамики | Batch for making ceramic tiles with accelerated roasting |

| US20070149383A1 (en) * | 2005-12-28 | 2007-06-28 | Caroma Insdustries Limited | Ceramic material, compositions and methods for manufacture thereof |

| RU2331608C2 (en) * | 2006-10-09 | 2008-08-20 | Юлия Алексеевна Щепочкина | Ceramic mixture for facing tile manufacturing |

| RU2474549C1 (en) * | 2011-10-24 | 2013-02-10 | Юлия Алексеевна Щепочкина | Ceramic mixture for facing tile fabrication |

| RU2480431C1 (en) * | 2011-09-30 | 2013-04-27 | Юлия Алексеевна Щепочкина | Ceramic mixture for making facing tiles |

| RU2562078C1 (en) * | 2014-10-21 | 2015-09-10 | Юлия Алексеевна Щепочкина | Ceramic mixture for facing tile manufacture |

-

2017

- 2017-03-28 RU RU2017110343A patent/RU2648124C1/en active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU937416A1 (en) * | 1980-11-14 | 1982-06-23 | Государственный научно-исследовательский институт строительной керамики | Ceramic composition for making tiles |

| SU1071601A1 (en) * | 1982-06-17 | 1984-02-07 | Государственный научно-исследовательский институт строительной керамики | Batch for making ceramic tiles with accelerated roasting |

| US20070149383A1 (en) * | 2005-12-28 | 2007-06-28 | Caroma Insdustries Limited | Ceramic material, compositions and methods for manufacture thereof |

| RU2331608C2 (en) * | 2006-10-09 | 2008-08-20 | Юлия Алексеевна Щепочкина | Ceramic mixture for facing tile manufacturing |

| RU2480431C1 (en) * | 2011-09-30 | 2013-04-27 | Юлия Алексеевна Щепочкина | Ceramic mixture for making facing tiles |

| RU2474549C1 (en) * | 2011-10-24 | 2013-02-10 | Юлия Алексеевна Щепочкина | Ceramic mixture for facing tile fabrication |

| RU2562078C1 (en) * | 2014-10-21 | 2015-09-10 | Юлия Алексеевна Щепочкина | Ceramic mixture for facing tile manufacture |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2467979C1 (en) | Ceramic mixture for making facing tiles | |

| RU2420482C1 (en) | Ceramic mixture for making glased tiles | |

| RU2562078C1 (en) | Ceramic mixture for facing tile manufacture | |

| RU2648124C1 (en) | Ceramic mixture for production of finish tiles and glazed tiles | |

| RU2394787C1 (en) | Ceramic mixture | |

| RU2474549C1 (en) | Ceramic mixture for facing tile fabrication | |

| RU2590159C1 (en) | Ceramic mixture for making facing tiles | |

| RU2555960C1 (en) | Ceramic mass for manufacturing ceramic tiles | |

| RU2620518C1 (en) | Ceramic mixture for making facing tiles and dutch tiles | |

| RU2466957C1 (en) | Ceramic mixture for glazed tile fabrication | |

| RU2646081C1 (en) | Ceramic mixture for making facing tiles | |

| RU2539071C1 (en) | Ceramic mixture for brick manufacture | |

| RU2563849C1 (en) | Ceramic mixture | |

| RU2536695C1 (en) | Ceramic mass | |

| RU2410353C1 (en) | Ceramic mass | |

| RU2481311C1 (en) | Ceramic mixture for making glazed tiles | |

| RU2658949C1 (en) | Ceramic mixture for making glazed tiles | |

| RU2500646C1 (en) | Ceramic mass for facing tile manufacturing | |

| RU2420481C1 (en) | Ceramic mixture for making glased tiles | |

| RU2532510C1 (en) | Ceramic mixture | |

| RU2516777C1 (en) | Ceramic mass | |

| RU2652009C1 (en) | Ceramic mixture | |

| RU2494072C1 (en) | Ceramic mixture for making facing tile | |

| RU2492154C1 (en) | Ceramic mixture for making facing tile | |

| RU2487847C1 (en) | Crude mixture for making facing tile |