RU2350684C2 - Способ получения плоской заготовки из циркониевого сплава, полученная этим способом плоская заготовка и элемент тепловыделяющей сборки ядерного реактора аэс, изготовленный из плоской заготовки - Google Patents

Способ получения плоской заготовки из циркониевого сплава, полученная этим способом плоская заготовка и элемент тепловыделяющей сборки ядерного реактора аэс, изготовленный из плоской заготовки Download PDFInfo

- Publication number

- RU2350684C2 RU2350684C2 RU2006106222/02A RU2006106222A RU2350684C2 RU 2350684 C2 RU2350684 C2 RU 2350684C2 RU 2006106222/02 A RU2006106222/02 A RU 2006106222/02A RU 2006106222 A RU2006106222 A RU 2006106222A RU 2350684 C2 RU2350684 C2 RU 2350684C2

- Authority

- RU

- Russia

- Prior art keywords

- region

- fuel assembly

- plate workpiece

- zirconium alloy

- quenching

- Prior art date

Links

- 229910001093 Zr alloy Inorganic materials 0.000 title claims abstract description 26

- 238000000034 method Methods 0.000 title claims abstract description 26

- 239000000446 fuel Substances 0.000 title claims abstract description 13

- 238000001816 cooling Methods 0.000 claims abstract description 20

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 19

- 238000005096 rolling process Methods 0.000 claims abstract description 15

- 238000009835 boiling Methods 0.000 claims abstract description 12

- 230000009467 reduction Effects 0.000 claims abstract description 12

- 229910052726 zirconium Inorganic materials 0.000 claims abstract description 6

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 claims abstract description 5

- 238000000137 annealing Methods 0.000 claims description 51

- 238000010791 quenching Methods 0.000 claims description 33

- 230000000171 quenching effect Effects 0.000 claims description 33

- 230000006835 compression Effects 0.000 claims description 26

- 238000007906 compression Methods 0.000 claims description 26

- 238000005275 alloying Methods 0.000 claims description 13

- 239000012535 impurity Substances 0.000 claims description 9

- 238000007493 shaping process Methods 0.000 claims description 6

- 239000000155 melt Substances 0.000 claims description 2

- 238000004519 manufacturing process Methods 0.000 abstract description 14

- 230000000694 effects Effects 0.000 abstract description 4

- 230000008569 process Effects 0.000 abstract description 3

- 238000005272 metallurgy Methods 0.000 abstract 1

- 239000000126 substance Substances 0.000 abstract 1

- 238000005496 tempering Methods 0.000 abstract 1

- 238000005097 cold rolling Methods 0.000 description 42

- 239000000523 sample Substances 0.000 description 22

- 229910045601 alloy Inorganic materials 0.000 description 16

- 239000000956 alloy Substances 0.000 description 16

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 15

- 238000010438 heat treatment Methods 0.000 description 11

- 239000000203 mixture Substances 0.000 description 9

- PXHVJJICTQNCMI-UHFFFAOYSA-N nickel Substances [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 9

- 229910052742 iron Inorganic materials 0.000 description 6

- 238000005452 bending Methods 0.000 description 5

- 239000013068 control sample Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 238000010583 slow cooling Methods 0.000 description 5

- 229910052718 tin Inorganic materials 0.000 description 5

- 239000012300 argon atmosphere Substances 0.000 description 4

- 239000013078 crystal Substances 0.000 description 4

- 229910052758 niobium Inorganic materials 0.000 description 4

- 238000001953 recrystallisation Methods 0.000 description 4

- 230000009471 action Effects 0.000 description 3

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 229910052804 chromium Inorganic materials 0.000 description 3

- 230000007797 corrosion Effects 0.000 description 3

- 238000005260 corrosion Methods 0.000 description 3

- 230000006378 damage Effects 0.000 description 3

- 238000005098 hot rolling Methods 0.000 description 3

- 229910052759 nickel Inorganic materials 0.000 description 3

- 230000003068 static effect Effects 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 238000005242 forging Methods 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 150000003839 salts Chemical class 0.000 description 2

- 238000009941 weaving Methods 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 238000003723 Smelting Methods 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000011651 chromium Substances 0.000 description 1

- 230000001010 compromised effect Effects 0.000 description 1

- 230000008094 contradictory effect Effects 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000008034 disappearance Effects 0.000 description 1

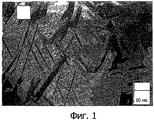

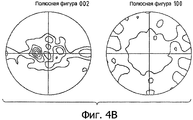

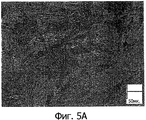

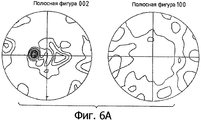

- 238000001000 micrograph Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000010955 niobium Substances 0.000 description 1

- 239000003758 nuclear fuel Substances 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000011135 tin Substances 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

- 150000003754 zirconium Chemical class 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C16/00—Alloys based on zirconium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B3/00—Rolling materials of special alloys so far as the composition of the alloy requires or permits special rolling methods or sequences ; Rolling of aluminium, copper, zinc or other non-ferrous metals

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/16—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of other metals or alloys based thereon

- C22F1/18—High-melting or refractory metals or alloys based thereon

- C22F1/186—High-melting or refractory metals or alloys based thereon of zirconium or alloys based thereon

-

- G—PHYSICS

- G21—NUCLEAR PHYSICS; NUCLEAR ENGINEERING

- G21C—NUCLEAR REACTORS

- G21C21/00—Apparatus or processes specially adapted to the manufacture of reactors or parts thereof

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E30/00—Energy generation of nuclear origin

- Y02E30/30—Nuclear fission reactors

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Crystallography & Structural Chemistry (AREA)

- Thermal Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Plasma & Fusion (AREA)

- General Engineering & Computer Science (AREA)

- High Energy & Nuclear Physics (AREA)

- Heat Treatment Of Sheet Steel (AREA)

- Metal Rolling (AREA)

- Heat Treatment Of Steel (AREA)

- Monitoring And Testing Of Nuclear Reactors (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0309474A FR2858332B1 (fr) | 2003-07-31 | 2003-07-31 | Procede de fabrication d'un produit plat en alliage de zirconium, produit plat ainsi obtenu et element d'un assemblage combustible pour reacteur de centrale nucleaire realise a partir de ce produit plat |

| FR0309474 | 2003-07-31 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2006106222A RU2006106222A (ru) | 2006-07-10 |

| RU2350684C2 true RU2350684C2 (ru) | 2009-03-27 |

Family

ID=34043714

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2006106222/02A RU2350684C2 (ru) | 2003-07-31 | 2004-07-20 | Способ получения плоской заготовки из циркониевого сплава, полученная этим способом плоская заготовка и элемент тепловыделяющей сборки ядерного реактора аэс, изготовленный из плоской заготовки |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US7630470B2 (enExample) |

| EP (1) | EP1649073B1 (enExample) |

| JP (1) | JP5646800B2 (enExample) |

| KR (1) | KR20060052939A (enExample) |

| CN (1) | CN100451159C (enExample) |

| CA (1) | CA2533172C (enExample) |

| FR (1) | FR2858332B1 (enExample) |

| RU (1) | RU2350684C2 (enExample) |

| WO (1) | WO2005021818A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2849865B1 (fr) * | 2003-01-13 | 2006-01-21 | Cezus Co Europ Zirconium | Procede de fabrication d'un demi-produit en alliage de zirconium pour l'elaboration d'un produit plat et utilisation |

| US9284629B2 (en) | 2004-03-23 | 2016-03-15 | Westinghouse Electric Company Llc | Zirconium alloys with improved corrosion/creep resistance due to final heat treatments |

| US10221475B2 (en) | 2004-03-23 | 2019-03-05 | Westinghouse Electric Company Llc | Zirconium alloys with improved corrosion/creep resistance |

| SE530783C2 (sv) * | 2007-01-16 | 2008-09-09 | Westinghouse Electric Sweden | Spridargaller för positinering av bränslestavar |

| KR101088111B1 (ko) | 2009-02-17 | 2011-12-02 | 한국원자력연구원 | 부식저항성과 크립저항성이 우수한 지르코늄 합금 조성물 |

| CN109801727B (zh) * | 2019-02-01 | 2019-12-24 | 中国原子能科学研究院 | 燃料板及其制备方法 |

| WO2020223107A1 (en) * | 2019-04-30 | 2020-11-05 | Westinghouse Electric Company Llc | Improved corrosion resistance of additively-manufactured zirconium alloys |

| CN110284027B (zh) * | 2019-08-06 | 2020-04-21 | 中国核动力研究设计院 | 一种耐碱性水质腐蚀的锆基合金 |

| CN110904359A (zh) * | 2019-12-18 | 2020-03-24 | 佛山科学技术学院 | 一种耐蚀锆合金 |

| CN115233001B (zh) * | 2022-07-28 | 2022-12-27 | 西安稀有金属材料研究院有限公司 | 一种高性能锆钆合金的制备方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1997040659A1 (en) * | 1996-04-26 | 1997-11-06 | Abb Atom Ab | Fuel boxes and a method for manufacturing fuel boxes |

| RU2110600C1 (ru) * | 1996-09-10 | 1998-05-10 | Открытое акционерное общество "Чепецкий механический завод" | Способ получения изделий из циркониевых сплавов |

| RU2184795C2 (ru) * | 1999-07-29 | 2002-07-10 | Открытое акционерное общество "Чепецкий механический завод" | Способ изготовления плоского профиля из циркониевых сплавов |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3776508A (en) * | 1961-05-26 | 1973-12-04 | Atomic Energy Commission | Process for massively hydriding zirconium-uranium fuel elements |

| US3336201A (en) * | 1965-02-16 | 1967-08-15 | Gen Electric Canada | Dual fuel cycle for nuclear reactors |

| US3865635A (en) * | 1972-09-05 | 1975-02-11 | Sandvik Ab | Method of making tubes and similar products of a zirconium alloy |

| US4017368A (en) * | 1974-11-11 | 1977-04-12 | General Electric Company | Process for electroplating zirconium alloys |

| NL7602275A (nl) * | 1975-03-14 | 1976-09-16 | Asea Atom Ab | Werkwijze voor een corrosiewerende behandeling van zirkoonlegering. |

| JPS607027B2 (ja) * | 1980-04-14 | 1985-02-21 | 住友金属工業株式会社 | 温間加工用チタニウムまたはジルコニウム冷延板の製法 |

| US4383853A (en) * | 1981-02-18 | 1983-05-17 | William J. McCollough | Corrosion-resistant Fe-Cr-uranium238 pellet and method for making the same |

| US4450016A (en) * | 1981-07-10 | 1984-05-22 | Santrade Ltd. | Method of manufacturing cladding tubes of a zirconium-based alloy for fuel rods for nuclear reactors |

| US4584030A (en) * | 1982-01-29 | 1986-04-22 | Westinghouse Electric Corp. | Zirconium alloy products and fabrication processes |

| SE434679B (sv) * | 1982-07-01 | 1984-08-06 | Asea Ab | Anordning vid hermetiskt slutna lastceller for eliminering av inverkan pa metverdet av en skillnad mellan trycket i ett givarrum och atmosferstrycket |

| US4595413A (en) * | 1982-11-08 | 1986-06-17 | Occidental Research Corporation | Group IVb transition metal based metal and processes for the production thereof |

| US4604148A (en) * | 1983-11-22 | 1986-08-05 | The United States Of America As Represented By The United States Department Of Energy | Method of increasing the phase stability and the compressive yield strength of uranium-1 to 3 wt. % zirconium alloy |

| FR2584097B1 (fr) * | 1985-06-27 | 1987-12-11 | Cezus Co Europ Zirconium | Procede de fabrication d'une ebauche de tube de gainage corroyee a froid en alliage de zirconium |

| DE3873643T2 (de) * | 1987-06-23 | 1993-03-25 | Commissariat Energie Atomique | Verfahren zur herstellung eines rohres auf zirconiumlegierungsbasis fuer kernkraftreaktoren und verwendung. |

| US5242515A (en) * | 1990-03-16 | 1993-09-07 | Westinghouse Electric Corp. | Zircaloy-4 alloy having uniform and nodular corrosion resistance |

| EP0488027B2 (en) * | 1990-11-28 | 2008-12-31 | Hitachi Ltd. | Method of manufacturing a zirconium based alloy fuel channel box |

| FR2673198B1 (fr) * | 1991-02-22 | 1993-12-31 | Cezus Cie Europ Zirconium | Procede de fabrication d'une bande ou tole en zircaloy 2 ou 4 et produit obtenu. |

| JP2560571B2 (ja) * | 1991-07-15 | 1996-12-04 | 株式会社日立製作所 | 燃料チャンネルボックスの製造方法及び燃料チャンネルボックス |

| JP2638351B2 (ja) * | 1991-09-20 | 1997-08-06 | 株式会社日立製作所 | 燃料集合体 |

| US5310431A (en) | 1992-10-07 | 1994-05-10 | Robert F. Buck | Creep resistant, precipitation-dispersion-strengthened, martensitic stainless steel and method thereof |

| US5437747A (en) * | 1993-04-23 | 1995-08-01 | General Electric Company | Method of fabricating zircalloy tubing having high resistance to crack propagation |

| US5319431A (en) * | 1993-06-30 | 1994-06-07 | Xerox Corporation | Apparatus for increased toner storage capacity |

| FR2711147B1 (fr) * | 1993-10-11 | 1995-11-17 | Cezus Co Europ Zirconium | Procédé de fabrication d'un produit plat en alliage de zirconium comprenant un réchauffage dans le domaine béta par infrarouges. |

| FR2713009B1 (fr) * | 1993-11-25 | 1996-01-26 | Framatome Sa | Procédé de fabrication d'un tube de gainage pour crayon de combustible nucléaire et tubes conformes à ceux ainsi obtenus. |

| FR2716897B1 (fr) * | 1994-03-02 | 1996-04-05 | Cezus Co Europ Zirconium | Procédé de fabrication d'un produit plat en alliage de zirconium ou en alliage de hafnium comprenant une poursuite du laminage à chaud après rechauffage par infrarouges et ses utilisations . |

| SE513488C2 (sv) * | 1994-06-22 | 2000-09-18 | Sandvik Ab | Sätt att tillverka rör av zirkoniumbaslegering för kärnreaktorer och användning av sättet vid tillverkning av sådana rör |

| US5618502A (en) * | 1995-07-17 | 1997-04-08 | Westinghouse Electric Corporation | Zirconium and hafnium separation in sulfate solutions using continuous ion exchange chromatography |

| JPH09257988A (ja) * | 1996-01-19 | 1997-10-03 | Nuclear Fuel Ind Ltd | 耐食性、特に耐一様腐食性と耐水素吸収性に優れたジルコニウム合金系原子炉炉心内構造材の製造方法 |

| JPH09249927A (ja) * | 1996-03-13 | 1997-09-22 | Hitachi Ltd | 低照射成長ジルコニウム基合金板とその製造法及び用途 |

| KR100449648B1 (ko) * | 1999-06-15 | 2004-09-22 | 학교법인 한양학원 | 플라스마 cf₄/o₂/n₂내의 산화악티늄족과 그에 관한 산화 혼합물의 효과적인 건식 에칭 방법 |

| US6554179B2 (en) * | 2001-07-06 | 2003-04-29 | General Atomics | Reaction brazing of tungsten or molybdenum body to carbonaceous support |

-

2003

- 2003-07-31 FR FR0309474A patent/FR2858332B1/fr not_active Expired - Lifetime

-

2004

- 2004-07-20 RU RU2006106222/02A patent/RU2350684C2/ru active

- 2004-07-20 EP EP04767740.6A patent/EP1649073B1/fr not_active Expired - Lifetime

- 2004-07-20 US US10/565,481 patent/US7630470B2/en not_active Expired - Fee Related

- 2004-07-20 CN CNB2004800217357A patent/CN100451159C/zh not_active Expired - Fee Related

- 2004-07-20 WO PCT/FR2004/001923 patent/WO2005021818A1/fr not_active Ceased

- 2004-07-20 KR KR1020067002054A patent/KR20060052939A/ko not_active Ceased

- 2004-07-20 JP JP2006521611A patent/JP5646800B2/ja not_active Expired - Fee Related

- 2004-07-20 CA CA2533172A patent/CA2533172C/fr not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1997040659A1 (en) * | 1996-04-26 | 1997-11-06 | Abb Atom Ab | Fuel boxes and a method for manufacturing fuel boxes |

| RU2110600C1 (ru) * | 1996-09-10 | 1998-05-10 | Открытое акционерное общество "Чепецкий механический завод" | Способ получения изделий из циркониевых сплавов |

| RU2184795C2 (ru) * | 1999-07-29 | 2002-07-10 | Открытое акционерное общество "Чепецкий механический завод" | Способ изготовления плоского профиля из циркониевых сплавов |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2533172C (fr) | 2011-04-12 |

| EP1649073B1 (fr) | 2018-08-08 |

| JP2007500788A (ja) | 2007-01-18 |

| RU2006106222A (ru) | 2006-07-10 |

| WO2005021818A1 (fr) | 2005-03-10 |

| FR2858332A1 (fr) | 2005-02-04 |

| FR2858332B1 (fr) | 2005-10-28 |

| CA2533172A1 (fr) | 2005-03-10 |

| EP1649073A1 (fr) | 2006-04-26 |

| CN100451159C (zh) | 2009-01-14 |

| US7630470B2 (en) | 2009-12-08 |

| US20060215806A1 (en) | 2006-09-28 |

| KR20060052939A (ko) | 2006-05-19 |

| JP5646800B2 (ja) | 2014-12-24 |

| CN1829815A (zh) | 2006-09-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4678521A (en) | Process for producing zirconium-based alloy and the product thereof | |

| RU2350684C2 (ru) | Способ получения плоской заготовки из циркониевого сплава, полученная этим способом плоская заготовка и элемент тепловыделяющей сборки ядерного реактора аэс, изготовленный из плоской заготовки | |

| CN101435063B (zh) | 一种提高冷成型β钛合金时效后塑性的热处理工艺 | |

| JP5916286B2 (ja) | 高耐食ジルコニウム合金材料の製造方法 | |

| RU2351687C2 (ru) | Способ получения плоской заготовки из циркониевого сплава, полученная этим способом плоская заготовка и решетка реактора аэс, выполненная из этой заготовки | |

| JPS6145699B2 (enExample) | ||

| EP3284836A1 (en) | Zirconium alloy having excellent corrosion resistance and creep resistance, and method for manufacturing same | |

| EP1969152B1 (en) | Zirconium strip material and process for making same | |

| KR101751521B1 (ko) | 마그네슘 합금 판재 제조방법 | |

| JPS6151626B2 (enExample) | ||

| Xu et al. | The effect of annealing and cold-drawing on the super-elasticity of the Ni-Ti shape memory alloy wire | |

| JP3955097B2 (ja) | 燃料ボックスと燃料ボックスを製造する方法 | |

| KR20110073950A (ko) | 고강도 및 고연성 티타늄 합금의 제조방법 | |

| CN114959230B (zh) | 铜镍锡合金带材或板材及其制备方法 | |

| JPS6026650A (ja) | 原子炉燃料用被覆管 | |

| JPH0421746B2 (enExample) | ||

| KR102589875B1 (ko) | 미세결정립 순수 타이타늄 및 그 제조 방법 | |

| JPS59226158A (ja) | 高耐食燃料構造部材の製造法 | |

| US20060081313A1 (en) | Method for the production of a semi-finished product made of zirconium alloy for the production of a flat product and use thereof | |

| CN120715059A (zh) | 一种电弧增材制造用高直线度钛合金丝材制备方法 | |

| JPS60155657A (ja) | Ti−Νi系超弾性合金の製造方法 | |

| JPH02270948A (ja) | ジルコニウム合金管の製法 | |

| JPH02270949A (ja) | ジルコニウム合金管の製法 | |

| JPS61143571A (ja) | ジルコニウム基合金の製造法 | |

| JPS60155656A (ja) | Ti−Νi系超弾性合金の製造方法 |