KR930006299B1 - 인청동 박판의 제조방법 - Google Patents

인청동 박판의 제조방법 Download PDFInfo

- Publication number

- KR930006299B1 KR930006299B1 KR1019880000839A KR880000839A KR930006299B1 KR 930006299 B1 KR930006299 B1 KR 930006299B1 KR 1019880000839 A KR1019880000839 A KR 1019880000839A KR 880000839 A KR880000839 A KR 880000839A KR 930006299 B1 KR930006299 B1 KR 930006299B1

- Authority

- KR

- South Korea

- Prior art keywords

- phosphor bronze

- ingot

- cooling

- molten metal

- manufacturing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/08—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of copper or alloys based thereon

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

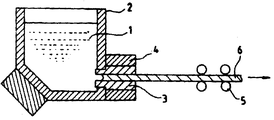

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

- B22D11/0622—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars formed by two casting wheels

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Continuous Casting (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP62029225A JPH07113142B2 (ja) | 1987-02-10 | 1987-02-10 | りん青銅薄板の製造方法 |

| JP?62-29225 | 1987-02-10 | ||

| JP62-29225 | 1987-02-10 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR880010149A KR880010149A (ko) | 1988-10-07 |

| KR930006299B1 true KR930006299B1 (ko) | 1993-07-12 |

Family

ID=12270276

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019880000839A Expired - Fee Related KR930006299B1 (ko) | 1987-02-10 | 1988-01-30 | 인청동 박판의 제조방법 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4927467A (enExample) |

| JP (1) | JPH07113142B2 (enExample) |

| KR (1) | KR930006299B1 (enExample) |

| DE (1) | DE3803194A1 (enExample) |

| FR (1) | FR2610551B1 (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01107943A (ja) * | 1987-10-20 | 1989-04-25 | Nisshin Steel Co Ltd | リン青銅の薄板連続鋳造方法 |

| US5074933A (en) * | 1989-07-25 | 1991-12-24 | Olin Corporation | Copper-nickel-tin-silicon alloys having improved processability |

| US5232610A (en) * | 1989-09-15 | 1993-08-03 | Mclaughlin Timothy M | Mold element construction |

| JPH049253A (ja) * | 1990-04-26 | 1992-01-14 | Mitsubishi Electric Corp | 銅合金の製造方法 |

| DE4126079C2 (de) * | 1991-08-07 | 1995-10-12 | Wieland Werke Ag | Bandgießverfahren für ausscheidungsbildende und/oder spannungsempfindliche und/oder seigerungsanfällige Kupferlegierungen |

| US5882442A (en) * | 1995-10-20 | 1999-03-16 | Olin Corporation | Iron modified phosphor-bronze |

| DE19843290A1 (de) * | 1998-09-22 | 2000-03-23 | Km Europa Metal Ag | Verfahren zur Lokalisierung von Elementkonzentrationen in einem Gußstrang und Vorrichtung des Verfahrens |

| JP2002294366A (ja) * | 2001-03-30 | 2002-10-09 | Nippon Mining & Metals Co Ltd | 限界曲げ半径にて安定して良好な曲げ加工性を有するりん青銅条 |

| JP5116976B2 (ja) * | 2006-02-10 | 2013-01-09 | 三菱伸銅株式会社 | 半融合金鋳造用原料黄銅合金 |

| JP2007211324A (ja) * | 2006-02-13 | 2007-08-23 | Sanbo Copper Alloy Co Ltd | 半融合金鋳造用原料りん青銅合金 |

| JP2007211325A (ja) * | 2006-02-13 | 2007-08-23 | Sanbo Copper Alloy Co Ltd | 半融合金鋳造用原料アルミニウム青銅合金 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3930895A (en) * | 1974-04-24 | 1976-01-06 | Amax Aluminum Company, Inc. | Special magnesium-manganese aluminum alloy |

| US4054173A (en) * | 1974-12-23 | 1977-10-18 | Hunter Engineering Co., Inc. | Apparatus for producing completely recrystallized metal sheet |

| JPS6043895B2 (ja) * | 1978-02-23 | 1985-10-01 | 東北大学金属材料研究所長 | 銅基合金 |

| SE448381B (sv) * | 1978-09-19 | 1987-02-16 | Tsuya Noboru | Sett att framstella ett tunt band av kiselstal, tunt kiselstalband och anvendning av dylikt |

| US4221257A (en) * | 1978-10-10 | 1980-09-09 | Allied Chemical Corporation | Continuous casting method for metallic amorphous strips |

| JPS55152155A (en) * | 1979-05-16 | 1980-11-27 | Sumitomo Special Metals Co Ltd | Fine crystalline strip material for high permeability magnetic material, preparation and product thereof |

| JPS57145945A (en) * | 1981-03-04 | 1982-09-09 | Hitachi Metals Ltd | Manufacture of magnetic alloy |

| JPS5897468A (ja) * | 1981-12-04 | 1983-06-09 | Kawasaki Steel Corp | 金属薄帯製造方法およびその装置 |

| JPS58196149A (ja) * | 1982-05-11 | 1983-11-15 | Furukawa Electric Co Ltd:The | 鉛又は鉛合金条の連続製造方法 |

| US4448852A (en) * | 1982-09-20 | 1984-05-15 | Allied Corporation | Homogeneous low melting point copper based alloys |

| US4586967A (en) * | 1984-04-02 | 1986-05-06 | Olin Corporation | Copper-tin alloys having improved wear properties |

| JPS61143524A (ja) * | 1984-12-14 | 1986-07-01 | Nippon Kokan Kk <Nkk> | 薄板状鋳片の製造方法 |

| CH671534A5 (enExample) * | 1986-03-14 | 1989-09-15 | Escher Wyss Ag | |

| US4716956A (en) * | 1986-12-03 | 1988-01-05 | Aluminum Company Of America | Roll caster feed tip and method |

-

1987

- 1987-02-10 JP JP62029225A patent/JPH07113142B2/ja not_active Expired - Fee Related

-

1988

- 1988-01-30 KR KR1019880000839A patent/KR930006299B1/ko not_active Expired - Fee Related

- 1988-02-03 DE DE3803194A patent/DE3803194A1/de active Granted

- 1988-02-09 FR FR8801505A patent/FR2610551B1/fr not_active Expired - Fee Related

- 1988-02-10 US US07/154,330 patent/US4927467A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US4927467A (en) | 1990-05-22 |

| FR2610551A1 (fr) | 1988-08-12 |

| DE3803194C2 (enExample) | 1989-11-02 |

| JPS63195253A (ja) | 1988-08-12 |

| KR880010149A (ko) | 1988-10-07 |

| FR2610551B1 (fr) | 1994-05-27 |

| DE3803194A1 (de) | 1988-08-18 |

| JPH07113142B2 (ja) | 1995-12-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR930006299B1 (ko) | 인청동 박판의 제조방법 | |

| JP2022028598A (ja) | 高強度高伝導率銅合金の高効率製造方法 | |

| KR20070027622A (ko) | 마그네슘 합금재의 제조방법 | |

| KR20090040408A (ko) | 구리합금 선재의 제조 방법 및 구리합금 선재 | |

| JPH02205232A (ja) | 引上げ連続鋳造法とその装置 | |

| EP0972591B1 (en) | Method and apparatus for casting molten metal, and cast piece | |

| EP2823914A1 (en) | Continuous casting method and continuous casting device for titanium ingots and titanium alloy ingots | |

| KR900006690B1 (ko) | 고규소철합금의 박판 제조방법 | |

| Soda et al. | Development of net-shape cast aluminium-yttrium alloy wires and their solidification structures | |

| US4665970A (en) | Method of producing a metallic member having a unidirectionally solidified structure | |

| KR20190120303A (ko) | 강의 연속 주조 방법 | |

| RU1839682C (ru) | Способ изготовлени металлической полосы | |

| JPH049253A (ja) | 銅合金の製造方法 | |

| CA1083017A (en) | Method of producing a continuously processed copper rod | |

| CN116179942A (zh) | 一种20MnCrS5钢及其制备方法和应用 | |

| JP2949715B2 (ja) | 塑性加工用金属の鋳造方法 | |

| KR101193065B1 (ko) | 스트립캐스팅을 이용한 비정질 합금판재의 제조방법 및 그장치 | |

| RU2790333C1 (ru) | Способ получения тонких микрокристаллических широких лент из нержавеющей хромоникелевой стали аустенитного класса методом спиннингования расплава | |

| JPH11285788A (ja) | 厚鋼板用大断面鋳片の連続鋳造方法 | |

| KR840001298B1 (ko) | 주강제품의 연속 주조방법 | |

| JPH0314541B2 (enExample) | ||

| JPS63123550A (ja) | ベリリウム銅合金の連続鋳塊及びその連続鋳造法 | |

| JPH0112579B2 (enExample) | ||

| KR100728099B1 (ko) | 가공성이 우수한 주철편과 그 제조 방법 | |

| CN109290537A (zh) | 一种原料纯铁小方坯的生产方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0109 | Patent application |

St.27 status event code: A-0-1-A10-A12-nap-PA0109 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| G160 | Decision to publish patent application | ||

| PG1605 | Publication of application before grant of patent |

St.27 status event code: A-2-2-Q10-Q13-nap-PG1605 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U11-oth-PR1002 Fee payment year number: 1 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| FPAY | Annual fee payment |

Payment date: 19980630 Year of fee payment: 6 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 6 |

|

| LAPS | Lapse due to unpaid annual fee | ||

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 19990713 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 19990713 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-5-5-R10-R17-oth-X000 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-5-5-R10-R18-oth-X000 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-4-4-P10-P22-nap-X000 |