KR20180098602A - 이중 탄성률 차량 서스펜션 시스템 - Google Patents

이중 탄성률 차량 서스펜션 시스템 Download PDFInfo

- Publication number

- KR20180098602A KR20180098602A KR1020187021292A KR20187021292A KR20180098602A KR 20180098602 A KR20180098602 A KR 20180098602A KR 1020187021292 A KR1020187021292 A KR 1020187021292A KR 20187021292 A KR20187021292 A KR 20187021292A KR 20180098602 A KR20180098602 A KR 20180098602A

- Authority

- KR

- South Korea

- Prior art keywords

- hydraulic

- vehicle

- modulus

- mode

- spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G17/00—Resilient suspensions having means for adjusting the spring or vibration-damper characteristics, for regulating the distance between a supporting surface and a sprung part of vehicle or for locking suspension during use to meet varying vehicular or surface conditions, e.g. due to speed or load

- B60G17/02—Spring characteristics, e.g. mechanical springs and mechanical adjusting means

- B60G17/027—Mechanical springs regulated by fluid means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G11/00—Resilient suspensions characterised by arrangement, location or kind of springs

- B60G11/32—Resilient suspensions characterised by arrangement, location or kind of springs having springs of different kinds

- B60G11/48—Resilient suspensions characterised by arrangement, location or kind of springs having springs of different kinds not including leaf springs

- B60G11/50—Resilient suspensions characterised by arrangement, location or kind of springs having springs of different kinds not including leaf springs having helical, spiral or coil springs, and also torsion-bar springs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G17/00—Resilient suspensions having means for adjusting the spring or vibration-damper characteristics, for regulating the distance between a supporting surface and a sprung part of vehicle or for locking suspension during use to meet varying vehicular or surface conditions, e.g. due to speed or load

- B60G17/02—Spring characteristics, e.g. mechanical springs and mechanical adjusting means

- B60G17/027—Mechanical springs regulated by fluid means

- B60G17/0272—Mechanical springs regulated by fluid means the mechanical spring being a coil spring

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G7/00—Pivoted suspension arms; Accessories thereof

- B60G7/001—Suspension arms, e.g. constructional features

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2202/00—Indexing codes relating to the type of spring, damper or actuator

- B60G2202/10—Type of spring

- B60G2202/12—Wound spring

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2202/00—Indexing codes relating to the type of spring, damper or actuator

- B60G2202/10—Type of spring

- B60G2202/13—Torsion spring

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2202/00—Indexing codes relating to the type of spring, damper or actuator

- B60G2202/10—Type of spring

- B60G2202/13—Torsion spring

- B60G2202/132—Torsion spring comprising a longitudinal torsion bar and/or tube

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2202/00—Indexing codes relating to the type of spring, damper or actuator

- B60G2202/40—Type of actuator

- B60G2202/41—Fluid actuator

- B60G2202/413—Hydraulic actuator

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2204/00—Indexing codes related to suspensions per se or to auxiliary parts

- B60G2204/40—Auxiliary suspension parts; Adjustment of suspensions

- B60G2204/421—Pivoted lever mechanisms for mounting suspension elements, e.g. Watt linkage

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Vehicle Body Suspensions (AREA)

Abstract

Description

도 1은 차량의 한 코너에 위치된 한 서스펜션 실시예의 개략도.

도 2는 도 1에 도시된 서스펜션에 사용되는 유압 록아웃 액츄에이터의 확대 투시도.

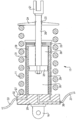

도 3은 도 2에 도시된 유압 록아웃 액츄에이터의 횡단면도.

도 4는 도 1에 도시된 서스펜션과 함께 사용되는 유압 조절 회로의 한 실시예의 개략도.

도 5는 원하는 조종 설정을 제공하기 위하여 원하는 낮은 탑승 높이를 제공하도록 사용되는 유압 조절 회로의 한 실시예의 개략도.

전술한 문단, 청구항들의 실시예, 특정예, 및 대안예 또는 하기 기술하는 설명 및 도면, 가령, 다양한 양태 혹은 각각의 개별 특징들은 모두 독립적으로 사용되거나 임의의 조합으로도 사용될 수 있다. 한 실시예에 대해 기술되는 특징들은, 이러한 특징들이 서로 모순되지 않는 한, 모든 실시예들에 적용될 수 있다.

Claims (4)

- 선택적으로 전환가능한 이중 탄성률 차량 서스펜션 시스템에 있어서, 상기 시스템은:

차량의 한 코너의 언스프렁 매스와 스프렁 매스 사이에 배열된 푸시로드 작동식 인보드 스프링을 포함하되, 상기 푸시로드 작동식 인보드 스프링은 제1 사전결정된 탄성률 K1의 토션 바 스프링과 제2 사전결정된 탄성률 K2의 코일 스프링을 포함하고, 이들은 직렬로 배열되어 총 조합 탄성률 KT을 제공하며;

코일 스프링과 병렬로 배열된 록아웃 액츄에이터를 포함하되, 상기 록아웃 액츄에이터는, 제1 모드에서 코일 스프링이 자유로이 이동될 수 있고 제2 모드에서는 코일 스프링의 움직임을 방지하도록 구성되며,

록아웃 액츄에이터가 제1의 언로킹 모드에 있을 때에는 차량의 총 서스펜션 탄성률은 급수 공식 1/KT = 1/ K1 + 1/K2에 의해 정의되며, 록아웃 액츄에이터가 제2의 로킹 모드에 있을 때에는 차량의 총 서스펜션 탄성률은 KT = K1에 의해 정의된 것과 같이 실질적으로 더 높아서, 낮은 탄성률의 최적의 탑승 안락성 설정과 높은 탄성률의 최적의 조종 설정을 선택적으로 제공하는 것을 특징으로 하는, 선택적으로 전환가능한 이중 탄성률 차량 서스펜션 시스템. - 제1항에 있어서, 록아웃 액츄에이터는 유압 실린더와 유압 회로를 포함하되, 상기 유압 회로는 제1의 언로킹 모드와 제2의 로킹 모드를 제공할 수 있도록 유압 실린더 내의 두 용적 사이의 연결을 선택적으로 개폐하는 것을 특징으로 하는, 선택적으로 전환가능한 이중 탄성률 차량 서스펜션 시스템.

- 제1항에 있어서, 록아웃 액츄에이터는 유압 실린더와 유압 회로를 포함하되, 상기 유압 회로는 제1의 언로킹 모드와 제2의 로킹 모드를 제공할 수 있도록 유압 실린더 내의 두 용적 사이의 연결을 선택적으로 개폐하며, 유압 회로는, 차량의 탑승 높이가 K1 탄성률 모드에서 결정될 수 있도록, 유압 액츄에이터에 전력을 공급하여 코일 스프링을 구동시켜 사전결정된 위치로 이동하도록 구성되는 것을 특징으로 하는, 선택적으로 전환가능한 이중 탄성률 차량 서스펜션 시스템.

- 제1항에 있어서, 록아웃 액츄에이터는 유압 실린더와 유압 회로를 포함하되, 상기 유압 회로는 제1의 언로킹 모드와 제2의 로킹 모드를 제공할 수 있도록 유압 실린더 내의 두 용적 사이의 연결을 선택적으로 개폐하며, 유압 회로는, K1 탄성률 모드의 차량의 탑승 높이가 1/K1 + 1/K2 탄성률 모드보다 상대적으로 낮게 결정될 수 있도록, 유압 액츄에이터에 전력을 공급하여 코일 스프링을 구동시켜 사전결정된 위치로 이동하도록 구성되는 것을 특징으로 하는, 선택적으로 전환가능한 이중 탄성률 차량 서스펜션 시스템.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201662276499P | 2016-01-08 | 2016-01-08 | |

| US62/276,499 | 2016-01-08 | ||

| PCT/US2017/012588 WO2017120509A1 (en) | 2016-01-08 | 2017-01-06 | Dual rate vehicle suspension system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180098602A true KR20180098602A (ko) | 2018-09-04 |

| KR102088121B1 KR102088121B1 (ko) | 2020-03-12 |

Family

ID=57868410

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187021292A Active KR102088121B1 (ko) | 2016-01-08 | 2017-01-06 | 이중 탄성률 차량 서스펜션 시스템 |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US10807434B2 (ko) |

| EP (1) | EP3400142B1 (ko) |

| JP (2) | JP2019501067A (ko) |

| KR (1) | KR102088121B1 (ko) |

| CN (1) | CN108473017B (ko) |

| AU (1) | AU2017206062A1 (ko) |

| BR (1) | BR112018013721B1 (ko) |

| CA (1) | CA3009807C (ko) |

| ES (1) | ES2817757T3 (ko) |

| MX (1) | MX2018008370A (ko) |

| RU (1) | RU2705472C1 (ko) |

| WO (1) | WO2017120509A1 (ko) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10639954B2 (en) * | 2016-09-23 | 2020-05-05 | Jay O'Connell | Multi-link suspension system |

| IT201800005419A1 (it) * | 2018-05-16 | 2019-11-16 | Sospensione automobilistica per auto sportiva | |

| DE102018131850A1 (de) * | 2018-12-12 | 2020-06-18 | Schaeffler Technologies AG & Co. KG | Radmodul für ein Kraftfahrzeug und entsprechendes Kraftfahrzeug |

| US11639081B2 (en) | 2020-07-29 | 2023-05-02 | Ferrari S.P.A. | Device and apparatus for the height adjustment of a road vehicle and relative road vehicle |

| US11648812B2 (en) | 2020-08-21 | 2023-05-16 | Toyota Motor Engineering & Manufacturing North America, Inc. | No roll torsion bar |

| US11571939B2 (en) | 2020-10-13 | 2023-02-07 | Xtravel Suspension, Llc | Suspension system |

| US11192414B1 (en) * | 2020-10-13 | 2021-12-07 | Xtravel Suspension, Llc | Suspension system |

| US20220250430A1 (en) * | 2021-02-11 | 2022-08-11 | GM Global Technology Operations LLC | Multilink mid-height suspension assembly for motor vehicles |

| WO2022253403A1 (en) * | 2021-05-31 | 2022-12-08 | Volvo Truck Corporation | A bump stop arrangement |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59180030U (ja) * | 1983-05-19 | 1984-12-01 | 三菱製鋼株式会社 | 可変ばね定数ばね懸架装置 |

| JPH1122775A (ja) * | 1997-07-07 | 1999-01-26 | Isuzu Motors Ltd | バネ定数可変バネ装置および車両懸架装置 |

| US20060197301A1 (en) * | 2005-03-02 | 2006-09-07 | Dr. Ing. H.C.F. Porsche Ag | Wheel suspension |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1022478B (de) | 1955-06-16 | 1958-01-09 | Daimler Benz Ag | Vorrichtung zur Einstellung der Federung fuer Kraftfahrzeuge, insbesondere zum Gewichtsausgleich fuer den verbrauchten Kraftstoff von Sport- und Rennwagen |

| US3083034A (en) | 1960-11-10 | 1963-03-26 | Ford Motor Co | Wheel suspension with ride control |

| US3773346A (en) | 1972-01-03 | 1973-11-20 | Moog Industries Inc | Vehicle suspension system |

| JPS5060716U (ko) * | 1973-10-02 | 1975-06-04 | ||

| US4145073A (en) * | 1977-04-07 | 1979-03-20 | Caterpillar Tractor Co. | Lockup system for a vehicle suspension mechanism |

| DE3737760A1 (de) | 1987-11-06 | 1989-05-18 | Pfister Gmbh | Verfahren zum optimieren der fahreigenschaft von fahrzeugen |

| JPH03273919A (ja) * | 1990-03-23 | 1991-12-05 | Nissan Shatai Co Ltd | 車高調整装置 |

| JPH0450019A (ja) * | 1990-06-19 | 1992-02-19 | Mazda Motor Corp | 車両のサスペンション装置 |

| DE4110651A1 (de) * | 1991-04-02 | 1992-10-08 | Ingelheim Peter Graf Von | Regelbares federsystem aus mehreren federn und anwendungen solcher federsysteme speziell bei fahrzeugfederungen |

| CA2117945C (en) | 1994-10-12 | 2003-03-25 | Laurence J. Holt | Suspension system |

| JPH08332822A (ja) * | 1995-06-08 | 1996-12-17 | Isuzu Motors Ltd | 車高調整機構 |

| DE19521861C1 (de) | 1995-06-16 | 1996-10-24 | Porsche Ag | Vorrichtung zur Beeinflussung der Federeigenschaften einer Schraubenfeder |

| JPH09207537A (ja) * | 1996-01-31 | 1997-08-12 | Kayaba Ind Co Ltd | ばね定数の切換構造 |

| US5725239A (en) | 1996-03-26 | 1998-03-10 | Monroe Auto Equipment | Adaptive load dependent suspension system |

| US5687960A (en) * | 1996-04-12 | 1997-11-18 | Hyundai Motor Company | Torsion bar assembly for vehicle suspension system |

| US6357771B1 (en) | 2000-05-25 | 2002-03-19 | Meritor Light Vehicle Systems, Inc. | Torsion bar with variable rate anchor arm for a vehicle suspension system |

| US6945522B2 (en) * | 2002-04-30 | 2005-09-20 | Meritor Heavy Vehicle Technology, Llc | Multi-rate torsion bar independent suspension spring |

| US6923434B2 (en) | 2003-11-10 | 2005-08-02 | The Goodyear Tire & Rubber Company | Dual height airspring having adjusted spring rate |

| JP4127298B2 (ja) * | 2006-06-14 | 2008-07-30 | トヨタ自動車株式会社 | 車輪車体間距離調整装置および車輪車体間距離調整システム |

| DE102007007630A1 (de) * | 2007-02-16 | 2008-08-21 | Bayerische Motoren Werke Aktiengesellschaft | Fahrzeug, insbesondere Motorrad, mit einem Federbein mit einstellbarer Federrate |

| CN100544981C (zh) * | 2007-12-11 | 2009-09-30 | 中国三江航天工业集团公司 | 扭杆螺旋弹簧复合悬架装置 |

| WO2010078471A1 (en) * | 2008-12-30 | 2010-07-08 | Darco Trust | Vehicle suspension system |

| US8356807B2 (en) | 2010-06-24 | 2013-01-22 | Miner Elastomer Products Corporation | Dual rate shock absorbing apparatus for a suspension system of a heavy off-road vehicle |

| DE102010033002A1 (de) | 2010-07-31 | 2012-02-02 | Audi Ag | Achssteller eines Kraftfahrzeugs |

| DE102012202988A1 (de) * | 2012-02-28 | 2013-08-29 | Zf Friedrichshafen Ag | Verbindungsanordnung für eine Fahrzeugradaufhängung |

| JP5936125B2 (ja) * | 2012-11-20 | 2016-06-15 | Kyb株式会社 | 車高調整装置と、車高調整装置の組み付け方法 |

| DE102013002713B4 (de) * | 2013-02-16 | 2014-08-28 | Audi Ag | Drehstabfederanordnung für eine Radaufhängung eines Kraftfahrzeugs |

| US9150070B2 (en) * | 2013-10-18 | 2015-10-06 | GM Global Technology Operations LLC | Actively controlled torsion bar suspension |

-

2017

- 2017-01-06 ES ES17701236T patent/ES2817757T3/es active Active

- 2017-01-06 MX MX2018008370A patent/MX2018008370A/es unknown

- 2017-01-06 BR BR112018013721-9A patent/BR112018013721B1/pt active IP Right Grant

- 2017-01-06 EP EP17701236.6A patent/EP3400142B1/en active Active

- 2017-01-06 JP JP2018535097A patent/JP2019501067A/ja active Pending

- 2017-01-06 CA CA3009807A patent/CA3009807C/en active Active

- 2017-01-06 AU AU2017206062A patent/AU2017206062A1/en not_active Abandoned

- 2017-01-06 CN CN201780005901.1A patent/CN108473017B/zh active Active

- 2017-01-06 RU RU2018128745A patent/RU2705472C1/ru not_active IP Right Cessation

- 2017-01-06 KR KR1020187021292A patent/KR102088121B1/ko active Active

- 2017-01-06 WO PCT/US2017/012588 patent/WO2017120509A1/en not_active Ceased

- 2017-01-06 US US16/066,161 patent/US10807434B2/en active Active

-

2020

- 2020-05-22 JP JP2020089884A patent/JP7012121B2/ja active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59180030U (ja) * | 1983-05-19 | 1984-12-01 | 三菱製鋼株式会社 | 可変ばね定数ばね懸架装置 |

| JPH1122775A (ja) * | 1997-07-07 | 1999-01-26 | Isuzu Motors Ltd | バネ定数可変バネ装置および車両懸架装置 |

| US20060197301A1 (en) * | 2005-03-02 | 2006-09-07 | Dr. Ing. H.C.F. Porsche Ag | Wheel suspension |

Also Published As

| Publication number | Publication date |

|---|---|

| JP7012121B2 (ja) | 2022-01-27 |

| US20190009632A1 (en) | 2019-01-10 |

| MX2018008370A (es) | 2019-07-04 |

| CA3009807A1 (en) | 2017-07-13 |

| EP3400142A1 (en) | 2018-11-14 |

| CN108473017A (zh) | 2018-08-31 |

| JP2019501067A (ja) | 2019-01-17 |

| CA3009807C (en) | 2019-09-17 |

| CN108473017B (zh) | 2021-02-26 |

| JP2020142797A (ja) | 2020-09-10 |

| EP3400142B1 (en) | 2020-06-17 |

| KR102088121B1 (ko) | 2020-03-12 |

| RU2705472C1 (ru) | 2019-11-07 |

| US10807434B2 (en) | 2020-10-20 |

| WO2017120509A1 (en) | 2017-07-13 |

| BR112018013721A2 (pt) | 2018-12-11 |

| AU2017206062A1 (en) | 2018-07-12 |

| BR112018013721B1 (pt) | 2023-09-26 |

| ES2817757T3 (es) | 2021-04-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102088121B1 (ko) | 이중 탄성률 차량 서스펜션 시스템 | |

| RU2408475C2 (ru) | Гидравлическая система подвески для транспортного средства | |

| JP3951728B2 (ja) | スタビライザ装置 | |

| EP2058155A1 (en) | Suspension device and method during spring action and/or damping action for a vehicle | |

| EP3290244A1 (en) | Combined spring compensation suspension device | |

| US11524541B2 (en) | Hydraulic suspension system for off-road vehicles | |

| JP2005503957A (ja) | 乗物用サスペンションシステム | |

| US20080203694A1 (en) | Vehicle | |

| JP7682259B2 (ja) | 調節可能なライドハイトを有するデュアルレート車両サスペンションシステム | |

| US11897307B1 (en) | Trailer suspension | |

| WO2018092110A1 (en) | Vehicle wheel suspension provided with active adjustment system for adjusting in a controlled manner the overall stiffness of the suspension | |

| US11565565B2 (en) | Vehicle overload suspension system | |

| DE102011076973A1 (de) | Verfahren zur Regelung der Dämpfkraft an einer Achse eines Fahrwerks für ein Kraftfahrzeug | |

| Harish et al. | Design and Analysis of Active Suspension System | |

| KR20050037743A (ko) | 스테빌라이저 바 제어시스템 | |

| AU2020396288A1 (en) | Vehicle component for a utility vehicle, in particular an off-road utility vehicle | |

| KR20100056705A (ko) | 현가장치용 쇽 업소버 | |

| KR19980059817A (ko) | 차량 현가장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PA0105 | International application |

St.27 status event code: A-0-1-A10-A15-nap-PA0105 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| D13-X000 | Search requested |

St.27 status event code: A-1-2-D10-D13-srh-X000 |

|

| D14-X000 | Search report completed |

St.27 status event code: A-1-2-D10-D14-srh-X000 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U12-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 6 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 7 |

|

| U11 | Full renewal or maintenance fee paid |

Free format text: ST27 STATUS EVENT CODE: A-4-4-U10-U11-OTH-PR1001 (AS PROVIDED BY THE NATIONAL OFFICE) Year of fee payment: 7 |