KR20180098376A - 축조 재료 용기 - Google Patents

축조 재료 용기 Download PDFInfo

- Publication number

- KR20180098376A KR20180098376A KR1020187021646A KR20187021646A KR20180098376A KR 20180098376 A KR20180098376 A KR 20180098376A KR 1020187021646 A KR1020187021646 A KR 1020187021646A KR 20187021646 A KR20187021646 A KR 20187021646A KR 20180098376 A KR20180098376 A KR 20180098376A

- Authority

- KR

- South Korea

- Prior art keywords

- reservoir

- container

- build

- exit

- wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/30—Auxiliary operations or equipment

- B29C64/307—Handling of material to be used in additive manufacturing

- B29C64/321—Feeding

- B29C64/329—Feeding using hoppers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C31/00—Handling, e.g. feeding of the material to be shaped, storage of plastics material before moulding; Automation, i.e. automated handling lines in plastics processing plants, e.g. using manipulators or robots

- B29C31/02—Dispensing from vessels, e.g. hoppers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F12/00—Apparatus or devices specially adapted for additive manufacturing; Auxiliary means for additive manufacturing; Combinations of additive manufacturing apparatus or devices with other processing apparatus or devices

- B22F12/50—Means for feeding of material, e.g. heads

- B22F12/52—Hoppers

-

- B22F3/1055—

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/141—Processes of additive manufacturing using only solid materials

- B29C64/153—Processes of additive manufacturing using only solid materials using layers of powder being selectively joined, e.g. by selective laser sintering or melting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/165—Processes of additive manufacturing using a combination of solid and fluid materials, e.g. a powder selectively bound by a liquid binder, catalyst, inhibitor or energy absorber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/20—Apparatus for additive manufacturing; Details thereof or accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/20—Apparatus for additive manufacturing; Details thereof or accessories therefor

- B29C64/255—Enclosures for the building material, e.g. powder containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/30—Auxiliary operations or equipment

- B29C64/307—Handling of material to be used in additive manufacturing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/30—Auxiliary operations or equipment

- B29C64/357—Recycling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C67/00—Shaping techniques not covered by groups B29C39/00 - B29C65/00, B29C70/00 or B29C73/00

- B29C67/24—Shaping techniques not covered by groups B29C39/00 - B29C65/00, B29C70/00 or B29C73/00 characterised by the choice of material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/302—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising aromatic vinyl (co)polymers, e.g. styrenic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/306—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising vinyl acetate or vinyl alcohol (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/34—Layered products comprising a layer of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y30/00—Apparatus for additive manufacturing; Details thereof or accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y40/00—Auxiliary operations or equipment, e.g. for material handling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y70/00—Materials specially adapted for additive manufacturing

- B33Y70/10—Composites of different types of material, e.g. mixtures of ceramics and polymers or mixtures of metals and biomaterials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/10—Formation of a green body

- B22F10/14—Formation of a green body by jetting of binder onto a bed of metal powder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/20—Direct sintering or melting

- B22F10/28—Powder bed fusion, e.g. selective laser melting [SLM] or electron beam melting [EBM]

-

- B22F2003/1056—

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2055/00—Use of specific polymers obtained by polymerisation reactions only involving carbon-to-carbon unsaturated bonds, not provided for in a single one of main groups B29K2023/00 - B29K2049/00, e.g. having a vinyl group, as moulding material

- B29K2055/02—ABS polymers, i.e. acrylonitrile-butadiene-styrene polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2101/00—Use of unspecified macromolecular compounds as moulding material

- B29K2101/10—Thermosetting resins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/25—Solid

- B29K2105/251—Particles, powder or granules

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2509/00—Use of inorganic materials not provided for in groups B29K2503/00 - B29K2507/00, as filler

- B29K2509/02—Ceramics

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2509/00—Use of inorganic materials not provided for in groups B29K2503/00 - B29K2507/00, as filler

- B29K2509/08—Glass

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2877/00—Use of PA, i.e. polyamides, e.g. polyesteramides or derivatives thereof, as mould material

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2004/00—Particle morphology

- C01P2004/60—Particles characterised by their size

- C01P2004/61—Micrometer sized, i.e. from 1-100 micrometer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Robotics (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Ceramic Engineering (AREA)

- Civil Engineering (AREA)

- Composite Materials (AREA)

- Structural Engineering (AREA)

- Producing Shaped Articles From Materials (AREA)

- Packages (AREA)

- On-Site Construction Work That Accompanies The Preparation And Application Of Concrete (AREA)

- Toys (AREA)

- Coating Apparatus (AREA)

Abstract

Description

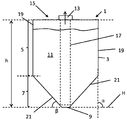

도 2a는 축조 재료의 용기의 다른 예의 도식을 예시하는 도면,

도 2b는 축조 재료의 용기의 또 다른 예의 도식을 예시하는 도면,

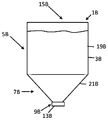

도 3은 축조 재료의 용기의 다른 예의 도식을 예시하는 도면,

도 3b는 축조 재료의 용기의 다른 예의 도식을 예시하는 도면,

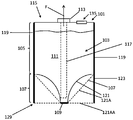

도 4는 축조 재료의 용기의 또 다른 예의 도식을 예시하는 도면,

도 4b는 진공 관의 단부 부분의 예의 도식을 예시하는 도면,

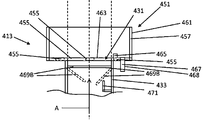

도 5는 축조 재료 출구 구조체의 예의 도식을 예시하는 도면,

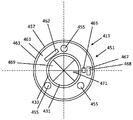

도 6은 축조 재료 출구 구조체의 예의 도식적 평면도를 예시하는 도면,

도 7은 도 6 및 도 8의 출구 구조체에 연결될 진공 관의 예의 도식적 정면도를 예시하는 도면,

도 8은 정면도로 도 6의 예시적인 출구 구조체의 도식적 정면도를 예시하는 도면,

도 9는 다수의 용기를 포함하는 적층 가공 시스템의 예의 도식을 예시하는 도면,

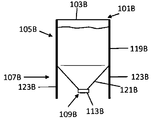

도 10은 축조 재료의 용기의 다른 예의 도식을 예시하는 도면,

도 11은 축조 재료 용기를 사용하는 방법의 예의 흐름도를 예시하는 도면,

도 12는 축조 재료 용기를 버퍼로서 사용하는 방법의 다른 예의 흐름도를 예시하는 도면,

도 13은 축조 재료 용기로부터 축조 재료를 수동으로 붓는 방법의 예의 흐름도를 예시하는 도면,

도 14는 출구 구조체 및 대응하는 스나우트(snout)의 예의 도식을 예시하는 도면,

도 15는 출구 구조체 및 대응하는 스나우트의 다른 예의 도식을 예시하는 도면.

Claims (20)

- 적층 가공 축조 재료 용기(additive manufacturing build material container)에 있어서,

축조 재료를 수용하는 저장소(reservoir)로서,

비교적 비-수렴 측벽을 갖는, 상기 저장소의 높이의 절반 초과의 상부 부분,

적어도 충전된 상태에서 수렴 측벽을 갖는, 상기 상부 부분과 하단부 사이의 하부 부분을 포함하는, 상기 저장소; 및

축조 재료가 상기 저장소를 빠져나가도록 허용하는 축조 재료 출구 구조체를 포함하는

적층 가공 축조 재료 용기. - 제 1 항에 있어서,

상기 상부 부분은 대체로 정육면체 형상이고, 상기 하부 부분은 대체로 피라미드 형상인

적층 가공 축조 재료 용기. - 제 1 항 또는 제 2 항에 있어서,

상기 출구 구조체는 상기 저장소의 상단부 부분에 출구 개구를 포함하는

적층 가공 축조 재료 용기. - 제 3 항에 있어서,

상기 출구 구조체는 외부 수집 시스템에 연결하고 상기 외부 수집 시스템으로부터 분리하는 어댑터를 포함하고, 상기 어댑터는 공기 또는 축조 재료 유동 방향에 대략 수직인, 상기 출구 개구 주위의 인터페이스 면(interface face)을 포함하며, 적어도 하나의 안내 특징부 및 적어도 하나의 추가 인터페이스 특징부가 상기 인터페이스 면에 제공되는

적층 가공 축조 재료 용기. - 제 4 항에 있어서,

상기 출구 구조체는 상기 수집 시스템의 센서를 트리거(trigger)하기 위한, 상기 출구 구조체의 면으로부터 상향 방향으로 돌출하는 센서 트리거 구조체를 포함하는

적층 가공 축조 재료 용기. - 제 4 항 또는 제 5 항에 있어서,

상기 출구 구조체는, 상기 어댑터가 상기 수집 시스템에 연결될 때, 축조 재료 파라미터를 상기 수집 시스템의 제 2 데이터 인터페이스에 전달하는 데이터 인터페이스를 포함하는

적층 가공 축조 재료 용기. - 제 3 항 내지 제 6 항 중 어느 한 항에 있어서,

상기 출구 구조체는, 상기 하단부로부터 축조 재료를 수집하고, 상기 축조 재료를 상기 출구 개구로 안내하는 종방향 수집 유닛을 포함하는

적층 가공 축조 재료 용기. - 제 7 항에 있어서,

상기 수집 유닛은, 상기 하단부에 있는 수집 영역으로부터 상기 축조 재료를 수집하고 상기 축조 재료를 상기 출구 개구로 안내하기 위해, 상기 비-수렴 벽 사이에서 그리고 상기 비-수렴 벽을 지나, 상기 저장소의 상단부 부분으로부터 하단부 부근까지 상기 저장소 내에서 연장되는 관을 포함하는

적층 가공 축조 재료 용기. - 제 8 항에 있어서,

출구 관의 단부 부분은 상기 저장소의 하단부 부분에 접촉하거나 거의 접촉하고, 측방향 개구를 갖는

적층 가공 축조 재료 용기. - 제 8 항 또는 제 9 항에 있어서,

출구 관은 상기 상단부 부분으로부터 상기 하단부까지 서로 평행하게 연장되는 축조 재료 출구 채널 및 통기 채널(vent channel)을 포함하는

적층 가공 축조 재료 용기. - 제 1 항 내지 제 10 항 중 어느 한 항에 있어서,

저장소 벽은 대략 1 * 109 N/m2 GPa 이하의 영률(Young's modulus)을 갖는

적층 가공 축조 재료 용기. - 제 1 항 내지 제 11 항 중 어느 한 항에 있어서,

저장소 벽은 비교적 가요성이고, 상기 용기는 상기 저장소의 소정 벽 부분의 휘어짐에 저항하는 보강 구조체를 추가로 포함하는

적층 가공 축조 재료 용기. - 제 12 항에 있어서,

상기 보강 구조체는 상기 저장소의 내부에 압력이 인가되는 경우 다른 비-부착된 부분의 휘어짐을 용이하게 하면서 상기 저장소의 소정 부분에 부착되는

적층 가공 축조 재료 용기. - 제 12 항 또는 제 13 항에 있어서,

상기 저장소는 비교적 낮은 공기/증기 투과성을 갖는 반면, 상기 보강 구조체는 상기 저장소보다 높은 공기/증기 투과성을 갖는

적층 가공 축조 재료 용기. - 제 1 항 내지 제 14 항 중 어느 한 항에 있어서,

상기 출구 구조체는 내부 밸브를 포함하며, 상기 내부 밸브는,

상기 출구 구조체가 상기 수집 시스템으로부터 분리될 때 축조 재료 입자가 빠져나가는 것을 억제하고,

상기 수집 시스템의 스나우트(snout)가 상기 출구 구조체에 연결될 때 개방되는

적층 가공 축조 재료 용기. - 제 1 항 내지 제 15 항 중 어느 한 항에 있어서,

통기를 용이하게 하기 위한, 상기 출구 구조체 옆의 공기/축조 재료 스루풋 구조체(throughput structure)를 포함하며, 상기 스루풋 구조체는, 상기 축조 재료 출구 구조체로부터 거리를 두고서, 상기 축조 재료 출구 구조체와 상기 용기의 측부 사이에 있어서의 상단부 부분에서 연장되고, 제거가능한 필터 구조체를 포함하는

적층 가공 축조 재료 용기. - 제 1 항 내지 제 16 항 중 어느 한 항에 있어서,

상기 용기는 분말 축조 재료를 수용하며, 분말은 120 미크론(micron) 미만의 평균 체적-기반 입자 직경(average volume-based particle diameter)을 갖는

적층 가공 축조 재료 용기. - 3D 프린팅 축조 재료 용기에 있어서,

가요성 재료를 포함하는 비교적 가요성의 저장소,

상기 비교적 가요성의 저장소의 일부분을 지지하기 위한, 상기 가요성 재료보다 강성인 비교적 강성의 재료를 포함하는 보강 구조체, 및

상기 저장소 내의 제 1 개구를 통해 상기 저장소의 내부에 대한 접근을 제공하는 출구 구조체를 포함하는

3D 프린팅 축조 재료 용기. - 제 18 항에 있어서,

상기 가요성 저장소는 플라스틱 백(bag)을 포함하고,

상기 보강 구조체는,

저장소 벽의 일부분을 지지하기 위한, 적어도 부분적으로 상기 백 주위에 있는 절첩가능한 구조체, 및

외측 판지 쉘(cardboard shell)을 포함하는

3D 프린팅 축조 재료 용기. - 제 18 항 또는 제 19 항에 있어서,

상기 제 1 개구로부터 떨어져 있는 제 2 개구 위의 스루풋 구조체를 포함하며,

상기 출구 구조체는 축조 재료 출구로서 기능하는 것이고, 상기 스루풋 구조체는 통기구로서 기능하는 것이며,

상기 스루풋 구조체는 공기를 통과시키면서 축조 재료를 차단하기 위해 상기 제 2 개구 위에 필터를 포함하고,

상기 필터는 축조 재료가 상기 제 2 개구를 통해 유동할 수 있게 하도록 분리될 수 있는

3D 프린팅 축조 재료 용기.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP2016/060790 WO2017194147A1 (en) | 2016-05-12 | 2016-05-12 | Build material container |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180098376A true KR20180098376A (ko) | 2018-09-03 |

| KR102171912B1 KR102171912B1 (ko) | 2020-11-02 |

Family

ID=56026848

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187021646A Active KR102171912B1 (ko) | 2016-05-12 | 2016-05-12 | 축조 재료 용기 |

Country Status (10)

| Country | Link |

|---|---|

| US (2) | US10632675B2 (ko) |

| EP (2) | EP3392011B1 (ko) |

| JP (1) | JP6674034B2 (ko) |

| KR (1) | KR102171912B1 (ko) |

| CN (1) | CN108698260B (ko) |

| BR (1) | BR112018015200A2 (ko) |

| ES (2) | ES2690768T3 (ko) |

| HU (2) | HUE049530T2 (ko) |

| PL (2) | PL3392011T3 (ko) |

| WO (1) | WO2017194147A1 (ko) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| PL3392011T3 (pl) * | 2016-05-12 | 2020-07-13 | Hewlett-Packard Development Company, L.P. | Pojemnik na materiał budulcowy |

| EP3386719B1 (en) * | 2016-05-12 | 2022-10-05 | Hewlett-Packard Development Company, L.P. | Build material container |

| WO2017194135A1 (en) * | 2016-05-12 | 2017-11-16 | Hewlett-Packard Development Company, L.P. | Build material container |

| CN108602257B (zh) * | 2016-05-12 | 2021-06-29 | 惠普发展公司有限责任合伙企业 | 构建材料容器 |

| WO2017194138A1 (en) * | 2016-05-12 | 2017-11-16 | Hewlett-Packard Development Company, L.P. | Build material container, and collection tube structure |

| WO2019216912A1 (en) * | 2018-05-11 | 2019-11-14 | Hewlett-Packard Development Company, L.P. | Extracting build material |

| CN114144305A (zh) * | 2018-08-30 | 2022-03-04 | 惠普发展公司,有限责任合伙企业 | 具有配合接口的增材制造设备 |

| GB2588125A (en) * | 2019-10-08 | 2021-04-21 | Xaar 3D Ltd | Interface device for a container for fluid material and for an apparatus for formation of three-dimensional objects from fluid material |

| WO2021076109A1 (en) * | 2019-10-15 | 2021-04-22 | Hewlett-Packard Development Company, L.P. | Three-dimensional printing with cellulose-based additives |

| EP3851266A1 (en) * | 2020-01-20 | 2021-07-21 | Vito NV | A system and method for manufacturing three-dimensional structures |

| CN111515394B (zh) * | 2020-05-18 | 2022-06-07 | 南京理工大学 | 一种激光立体成形惰性气氛保护箱 |

| CN111873421A (zh) * | 2020-06-29 | 2020-11-03 | 北京科技大学 | 下送粉式梯度粉层铺放装置及铺放粉层方法 |

| WO2022087046A1 (en) * | 2020-10-21 | 2022-04-28 | General Electric Company | Material supply systems and methods for using the same |

| EP4232267A1 (en) | 2020-10-21 | 2023-08-30 | General Electric Company | Material supply system and method for using the same |

| WO2022093942A1 (en) | 2020-10-29 | 2022-05-05 | General Electric Company | Additive manufacturing apparatuses with removable build boxes and build box management systems |

| US11904528B2 (en) | 2021-02-23 | 2024-02-20 | Mighty Buildings, Inc. | Three-dimensional printing of free-radical polymerizable composites with continuous fiber reinforcement for building components and buildings |

| US20230226763A1 (en) * | 2022-01-19 | 2023-07-20 | Fermi Research Alliance, Llc | Additive manufacturing platform system |

| AU2023367723A1 (en) * | 2022-10-24 | 2025-05-01 | Cdf Corporation | Container |

| EP4647244A1 (de) | 2024-05-06 | 2025-11-12 | OSSBERGER GmbH + Co KG | Baumaterialbehälter, ein herstellungsverfahren dafür und ein aufbereitungsverfahren für baumaterial damit |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3275197A (en) * | 1963-10-24 | 1966-09-27 | Interconsult Aktiebolag | Inflatable discharge device |

| JP2002205791A (ja) * | 2000-10-31 | 2002-07-23 | Raisen:Kk | 折り畳み式コンテナー |

| JP2006312309A (ja) * | 2005-03-31 | 2006-11-16 | Three D Syst Inc | 空気圧粉末搬送システム |

| JP2009201543A (ja) * | 2008-02-26 | 2009-09-10 | Fujinon Corp | 内視鏡システム |

| US20130164960A1 (en) * | 2011-12-22 | 2013-06-27 | Stratasys, Inc. | Universal adapter for consumable assembly used with additive manufacturing system |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3696952A (en) | 1970-03-23 | 1972-10-10 | Sea Land Service | Bulk cargo handling system and method |

| US4499669A (en) * | 1982-09-30 | 1985-02-19 | Miller Hofft, Inc. | Combination dryer and surge bin |

| WO1995034468A1 (en) | 1994-06-14 | 1995-12-21 | Soligen, Inc. | Powder handling apparatus for additive fabrication equipment |

| US6930791B2 (en) | 2001-02-27 | 2005-08-16 | Eastman Kodak Company | Method for selecting a finishing device for digital printing |

| US6877933B2 (en) | 2001-09-20 | 2005-04-12 | Asm Technology Singapore Pte. Ltd. | Pellet feeding system for a molding machine |

| CA2523284C (en) * | 2004-10-12 | 2011-03-22 | Pactiv Corporation | Methods of reducing the stacking height of containers, lids, and bases |

| JP2006303713A (ja) | 2005-04-18 | 2006-11-02 | Sharp Corp | 画像形成装置および画像形成制御方法 |

| JP4464312B2 (ja) | 2005-04-26 | 2010-05-19 | キヤノン株式会社 | 画像形成システム、情報処理装置及びその制御方法 |

| CA2622617A1 (en) * | 2005-09-20 | 2007-04-12 | Pts Software Bv | An apparatus for building a three-dimensional article and a method for building a three-dimensional article |

| CN2918329Y (zh) | 2006-03-01 | 2007-07-04 | 吴耀明 | 真空粉末上料机 |

| KR101436647B1 (ko) | 2006-05-26 | 2014-09-02 | 3디 시스템즈 인코오퍼레이티드 | 3d 프린터 내에서 재료를 처리하기 위한 인쇄 헤드 및 장치 및 방법 |

| US7311474B1 (en) * | 2007-01-04 | 2007-12-25 | Itswa Co., Ltd. | Pellet loader |

| DE102007005307A1 (de) | 2007-02-02 | 2008-08-07 | Itw Gema Ag | Entleervorrichtung für Pulversäcke für Pulversprühbeschichtungsanlagen |

| US8027044B2 (en) | 2007-03-23 | 2011-09-27 | Canon Kabushiki Kaisha | Image forming apparatus, print job processing method, and program |

| US7690634B2 (en) | 2007-04-30 | 2010-04-06 | Xerox Corporation | Method of processing and printing print job portions for enabling bindery efficiencies |

| JP5247114B2 (ja) | 2007-08-14 | 2013-07-24 | 敏治 大坂 | 包装器材 |

| US8079492B2 (en) * | 2008-03-25 | 2011-12-20 | Meissner Filtration Products, Inc. | Disposable containers and method of making the same |

| FI124163B (sv) * | 2008-06-30 | 2014-04-15 | Uponor Infra Oy | Behållare |

| US8856226B2 (en) | 2009-01-30 | 2014-10-07 | Nokia Corporation | Method, apparatus, and computer program product for context-based contact information management |

| US8643856B2 (en) | 2010-02-02 | 2014-02-04 | Ricoh Company, Ltd. | Methods and systems for network printing with user selectable settings |

| US20110220707A1 (en) * | 2010-03-09 | 2011-09-15 | Solimini Michael E | Five Side Panel Shipping and Storage System |

| WO2012012629A1 (en) | 2010-07-22 | 2012-01-26 | Sun Chemical Corporation | Processes for filling, transporting and delivering of a viscous fluid and use of a coating composition |

| DE102010043166A1 (de) * | 2010-10-29 | 2012-05-03 | Eos Gmbh Electro Optical Systems | Vorrichtung zur Behandlung von Pulver für eine Vorrichtung zum Herstellen eines dreidimensionalen Objekts und Vorrichtung zum Herstellen eines dreidimensionalen Objekts |

| CN201949844U (zh) | 2010-12-13 | 2011-08-31 | 安徽好思家涂料有限公司 | 乳胶漆粉体真空吸料分散装置 |

| CN202609624U (zh) | 2012-06-05 | 2012-12-19 | 滁州斯迈特复合材料有限公司 | 硅胶生产的粉体加料机 |

| CN204019803U (zh) | 2014-08-04 | 2014-12-17 | 北京南极熊科技有限公司 | 一种用于3d打印机的供料装置 |

| GB2520161B (en) * | 2014-09-24 | 2015-10-07 | Lpw Technology Ltd | Transport of Powders |

| CN104842563B (zh) | 2015-05-12 | 2017-11-14 | 杭州先临三维科技股份有限公司 | 一种3d打印机系统 |

| PL3392011T3 (pl) * | 2016-05-12 | 2020-07-13 | Hewlett-Packard Development Company, L.P. | Pojemnik na materiał budulcowy |

| JP7004701B2 (ja) * | 2016-09-12 | 2022-01-21 | マウザー-ヴェルケ ゲゼルシャフト ミット ベシュレンクテル ハフツング | パレットコンテナ |

-

2016

- 2016-05-12 PL PL18176807T patent/PL3392011T3/pl unknown

- 2016-05-12 US US16/069,075 patent/US10632675B2/en active Active

- 2016-05-12 EP EP18176807.8A patent/EP3392011B1/en active Active

- 2016-05-12 EP EP16724008.4A patent/EP3259106B1/en active Active

- 2016-05-12 PL PL16724008T patent/PL3259106T3/pl unknown

- 2016-05-12 HU HUE18176807A patent/HUE049530T2/hu unknown

- 2016-05-12 JP JP2018539900A patent/JP6674034B2/ja active Active

- 2016-05-12 ES ES16724008.4T patent/ES2690768T3/es active Active

- 2016-05-12 KR KR1020187021646A patent/KR102171912B1/ko active Active

- 2016-05-12 ES ES18176807T patent/ES2788401T3/es active Active

- 2016-05-12 CN CN201680080341.1A patent/CN108698260B/zh active Active

- 2016-05-12 BR BR112018015200A patent/BR112018015200A2/pt active Search and Examination

- 2016-05-12 HU HUE16724008A patent/HUE039844T2/hu unknown

- 2016-05-12 WO PCT/EP2016/060790 patent/WO2017194147A1/en not_active Ceased

-

2020

- 2020-03-18 US US16/822,395 patent/US11364682B2/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3275197A (en) * | 1963-10-24 | 1966-09-27 | Interconsult Aktiebolag | Inflatable discharge device |

| JP2002205791A (ja) * | 2000-10-31 | 2002-07-23 | Raisen:Kk | 折り畳み式コンテナー |

| JP2006312309A (ja) * | 2005-03-31 | 2006-11-16 | Three D Syst Inc | 空気圧粉末搬送システム |

| JP2009201543A (ja) * | 2008-02-26 | 2009-09-10 | Fujinon Corp | 内視鏡システム |

| US20130164960A1 (en) * | 2011-12-22 | 2013-06-27 | Stratasys, Inc. | Universal adapter for consumable assembly used with additive manufacturing system |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108698260A (zh) | 2018-10-23 |

| PL3259106T3 (pl) | 2019-01-31 |

| ES2690768T3 (es) | 2018-11-22 |

| HUE049530T2 (hu) | 2020-09-28 |

| ES2788401T3 (es) | 2020-10-21 |

| CN108698260B (zh) | 2021-02-12 |

| US20190061251A1 (en) | 2019-02-28 |

| US11364682B2 (en) | 2022-06-21 |

| BR112018015200A2 (pt) | 2018-12-11 |

| KR102171912B1 (ko) | 2020-11-02 |

| WO2017194147A1 (en) | 2017-11-16 |

| EP3392011A1 (en) | 2018-10-24 |

| EP3392011B1 (en) | 2020-03-11 |

| JP6674034B2 (ja) | 2020-04-01 |

| US20200215753A1 (en) | 2020-07-09 |

| US10632675B2 (en) | 2020-04-28 |

| EP3259106A1 (en) | 2017-12-27 |

| HUE039844T2 (hu) | 2019-02-28 |

| EP3259106B1 (en) | 2018-08-29 |

| PL3392011T3 (pl) | 2020-07-13 |

| JP2019513091A (ja) | 2019-05-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102171912B1 (ko) | 축조 재료 용기 | |

| US11110659B2 (en) | Build material container, and collection tube structure | |

| CN108602256B (zh) | 一种构建材料源容器 | |

| US10751941B2 (en) | Build material container | |

| CN108602258B (zh) | 构建材料容器 | |

| KR102144300B1 (ko) | 축조 재료 용기 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| AMND | Amendment | ||

| PA0105 | International application |

Patent event date: 20180726 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20191219 Patent event code: PE09021S01D |

|

| AMND | Amendment | ||

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20200630 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20191219 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |

|

| AMND | Amendment | ||

| PX0901 | Re-examination |

Patent event code: PX09011S01I Patent event date: 20200630 Comment text: Decision to Refuse Application Patent event code: PX09012R01I Patent event date: 20200214 Comment text: Amendment to Specification, etc. Patent event code: PX09012R01I Patent event date: 20180726 Comment text: Amendment to Specification, etc. |

|

| PX0701 | Decision of registration after re-examination |

Patent event date: 20200922 Comment text: Decision to Grant Registration Patent event code: PX07013S01D Patent event date: 20200828 Comment text: Amendment to Specification, etc. Patent event code: PX07012R01I Patent event date: 20200630 Comment text: Decision to Refuse Application Patent event code: PX07011S01I Patent event date: 20200214 Comment text: Amendment to Specification, etc. Patent event code: PX07012R01I Patent event date: 20180726 Comment text: Amendment to Specification, etc. Patent event code: PX07012R01I |

|

| X701 | Decision to grant (after re-examination) | ||

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 20201026 Patent event code: PR07011E01D |

|

| PR1002 | Payment of registration fee |

Payment date: 20201026 End annual number: 3 Start annual number: 1 |

|

| PG1601 | Publication of registration | ||

| PR1001 | Payment of annual fee |

Payment date: 20230921 Start annual number: 4 End annual number: 4 |

|

| PR1001 | Payment of annual fee |