KR20170081663A - 복합재 접합 - Google Patents

복합재 접합 Download PDFInfo

- Publication number

- KR20170081663A KR20170081663A KR1020177014933A KR20177014933A KR20170081663A KR 20170081663 A KR20170081663 A KR 20170081663A KR 1020177014933 A KR1020177014933 A KR 1020177014933A KR 20177014933 A KR20177014933 A KR 20177014933A KR 20170081663 A KR20170081663 A KR 20170081663A

- Authority

- KR

- South Korea

- Prior art keywords

- matrix resin

- composite substrate

- resin

- cured

- curing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/12—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by using adhesives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

- B32B37/144—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers using layers with different mechanical or chemical conditions or properties, e.g. layers with different thermal shrinkage, layers under tension during bonding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/4805—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding characterised by the type of adhesives

- B29C65/483—Reactive adhesives, e.g. chemically curing adhesives

- B29C65/4835—Heat curing adhesives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/50—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like

- B29C65/5042—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like covering both elements to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/50—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like

- B29C65/5057—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like positioned between the surfaces to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/02—Preparation of the material, in the area to be joined, prior to joining or welding

- B29C66/022—Mechanical pre-treatments, e.g. reshaping

- B29C66/0224—Mechanical pre-treatments, e.g. reshaping with removal of material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/11—Joint cross-sections comprising a single joint-segment, i.e. one of the parts to be joined comprising a single joint-segment in the joint cross-section

- B29C66/112—Single lapped joints

- B29C66/1122—Single lap to lap joints, i.e. overlap joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/45—Joining of substantially the whole surface of the articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/72—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined

- B29C66/721—Fibre-reinforced materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/73—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset

- B29C66/737—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the state of the material of the parts to be joined

- B29C66/7375—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the state of the material of the parts to be joined uncured, partially cured or fully cured

- B29C66/73753—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the state of the material of the parts to be joined uncured, partially cured or fully cured the to-be-joined area of at least one of the parts to be joined being partially cured, i.e. partially cross-linked, partially vulcanized

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/26—Layered products comprising a layer of synthetic resin characterised by the use of special additives using curing agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/38—Layered products comprising a layer of synthetic resin comprising epoxy resins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G59/00—Polycondensates containing more than one epoxy group per molecule; Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups

- C08G59/18—Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups ; e.g. general methods of curing

- C08G59/40—Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups ; e.g. general methods of curing characterised by the curing agents used

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/12—Bonding of a preformed macromolecular material to the same or other solid material such as metal, glass, leather, e.g. using adhesives

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/12—Bonding of a preformed macromolecular material to the same or other solid material such as metal, glass, leather, e.g. using adhesives

- C08J5/124—Bonding of a preformed macromolecular material to the same or other solid material such as metal, glass, leather, e.g. using adhesives using adhesives based on a macromolecular component

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/241—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres

- C08J5/244—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres using glass fibres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/246—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using polymer based synthetic fibres

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J5/00—Adhesive processes in general; Adhesive processes not provided for elsewhere, e.g. relating to primers

- C09J5/02—Adhesive processes in general; Adhesive processes not provided for elsewhere, e.g. relating to primers involving pretreatment of the surfaces to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D3/00—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials

- B05D3/007—After-treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/02—Preparation of the material, in the area to be joined, prior to joining or welding

- B29C66/022—Mechanical pre-treatments, e.g. reshaping

- B29C66/0224—Mechanical pre-treatments, e.g. reshaping with removal of material

- B29C66/02245—Abrading, e.g. grinding, sanding, sandblasting or scraping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/02—Composition of the impregnated, bonded or embedded layer

- B32B2260/021—Fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/04—Impregnation, embedding, or binder material

- B32B2260/046—Synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/72—Cured, e.g. vulcanised, cross-linked

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2363/00—Epoxy resins

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2363/00—Characterised by the use of epoxy resins; Derivatives of epoxy resins

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2463/00—Characterised by the use of epoxy resins; Derivatives of epoxy resins

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2463/00—Presence of epoxy resin

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2463/00—Presence of epoxy resin

- C09J2463/006—Presence of epoxy resin in the substrate

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2463/00—Presence of epoxy resin

- C09J2463/008—Presence of epoxy resin in the pretreated surface to be joined

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Mechanical Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Polymers & Plastics (AREA)

- Medicinal Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Reinforced Plastic Materials (AREA)

- Laminated Bodies (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Moulding By Coating Moulds (AREA)

- Lining Or Joining Of Plastics Or The Like (AREA)

- Adhesive Tapes (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

Abstract

Description

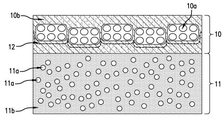

도 2는 본 발명의 다른 양태에 따라, 표면 수지 필름이 상부에 형성된 복합 기재를 개략적으로 예시한 것이다.

도 3은 표면 처리 후 2개의 복합 기재의 접착제 접합을 예시한 것이다.

도 4는 한 양태에 따른 표면 처리 수지 대(vs.) 표준 프리프레그 수지의 DSC 측정의 트레이스(trace)이다.

| 기재(또는 프리프레그) 경화제 | 표면 처리 경화제 |

| 1,3-비스(4-아미노페녹시)벤젠 | 4,4'-디아미노디페닐설폰 |

| 4,4'-디아미노디페닐설폰 | 멜라민 |

| 4,4'-디아미노디페닐설폰, 디시아노구아나딘 | 4,4'-디아미노디페닐설폰 |

| 4,4'-디아미노디페닐설폰, 디시아노구아나딘 | 멜라민 |

| 3,3'-디아미노디페닐설폰 | 멜라민 |

| 1,3-비스(4-아미노페녹시)벤젠 | (3-(4-아미노벤조일)옥시페닐)-4-아미노벤조에이트 |

| 3,3'-디아미노디페닐설폰 | 4,4'-디아미노디페닐설폰 |

| 비스-아닐린 M | 4,4'-디아미노디페닐설폰 |

| 4,4'-디아미노디페닐설폰 | (3-(4-아미노벤조일)옥시페닐)-4-아미노벤조에이트 |

| 비스-아닐린 P | 3,3'-디아미노디페닐설폰 |

| 3,3'-디아미노디페닐설폰, 이소프탈릭 디하이드라자이드 | 멜라민 |

| 파괴인성 | 실시예 1 | 실시예 2 | 실시예 3 |

| G1c(주울/㎡) | 1802 | 116 | 1211 |

Claims (28)

- (a) 제1 경화성 매트릭스 수지로 함침된 강화 섬유를 함유하는 복합 기재를 제공하는 단계;

(b) 복합 기재의 표면 위에, 제1 매트릭스 수지와 다른 제2 경화성 매트릭스 수지를 함유하는 표면 처리 층을 적용하는 단계;

(c) 복합 기재는 완전 경화되지만 표면 처리 층은 부분 경화된 상태로 남아 있을 때까지 복합 기재와 표면 처리 층을 공경화시키는 단계를 함유하고,

상기 제2 매트릭스 수지는 제1 매트릭스 수지보다 느린 속도로 경화하도록 조제하고, 공경화 (c) 이후, 표면 처리 층은 화학적 활성 작용기를 가진 접합성 표면을 제공하는 것인, 접착제 접합전의 표면 제조 방법. - 제1항에 있어서, 표면 처리 층이 내부에 매립된 직물 또는 강화 섬유를 함유하지 않는 수지 필름인 표면 제조 방법.

- 제1항에 있어서, 표면 처리 층이 제2 경화성 매트릭스 수지가 주입된 제직물을 함유하고, 공경화 (c) 이후, 표면 처리 층은 복합 기재의 표면으로부터 제거되어 복합 기재의 표면 위에 부분 경화된 매트릭스 수지 박막을 남기고, 이 박막은 화학적 활성 작용기를 가진 조면화된 접합성 표면을 제공하는 것인, 표면 제조 방법.

- 제1항에 있어서, 제1 및 제2 경화성 매트릭스 수지가 하나 이상의 다작용기성 에폭시 수지를 함유하는 표면 제조 방법.

- 제1항에 있어서, 제1 및 제2 매트릭스 수지가 다른 속도로 경화에 영향을 미치도록 선택한 다른 경화제를 함유하는 표면 제조 방법.

- 제5항에 있어서,

제1 및 제2 매트릭스 수지가 하나 이상의 에폭시 수지를 함유하고,

제1 및 제2 매트릭스 수지용 경화제가 멜라민 및 치환된 멜라민 유도체, 폴리머캅탄, 폴리아미드, 지방족 폴리아민, 방향족 폴리아민 유도체, 3차 아민 삼불화붕소 복합체, 산 무수물, 이미다졸, 방향족 폴리아민, 시아노구아나딘, 페놀 노볼락으로 이루어진 그룹 중에서 선택되고,

제1 매트릭스 수지용 경화제는 제2 매트릭스 수지용 경화제에 비해 제1 매트릭스 수지를 더 빠른 속도로 경화시킬 수 있는 것으로 선택하는 것인, 표면 제조 방법. - 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 1,3-비스(4-아미노페녹시)벤젠을 함유하고, 제2 매트릭스 수지가 4,4'-디아미노디페닐설폰 또는 (3-(4-아미노벤조일)옥시페닐)-4-아미노벤조에이트를 함유하는, 표면 제조 방법.

- 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 4,4'-디아미노디페닐설폰 또는 3,3'-디아미노디페닐설폰을 함유하고, 제2 매트릭스 수지가 멜라민을 함유하는, 표면 제조 방법.

- 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 4,4'-디아미노디페닐설폰과 디시아노구아나딘의 배합물을 함유하고, 제2 매트릭스 수지가 4,4'-디아미노디페닐설폰 또는 멜라민을 함유하는, 표면 제조 방법.

- 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 3,3'-디아미노디페닐설폰을 함유하고, 제2 매트릭스 수지가 4,4'-디아미노디페닐설폰을 함유하는, 표면 제조 방법.

- 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 비스-아닐린 M을 함유하고 제2 매트릭스 수지가 4,4'-디아미노디페닐설폰을 함유하는, 표면 제조 방법.

- 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 4,4'-디아미노디페닐설폰을 함유하고, 제2 매트릭스 수지가 (3-(4-아미노벤조일)옥시페닐)-4-아미노벤조에이트를 함유하는, 표면 제조 방법.

- 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 비스-아닐린 P를 함유하고, 제2 매트릭스 수지가 3,3'-디아미노디페닐설폰을 함유하는, 표면 제조 방법.

- 제6항에 있어서, 경화제로써, 제1 매트릭스 수지가 3,3'-디아미노디페닐설폰과 이소프탈산 디하이드라자이드의 배합물을 함유하고, 제2 매트릭스 수지가 멜라민을 함유하는, 표면 제조 방법.

- 제1항 내지 제4항 중 어느 한 항에 있어서, 경화성 제2 매트릭스 수지가 하나 이상의 열경화 수지, 경화제 및 이 제2 매트릭스 수지에 존재하는 하나 이상의 열경화 수지와 경화제 사이의 반응 속도를 지연시킬 수 있는 억제제를 함유하는, 표면 제조 방법.

- 제15항에 있어서, 억제제가 붕산; 트리플루오로보란; 알킬 보레이트; 알킬 보란; 트리메톡시보록신; pKa가 1 내지 3인 유기 산, 예컨대 말레산, 살리실산, 옥살산; 금속 산화물, 금속 수산화물 및 금속 알콕사이드(이때 금속은 아연, 주석, 티탄, 코발트, 망간, 철, 규소, 붕소 또는 알루미늄이다); 이의 조합으로 이루어진 그룹 중에서 선택되는, 표면 제조 방법.

- 제1항 내지 제4항 중 어느 한 항에 있어서, 경화성 제1 매트릭스 수지가 하나 이상의 열경화 수지, 경화제 및 상기 하나 이상의 열경화 수지와 경화제 사이의 반응 속도를 증가시킬 수 있는 가속화제를 함유하는, 표면 제조 방법.

- 제17항에 있어서, 제1 매트릭스 수지가 하나 이상의 에폭시 수지를 함유하고, 가속화제가 아민, 포스핀, 복소환식 질소, 암모늄, 포스포늄, 아르세늄 또는 설포늄 모이어티를 함유하는 화합물 중에서 선택되는 것인, 표면 제조 방법.

- 제17항에 있어서, 제1 매트릭스 수지가 하나 이상의 에폭시 수지를 함유하고 가속화제가 벤즈이미다졸, 이미다졸, 이미다졸리딘, 이미다졸린, 옥사졸, 피롤, 티아졸, 피리딘, 피라진, 모르폴린, 피리다진, 피리미딘, 피롤리딘, 피라졸, 퀴녹살린, 퀴나졸린, 프탈로진, 퀴놀린, 퓨린, 인다졸, 인돌, 인돌라진, 페나진, 페나르사진, 페노티아진, 피롤린, 인돌린, 피페리딘, 피페라진 및 이의 조합으로 이루어진 그룹 중에서 선택되는, 표면 제조 방법.

- 제1항 내지 제19항 중 어느 한 항에 기재된 방법에 의해 생산된 화학적 활성 작용기가 있는 접합성 표면을 가진 경화된 복합 기재.

- (a) 제1 경화성 매트릭스 수지로 함침된 강화 섬유를 함유하는 제1 복합 기재를 제공하는 단계;

(b) 제1 복합 기재의 표면 위에, 제1 매트릭스 수지보다 느린 속도로 경화하도록 조제된 제2 경화성 매트릭스 수지로 함침된 제직물을 함유하는, 제거가능한 수지 풍부한 박리 층을 적용하는 단계;

(c) 제1 복합 기재는 완전 경화되지만, 박리 층 내의 제2 매트릭스 수지는 부분 경화된 상태일 때까지 제1 복합 기재와 박리 층을 공경화시키는 단계;

(d) 제1 복합 기재의 표면으로부터 박리 층을 제거하고, 제1 복합 기재의 표면 위에 부분 경화된 제2 매트릭스 수지 박막을 남겨, 이 박막이 화학적 활성 작용기가 있는 조면화된 접합성 표면을 제공하는 단계;

(e) 복합 기재 사이에 경화성 접착제 필름을 이용하여 제2 복합 기재에 상기 경화된 제1 복합 기재를 결합시키되,

상기 경화성 접착제 필름이 상기 제1 복합 기재의 접합성 표면 위에 존재하는 화학적 활성 작용기와 반응할 수 있는 화학적 활성 작용기를 함유하는 것인 단계; 및

(f) 접착제 필름을 경화시켜 공유 접합된 구조를 형성시키는 단계를 함유하는 접합 방법. - (a) 제1 경화성 매트릭스 수지로 함침된 강화 섬유를 함유하는 제1 복합 기재를 제공하는 단계;

(b) 제1 복합 기재의 표면 위에, 제2 경화성 매트릭스 수지로 제조되고 제1 매트릭스 수지보다 느린 속도로 경화하도록 조제된 수지 필름을 적용하는 단계;

(c) 상기 제1 복합 기재는 완전 경화하지만 상기 수지 필름은 부분 경화된 채 남아 있을 때까지 상기 제1 복합 기재와 상기 수지 필름을 공경화시켜, 화학적 활성 작용기를 가진 접합성 표면을 제공하는 단계;

(e) 경화된 제1 복합 기재와 제2 복합 기재를 이 복합 기재들 사이에 경화성 접착제 필름을 이용하여 결합시키고, 이때 경화성 접착제 필름은 제1 복합 기재의 접합성 표면 위에 있는 화학적 활성 작용기와 반응할 수 있는 화학적 활성 작용기를 함유하는 것인 단계; 및

(f) 접착제 필름을 경화시켜 공유 접합된 구조를 형성시키는 단계를 함유하는 접합 방법. - 제21항 또는 제22항에 있어서, 제2 복합 기재가 경화된 제1 복합 기재에 결합되기 전에 경화되는, 접합 방법.

- 제21항에 있어서, 경화된 제2 복합 기재가, 상기 경화된 제1 복합 기재의 조면화된 접합성 표면을 형성하는데 사용했던 방법과 동일한 방법으로 제조한 화학적 활성 작용기를 가진 조면화된 접합성 표면을 함유하는, 접합 방법.

- 제21항 또는 제22항에 있어서, 제2 복합 기재가 제1 복합 기재에 결합되기 전에 부분 경화되거나 경화되지 않고, 단계 (f)에서 경화 동안, 접착제 필름과 제2 복합 기재가 동시에 경화되는, 접합 방법.

- 제21항 내지 제25항 중 어느 한 항에 있어서, 제1 및 제2 경화성 매트릭스 수지가 다른 속도로 경화에 영향을 미치도록 선택한 다른 경화제를 함유하는 접합 방법.

- 제26항에 있어서,

제1 및 제2 경화성 매트릭스 수지가 하나 이상의 에폭시 수지를 함유하고,

제1 및 제2 매트릭스 수지용 경화제가 멜라민 및 치환된 멜라민 유도체, 폴리머캅탄, 폴리아미드, 지방족 폴리아민, 방향족 폴리아민 유도체, 3차 아민 삼불화붕소 복합체, 산 무수물, 이미다졸, 방향족 폴리아민, 시아노구아나딘, 페놀 노볼락으로 이루어진 그룹 중에서 선택되고,

제1 및 제2 매트릭스 수지용 경화제는 제1 매트릭스 수지를 제2 매트릭스 수지에 비해 더 빠른 속도로 경화시킬 수 있는 것으로 선택하는 것인 접합 방법. - 제21항 내지 제27항 중 어느 한 항에 있어서, 경화성 접착제 필름이 경화제로써 적어도 하나의 아민 화합물과 적어도 하나의 다작용기성 에폭시 수지를 함유하는 접합 방법.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201462074266P | 2014-11-03 | 2014-11-03 | |

| US62/074,266 | 2014-11-03 | ||

| PCT/US2015/056551 WO2016073192A1 (en) | 2014-11-03 | 2015-10-21 | Bonding of composite materials |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20170081663A true KR20170081663A (ko) | 2017-07-12 |

Family

ID=55851661

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020177014933A Abandoned KR20170081663A (ko) | 2014-11-03 | 2015-10-21 | 복합재 접합 |

Country Status (12)

| Country | Link |

|---|---|

| US (2) | US9789646B2 (ko) |

| EP (1) | EP3227363B1 (ko) |

| JP (1) | JP6660397B2 (ko) |

| KR (1) | KR20170081663A (ko) |

| CN (1) | CN107207749B (ko) |

| AU (1) | AU2015343586B2 (ko) |

| BR (1) | BR112017009032B1 (ko) |

| CA (1) | CA2966496C (ko) |

| ES (1) | ES2842278T3 (ko) |

| RU (1) | RU2708209C2 (ko) |

| TW (1) | TWI652171B (ko) |

| WO (1) | WO2016073192A1 (ko) |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10369767B2 (en) | 2015-09-23 | 2019-08-06 | United States Of America As Represented By The Administrator Of Nasa | Blocking/deblocking resin systems for use as a “co-cure-ply” in the fabrication of large-scale composite structure |

| US10549516B2 (en) | 2015-09-23 | 2020-02-04 | United States Of America As Represented By The Administrator Of Nasa | Off-set resin formulations and blocking/deblocking resin systems for use as a “co-cure-ply” in the fabrication of large-scale composite structure |

| US10661511B2 (en) * | 2015-09-24 | 2020-05-26 | The Boeing Company | Anisotropic reinforcement of composite structures |

| KR20180059824A (ko) * | 2015-09-28 | 2018-06-05 | 도레이 카부시키가이샤 | 경화 속도가 변화하는 수지 조성물을 구비한 프리프레그 |

| CN105921388B (zh) * | 2016-05-20 | 2017-06-13 | 依波精品(深圳)有限公司 | 一种金合金制品防腐蚀表面处理方法 |

| JP6539234B2 (ja) * | 2016-07-25 | 2019-07-03 | 富士高分子工業株式会社 | 複合シート及びその製造方法 |

| US20190263072A1 (en) * | 2016-09-09 | 2019-08-29 | Cytec Industries Inc. | Bonding of composite substrates |

| KR101983028B1 (ko) * | 2016-10-31 | 2019-05-29 | 코나아이 (주) | 하이브리드 소재의 메탈카드 제조방법 |

| CN107470105A (zh) * | 2017-07-04 | 2017-12-15 | 当涂县宏宇金属炉料有限责任公司 | 一种金属漆前表面处理工艺 |

| US10814564B2 (en) * | 2017-10-11 | 2020-10-27 | Divergent Technologies, Inc. | Composite material inlay in additively manufactured structures |

| EP3727804B1 (en) * | 2017-12-21 | 2022-05-18 | Cytec Industries Inc. | Peel ply for surface preparation and bonding method using the same |

| JPWO2019124203A1 (ja) * | 2017-12-22 | 2020-10-22 | 東レ株式会社 | テープ状プリプレグ及びその製造方法 |

| HRP20220830T1 (hr) * | 2018-01-11 | 2022-10-14 | Nanocore Aps | Kompozitni materijali koji sadrže mehaničke ligande |

| US10843413B2 (en) * | 2018-03-26 | 2020-11-24 | Textron Innovations Inc. | Methods for forming bonded structures |

| CN108587067B (zh) * | 2018-05-10 | 2020-05-01 | 江苏兆鋆新材料股份有限公司 | 一种高模量高韧性环氧树脂碳纤维预浸料及其制备方法 |

| DE102018111306B4 (de) * | 2018-05-11 | 2022-10-20 | Deutsches Zentrum für Luft- und Raumfahrt e.V. | Verfahren zum Applizieren eines Werkstoffes auf ein Faserverbundbauteil |

| CN109615032B (zh) * | 2018-11-07 | 2021-12-17 | 歌尔光学科技有限公司 | 一种涂胶固化系统的控制方法、装置及涂胶固化系统 |

| DE102018130330B4 (de) * | 2018-11-29 | 2023-02-09 | Deutsches Zentrum für Luft- und Raumfahrt e.V. | Verfahren zur Herstellung eines Prüfkörpers |

| CN109666297B (zh) * | 2018-11-30 | 2021-08-03 | 中国航空工业集团公司基础技术研究院 | 一种牺牲层用紫外荧光双马来酰亚胺树脂碳纤维预浸料 |

| US11390060B2 (en) * | 2018-12-20 | 2022-07-19 | Cytec Industries Inc. | Surface treatment to enhance bonding of composite materials |

| US10974478B2 (en) * | 2019-03-08 | 2021-04-13 | The Boeing Company | Interleaved layer construction and a plank for stiffening a panel |

| US12083625B2 (en) | 2019-04-05 | 2024-09-10 | Rtx Corporation | Laser surface treatment on stainless steel and nickel alloys for adhesive bonding |

| CN110370476B (zh) * | 2019-06-30 | 2021-04-06 | 惠州泓海新材料科技有限公司 | 一种环氧树脂增强云母石的加工工艺 |

| JP7263166B2 (ja) * | 2019-07-16 | 2023-04-24 | 三菱重工業株式会社 | 複合材接合体の製造方法 |

| US11559957B2 (en) * | 2020-01-24 | 2023-01-24 | The Boeing Company | Reactivation of co-cured film layers |

| US11578604B2 (en) * | 2020-03-17 | 2023-02-14 | Raytheon Technologies Corporation | Adhesive bonded composite-to-metal hybrid vanes and method of manufacture |

| WO2022208165A1 (en) * | 2021-03-31 | 2022-10-06 | Toray Industries, Inc. | Epoxy resin composition, prepreg, and fiber-reinforced composite material |

| EP4074494A1 (en) * | 2021-04-12 | 2022-10-19 | The Boeing Company | Methods of forming uncured sealant assemblies and using such assemblies for sealing and bonding parts |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1422396A (en) * | 1973-01-26 | 1976-01-28 | Ciba Geigy Ag | Film adhesives |

| JPS556317B2 (ko) * | 1973-06-20 | 1980-02-15 | ||

| US4307212A (en) | 1980-08-14 | 1981-12-22 | General Electric Company | Curable epoxy resins |

| JPS60243113A (ja) * | 1984-05-17 | 1985-12-03 | Sumitomo Chem Co Ltd | 強靭性に優れたエポキシ樹脂組成物 |

| JPS61252284A (ja) * | 1985-04-30 | 1986-11-10 | Nitto Electric Ind Co Ltd | 樹脂製補強材 |

| GB9821991D0 (en) | 1998-10-08 | 1998-12-02 | Thorstone Business Man Ltd | Coatings |

| US6316099B1 (en) * | 1999-03-31 | 2001-11-13 | 3M Innovative Properties Company | Multi-layered sealant |

| JP2001310929A (ja) * | 2000-04-28 | 2001-11-06 | Sanoya Sangyo Kk | 中性子遮蔽能を有するエポキシ樹脂組成物及び該エポキシ樹脂組成物を硬化した透明遮蔽材 |

| JP2001323126A (ja) * | 2000-05-15 | 2001-11-20 | Nippon Zeon Co Ltd | 硬化性樹脂組成物 |

| JP3862004B2 (ja) * | 2002-05-10 | 2006-12-27 | 信越化学工業株式会社 | 耐熱性樹脂組成物及びそれを用いた接着フィルム |

| GB2409837B (en) * | 2004-01-10 | 2006-09-06 | Hexcel Composites Ltd | Fibre reinforced resin assembly |

| US20060182949A1 (en) * | 2005-02-17 | 2006-08-17 | 3M Innovative Properties Company | Surfacing and/or joining method |

| JP2009221390A (ja) * | 2008-03-18 | 2009-10-01 | Jamco Corp | 複合材連続成形用プリプレグピールプライ |

| US20120010329A1 (en) * | 2009-02-24 | 2012-01-12 | Hunter Gary A | Curable epoxy resin compositions and cured products therefrom |

| JP5811883B2 (ja) * | 2011-02-25 | 2015-11-11 | 東レ株式会社 | 繊維強化複合材料用エポキシ樹脂組成物、プリプレグおよび繊維強化複合材料 |

| CN103946012B (zh) * | 2011-12-30 | 2016-01-20 | 氰特科技股份有限公司 | 剥离层、使用其的表面制备和结合复合结构的方法 |

| US9254622B2 (en) * | 2012-04-23 | 2016-02-09 | University Of Washington | Bond ply for adhesive bonding of composites and associated systems and methods |

| CN104837605A (zh) * | 2012-11-26 | 2015-08-12 | 塞特工业公司 | 复合材料的结合 |

| JP6216133B2 (ja) * | 2013-03-25 | 2017-10-18 | 互応化学工業株式会社 | 2液混合型の主剤及び硬化剤、並びにプリント配線板の製造方法 |

| JP6119376B2 (ja) * | 2013-03-29 | 2017-04-26 | 三菱化学株式会社 | エポキシ樹脂、エポキシ樹脂組成物及び硬化物 |

| CA2921904C (en) * | 2013-08-22 | 2021-03-16 | Cytec Industries Inc. | Bonding of composite materials |

-

2015

- 2015-10-21 WO PCT/US2015/056551 patent/WO2016073192A1/en not_active Ceased

- 2015-10-21 CN CN201580059804.1A patent/CN107207749B/zh active Active

- 2015-10-21 AU AU2015343586A patent/AU2015343586B2/en not_active Ceased

- 2015-10-21 RU RU2017119030A patent/RU2708209C2/ru active

- 2015-10-21 KR KR1020177014933A patent/KR20170081663A/ko not_active Abandoned

- 2015-10-21 CA CA2966496A patent/CA2966496C/en active Active

- 2015-10-21 BR BR112017009032-5A patent/BR112017009032B1/pt active IP Right Grant

- 2015-10-21 ES ES15798262T patent/ES2842278T3/es active Active

- 2015-10-21 JP JP2017543721A patent/JP6660397B2/ja active Active

- 2015-10-21 EP EP15798262.0A patent/EP3227363B1/en active Active

- 2015-10-27 US US14/923,972 patent/US9789646B2/en active Active

- 2015-11-02 TW TW104136075A patent/TWI652171B/zh not_active IP Right Cessation

-

2017

- 2017-09-18 US US15/707,160 patent/US10315404B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| BR112017009032B1 (pt) | 2021-10-26 |

| RU2017119030A (ru) | 2018-12-05 |

| AU2015343586A1 (en) | 2017-05-04 |

| RU2708209C2 (ru) | 2019-12-04 |

| TW201634291A (zh) | 2016-10-01 |

| WO2016073192A1 (en) | 2016-05-12 |

| EP3227363A1 (en) | 2017-10-11 |

| JP6660397B2 (ja) | 2020-03-11 |

| TWI652171B (zh) | 2019-03-01 |

| ES2842278T3 (es) | 2021-07-13 |

| US20160121591A1 (en) | 2016-05-05 |

| BR112017009032A2 (pt) | 2018-02-06 |

| US9789646B2 (en) | 2017-10-17 |

| CA2966496C (en) | 2022-08-16 |

| US10315404B2 (en) | 2019-06-11 |

| US20180001572A1 (en) | 2018-01-04 |

| AU2015343586B2 (en) | 2019-05-09 |

| CA2966496A1 (en) | 2016-05-12 |

| EP3227363B1 (en) | 2020-10-07 |

| CN107207749A (zh) | 2017-09-26 |

| JP2018502753A (ja) | 2018-02-01 |

| RU2017119030A3 (ko) | 2019-04-12 |

| CN107207749B (zh) | 2021-03-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10315404B2 (en) | Bonding of composite materials | |

| US10773508B2 (en) | Bonding of composite materials | |

| JP7247194B2 (ja) | 表面処理用の剥離層及びそれを使用する接着方法 | |

| US20190263072A1 (en) | Bonding of composite substrates | |

| EP3728422B1 (en) | Bonding method using a toughened adhesive |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

St.27 status event code: A-0-1-A10-A15-nap-PA0105 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-3-3-R10-R18-oth-X000 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| A201 | Request for examination | ||

| E13-X000 | Pre-grant limitation requested |

St.27 status event code: A-2-3-E10-E13-lim-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| PC1904 | Unpaid initial registration fee |

St.27 status event code: A-2-2-U10-U14-oth-PC1904 St.27 status event code: N-2-6-B10-B12-nap-PC1904 |

|

| R18 | Changes to party contact information recorded |

Free format text: ST27 STATUS EVENT CODE: A-3-3-R10-R18-OTH-X000 (AS PROVIDED BY THE NATIONAL OFFICE) |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-3-3-R10-R18-oth-X000 |