KR20150079970A - 코팅된 스냅 커터 블레이드와 그 제조 방법 - Google Patents

코팅된 스냅 커터 블레이드와 그 제조 방법 Download PDFInfo

- Publication number

- KR20150079970A KR20150079970A KR1020157014925A KR20157014925A KR20150079970A KR 20150079970 A KR20150079970 A KR 20150079970A KR 1020157014925 A KR1020157014925 A KR 1020157014925A KR 20157014925 A KR20157014925 A KR 20157014925A KR 20150079970 A KR20150079970 A KR 20150079970A

- Authority

- KR

- South Korea

- Prior art keywords

- blade

- snap

- edge

- cutter blade

- core

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 10

- 238000005520 cutting process Methods 0.000 claims abstract description 60

- 238000000576 coating method Methods 0.000 claims abstract description 58

- 239000011248 coating agent Substances 0.000 claims abstract description 48

- 230000003014 reinforcing effect Effects 0.000 claims abstract description 7

- 238000000926 separation method Methods 0.000 claims description 16

- 238000005452 bending Methods 0.000 claims description 13

- 238000000034 method Methods 0.000 claims description 12

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 claims description 6

- 239000000463 material Substances 0.000 claims description 5

- 229910052751 metal Inorganic materials 0.000 claims description 4

- 239000002184 metal Substances 0.000 claims description 4

- 230000002708 enhancing effect Effects 0.000 claims description 3

- UQZIWOQVLUASCR-UHFFFAOYSA-N alumane;titanium Chemical compound [AlH3].[Ti] UQZIWOQVLUASCR-UHFFFAOYSA-N 0.000 claims description 2

- 239000008199 coating composition Substances 0.000 claims description 2

- 239000011701 zinc Substances 0.000 claims description 2

- 229910000851 Alloy steel Inorganic materials 0.000 claims 1

- 229910000975 Carbon steel Inorganic materials 0.000 claims 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 claims 1

- 239000010962 carbon steel Substances 0.000 claims 1

- 238000003763 carbonization Methods 0.000 claims 1

- 238000012986 modification Methods 0.000 claims 1

- 230000004048 modification Effects 0.000 claims 1

- 238000005121 nitriding Methods 0.000 claims 1

- 229910052725 zinc Inorganic materials 0.000 claims 1

- 239000011162 core material Substances 0.000 description 23

- 230000000052 comparative effect Effects 0.000 description 16

- 238000005259 measurement Methods 0.000 description 7

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 5

- 229910052799 carbon Inorganic materials 0.000 description 5

- 238000005240 physical vapour deposition Methods 0.000 description 5

- 239000002994 raw material Substances 0.000 description 5

- 238000005728 strengthening Methods 0.000 description 5

- 229910000831 Steel Inorganic materials 0.000 description 4

- 239000010959 steel Substances 0.000 description 4

- 238000005299 abrasion Methods 0.000 description 3

- 239000011651 chromium Substances 0.000 description 3

- 238000000151 deposition Methods 0.000 description 3

- 230000008021 deposition Effects 0.000 description 3

- 229910001220 stainless steel Inorganic materials 0.000 description 3

- INZDTEICWPZYJM-UHFFFAOYSA-N 1-(chloromethyl)-4-[4-(chloromethyl)phenyl]benzene Chemical compound C1=CC(CCl)=CC=C1C1=CC=C(CCl)C=C1 INZDTEICWPZYJM-UHFFFAOYSA-N 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 2

- 229910001315 Tool steel Inorganic materials 0.000 description 2

- 238000007545 Vickers hardness test Methods 0.000 description 2

- 229910026551 ZrC Inorganic materials 0.000 description 2

- OTCHGXYCWNXDOA-UHFFFAOYSA-N [C].[Zr] Chemical compound [C].[Zr] OTCHGXYCWNXDOA-UHFFFAOYSA-N 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000010894 electron beam technology Methods 0.000 description 2

- 238000007733 ion plating Methods 0.000 description 2

- 150000002500 ions Chemical class 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- NFFIWVVINABMKP-UHFFFAOYSA-N methylidynetantalum Chemical compound [Ta]#C NFFIWVVINABMKP-UHFFFAOYSA-N 0.000 description 2

- 238000004544 sputter deposition Methods 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 229910003468 tantalcarbide Inorganic materials 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- MTPVUVINMAGMJL-UHFFFAOYSA-N trimethyl(1,1,2,2,2-pentafluoroethyl)silane Chemical compound C[Si](C)(C)C(F)(F)C(F)(F)F MTPVUVINMAGMJL-UHFFFAOYSA-N 0.000 description 2

- 238000001771 vacuum deposition Methods 0.000 description 2

- ONDPHDOFVYQSGI-UHFFFAOYSA-N zinc nitrate Chemical compound [Zn+2].[O-][N+]([O-])=O.[O-][N+]([O-])=O ONDPHDOFVYQSGI-UHFFFAOYSA-N 0.000 description 2

- 101150019161 SKS2 gene Proteins 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 1

- QISGROBHHFQWKS-UHFFFAOYSA-N [C].[Nb] Chemical compound [C].[Nb] QISGROBHHFQWKS-UHFFFAOYSA-N 0.000 description 1

- WIGAYVXYNSVZAV-UHFFFAOYSA-N ac1lavbc Chemical compound [W].[W] WIGAYVXYNSVZAV-UHFFFAOYSA-N 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- CXOWYMLTGOFURZ-UHFFFAOYSA-N azanylidynechromium Chemical compound [Cr]#N CXOWYMLTGOFURZ-UHFFFAOYSA-N 0.000 description 1

- CFJRGWXELQQLSA-UHFFFAOYSA-N azanylidyneniobium Chemical compound [Nb]#N CFJRGWXELQQLSA-UHFFFAOYSA-N 0.000 description 1

- SKKMWRVAJNPLFY-UHFFFAOYSA-N azanylidynevanadium Chemical compound [V]#N SKKMWRVAJNPLFY-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- VDZMENNHPJNJPP-UHFFFAOYSA-N boranylidyneniobium Chemical compound [Nb]#B VDZMENNHPJNJPP-UHFFFAOYSA-N 0.000 description 1

- LAROCDZIZGIQGR-UHFFFAOYSA-N boron;vanadium Chemical compound B#[V]#B LAROCDZIZGIQGR-UHFFFAOYSA-N 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000005137 deposition process Methods 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 229910052746 lanthanum Inorganic materials 0.000 description 1

- FZLIPJUXYLNCLC-UHFFFAOYSA-N lanthanum atom Chemical compound [La] FZLIPJUXYLNCLC-UHFFFAOYSA-N 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- JAGQSESDQXCFCH-UHFFFAOYSA-N methane;molybdenum Chemical compound C.[Mo].[Mo] JAGQSESDQXCFCH-UHFFFAOYSA-N 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000005268 plasma chemical vapour deposition Methods 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- 238000002230 thermal chemical vapour deposition Methods 0.000 description 1

- 238000007751 thermal spraying Methods 0.000 description 1

- UONOETXJSWQNOL-UHFFFAOYSA-N tungsten carbide Chemical compound [W+]#[C-] UONOETXJSWQNOL-UHFFFAOYSA-N 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

- ZVWKZXLXHLZXLS-UHFFFAOYSA-N zirconium nitride Chemical compound [Zr]#N ZVWKZXLXHLZXLS-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

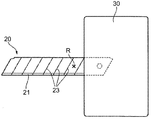

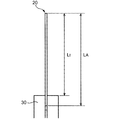

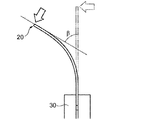

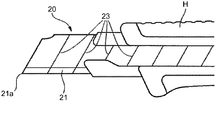

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26B—HAND-HELD CUTTING TOOLS NOT OTHERWISE PROVIDED FOR

- B26B9/00—Blades for hand knives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D53/00—Making other particular articles

- B21D53/60—Making other particular articles cutlery wares; garden tools or the like

- B21D53/64—Making other particular articles cutlery wares; garden tools or the like knives; scissors; cutting blades

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26B—HAND-HELD CUTTING TOOLS NOT OTHERWISE PROVIDED FOR

- B26B1/00—Hand knives with adjustable blade; Pocket knives

- B26B1/08—Hand knives with adjustable blade; Pocket knives with sliding blade

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/34—Nitrides

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Forests & Forestry (AREA)

- General Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Knives (AREA)

- Nonmetal Cutting Devices (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JPJP-P-2012-247535 | 2012-11-09 | ||

| JP2012247535A JP2014094163A (ja) | 2012-11-09 | 2012-11-09 | カッターブレード |

| PCT/US2013/069179 WO2014074838A1 (en) | 2012-11-09 | 2013-11-08 | Coated snap cutter blade and method of making same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20150079970A true KR20150079970A (ko) | 2015-07-08 |

Family

ID=49681132

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020157014925A Withdrawn KR20150079970A (ko) | 2012-11-09 | 2013-11-08 | 코팅된 스냅 커터 블레이드와 그 제조 방법 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20150273705A1 (enExample) |

| EP (1) | EP2917003A1 (enExample) |

| JP (2) | JP2014094163A (enExample) |

| KR (1) | KR20150079970A (enExample) |

| CN (1) | CN104812538A (enExample) |

| AU (1) | AU2013342193B2 (enExample) |

| TW (1) | TWI616292B (enExample) |

| WO (1) | WO2014074838A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017047870A1 (ko) * | 2015-09-15 | 2017-03-23 | 주식회사 도루코 | 분절 가능한 양날형 면도날 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016015771A1 (en) * | 2014-07-31 | 2016-02-04 | Bic-Violex Sa | Razor blade coating |

| TWI542457B (zh) * | 2014-10-17 | 2016-07-21 | 三星國際機械股份有限公司 | 用以切割膜之刀具與設備 |

| CN104999485B (zh) * | 2015-08-20 | 2019-07-23 | 珠海新秀丽家居用品有限公司 | 具有超薄定刀的新型个人护理修剪器 |

| KR101643118B1 (ko) * | 2016-01-28 | 2016-07-27 | 강태욱 | 부분 절개가 가능한 교체용 톱날 |

| CN106756859A (zh) * | 2016-11-23 | 2017-05-31 | 俞虹 | 用于钕铁硼铁氧体表面防腐方法 |

| TWI652154B (zh) | 2017-01-10 | 2019-03-01 | 三匠科技股份有限公司 | 替換刀片 |

| JP7080163B2 (ja) * | 2018-12-06 | 2022-06-03 | 株式会社クボタ | 切断刃、農業機械および切断刃の製造方法 |

| KR20210039205A (ko) * | 2019-10-01 | 2021-04-09 | 주식회사 도루코 | 면도날 |

| CH717104B1 (de) * | 2020-01-31 | 2023-08-15 | Proverum Ag | Messerklinge. |

| US11433560B2 (en) * | 2020-02-07 | 2022-09-06 | Vincent Leon Giles | Drywall knife |

| CN116615318A (zh) * | 2020-11-03 | 2023-08-18 | 吉列有限责任公司 | 具有基于硼化铬的涂层的剃刀刀片 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3636955A (en) * | 1969-12-03 | 1972-01-25 | Deknatel Inc | Surgical cutting needle |

| GB1523168A (en) | 1975-09-10 | 1978-08-31 | Plas Plugs Ltd | Hand grip for a hand knife |

| US4170062A (en) | 1978-07-06 | 1979-10-09 | Kai Cutlery Center Co., Ltd. | Extensible knife with blade position adjustment |

| JPS58136077U (ja) * | 1982-03-10 | 1983-09-13 | 株式会社田島製作所 | 切つ先の折取り更新替え刃 |

| US4534827A (en) * | 1983-08-26 | 1985-08-13 | Henderson Donald W | Cutting implement and method of making same |

| JPH01280492A (ja) * | 1988-01-21 | 1989-11-10 | Sangi:Kk | 刃物 |

| JPH01190386A (ja) * | 1988-01-26 | 1989-07-31 | Kawatetsu Techno Res Corp | 料理用刃物 |

| US5077901A (en) * | 1990-05-18 | 1992-01-07 | Warner Joseph A | Ceramic blades and production methodology therefor |

| JP3161346B2 (ja) | 1996-11-18 | 2001-04-25 | 三菱マテリアル株式会社 | すぐれた耐摩耗性と耐チッピング性を有する炭窒化チタン基サーメット製スローアウエイ型切削チップ |

| US6260280B1 (en) * | 2000-02-11 | 2001-07-17 | Keith Rapisardi | Knife with ceramic blade |

| JP4787415B2 (ja) * | 2001-02-22 | 2011-10-05 | 株式会社貝印刃物開発センター | カッターの刃及びカッターの刃の製造方法 |

| JP2003024658A (ja) * | 2001-07-16 | 2003-01-28 | Tsutomu Araki | 折刃式刃板 |

| GB0207375D0 (en) * | 2002-03-28 | 2002-05-08 | Hardide Ltd | Cutting tool with hard coating |

| WO2004078424A2 (en) * | 2003-03-05 | 2004-09-16 | Irwin Industrial Tool Company | Composite utility blade, and method of making such a blade |

| US8322253B2 (en) * | 2005-07-08 | 2012-12-04 | Stanley Black & Decker, Inc. | Method of manufacturing a utility knife blade having an induction hardened cutting edge |

| US8161654B2 (en) * | 2006-04-20 | 2012-04-24 | Irwin Industrial Tool Company | Four point utility blade and method |

| CN201095117Y (zh) * | 2007-08-01 | 2008-08-06 | 周永亮 | 一种刀片 |

| DE202008001869U1 (de) * | 2008-02-08 | 2008-05-15 | Becker, Peter, Dipl.-Architekt | Abbrechklingen |

| US20100088901A1 (en) * | 2008-07-25 | 2010-04-15 | University Of Delaware | Snap-off blade knife with safety stop |

| US20100071216A1 (en) * | 2008-09-22 | 2010-03-25 | Joseph Thomas Novak | Serrated snap-off utility knife blade |

| CN201720859U (zh) * | 2010-04-15 | 2011-01-26 | 周航 | 两头都可使用的刀片 |

| US9662796B2 (en) * | 2012-04-26 | 2017-05-30 | Thomas Scimone | Ceramic cutting blades |

-

2012

- 2012-11-09 JP JP2012247535A patent/JP2014094163A/ja active Pending

-

2013

- 2013-11-08 CN CN201380058534.3A patent/CN104812538A/zh active Pending

- 2013-11-08 JP JP2015541927A patent/JP2016501053A/ja active Pending

- 2013-11-08 WO PCT/US2013/069179 patent/WO2014074838A1/en not_active Ceased

- 2013-11-08 TW TW102140806A patent/TWI616292B/zh not_active IP Right Cessation

- 2013-11-08 AU AU2013342193A patent/AU2013342193B2/en not_active Ceased

- 2013-11-08 KR KR1020157014925A patent/KR20150079970A/ko not_active Withdrawn

- 2013-11-08 US US14/441,639 patent/US20150273705A1/en not_active Abandoned

- 2013-11-08 EP EP13798791.3A patent/EP2917003A1/en not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017047870A1 (ko) * | 2015-09-15 | 2017-03-23 | 주식회사 도루코 | 분절 가능한 양날형 면도날 |

| US10478983B2 (en) | 2015-09-15 | 2019-11-19 | Dorco Co,. Ltd. | Snap-off double-edged razor blade |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2013342193A1 (en) | 2015-05-28 |

| WO2014074838A1 (en) | 2014-05-15 |

| JP2016501053A (ja) | 2016-01-18 |

| TWI616292B (zh) | 2018-03-01 |

| AU2013342193B2 (en) | 2016-10-06 |

| TW201436966A (zh) | 2014-10-01 |

| US20150273705A1 (en) | 2015-10-01 |

| CN104812538A (zh) | 2015-07-29 |

| JP2014094163A (ja) | 2014-05-22 |

| EP2917003A1 (en) | 2015-09-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20150079970A (ko) | 코팅된 스냅 커터 블레이드와 그 제조 방법 | |

| EP2130653B1 (en) | Blade member | |

| JP5056949B2 (ja) | 被覆部材 | |

| US7060367B2 (en) | Cutting blade and method of producing the same | |

| CN106457411B (zh) | 切削工具 | |

| JP6609621B2 (ja) | カミソリ刃コーティング | |

| EP3374139B1 (en) | Razor blade | |

| KR101311554B1 (ko) | 전단용 금형 및 그 제조 방법 | |

| KR20150040963A (ko) | Tialn-피복 공구 | |

| WO2004078424A2 (en) | Composite utility blade, and method of making such a blade | |

| EP4240567A2 (en) | Razor blades with chromium boride-based coatings | |

| WO2017179657A1 (ja) | 切削インサート及び切削工具 | |

| JP3402849B2 (ja) | 刃及び刃の製造方法 | |

| EP3467150B9 (en) | Hard coating for cutting tools | |

| JP2010120100A (ja) | 旋削加工用硬質皮膜被覆工具 | |

| JP3199679U (ja) | 硬質膜からなる小刃を付けた片刃研ぎ刃物 | |

| JP5349164B2 (ja) | 切削工具 | |

| WO2023162682A1 (ja) | 被覆工具および切削工具 | |

| US20220347876A1 (en) | Metals for razor blade applications | |

| WO2023162683A1 (ja) | 被覆工具および切削工具 | |

| TW202500345A (zh) | 切片機用刀片 | |

| JP2024066361A (ja) | 表面被覆工具 | |

| JP2009061572A (ja) | 切削工具 | |

| KR20120106179A (ko) | 예리함이 오래 유지되는 칼날 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20150604 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |