KR20140045389A - 모듈식 성형 시스템 - Google Patents

모듈식 성형 시스템 Download PDFInfo

- Publication number

- KR20140045389A KR20140045389A KR1020137032913A KR20137032913A KR20140045389A KR 20140045389 A KR20140045389 A KR 20140045389A KR 1020137032913 A KR1020137032913 A KR 1020137032913A KR 20137032913 A KR20137032913 A KR 20137032913A KR 20140045389 A KR20140045389 A KR 20140045389A

- Authority

- KR

- South Korea

- Prior art keywords

- segment

- teeth

- segments

- generally

- adjacent

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000465 moulding Methods 0.000 title abstract description 10

- 239000000463 material Substances 0.000 claims abstract description 29

- 229910052751 metal Inorganic materials 0.000 claims abstract description 8

- 239000002184 metal Substances 0.000 claims abstract description 8

- 238000000034 method Methods 0.000 claims description 30

- 230000004323 axial length Effects 0.000 claims description 2

- 230000015572 biosynthetic process Effects 0.000 abstract description 2

- 238000004519 manufacturing process Methods 0.000 description 5

- 230000008439 repair process Effects 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

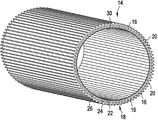

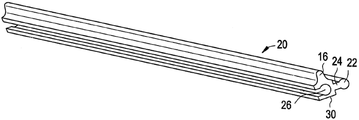

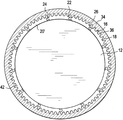

- B29D29/00—Producing belts or bands

- B29D29/08—Toothed driving belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/30—Mounting, exchanging or centering

- B29C33/301—Modular mould systems [MMS], i.e. moulds built up by stacking mould elements, e.g. plates, blocks, rods

- B29C33/302—Assembling a large number of mould elements to constitute one cavity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/42—Moulds or cores; Details thereof or accessories therefor characterised by the shape of the moulding surface, e.g. ribs or grooves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/44—Moulds or cores; Details thereof or accessories therefor with means for, or specially constructed to facilitate, the removal of articles, e.g. of undercut articles

- B29C33/48—Moulds or cores; Details thereof or accessories therefor with means for, or specially constructed to facilitate, the removal of articles, e.g. of undercut articles with means for collapsing or disassembling

- B29C33/485—Moulds or cores; Details thereof or accessories therefor with means for, or specially constructed to facilitate, the removal of articles, e.g. of undercut articles with means for collapsing or disassembling cores or mandrels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/021—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles characterised by the shape of the surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D29/00—Producing belts or bands

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49544—Roller making

- Y10T29/49547—Assembling preformed components

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49544—Roller making

- Y10T29/49547—Assembling preformed components

- Y10T29/49558—Includes securing removable cover on roller

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49544—Roller making

- Y10T29/4956—Fabricating and shaping roller work contacting surface element

- Y10T29/49561—Fabricating and shaping roller work contacting surface element toothed roller

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Devices For Conveying Motion By Means Of Endless Flexible Members (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/164,377 | 2011-06-20 | ||

| US13/164,377 US8512614B2 (en) | 2011-06-20 | 2011-06-20 | Modular molding system |

| PCT/US2012/043048 WO2012177583A1 (en) | 2011-06-20 | 2012-06-19 | Modular molding system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20140045389A true KR20140045389A (ko) | 2014-04-16 |

Family

ID=47353059

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020137032913A Withdrawn KR20140045389A (ko) | 2011-06-20 | 2012-06-19 | 모듈식 성형 시스템 |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US8512614B2 (cg-RX-API-DMAC7.html) |

| EP (1) | EP2720857A4 (cg-RX-API-DMAC7.html) |

| JP (1) | JP2014516848A (cg-RX-API-DMAC7.html) |

| KR (1) | KR20140045389A (cg-RX-API-DMAC7.html) |

| CN (1) | CN103228427A (cg-RX-API-DMAC7.html) |

| AR (1) | AR086964A1 (cg-RX-API-DMAC7.html) |

| AU (1) | AU2012273233A1 (cg-RX-API-DMAC7.html) |

| BR (1) | BR112013032747A2 (cg-RX-API-DMAC7.html) |

| CA (1) | CA2836603A1 (cg-RX-API-DMAC7.html) |

| MX (1) | MX2013014730A (cg-RX-API-DMAC7.html) |

| WO (1) | WO2012177583A1 (cg-RX-API-DMAC7.html) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| MX2014006651A (es) * | 2011-12-05 | 2014-09-04 | Dayco Ip Holdings Llc | Mandril modular para un sistema de moldeo. |

| TW201325884A (zh) * | 2011-12-29 | 2013-07-01 | Hon Hai Prec Ind Co Ltd | 光學薄膜壓印滾輪及該滾輪之製作方法 |

| FR3043006B1 (fr) * | 2015-10-30 | 2018-04-06 | Constructions Industrielles De La Mediterranee Cnim | Mandrin metallique creux demontable pour le bobinage d'une capacite composite, telle qu'un reservoir de propulseur a poudre d'une fusee |

| SG11202005367SA (en) * | 2017-11-29 | 2020-07-29 | St Eng Aerospace Ltd | Core assembly for moulding and method of moulding thereof |

Family Cites Families (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL88412C (cg-RX-API-DMAC7.html) | 1952-12-23 | |||

| US3032288A (en) | 1960-04-25 | 1962-05-01 | Arthur T Williams | Expansible rotatable mandrel |

| US3486626A (en) | 1968-02-01 | 1969-12-30 | Sam Close | Replaceable medium,extended area filter unit |

| US3738187A (en) * | 1971-10-14 | 1973-06-12 | C Hisserich | Hunting-tooth timing bolt |

| IT1010109B (it) * | 1974-04-26 | 1977-01-10 | Pirelli | Stampo per la fabbricazione di cinghie dentate a doppia denta tura e cinghe dentate cosi ot tenute |

| US4000240A (en) * | 1975-04-17 | 1976-12-28 | Teletype Corporation | Process of molding a reinforced flexible belt |

| IT1166847B (it) * | 1979-05-25 | 1987-05-06 | Pirelli | Cinghia dentata |

| US4838843A (en) * | 1982-04-16 | 1989-06-13 | The Gates Rubber Company | Toothed belt |

| US4754543A (en) | 1986-06-30 | 1988-07-05 | Dayco Products, Inc. | Method of making expandable and collapsible mandrel |

| US5176867A (en) | 1989-08-02 | 1993-01-05 | Dayco Products, Inc. | Method of making a toothed belt construction with an endless preformed fabric sleeve |

| JPH04161321A (ja) * | 1990-10-25 | 1992-06-04 | Jietsuto:Kk | ビード成形金型 |

| CA2077400A1 (en) | 1991-10-08 | 1993-04-09 | Mikhail Leyderman | Mandrel and a method of making a rigid tubular article |

| US5266137A (en) | 1992-11-10 | 1993-11-30 | Hollingsworth Ritch D | Rigid segmented mandrel with inflatable support |

| JPH0891528A (ja) * | 1994-09-29 | 1996-04-09 | Toray Ind Inc | コンベアチェーン |

| JP2843549B2 (ja) | 1996-04-23 | 1999-01-06 | 三ツ星ベルト株式会社 | ダブルコグベルトの製造方法 |

| FR2753766B1 (fr) * | 1996-09-20 | 1998-11-27 | Courroie striee, son procede de fabrication et dispositif de transmission la comprenant | |

| JP3604073B2 (ja) * | 1999-11-17 | 2004-12-22 | 株式会社弥刀化工 | 擬竹材の節付け装置 |

| US6554377B2 (en) | 2001-07-19 | 2003-04-29 | The Goodyear Tire & Rubber Company | Rubber track and improved method and method for producing the track |

| JP3964725B2 (ja) * | 2002-01-21 | 2007-08-22 | 本田技研工業株式会社 | 歯付きベルト伝動装置 |

| JP4256204B2 (ja) * | 2002-06-28 | 2009-04-22 | 三ツ星ベルト株式会社 | 伝動ベルトの製造方法 |

| US6949211B2 (en) * | 2003-04-16 | 2005-09-27 | The Goodyear & Rubber Company | Means of manufacturing plural optimized cogged drive belts |

| US7189069B2 (en) | 2003-10-03 | 2007-03-13 | The Goodyear Tire & Rubber Company | Mold for forming an annular tread belt |

| US8002922B2 (en) * | 2005-07-19 | 2011-08-23 | Mitsuboshi Belting Ltd. | Power transmission belt and method of making a power transmission belt |

| US7704067B2 (en) | 2006-02-07 | 2010-04-27 | Tiodize Company, Inc. | Method and mold for making non-metallic fiber reinforced parts |

| US20070244263A1 (en) * | 2006-04-13 | 2007-10-18 | Burrowes Thomas G | Elastomeric composition for transmission belt |

| US8206251B2 (en) * | 2009-04-30 | 2012-06-26 | The Gates Corporation | Double cogged V-belt for variable speed drive |

-

2011

- 2011-06-20 US US13/164,377 patent/US8512614B2/en not_active Expired - Fee Related

-

2012

- 2012-06-15 AR ARP120102149A patent/AR086964A1/es not_active Application Discontinuation

- 2012-06-19 WO PCT/US2012/043048 patent/WO2012177583A1/en not_active Ceased

- 2012-06-19 CA CA2836603A patent/CA2836603A1/en not_active Abandoned

- 2012-06-19 BR BR112013032747A patent/BR112013032747A2/pt not_active IP Right Cessation

- 2012-06-19 MX MX2013014730A patent/MX2013014730A/es unknown

- 2012-06-19 JP JP2014517075A patent/JP2014516848A/ja active Pending

- 2012-06-19 AU AU2012273233A patent/AU2012273233A1/en not_active Abandoned

- 2012-06-19 KR KR1020137032913A patent/KR20140045389A/ko not_active Withdrawn

- 2012-06-19 CN CN2012800035832A patent/CN103228427A/zh active Pending

- 2012-06-19 EP EP20120802944 patent/EP2720857A4/en not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| BR112013032747A2 (pt) | 2017-01-31 |

| CN103228427A (zh) | 2013-07-31 |

| AR086964A1 (es) | 2014-02-05 |

| US20120319324A1 (en) | 2012-12-20 |

| MX2013014730A (es) | 2014-02-11 |

| EP2720857A4 (en) | 2014-09-03 |

| JP2014516848A (ja) | 2014-07-17 |

| CA2836603A1 (en) | 2012-12-27 |

| EP2720857A1 (en) | 2014-04-23 |

| US8512614B2 (en) | 2013-08-20 |

| WO2012177583A1 (en) | 2012-12-27 |

| AU2012273233A1 (en) | 2014-01-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101395490B1 (ko) | 맨드렐 조립체 | |

| JP6076251B2 (ja) | タイヤ加硫成形用金型およびそれを用いたタイヤの製造方法 | |

| CN101198809A (zh) | 链轮 | |

| KR20140045389A (ko) | 모듈식 성형 시스템 | |

| WO2009031204A1 (ja) | 積層鉄心及びその製造方法 | |

| EP1652659B1 (en) | Core for the manufacture of tires | |

| CN109695697B (zh) | 齿轮及齿轮制造方法 | |

| KR20140102652A (ko) | 성형 시스템용 모듈식 맨드릴 | |

| JP5492149B2 (ja) | 剛性中子、及びそれを用いたタイヤの製造方法 | |

| JP2014516848A5 (cg-RX-API-DMAC7.html) | ||

| JP5268631B2 (ja) | 未加硫タイヤブランクを加硫するための金型 | |

| CA2815414A1 (en) | Coupling device for tube with annular corrugations | |

| DE112011101151T5 (de) | Verfahren zur Herstellung eines Luftreifens | |

| US20080054715A1 (en) | Bicycle wheel hub | |

| CN109737197B (zh) | 齿轮及齿轮制造方法 | |

| US20170057187A1 (en) | Rigid inner mold for forming tire, and method of manufacturing tire using the same | |

| CN209990871U (zh) | 齿轮 | |

| JP5364124B2 (ja) | 剛性中子の保持構造 | |

| WO2015133452A1 (ja) | タイヤ形成用の剛性中子、及びそれを用いたタイヤの製造方法 | |

| JP4837341B2 (ja) | ゴムクローラ製造方法およびその装置 | |

| JP5203799B2 (ja) | ベルト製造用金型 | |

| JP7115078B2 (ja) | タイヤ製造用の剛性コアおよびタイヤの製造方法 | |

| JP4541112B2 (ja) | 積層モールドとその製造方法 | |

| JP3170008B2 (ja) | 自在フランジ付きゴム継手、その製造方法及び製造装置 | |

| JPH03204320A (ja) | 非金属タイヤチェーン及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20131211 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |