KR20130138805A - 정유 공정 노를 위한 알루미나-형성 이원금속 관 및 이의 제조 및 사용 방법 - Google Patents

정유 공정 노를 위한 알루미나-형성 이원금속 관 및 이의 제조 및 사용 방법 Download PDFInfo

- Publication number

- KR20130138805A KR20130138805A KR1020137012848A KR20137012848A KR20130138805A KR 20130138805 A KR20130138805 A KR 20130138805A KR 1020137012848 A KR1020137012848 A KR 1020137012848A KR 20137012848 A KR20137012848 A KR 20137012848A KR 20130138805 A KR20130138805 A KR 20130138805A

- Authority

- KR

- South Korea

- Prior art keywords

- tube layer

- alumina

- inner tube

- weight percent

- bulk alloy

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L9/00—Rigid pipes

- F16L9/02—Rigid pipes of metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K10/00—Welding or cutting by means of a plasma

- B23K10/02—Plasma welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K10/00—Welding or cutting by means of a plasma

- B23K10/02—Plasma welding

- B23K10/027—Welding for purposes other than joining, e.g. build-up welding

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G75/00—Inhibiting corrosion or fouling in apparatus for treatment or conversion of hydrocarbon oils, in general

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G9/00—Thermal non-catalytic cracking, in the absence of hydrogen, of hydrocarbon oils

- C10G9/14—Thermal non-catalytic cracking, in the absence of hydrogen, of hydrocarbon oils in pipes or coils with or without auxiliary means, e.g. digesters, soaking drums, expansion means

- C10G9/18—Apparatus

- C10G9/20—Tube furnaces

- C10G9/203—Tube furnaces chemical composition of the tubes

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/03—Alloys based on nickel or cobalt based on nickel

- C22C19/05—Alloys based on nickel or cobalt based on nickel with chromium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L9/00—Rigid pipes

- F16L9/02—Rigid pipes of metal

- F16L9/04—Reinforced pipes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/18—Dissimilar materials

- B23K2103/20—Ferrous alloys and aluminium or alloys thereof

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Organic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Physics & Mathematics (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Plasma & Fusion (AREA)

- Thermal Sciences (AREA)

- Production Of Liquid Hydrocarbon Mixture For Refining Petroleum (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US40542710P | 2010-10-21 | 2010-10-21 | |

| US61/405,427 | 2010-10-21 | ||

| US13/271,856 | 2011-10-12 | ||

| US13/271,856 US8808867B2 (en) | 2010-10-21 | 2011-10-12 | Alumina forming bimetallic tube for refinery process furnaces and method of making and using |

| PCT/US2011/056528 WO2012054377A1 (en) | 2010-10-21 | 2011-10-17 | Alumina forming bimetallic tube for refinery process furnaces and method of making and using |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20130138805A true KR20130138805A (ko) | 2013-12-19 |

Family

ID=48525244

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020137012848A Withdrawn KR20130138805A (ko) | 2010-10-21 | 2011-10-17 | 정유 공정 노를 위한 알루미나-형성 이원금속 관 및 이의 제조 및 사용 방법 |

Country Status (7)

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8877342B2 (en) | 2010-10-21 | 2014-11-04 | Exxonmobil Research And Engineering Company | Alumina forming bimetallic tube for refinery process furnaces and method of making and using |

| JP2015526586A (ja) * | 2012-04-13 | 2015-09-10 | エクソンモービル リサーチ アンド エンジニアリング カンパニーExxon Research And Engineering Company | 精製所プロセス炉のためのアルミナ形成バイメタル管、ならびにその製造および使用方法 |

| US11674212B2 (en) | 2014-03-28 | 2023-06-13 | Kubota Corporation | Cast product having alumina barrier layer |

| JP6247977B2 (ja) * | 2014-03-28 | 2017-12-13 | 株式会社クボタ | アルミナバリア層を有する鋳造製品 |

| JP6434306B2 (ja) * | 2014-12-26 | 2018-12-05 | 株式会社クボタ | アルミナバリア層を有する耐熱管 |

| CN106273887A (zh) * | 2016-08-15 | 2017-01-04 | 苏州润利电器有限公司 | 一种五金冲压件用双层复合耐用合金 |

| CN106273886A (zh) * | 2016-08-15 | 2017-01-04 | 苏州润利电器有限公司 | 一种五金冲压件用双层复合安全合金 |

| KR20230106174A (ko) * | 2020-11-13 | 2023-07-12 | 닛폰세이테츠 가부시키가이샤 | 이중관 및 용접 이음 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5829355B2 (ja) * | 1979-07-17 | 1983-06-22 | 三井造船株式会社 | 炭化水素の熱分解装置 |

| US4679294A (en) * | 1982-07-09 | 1987-07-14 | Lomax Donald P | Method for making a trimetallic cylinder |

| JP2631648B2 (ja) * | 1986-10-23 | 1997-07-16 | 臼井国際産業株式会社 | 耐食性並びに流体への酸化防止被膜を有する電縫鋼管およびその製造方法 |

| JP2001107833A (ja) * | 1999-10-08 | 2001-04-17 | Toshiba Corp | 水力機械およびその製造方法 |

| KR20030024685A (ko) * | 2000-06-08 | 2003-03-26 | 서피스 엔지니어드 프로덕츠 코포레이션 | 고온 스테인레스강을 위한 코팅 시스템 |

| US6648988B2 (en) * | 2001-08-17 | 2003-11-18 | Exxonmobil Research And Engineering Company | Furnace run length extension by fouling control |

| EP1717330B1 (en) * | 2004-02-12 | 2018-06-13 | Nippon Steel & Sumitomo Metal Corporation | Metal tube for use in carburizing gas atmosphere |

| US7354660B2 (en) * | 2005-05-10 | 2008-04-08 | Exxonmobil Research And Engineering Company | High performance alloys with improved metal dusting corrosion resistance |

| CN101379362B (zh) * | 2005-12-21 | 2012-03-28 | 埃克森美孚研究工程公司 | 用于减少结焦的防腐蚀材料、具有改进的防腐蚀性和抗结焦性的传热组件以及减少结焦的方法 |

| CN101512674A (zh) * | 2006-07-18 | 2009-08-19 | 埃克森美孚研究工程公司 | 具有改进的抗金属灰化腐蚀性的高性能涂覆材料 |

| US8748008B2 (en) * | 2008-06-12 | 2014-06-10 | Exxonmobil Research And Engineering Company | High performance coatings and surfaces to mitigate corrosion and fouling in fired heater tubes |

| US8808867B2 (en) * | 2010-10-21 | 2014-08-19 | Exxonmobil Research And Engineering Company | Alumina forming bimetallic tube for refinery process furnaces and method of making and using |

-

2011

- 2011-10-17 BR BR112013009481A patent/BR112013009481A2/pt not_active IP Right Cessation

- 2011-10-17 EP EP11834922.4A patent/EP2629903A1/en not_active Withdrawn

- 2011-10-17 WO PCT/US2011/056528 patent/WO2012054377A1/en active Application Filing

- 2011-10-17 CN CN2011800615015A patent/CN103282137A/zh active Pending

- 2011-10-17 JP JP2013534985A patent/JP2014501620A/ja active Pending

- 2011-10-17 CA CA2815357A patent/CA2815357A1/en not_active Abandoned

- 2011-10-17 KR KR1020137012848A patent/KR20130138805A/ko not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| CN103282137A (zh) | 2013-09-04 |

| WO2012054377A1 (en) | 2012-04-26 |

| BR112013009481A2 (pt) | 2016-07-26 |

| CA2815357A1 (en) | 2012-04-26 |

| JP2014501620A (ja) | 2014-01-23 |

| EP2629903A1 (en) | 2013-08-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

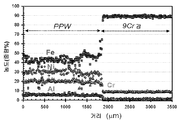

| US8808867B2 (en) | Alumina forming bimetallic tube for refinery process furnaces and method of making and using | |

| KR101897306B1 (ko) | 알루미나-형성 이원금속 관 및 이의 제조 및 사용 방법 | |

| JP5323186B2 (ja) | 加熱炉管における腐食および汚染を軽減するための高性能コーティングおよび表面 | |

| US8877342B2 (en) | Alumina forming bimetallic tube for refinery process furnaces and method of making and using | |

| KR20130138805A (ko) | 정유 공정 노를 위한 알루미나-형성 이원금속 관 및 이의 제조 및 사용 방법 | |

| JP6499761B2 (ja) | 伝熱チューブ及び熱分解方法 | |

| KR20150008103A (ko) | 정유 공정 로를 위한 알루미나-형성 이원금속 관 및 이의 제조 및 사용 방법 | |

| US20140246013A1 (en) | High performance fired heater tubes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20130520 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |