KR20060123144A - 포토레지스트 스트립 동안의 배리어 재료의 손실 최소화 - Google Patents

포토레지스트 스트립 동안의 배리어 재료의 손실 최소화 Download PDFInfo

- Publication number

- KR20060123144A KR20060123144A KR1020067009102A KR20067009102A KR20060123144A KR 20060123144 A KR20060123144 A KR 20060123144A KR 1020067009102 A KR1020067009102 A KR 1020067009102A KR 20067009102 A KR20067009102 A KR 20067009102A KR 20060123144 A KR20060123144 A KR 20060123144A

- Authority

- KR

- South Korea

- Prior art keywords

- layer

- silicon

- photoresist

- gas mixture

- dielectric

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

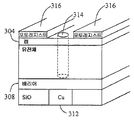

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76801—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing

- H01L21/76802—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics

- H01L21/76807—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics for dual damascene structures

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/306—Chemical or electrical treatment, e.g. electrolytic etching

- H01L21/3065—Plasma etching; Reactive-ion etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3105—After-treatment

- H01L21/311—Etching the insulating layers by chemical or physical means

- H01L21/31127—Etching organic layers

- H01L21/31133—Etching organic layers by chemical means

- H01L21/31138—Etching organic layers by chemical means by dry-etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3105—After-treatment

- H01L21/311—Etching the insulating layers by chemical or physical means

- H01L21/31144—Etching the insulating layers by chemical or physical means using masks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/34—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies not provided for in groups H01L21/18, H10D48/04 and H10D48/07, with or without impurities, e.g. doping materials

- H01L21/46—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/428

- H01L21/461—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/428 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76801—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/26—Processing photosensitive materials; Apparatus therefor

- G03F7/42—Stripping or agents therefor

- G03F7/427—Stripping or agents therefor using plasma means only

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P80/00—Climate change mitigation technologies for sector-wide applications

- Y02P80/30—Reducing waste in manufacturing processes; Calculations of released waste quantities

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Plasma & Fusion (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

- Drying Of Semiconductors (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/712,326 | 2003-11-12 | ||

| US10/712,326 US20050101135A1 (en) | 2003-11-12 | 2003-11-12 | Minimizing the loss of barrier materials during photoresist stripping |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20060123144A true KR20060123144A (ko) | 2006-12-01 |

Family

ID=34552671

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020067009102A Withdrawn KR20060123144A (ko) | 2003-11-12 | 2004-11-09 | 포토레지스트 스트립 동안의 배리어 재료의 손실 최소화 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20050101135A1 (enExample) |

| EP (1) | EP1683192A1 (enExample) |

| JP (1) | JP2007511099A (enExample) |

| KR (1) | KR20060123144A (enExample) |

| CN (1) | CN1868039A (enExample) |

| IL (1) | IL174648A0 (enExample) |

| TW (1) | TW200524051A (enExample) |

| WO (1) | WO2005048335A1 (enExample) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7517801B1 (en) * | 2003-12-23 | 2009-04-14 | Lam Research Corporation | Method for selectivity control in a plasma processing system |

| US8222155B2 (en) * | 2004-06-29 | 2012-07-17 | Lam Research Corporation | Selectivity control in a plasma processing system |

| US7396769B2 (en) * | 2004-08-02 | 2008-07-08 | Lam Research Corporation | Method for stripping photoresist from etched wafer |

| US7479457B2 (en) * | 2005-09-08 | 2009-01-20 | Lam Research Corporation | Gas mixture for removing photoresist and post etch residue from low-k dielectric material and method of use thereof |

| JP2007180420A (ja) * | 2005-12-28 | 2007-07-12 | Fujitsu Ltd | 半導体装置の製造方法及び磁気ヘッドの製造方法 |

| US7244313B1 (en) * | 2006-03-24 | 2007-07-17 | Applied Materials, Inc. | Plasma etch and photoresist strip process with intervening chamber de-fluorination and wafer de-fluorination steps |

| US7932181B2 (en) * | 2006-06-20 | 2011-04-26 | Lam Research Corporation | Edge gas injection for critical dimension uniformity improvement |

| WO2009039551A1 (en) * | 2007-09-26 | 2009-04-02 | Silverbrook Research Pty Ltd | Method of removing photoresist |

| US20090078675A1 (en) * | 2007-09-26 | 2009-03-26 | Silverbrook Research Pty Ltd | Method of removing photoresist |

| JP5532826B2 (ja) * | 2009-11-04 | 2014-06-25 | 富士通セミコンダクター株式会社 | 半導体素子の製造方法 |

| CN102877041B (zh) * | 2011-07-14 | 2014-11-19 | 中国科学院微电子研究所 | 薄膜沉积方法以及半导体器件制造方法 |

| CN102610511A (zh) * | 2012-03-21 | 2012-07-25 | 中微半导体设备(上海)有限公司 | 光刻胶的去除方法 |

| US8901007B2 (en) * | 2013-01-03 | 2014-12-02 | Taiwan Semiconductor Manufacturing Co., Ltd. | Addition of carboxyl groups plasma during etching for interconnect reliability enhancement |

| US10354860B2 (en) * | 2015-01-29 | 2019-07-16 | Versum Materials Us, Llc | Method and precursors for manufacturing 3D devices |

| JP6523091B2 (ja) | 2015-07-24 | 2019-05-29 | 株式会社Kokusai Electric | 半導体装置の製造方法、基板処理装置およびプログラム |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH09330911A (ja) * | 1996-06-11 | 1997-12-22 | Toshiba Corp | 半導体装置の製造方法 |

| US6455232B1 (en) * | 1998-04-14 | 2002-09-24 | Applied Materials, Inc. | Method of reducing stop layer loss in a photoresist stripping process using a fluorine scavenger |

| JP3803523B2 (ja) * | 1999-12-28 | 2006-08-02 | 株式会社東芝 | ドライエッチング方法及び半導体装置の製造方法 |

| US6372636B1 (en) * | 2000-06-05 | 2002-04-16 | Chartered Semiconductor Manufacturing Ltd. | Composite silicon-metal nitride barrier to prevent formation of metal fluorides in copper damascene |

| US6352921B1 (en) * | 2000-07-19 | 2002-03-05 | Chartered Semiconductor Manufacturing Ltd. | Use of boron carbide as an etch-stop and barrier layer for copper dual damascene metallization |

| US6479391B2 (en) * | 2000-12-22 | 2002-11-12 | Intel Corporation | Method for making a dual damascene interconnect using a multilayer hard mask |

| US6647994B1 (en) * | 2002-01-02 | 2003-11-18 | Taiwan Semiconductor Manufacturing Company | Method of resist stripping over low-k dielectric material |

| JP4326746B2 (ja) * | 2002-01-07 | 2009-09-09 | 東京エレクトロン株式会社 | プラズマ処理方法 |

-

2003

- 2003-11-12 US US10/712,326 patent/US20050101135A1/en not_active Abandoned

-

2004

- 2004-11-09 KR KR1020067009102A patent/KR20060123144A/ko not_active Withdrawn

- 2004-11-09 WO PCT/US2004/037376 patent/WO2005048335A1/en not_active Ceased

- 2004-11-09 CN CNA200480029601XA patent/CN1868039A/zh active Pending

- 2004-11-09 EP EP04818668A patent/EP1683192A1/en not_active Withdrawn

- 2004-11-09 JP JP2006539755A patent/JP2007511099A/ja active Pending

- 2004-11-10 TW TW093134300A patent/TW200524051A/zh unknown

-

2006

- 2006-03-30 IL IL174648A patent/IL174648A0/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| WO2005048335A1 (en) | 2005-05-26 |

| TW200524051A (en) | 2005-07-16 |

| IL174648A0 (en) | 2006-08-20 |

| US20050101135A1 (en) | 2005-05-12 |

| JP2007511099A (ja) | 2007-04-26 |

| CN1868039A (zh) | 2006-11-22 |

| EP1683192A1 (en) | 2006-07-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6168726B1 (en) | Etching an oxidized organo-silane film | |

| KR100896160B1 (ko) | 실리콘 카바이드 플라즈마 식각 방법 | |

| US6211092B1 (en) | Counterbore dielectric plasma etch process particularly useful for dual damascene | |

| US6284149B1 (en) | High-density plasma etching of carbon-based low-k materials in a integrated circuit | |

| KR100849707B1 (ko) | 탄소-도우핑된 저유전체들의 선택적 식각 | |

| US7129171B2 (en) | Selective oxygen-free etching process for barrier materials | |

| US6670278B2 (en) | Method of plasma etching of silicon carbide | |

| KR100778260B1 (ko) | 수소로 포토레지스트를 포스트 에칭 박리하기 위한 프로세스 | |

| US7273566B2 (en) | Gas compositions | |

| KR20060123144A (ko) | 포토레지스트 스트립 동안의 배리어 재료의 손실 최소화 | |

| US6647994B1 (en) | Method of resist stripping over low-k dielectric material | |

| US7202177B2 (en) | Nitrous oxide stripping process for organosilicate glass | |

| US6916697B2 (en) | Etch back process using nitrous oxide |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20060510 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| G170 | Re-publication after modification of scope of protection [patent] | ||

| PG1701 | Publication of correction | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |