KR0155152B1 - 세척장치 - Google Patents

세척장치 Download PDFInfo

- Publication number

- KR0155152B1 KR0155152B1 KR1019890012290A KR890012290A KR0155152B1 KR 0155152 B1 KR0155152 B1 KR 0155152B1 KR 1019890012290 A KR1019890012290 A KR 1019890012290A KR 890012290 A KR890012290 A KR 890012290A KR 0155152 B1 KR0155152 B1 KR 0155152B1

- Authority

- KR

- South Korea

- Prior art keywords

- nozzle flow

- flow passage

- cleaning material

- passage

- cleaning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C3/00—Abrasive blasting machines or devices; Plants

- B24C3/02—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other

- B24C3/06—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other movable; portable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C3/00—Abrasive blasting machines or devices; Plants

- B24C3/02—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other

- B24C3/06—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other movable; portable

- B24C3/062—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other movable; portable for vertical surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C3/00—Abrasive blasting machines or devices; Plants

- B24C3/02—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other

- B24C3/06—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other movable; portable

- B24C3/065—Abrasive blasting machines or devices; Plants characterised by the arrangement of the component assemblies with respect to each other movable; portable with suction means for the abrasive and the waste material

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Environmental & Geological Engineering (AREA)

- Cleaning In General (AREA)

- Cleaning By Liquid Or Steam (AREA)

Abstract

Description

Claims (5)

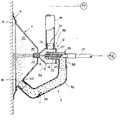

- 세척될 표면(8)의 반대 방향에 위치하는 제1노즐 유동 통로(22)와, 제1노즐 유동 통로(22)의 상류측에서 이격된 제2노즐 유동 통로(38)와,재충돌된 세척 재료의 유입 통로(34), 및 배출 통로(26)를 갖는 세척 헤드(12)와, 세척 재료를 포함하는 가압 유체 흐름을 제2 노즐 유동 통로(38)로 공급하기 위한 수단(42)과, 배출 통로(26)에서 유체를 흡입하기 위한 수단(46)과, 상기 표면(8)에 충돌된 세척 재료를 제1노즐 유동 통로(22)에서 재충돌된 세척 재료 유입 통로(34)로 되돌리기 위한 수단(54)을 구비하는 세척 장치에 있어서, 제1 노즐 유동 통로(22)의 단면적은 제2 노즐 유동 통로(38)의 단면적보다 충분히 크며; 상기 세척 재료 공급 수단(42)으로부터 제2노즐 유동 통로(38)로 공급된 세척 재료를 포함하는 가압 유체 흐름은 제2 노즐 유동 통로(38)를 통과하여 제1노즐 유동 통로(22)내로 전진하고, 제1노즐 유동 통로로부터 상기 표면(8)에 충돌하게 되고; 세척 재료를 포함하는 가압 유체 흐름의 유동은 제1노즐 유동 통로(22)에서 흡입 작용을 생성하며, 재충돌된 세척 재료의 유입 통로(34)로 되돌려진 세척 재료의 일부는 흡입 작용에 의하여 제1노즐 유동 통로(22)흡입되며, 제1노즐 유동 통로(22)로부터 상기 표면(8)에 재충돌되는 한편 충돌된 세척 재료의 유입 통로(34)로 되돌려진 세척 재료의 나머지의 일부는 배출 통로로부터 흡입된 유체에 의하여 부유 운반되는 세척 장치.

- 제1항에 있어서, 제1노즐 유동 통로(22)와 제2노즐 유동 통로(38)는 서로 동일 방향으로 직선적으로 연장되는 세척 장치.

- 제1항에 있어서, 제1 노즐 유동 통로(22)의 단면적은 제2노즐 유동 통로(38)의 단면적의 2배 내지 8배인 세척 장치.

- 제1항에 있어서, 재충돌된 세척 재료의 유입 통로의 하류측 단부는 제2노즐 유동 통로(38)의 외부로 동일 방향으로 연장되는 세척 장치.

- 제1항에 있어서, 상기 장치는 세척된 표면(8)과 협력하여 압력 감소 공간(10)을 한정하는 폐쇄 부재(4)를 포함하고, 제1노즐 유동 통로(22)의 끝 부분은 압력 감소 공간(10)내에 위치하며, 세척 재료 되돌림 수단(54)은 압력 감소 공간(10)에서 재충돌된 세척 재료의 유입 통로(34)까지 걸치는 재충돌된 세척 재료의 되돌림 통로(54)로 구성되며, 흡인 수단(46)은 재충돌된 세척 재료의 되돌림 통로(54)와, 재충돌된 세척 재료의 유입 통로(34)와, 배출 통로(26)를 거쳐서 압력 감소 공간(10)으로부터 유체를 흡입하며, 제1노즐 유동 통로(22)로부터 표면(8)에 충돌된 세척 재료는 재충돌된 세척 재료의 유입 통로(34)로 되돌려지는 한편, 압력 감소 공간(10)으로부터 흡입된 유체에 의해 부유 운반되는 세척 장치.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP214536 | 1988-08-29 | ||

| JP21453688 | 1988-08-29 | ||

| JP63-214536 | 1988-08-29 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR900002898A KR900002898A (ko) | 1990-03-23 |

| KR0155152B1 true KR0155152B1 (ko) | 1999-01-15 |

Family

ID=16657358

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019890012290A Expired - Fee Related KR0155152B1 (ko) | 1988-08-29 | 1989-08-29 | 세척장치 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4984396A (ko) |

| EP (1) | EP0359000B1 (ko) |

| KR (1) | KR0155152B1 (ko) |

| CA (1) | CA1325954C (ko) |

| DE (1) | DE68905728T2 (ko) |

| ES (1) | ES2039779T3 (ko) |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8908843D0 (en) * | 1989-04-19 | 1989-06-07 | Vapormatt Ltd | Improvements in or relating to the treatment of surfaces |

| US5551909A (en) * | 1990-12-28 | 1996-09-03 | Bailey; Donald C. | Method and apparatus for cleaning with high pressure liquid at low flow rates |

| US5138800A (en) * | 1991-04-30 | 1992-08-18 | Compustrip Systems Ltd. | Positioning apparatus for supporting and guiding a tool |

| JP3028148B2 (ja) * | 1991-05-24 | 2000-04-04 | 不可止 浦上 | 遠心投射装置 |

| EP0574771B1 (de) * | 1992-06-19 | 1997-04-23 | Ivan Markocic | Strahlmittelanlage |

| US5545074A (en) * | 1994-12-28 | 1996-08-13 | Jacobs; Patrick T. | Abrasive blasting system with waste water recycling |

| DE19520551A1 (de) * | 1995-06-06 | 1996-12-12 | Roland Man Druckmasch | Verfahren und Vorrichtung zum Reinigen eines Zylinders einer Rotations-Druckmaschine |

| US5921846A (en) * | 1997-03-21 | 1999-07-13 | The Johns Hopkins University | Lubricated high speed fluid cutting jet |

| US6066032A (en) * | 1997-05-02 | 2000-05-23 | Eco Snow Systems, Inc. | Wafer cleaning using a laser and carbon dioxide snow |

| RU2129949C1 (ru) * | 1997-05-27 | 1999-05-10 | Казаков Владимир Михайлович | Устройство для дробеструйной обработки поверхностей |

| US5957761A (en) * | 1997-11-12 | 1999-09-28 | Northrop Grumman Corporation | Closed circuit media capture and recovery head for the portable wheat starch media blast system |

| DE19802308C2 (de) * | 1998-01-22 | 2001-05-31 | Horst Laug | Absaugvorrichtung für Sandstrahl- und Flüssigkeitsdruckdüsen |

| EP1038674A1 (en) * | 1999-02-26 | 2000-09-27 | Alfred M. Petersen | Blast cleaning apparatus for printing machines |

| KR20030015089A (ko) * | 2001-08-14 | 2003-02-20 | 엘지.필립스디스플레이(주) | 평면 음극선관용 댐퍼스프링 |

| GB2410710A (en) * | 2003-12-12 | 2005-08-10 | Pentagon Glass Tech Ltd | Pneumatic etching device |

| NL1027172C2 (nl) * | 2004-10-05 | 2006-04-06 | Hoek Loos Nv | Straalpistool. |

| RU2314188C2 (ru) * | 2005-11-21 | 2008-01-10 | Рязанский военный автомобильный институт имени генерала армии В.П. ДУБЫНИНА | Абразивно-струйный аппарат |

| RU2310554C2 (ru) * | 2005-11-28 | 2007-11-20 | Виктор Петрович Крючков | Устройство для абразивно-струйной обработки поверхности |

| RU2314907C1 (ru) * | 2006-04-13 | 2008-01-20 | Олег Иванович Гречишкин | Инструмент для абразивно-струйной обработки с удалением отработанного рабочего тела |

| JP2010540556A (ja) * | 2007-09-26 | 2010-12-24 | マウント サイナイ スクール オブ メディシン | アザシチジン類似体およびその使用 |

| TWI531446B (zh) * | 2008-08-07 | 2016-05-01 | 不二製作所股份有限公司 | 噴砂方法及具有研磨料回收系統的設備、薄膜太陽能電池板的加工處理方法及以此方法加工處理的薄膜太陽能電池板 |

| CN102413989A (zh) * | 2009-04-21 | 2012-04-11 | 夏普株式会社 | 喷丸装置和喷丸加工方法 |

| JP5746901B2 (ja) * | 2011-04-14 | 2015-07-08 | 株式会社不二製作所 | 研磨方法及びブラスト加工装置のノズル構造 |

| US20140373303A1 (en) * | 2013-06-24 | 2014-12-25 | Phuong Taylor Nguyen | Padeye or Tie-Down Cleaning System |

| JP6128101B2 (ja) * | 2014-11-21 | 2017-05-17 | トヨタ自動車株式会社 | レーザクラッド装置 |

| DE102017220032A1 (de) * | 2017-11-10 | 2019-05-16 | Premium Aerotec Gmbh | Verfahren zur behandlung einer oberfläche eines faserverbundbauteils |

| RU202626U1 (ru) * | 2020-10-23 | 2021-03-01 | Акционерное общество "Национальный центр вертолетостроения им. М.Л. Миля и Н.И. Камова" (АО "НЦВ Миль и Камов") | Устройство для упрочняющей обработки деталей с отверстиями |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE268568C (ko) * | ||||

| US818776A (en) * | 1905-05-05 | 1906-04-24 | John D Murray | Sand-blast apparatus. |

| US3212217A (en) * | 1963-05-28 | 1965-10-19 | Tex Tube Inc | Cleaning device |

| US3925935A (en) * | 1974-03-20 | 1975-12-16 | Robert U Ricklefs | Abrading system |

| US4095378A (en) * | 1975-12-18 | 1978-06-20 | Uragami Fukashi | Device capable of suction-adhering to a wall surface and moving therealong |

| JPS5281792A (en) * | 1975-12-29 | 1977-07-08 | Atsuji Tekko Kk | Wall face grinding and cleaning machine |

| JPS5969262A (ja) * | 1982-10-11 | 1984-04-19 | Fukashi Uragami | 研掃装置 |

| JPS63196379A (ja) * | 1987-02-10 | 1988-08-15 | Osaka Gas Co Ltd | 研掃材飛散防止方法及び装置 |

-

1989

- 1989-08-22 US US07/396,967 patent/US4984396A/en not_active Expired - Fee Related

- 1989-08-24 DE DE89115634T patent/DE68905728T2/de not_active Expired - Fee Related

- 1989-08-24 ES ES198989115634T patent/ES2039779T3/es not_active Expired - Lifetime

- 1989-08-24 EP EP89115634A patent/EP0359000B1/en not_active Expired - Lifetime

- 1989-08-28 CA CA000609525A patent/CA1325954C/en not_active Expired - Fee Related

- 1989-08-29 KR KR1019890012290A patent/KR0155152B1/ko not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE68905728T2 (de) | 1993-10-07 |

| DE68905728D1 (de) | 1993-05-06 |

| US4984396A (en) | 1991-01-15 |

| EP0359000A1 (en) | 1990-03-21 |

| KR900002898A (ko) | 1990-03-23 |

| EP0359000B1 (en) | 1993-03-31 |

| CA1325954C (en) | 1994-01-11 |

| ES2039779T3 (es) | 1993-10-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR0155152B1 (ko) | 세척장치 | |

| JPH0258065B2 (ko) | ||

| US7891954B2 (en) | Method and apparatus for conveying material and ejector apparatus | |

| US5664992A (en) | Apparatus and method for cleaning tubular members | |

| EP0543387B1 (en) | Improvements in automatic pool cleaners | |

| JPH01270960A (ja) | 遠心分離型塗料ミスト含有気体浄化装置 | |

| US4274812A (en) | Jet pump | |

| US5107632A (en) | Device for separating blasting dust from blasting agent | |

| GB2270463A (en) | Suction apparatus for cleaning or other purposes | |

| US4475447A (en) | Spray booth apparatus | |

| EP1058046B1 (en) | Surge suppression apparatus | |

| JP2720208B2 (ja) | 研掃装置 | |

| CN111957639B (zh) | 一种用于清洗物体表面的清洗头 | |

| US5846303A (en) | Scrubber for cleaning exhaust air contaminated with paint particles | |

| US5656047A (en) | Wet gas scrubber | |

| SU797739A1 (ru) | Струйный газопромыватель | |

| JPH0474057B2 (ko) | ||

| SU1500791A1 (ru) | Эжектор | |

| SU1219113A1 (ru) | Пеногаситель | |

| SU1758243A1 (ru) | Устройство дл отсоса и подавлени пыли при работе горных машин | |

| JPH0258064B2 (ko) | ||

| HK1117120B (en) | Method and apparatus for conveying material and ejector apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

St.27 status event code: A-0-1-A10-A12-nap-PA0109 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| A201 | Request for examination | ||

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U11-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| LAPS | Lapse due to unpaid annual fee | ||

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 20010715 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 20010715 |