JP7588936B2 - 成形品取出機の制御装置 - Google Patents

成形品取出機の制御装置 Download PDFInfo

- Publication number

- JP7588936B2 JP7588936B2 JP2020202992A JP2020202992A JP7588936B2 JP 7588936 B2 JP7588936 B2 JP 7588936B2 JP 2020202992 A JP2020202992 A JP 2020202992A JP 2020202992 A JP2020202992 A JP 2020202992A JP 7588936 B2 JP7588936 B2 JP 7588936B2

- Authority

- JP

- Japan

- Prior art keywords

- torque

- unit

- command

- molded product

- control device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C37/0003—Discharging moulded articles from the mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/40—Removing or ejecting moulded articles

- B29C45/42—Removing or ejecting moulded articles using means movable from outside the mould between mould parts, e.g. robots

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G43/00—Control devices, e.g. for safety, warning or fault-correcting

- B65G43/08—Control devices operated by article or material being fed, conveyed or discharged

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C37/0003—Discharging moulded articles from the mould

- B29C37/0007—Discharging moulded articles from the mould using means operable from outside the mould for moving between mould parts, e.g. robots

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/76—Measuring, controlling or regulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/84—Safety devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/74—Feeding, transfer, or discharging devices of particular kinds or types

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/18—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form

- G05B19/406—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form characterised by monitoring or safety

- G05B19/4062—Monitoring servoloop, e.g. overload of servomotor, loss of feedback or reference

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C2037/90—Measuring, controlling or regulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C2037/90—Measuring, controlling or regulating

- B29C2037/903—Measuring, controlling or regulating by means of a computer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C2037/94—Safety devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/76—Measuring, controlling or regulating

- B29C45/7626—Measuring, controlling or regulating the ejection or removal of moulded articles

- B29C2045/7633—Take out or gripping means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76003—Measured parameter

- B29C2945/7602—Torque

- B29C2945/76023—Torque derivative, change thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76177—Location of measurement

- B29C2945/76314—Auxiliary devices

- B29C2945/76317—Auxiliary devices robots, grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76344—Phase or stage of measurement

- B29C2945/76421—Removing or handling ejected articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76494—Controlled parameter

- B29C2945/76568—Position

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76655—Location of control

- B29C2945/76792—Auxiliary devices

- B29C2945/76795—Auxiliary devices robots, grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76822—Phase or stage of control

- B29C2945/76899—Removing or handling ejected articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76929—Controlling method

- B29C2945/76939—Using stored or historical data sets

- B29C2945/76943—Using stored or historical data sets compare with thresholds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G2203/00—Indexing code relating to control or detection of the articles or the load carriers during conveying

- B65G2203/02—Control or detection

- B65G2203/0266—Control or detection relating to the load carrier(s)

- B65G2203/0283—Position of the load carrier

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G2203/00—Indexing code relating to control or detection of the articles or the load carriers during conveying

- B65G2203/02—Control or detection

- B65G2203/0266—Control or detection relating to the load carrier(s)

- B65G2203/0291—Speed of the load carrier

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/45—Nc applications

- G05B2219/45137—Punch, stamp, also with use die, mould

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Robotics (AREA)

- Human Computer Interaction (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- Numerical Control (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Control Of Position Or Direction (AREA)

Description

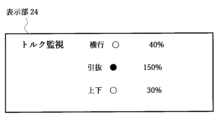

トルク検知部は、取出ヘッドに種々の方向から作用するトルクの作用方向を検知できるように構成されているのが好ましい。例えばサーボモータが駆動する軸数が、5軸、6軸等の多軸の場合には、多軸のすべてのトルクを検出できるようにトルク検知部を構成すればよい。また取出ヘッドが姿勢制御装置に装着される場合には、姿勢制御装置から取出ヘッドに加わるトルクも、トルク検知部で検知できるようにすればよい。さらに手動操作をするために使用される入力部の表示部には、トルク検知部が検知するすべてのトルクの大きさに比例するトルク表示を示すのが好ましい。これらのトルク表示は、数値表示、バーグラフ表示、メータ表示な任意の表示をすることができる。また入力部の表示部のトルク表示に隣接して、退避方向を示唆する示唆表示がそれぞれ示されているのが好ましい。この示唆は、文字表示でも、マーク表示でも、またランプ表示等のいずれでもよい。

3 取出ヘッド

5 上下フレーム

7 搬送機構

9 サーボモータ

10 エンコーダ

11 制御装置

13 サーボ系制御部

14 手動指令発生部

15 ティーチングデータ取得部

17 トルク検知部

19 衝突検知部

21 偏差クリア部

23 入力部

24 表示部

25 アラーム

Claims (9)

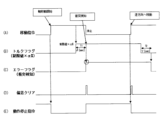

- 成形品取出機における取出ヘッドを有するフレームを駆動するサーボモータの駆動部の位置及び速度をエンコーダにより検出して、検出値と位置指令及び速度指令の値との偏差を求め、この偏差により前記駆動部の位置及び速度のフィードバック制御を行って前記サーボモータを制御するサーボ系制御部と、前記サーボ系制御部を手動操作する際の手動指令を発生する手動指令発生部を備えた成形品取出機の制御装置において、

前記手動指令発生部から出力される前記手動指令により前記サーボ系制御部に動作指令を与えて前記サーボモータを手動操作する際に前記フレームに加わるトルクを検知するトルク検知部と、

前記トルク検知部の検出値が予め定めた値より大きくなったときに前記取出ヘッドが周辺物に衝突したものとして動作停止指令を出力する衝突検知部と、

前記動作停止指令が出力されたときに、前記サーボ系制御部のオン状態を維持して前記トルクを保持した状態で、前記サーボ系制御部中の前記偏差を0にするクリア動作を行う偏差クリア部をさらに備えたことを特徴とする成形品取出機の制御装置。 - 前記衝突検知部は、前記予め定めた値を自動運転時の制限値よりも低い値とする請求項1に記載の成形品取出機の制御装置。

- 前記衝突検知部は、前記トルク検知部の前記検出値が前記予め定めた値より大きくなったことを所定時間、検知し続けたときに前記取出ヘッドが周辺物に衝突したものとして動作停止指令を出力する請求項1または2に記載の成形品取出機の制御装置。

- 前記衝突検知部は、前記動作停止指令を出力すると同時にアラーム信号を出力し、衝突検知後の退避時に前記サーボ系制御部に再度前記手動指令発生部から移動指令が入力されて前記トルク検知部の前記検出値が前記予め定めた値より小さくなった後、所定時間が経過するまで前記アラーム信号を出力し続ける請求項3に記載の成形品取出機の制御装置。

- 前記偏差クリア部は、再度前記手動指令発生部から前記移動指令が入力されると再度前記クリア動作を行う請求項4に記載の成形品取出機の制御装置。

- 前記トルク検知部は、前記取出ヘッドに作用するトルクの作用方向を検知できるように構成されており、

前記手動操作をするために使用される入力部の表示部には、前記トルクの作用方向と前記トルクの大きさに比例するトルク表示が示されている請求項1乃至5のいずれか1項に記載の成形品取出機の制御装置。 - 前記表示部には前記トルク表示に隣接して、退避方向を示唆する示唆表示が示されている請求項6に記載の成形品取出機の制御装置。

- 前記トルク検知部は、前記取出ヘッドに作用する横行方向のトルク、引抜方向のトルク及び上下方向のトルクを検知できるように構成されており、

前記手動操作をするために使用される入力部の表示部には、前記横行方向のトルク、前記引抜方向のトルク及び前記上下方向のトルクの大きさに比例する3つのトルク表示が示されている請求項6に記載の成形品取出機の制御装置。 - 前記表示部には前記3つのトルク表示に隣接して、退避方向を示唆する3つの示唆表示がそれぞれ示されている請求項8に記載の成形品取出機の制御装置。

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020202992A JP7588936B2 (ja) | 2020-12-07 | 2020-12-07 | 成形品取出機の制御装置 |

| US17/542,866 US12246474B2 (en) | 2020-12-07 | 2021-12-06 | Control system for apparatus for taking out molded product that detects collision based on torque |

| CN202111479367.2A CN114590553B (zh) | 2020-12-07 | 2021-12-06 | 成形品取出机的控制装置 |

| EP21212561.1A EP4008517B1 (en) | 2020-12-07 | 2021-12-06 | Control system for apparatus for taking out molded product |

| KR1020210173489A KR20220080721A (ko) | 2020-12-07 | 2021-12-07 | 성형품 취출기의 제어 장치 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020202992A JP7588936B2 (ja) | 2020-12-07 | 2020-12-07 | 成形品取出機の制御装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2022090541A JP2022090541A (ja) | 2022-06-17 |

| JP7588936B2 true JP7588936B2 (ja) | 2024-11-25 |

Family

ID=79185632

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020202992A Active JP7588936B2 (ja) | 2020-12-07 | 2020-12-07 | 成形品取出機の制御装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US12246474B2 (ja) |

| EP (1) | EP4008517B1 (ja) |

| JP (1) | JP7588936B2 (ja) |

| KR (1) | KR20220080721A (ja) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000271886A (ja) | 1999-03-26 | 2000-10-03 | Fanuc Ltd | 産業用ロボット |

| JP2015217468A (ja) | 2014-05-16 | 2015-12-07 | キヤノン株式会社 | ロボットシステムの制御方法、プログラム、記録媒体、ロボットシステム、及び診断装置 |

| JP2017019057A (ja) | 2015-07-13 | 2017-01-26 | セイコーエプソン株式会社 | ロボット制御装置、ロボットおよびロボットシステム |

| JP2017030058A (ja) | 2015-07-29 | 2017-02-09 | セイコーエプソン株式会社 | ロボット、ロボット制御装置およびロボットシステム |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS526555B2 (ja) | 1972-10-30 | 1977-02-23 | ||

| US4065212A (en) | 1975-06-30 | 1977-12-27 | International Business Machines Corporation | Inspection tool |

| JP2665984B2 (ja) | 1989-12-26 | 1997-10-22 | ファナック株式会社 | 外乱推定オブザーバによる衝突検出方法 |

| JP2608161B2 (ja) * | 1990-03-29 | 1997-05-07 | ファナック株式会社 | 産業用ロボットの停止制御方法 |

| JP3079047B2 (ja) * | 1996-10-22 | 2000-08-21 | ファナック株式会社 | 電動式射出成形機の可動部材衝突検知装置 |

| JP4055090B2 (ja) * | 1997-07-08 | 2008-03-05 | 株式会社安川電機 | ロボットの制御装置 |

| JP2000277039A (ja) * | 1999-03-26 | 2000-10-06 | Toshiba Corp | 画像表示装置およびその製造方法 |

| JP3526555B2 (ja) | 2001-03-01 | 2004-05-17 | 株式会社スター精機 | 成型品取出機のチャック部移動制御方法 |

| WO2009128156A1 (ja) * | 2008-04-17 | 2009-10-22 | 三菱電機株式会社 | 加工機における衝突検出装置及び衝突検出方法 |

| US20120330456A1 (en) * | 2010-03-08 | 2012-12-27 | Mitsubishi Electric Corporation | Numerical control device and control method of numerical control device |

| CN106239516B (zh) * | 2015-06-03 | 2021-09-24 | 精工爱普生株式会社 | 机器人控制装置、机器人以及机器人系统 |

| CN110869183B (zh) * | 2017-07-21 | 2022-04-01 | 赫斯基注塑系统有限公司 | 对用于模制机的保护装置进行编程的方法和系统 |

| JP6731893B2 (ja) * | 2017-07-31 | 2020-07-29 | ヤンマーパワーテクノロジー株式会社 | 作業車両 |

| CN112739515B (zh) * | 2018-09-21 | 2022-11-29 | 佳能弗吉尼亚股份有限公司 | 注射模制系统 |

| EP3689555A1 (de) * | 2019-02-04 | 2020-08-05 | Siemens Aktiengesellschaft | Kraftbegrenztes verfahren mindestens eines elements einer produktionsmaschine im manuellen betrieb |

-

2020

- 2020-12-07 JP JP2020202992A patent/JP7588936B2/ja active Active

-

2021

- 2021-12-06 US US17/542,866 patent/US12246474B2/en active Active

- 2021-12-06 EP EP21212561.1A patent/EP4008517B1/en active Active

- 2021-12-07 KR KR1020210173489A patent/KR20220080721A/ko active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000271886A (ja) | 1999-03-26 | 2000-10-03 | Fanuc Ltd | 産業用ロボット |

| JP2015217468A (ja) | 2014-05-16 | 2015-12-07 | キヤノン株式会社 | ロボットシステムの制御方法、プログラム、記録媒体、ロボットシステム、及び診断装置 |

| JP2017019057A (ja) | 2015-07-13 | 2017-01-26 | セイコーエプソン株式会社 | ロボット制御装置、ロボットおよびロボットシステム |

| JP2017030058A (ja) | 2015-07-29 | 2017-02-09 | セイコーエプソン株式会社 | ロボット、ロボット制御装置およびロボットシステム |

Also Published As

| Publication number | Publication date |

|---|---|

| US20220176596A1 (en) | 2022-06-09 |

| JP2022090541A (ja) | 2022-06-17 |

| EP4008517B1 (en) | 2025-11-26 |

| EP4008517A1 (en) | 2022-06-08 |

| CN114590553A (zh) | 2022-06-07 |

| US12246474B2 (en) | 2025-03-11 |

| KR20220080721A (ko) | 2022-06-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4261470B2 (ja) | 制御装置 | |

| EP0540753B1 (en) | System for controlling industrial robot | |

| US6409495B1 (en) | Mold protection device for injection molding machine | |

| EP0566741A1 (en) | Abnormal load detecting method | |

| JP2003326438A (ja) | 工具異常検出装置 | |

| US20190258223A1 (en) | Failure prediction device and machine learning device | |

| CN110196573B (zh) | 异常因素确定装置 | |

| EP1535706A1 (en) | Robot controller and robot system | |

| KR0144650B1 (ko) | 서보모터의 이상부하 검출 제어방법 | |

| JP4897632B2 (ja) | 衝突検出機能を有する工作機械の制御装置 | |

| JP2005327191A (ja) | サーボ制御装置 | |

| EP0203199A1 (en) | Injection molding machine which uses a servo motor and which is provided with a protecting function | |

| JP7588936B2 (ja) | 成形品取出機の制御装置 | |

| JP6440984B2 (ja) | 停止距離による加減速制御を行う数値制御装置 | |

| CN114590553B (zh) | 成形品取出机的控制装置 | |

| JP3217334B2 (ja) | 自動機械のための制御装置 | |

| JP6077497B2 (ja) | 繰返し加工を行う数値制御装置 | |

| JP2005052941A (ja) | ワーク載置装置 | |

| JP6441253B2 (ja) | 干渉検出後の対策を容易にする数値制御装置 | |

| JP4258718B2 (ja) | ロボット制御装置 | |

| US11378937B2 (en) | Numerical controller for controlling acceleration and deceleration of spindle feed rate | |

| JPH0976144A (ja) | 工作機械における加工状態監視方法 | |

| US11820007B2 (en) | Abnormality detection device and abnormality detection method | |

| JP2005321979A (ja) | 数値制御装置 | |

| EP4488013A1 (en) | Collision detection method and collision detection system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20230816 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20231025 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20240726 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240806 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20241007 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20241112 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20241112 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7588936 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |