JP7039492B2 - 溶液紡糸ポリアミドナノファイバー不織布 - Google Patents

溶液紡糸ポリアミドナノファイバー不織布 Download PDFInfo

- Publication number

- JP7039492B2 JP7039492B2 JP2018564364A JP2018564364A JP7039492B2 JP 7039492 B2 JP7039492 B2 JP 7039492B2 JP 2018564364 A JP2018564364 A JP 2018564364A JP 2018564364 A JP2018564364 A JP 2018564364A JP 7039492 B2 JP7039492 B2 JP 7039492B2

- Authority

- JP

- Japan

- Prior art keywords

- nonwoven fabric

- fabric product

- polyamide

- nanofiber

- product according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002121 nanofiber Substances 0.000 title claims description 117

- 239000004745 nonwoven fabric Substances 0.000 title claims description 117

- 239000004952 Polyamide Substances 0.000 title claims description 66

- 229920002647 polyamide Polymers 0.000 title claims description 66

- 239000000835 fiber Substances 0.000 claims description 81

- 238000004519 manufacturing process Methods 0.000 claims description 52

- 229920000642 polymer Polymers 0.000 claims description 37

- 238000000034 method Methods 0.000 claims description 34

- 230000035699 permeability Effects 0.000 claims description 31

- 238000009987 spinning Methods 0.000 claims description 31

- 239000000203 mixture Substances 0.000 claims description 29

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 claims description 28

- 239000002904 solvent Substances 0.000 claims description 18

- OSWFIVFLDKOXQC-UHFFFAOYSA-N 4-(3-methoxyphenyl)aniline Chemical compound COC1=CC=CC(C=2C=CC(N)=CC=2)=C1 OSWFIVFLDKOXQC-UHFFFAOYSA-N 0.000 claims description 13

- 235000019253 formic acid Nutrition 0.000 claims description 13

- 229920001577 copolymer Polymers 0.000 claims description 10

- 229920002302 Nylon 6,6 Polymers 0.000 claims description 9

- BYEAHWXPCBROCE-UHFFFAOYSA-N 1,1,1,3,3,3-hexafluoropropan-2-ol Chemical compound FC(F)(F)C(O)C(F)(F)F BYEAHWXPCBROCE-UHFFFAOYSA-N 0.000 claims description 8

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 claims description 8

- DTQVDTLACAAQTR-UHFFFAOYSA-N Trifluoroacetic acid Chemical compound OC(=O)C(F)(F)F DTQVDTLACAAQTR-UHFFFAOYSA-N 0.000 claims description 8

- 239000000956 alloy Substances 0.000 claims description 8

- 229910045601 alloy Inorganic materials 0.000 claims description 8

- RLSSMJSEOOYNOY-UHFFFAOYSA-N m-cresol Chemical compound CC1=CC=CC(O)=C1 RLSSMJSEOOYNOY-UHFFFAOYSA-N 0.000 claims description 8

- 229920002292 Nylon 6 Polymers 0.000 claims description 7

- 150000002989 phenols Chemical class 0.000 claims description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 3

- 239000000047 product Substances 0.000 description 94

- 238000001914 filtration Methods 0.000 description 38

- 239000000758 substrate Substances 0.000 description 37

- 239000007789 gas Substances 0.000 description 28

- 239000000463 material Substances 0.000 description 28

- 238000000151 deposition Methods 0.000 description 26

- 230000008021 deposition Effects 0.000 description 23

- 229920001778 nylon Polymers 0.000 description 15

- 238000012360 testing method Methods 0.000 description 14

- 229920001410 Microfiber Polymers 0.000 description 10

- 239000004677 Nylon Substances 0.000 description 10

- 230000000052 comparative effect Effects 0.000 description 9

- 238000007380 fibre production Methods 0.000 description 8

- 239000003658 microfiber Substances 0.000 description 8

- 239000003380 propellant Substances 0.000 description 7

- 238000012546 transfer Methods 0.000 description 6

- 230000008569 process Effects 0.000 description 5

- 230000004888 barrier function Effects 0.000 description 4

- -1 derivatives Polymers 0.000 description 4

- 238000009826 distribution Methods 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 229920003231 aliphatic polyamide Polymers 0.000 description 3

- 238000001523 electrospinning Methods 0.000 description 3

- 239000004744 fabric Substances 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 238000002074 melt spinning Methods 0.000 description 3

- 238000004806 packaging method and process Methods 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 238000005273 aeration Methods 0.000 description 2

- 238000004458 analytical method Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 230000006837 decompression Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 239000007943 implant Substances 0.000 description 2

- 239000012528 membrane Substances 0.000 description 2

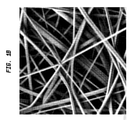

- 238000001000 micrograph Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 239000000178 monomer Substances 0.000 description 2

- 229920006254 polymer film Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 239000004953 Aliphatic polyamide Substances 0.000 description 1

- 241000272814 Anser sp. Species 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 241000549556 Nanos Species 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 238000012644 addition polymerization Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 125000003368 amide group Chemical group 0.000 description 1

- 235000013361 beverage Nutrition 0.000 description 1

- 230000001588 bifunctional effect Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 231100000357 carcinogen Toxicity 0.000 description 1

- 239000003183 carcinogenic agent Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000009986 fabric formation Methods 0.000 description 1

- 239000002657 fibrous material Substances 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 239000013538 functional additive Substances 0.000 description 1

- 229920006130 high-performance polyamide Polymers 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 235000013372 meat Nutrition 0.000 description 1

- 239000012768 molten material Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 239000011236 particulate material Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 229920013639 polyalphaolefin Polymers 0.000 description 1

- 229920006122 polyamide resin Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920002959 polymer blend Polymers 0.000 description 1

- 229920005594 polymer fiber Polymers 0.000 description 1

- 229920005597 polymer membrane Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 239000012462 polypropylene substrate Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 235000020994 smoked meat Nutrition 0.000 description 1

- 230000000391 smoking effect Effects 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 230000005514 two-phase flow Effects 0.000 description 1

- 238000009834 vaporization Methods 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/08—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating

- D04H3/16—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating with bonds between thermoplastic filaments produced in association with filament formation, e.g. immediately following extrusion

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4326—Condensation or reaction polymers

- D04H1/4334—Polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D39/00—Filtering material for liquid or gaseous fluids

- B01D39/14—Other self-supporting filtering material ; Other filtering material

- B01D39/16—Other self-supporting filtering material ; Other filtering material of organic material, e.g. synthetic fibres

- B01D39/1607—Other self-supporting filtering material ; Other filtering material of organic material, e.g. synthetic fibres the material being fibrous

- B01D39/1623—Other self-supporting filtering material ; Other filtering material of organic material, e.g. synthetic fibres the material being fibrous of synthetic origin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D46/00—Filters or filtering processes specially modified for separating dispersed particles from gases or vapours

- B01D46/54—Particle separators, e.g. dust precipitators, using ultra-fine filter sheets or diaphragms

- B01D46/546—Particle separators, e.g. dust precipitators, using ultra-fine filter sheets or diaphragms using nano- or microfibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/54—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving

- D04H1/56—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving in association with fibre formation, e.g. immediately following extrusion of staple fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/70—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres

- D04H1/72—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres the fibres being randomly arranged

- D04H1/732—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres the fibres being randomly arranged by fluid current, e.g. air-lay

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/005—Synthetic yarns or filaments

- D04H3/009—Condensation or reaction polymers

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/02—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of forming fleeces or layers, e.g. reorientation of yarns or filaments

- D04H3/03—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of forming fleeces or layers, e.g. reorientation of yarns or filaments at random

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2239/00—Aspects relating to filtering material for liquid or gaseous fluids

- B01D2239/02—Types of fibres, filaments or particles, self-supporting or supported materials

- B01D2239/0208—Single-component fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2239/00—Aspects relating to filtering material for liquid or gaseous fluids

- B01D2239/06—Filter cloth, e.g. knitted, woven non-woven; self-supported material

- B01D2239/0604—Arrangement of the fibres in the filtering material

- B01D2239/0618—Non-woven

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2239/00—Aspects relating to filtering material for liquid or gaseous fluids

- B01D2239/10—Filtering material manufacturing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2239/00—Aspects relating to filtering material for liquid or gaseous fluids

- B01D2239/12—Special parameters characterising the filtering material

- B01D2239/1233—Fibre diameter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2239/00—Aspects relating to filtering material for liquid or gaseous fluids

- B01D2239/12—Special parameters characterising the filtering material

- B01D2239/1258—Permeability

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2501/00—Wearing apparel

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2505/00—Industrial

- D10B2505/04—Filters

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Nanotechnology (AREA)

- Nonwoven Fabrics (AREA)

- Spinning Methods And Devices For Manufacturing Artificial Fibers (AREA)

- Artificial Filaments (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201662348524P | 2016-06-10 | 2016-06-10 | |

| US201662348462P | 2016-06-10 | 2016-06-10 | |

| US62/348,524 | 2016-06-10 | ||

| US62/348,462 | 2016-06-10 | ||

| PCT/US2017/036062 WO2017214085A1 (en) | 2016-06-10 | 2017-06-06 | Solution-spun polyamide nanofiber nonwovens |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2019518148A JP2019518148A (ja) | 2019-06-27 |

| JP2019518148A5 JP2019518148A5 (enExample) | 2020-06-25 |

| JP7039492B2 true JP7039492B2 (ja) | 2022-03-22 |

Family

ID=60578959

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018564364A Active JP7039492B2 (ja) | 2016-06-10 | 2017-06-06 | 溶液紡糸ポリアミドナノファイバー不織布 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20190194847A1 (enExample) |

| EP (1) | EP3468424B1 (enExample) |

| JP (1) | JP7039492B2 (enExample) |

| KR (1) | KR102299766B1 (enExample) |

| CN (1) | CN109561771B (enExample) |

| CA (1) | CA3026497C (enExample) |

| TW (1) | TWI772306B (enExample) |

| WO (1) | WO2017214085A1 (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| MX2019014732A (es) | 2017-06-08 | 2020-08-03 | Ascend Performance Mat Operations Llc | Nanofibras de poliamida no tejidas. |

| US11376534B2 (en) | 2017-06-08 | 2022-07-05 | Ascend Performance Materials Operations Llc | Polyamide nanofiber nonwovens for filters |

| MX2020013310A (es) | 2018-06-08 | 2021-05-27 | Ascend Performance Mat Operations Llc | Productos no tejidos de nanofibras afinables. |

| WO2020132002A1 (en) | 2018-12-18 | 2020-06-25 | Ascend Performance Materials Operations Llc | Antimicrobial nonwoven polyamides with zinc content |

| US20200345183A1 (en) * | 2019-05-01 | 2020-11-05 | Robert Scott Boyd | Cover for an eating utensil |

| JP7340037B2 (ja) * | 2019-05-01 | 2023-09-06 | アセンド・パフォーマンス・マテリアルズ・オペレーションズ・リミテッド・ライアビリティ・カンパニー | ポリアミドナノファイバー層を含むろ過媒体 |

| KR20220100855A (ko) * | 2019-09-13 | 2022-07-18 | 더 노스 훼이스 어패럴 코오포레이션 | 막을 갖는 복합 재료 |

| TW202136604A (zh) | 2019-12-18 | 2021-10-01 | 美商阿散德性能材料營運公司 | 生產具有鋅含量的纖維和織物的方法 |

| CN113117434B (zh) * | 2019-12-30 | 2022-11-22 | 西安工程大学 | 柔性网状脉结构陶瓷纳米纤维超高温过滤膜的制备方法 |

| CN111298520A (zh) * | 2020-02-24 | 2020-06-19 | 深圳维度新材料有限公司 | 复合材料层的制备方法、复合材料层及口罩 |

| MX2023005110A (es) | 2020-10-30 | 2023-08-04 | Ascend Performance Mat Operations Llc | Materiales no tejidos de poliamida en compuestos multicapa para absorción de sonido. |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008274512A (ja) | 2007-04-03 | 2008-11-13 | Nisshinbo Ind Inc | 抗菌性ナノファイバー |

| JP2010236138A (ja) | 2009-03-31 | 2010-10-21 | Toray Ind Inc | 防水透湿繊維積層体 |

| JP2012510006A (ja) | 2008-11-25 | 2012-04-26 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | 不織ポリマーウェブ |

| JP2012167416A (ja) | 2011-01-28 | 2012-09-06 | Toray Ind Inc | ポリアミド繊維の製造方法 |

| JP2013511627A (ja) | 2009-11-19 | 2013-04-04 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | 高湿度環境用濾過媒体 |

| WO2016007345A1 (en) | 2014-07-07 | 2016-01-14 | E. I. Du Pont De Nemours And Company | Composite filtration membranes comprising a casted membrane on a nanofiber sheet |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0673654A (ja) * | 1992-08-27 | 1994-03-15 | Unitika Ltd | ポリアミド系極細繊維不織布及びその製造方法 |

| US5558826A (en) * | 1995-02-07 | 1996-09-24 | E. I. Du Pont De Nemours And Company | High speed process for making fully-oriented nylon yarns |

| KR100549140B1 (ko) * | 2002-03-26 | 2006-02-03 | 이 아이 듀폰 디 네모아 앤드 캄파니 | 일렉트로-브로운 방사법에 의한 초극세 나노섬유 웹제조방법 |

| US20080070463A1 (en) * | 2006-09-20 | 2008-03-20 | Pankaj Arora | Nanowebs |

| US20080104738A1 (en) * | 2006-11-03 | 2008-05-08 | Conley Jill A | Liquid water resistant and water vapor permeable garments |

| US7993523B2 (en) * | 2007-03-06 | 2011-08-09 | E. I. Du Pont De Nemours And Company | Liquid filtration media |

| JP5393662B2 (ja) * | 2007-06-22 | 2014-01-22 | イノベイティブ サーフェイス テクノロジーズ, インコーポレイテッド | 潜在反応基を含有するナノ繊維 |

| WO2009064311A1 (en) * | 2007-11-13 | 2009-05-22 | E. I. Du Pont De Nemours And Company | Breathable garment having a fluid drainage layer |

| US9834865B2 (en) * | 2007-12-17 | 2017-12-05 | E I Du Pont De Nemours And Company | Centrifugal solution spun nanofiber process |

| MX345584B (es) * | 2008-10-10 | 2017-02-07 | Invista Tech Sarl | Fibra cortada de nailon de capacidad que soporta alta carga e hilos mezclados de nailon y telas fabricadas con los mismos. |

| EP3168019A1 (en) * | 2013-07-05 | 2017-05-17 | The North Face Apparel Corp. | Forcespinning of fibers and filaments |

| WO2015053444A1 (ko) * | 2013-10-07 | 2015-04-16 | (주)에프티이앤이 | 기재 사이에 나노섬유를 포함하는 필터 및 이의 제조방법 |

| DK3068942T3 (da) * | 2013-11-14 | 2020-03-16 | Invista Textiles Uk Ltd | Jordafvisende fiber og fremgangsmåder til fremstilling heraf |

| CN105597428B (zh) * | 2016-02-23 | 2017-11-07 | 绿纳科技有限责任公司 | 一种用于去除污水中Cr(VI)的纳米纤维过滤材料的制备方法 |

-

2017

- 2017-06-06 KR KR1020197000767A patent/KR102299766B1/ko active Active

- 2017-06-06 WO PCT/US2017/036062 patent/WO2017214085A1/en not_active Ceased

- 2017-06-06 EP EP17810819.7A patent/EP3468424B1/en active Active

- 2017-06-06 CA CA3026497A patent/CA3026497C/en active Active

- 2017-06-06 JP JP2018564364A patent/JP7039492B2/ja active Active

- 2017-06-06 TW TW106118684A patent/TWI772306B/zh active

- 2017-06-06 US US16/308,251 patent/US20190194847A1/en not_active Abandoned

- 2017-06-06 CN CN201780048033.5A patent/CN109561771B/zh active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008274512A (ja) | 2007-04-03 | 2008-11-13 | Nisshinbo Ind Inc | 抗菌性ナノファイバー |

| JP2012510006A (ja) | 2008-11-25 | 2012-04-26 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | 不織ポリマーウェブ |

| JP2010236138A (ja) | 2009-03-31 | 2010-10-21 | Toray Ind Inc | 防水透湿繊維積層体 |

| JP2013511627A (ja) | 2009-11-19 | 2013-04-04 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | 高湿度環境用濾過媒体 |

| JP2012167416A (ja) | 2011-01-28 | 2012-09-06 | Toray Ind Inc | ポリアミド繊維の製造方法 |

| WO2016007345A1 (en) | 2014-07-07 | 2016-01-14 | E. I. Du Pont De Nemours And Company | Composite filtration membranes comprising a casted membrane on a nanofiber sheet |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI772306B (zh) | 2022-08-01 |

| KR102299766B1 (ko) | 2021-09-07 |

| KR20190016100A (ko) | 2019-02-15 |

| CN109561771A (zh) | 2019-04-02 |

| CA3026497A1 (en) | 2017-12-14 |

| WO2017214085A1 (en) | 2017-12-14 |

| CN109561771B (zh) | 2021-01-08 |

| JP2019518148A (ja) | 2019-06-27 |

| EP3468424A4 (en) | 2020-02-12 |

| TW201819703A (zh) | 2018-06-01 |

| US20190194847A1 (en) | 2019-06-27 |

| CA3026497C (en) | 2023-09-19 |

| EP3468424A1 (en) | 2019-04-17 |

| EP3468424B1 (en) | 2021-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7039492B2 (ja) | 溶液紡糸ポリアミドナノファイバー不織布 | |

| JP6901594B2 (ja) | ポリアミドナノファイバー不織布 | |

| CN107208336B (zh) | 用于呼吸装置和面罩的熔纺过滤介质 | |

| JP5583008B2 (ja) | 短繊維を有するメルトブローン繊維ウェブを含む成形レスピレータ | |

| KR101453591B1 (ko) | 스테이플 섬유를 갖는 멜트블로운 섬유 웨브 | |

| JP5819832B2 (ja) | ナノ繊維ウェブを形成するためのノズル、装置、システム及び方法、並びにこの方法によって作製される物品 | |

| TWI772777B (zh) | 具有奈米纖維層的非織造多層結構 | |

| JP6554462B2 (ja) | 空気濾過媒体としてのエレクトレットナノファイバーウェブ | |

| KR101918913B1 (ko) | 공-혼합된 구조물을 형성하기 위한 멀티-다이 멜트 블로잉 시스템 및 이의 형성 방법 | |

| JP7701349B2 (ja) | 混合直径細繊維を含む濾材層 | |

| EP3060710A1 (en) | Electret nanofibrous web | |

| JP7299316B2 (ja) | メルトブロー不織布、フィルター、及びメルトブロー不織布の製造方法 | |

| JP4069057B2 (ja) | 高性能エアフィルタ | |

| JP7395512B2 (ja) | 調節可能なナノファイバー不織布製品 | |

| HK40005712B (en) | Solution-spun polyamide nanofiber nonwovens | |

| HK40005712A (en) | Solution-spun polyamide nanofiber nonwovens | |

| Buivydienė | Formation of fibrous materials for air filtration applications via melt electrospinning | |

| US20250163621A1 (en) | Biodegradable and hydrophobic polylactic acid (pla ) non-woven material and process for manufacturing thereof | |

| JP4906675B2 (ja) | エアフィルター用不織布および空気清浄用フィルター |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200514 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200514 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20210323 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210331 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210628 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20211130 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20220215 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20220302 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20220309 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7039492 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |