JP6836152B2 - 転がり軸受用シールの圧縮加硫成形用金型、及び転がり軸受用シールの製造方法 - Google Patents

転がり軸受用シールの圧縮加硫成形用金型、及び転がり軸受用シールの製造方法 Download PDFInfo

- Publication number

- JP6836152B2 JP6836152B2 JP2017012017A JP2017012017A JP6836152B2 JP 6836152 B2 JP6836152 B2 JP 6836152B2 JP 2017012017 A JP2017012017 A JP 2017012017A JP 2017012017 A JP2017012017 A JP 2017012017A JP 6836152 B2 JP6836152 B2 JP 6836152B2

- Authority

- JP

- Japan

- Prior art keywords

- seal

- mold

- rolling bearing

- diameter side

- core metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/16—Sealings between relatively-moving surfaces

- F16J15/32—Sealings between relatively-moving surfaces with elastic sealings, e.g. O-rings

- F16J15/3204—Sealings between relatively-moving surfaces with elastic sealings, e.g. O-rings with at least one lip

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

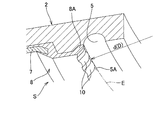

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/18—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/02—Moulds or cores; Details thereof or accessories therefor with incorporated heating or cooling means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/12—Moulds or cores; Details thereof or accessories therefor with incorporated means for positioning inserts, e.g. labels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/42—Moulds or cores; Details thereof or accessories therefor characterised by the shape of the moulding surface, e.g. ribs or grooves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/36—Moulds for making articles of definite length, i.e. discrete articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/36—Moulds for making articles of definite length, i.e. discrete articles

- B29C43/38—Moulds for making articles of definite length, i.e. discrete articles with means to avoid flashes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/38—Cutting-off equipment for sprues or ingates

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

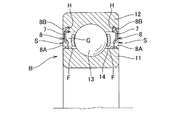

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/04—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for radial load mainly

- F16C19/06—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for radial load mainly with a single row or balls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/72—Sealings

- F16C33/76—Sealings of ball or roller bearings

- F16C33/78—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/72—Sealings

- F16C33/76—Sealings of ball or roller bearings

- F16C33/78—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members

- F16C33/7816—Details of the sealing or parts thereof, e.g. geometry, material

- F16C33/7833—Special methods of manufacture

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/36—Moulds for making articles of definite length, i.e. discrete articles

- B29C2043/3602—Moulds for making articles of definite length, i.e. discrete articles with means for positioning, fastening or clamping the material to be formed or preforms inside the mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/24—Condition, form or state of moulded material or of the material to be shaped crosslinked or vulcanised

- B29K2105/246—Uncured, e.g. green

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2705/00—Use of metals, their alloys or their compounds, for preformed parts, e.g. for inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/26—Sealing devices, e.g. packaging for pistons or pipe joints

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Thermal Sciences (AREA)

- Sealing With Elastic Sealing Lips (AREA)

- Sealing Of Bearings (AREA)

- Rolling Contact Bearings (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017012017A JP6836152B2 (ja) | 2017-01-26 | 2017-01-26 | 転がり軸受用シールの圧縮加硫成形用金型、及び転がり軸受用シールの製造方法 |

| EP17894047.4A EP3575640A4 (en) | 2017-01-26 | 2017-10-17 | PRESSURE VULCANIZATION CASTING FORM FOR ROLLING BEARING SEAL AND PROCESS FOR PRODUCING A ROLLING BEARING SEAL |

| CN201780082936.5A CN110168261B (zh) | 2017-01-26 | 2017-10-17 | 滚动轴承用密封件的压缩硫化成形用金属模及滚动轴承用密封件的制造方法 |

| PCT/JP2017/037490 WO2018138981A1 (ja) | 2017-01-26 | 2017-10-17 | 転がり軸受用シールの圧縮加硫成形用金型、及び転がり軸受用シールの製造方法 |

| US16/479,140 US11440226B2 (en) | 2017-01-26 | 2017-10-17 | Compression vulcanization molding mold for rolling bearing seal, and method for manufacturing rolling bearing seal |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017012017A JP6836152B2 (ja) | 2017-01-26 | 2017-01-26 | 転がり軸受用シールの圧縮加硫成形用金型、及び転がり軸受用シールの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2018119624A JP2018119624A (ja) | 2018-08-02 |

| JP2018119624A5 JP2018119624A5 (enExample) | 2019-10-31 |

| JP6836152B2 true JP6836152B2 (ja) | 2021-02-24 |

Family

ID=62978247

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017012017A Active JP6836152B2 (ja) | 2017-01-26 | 2017-01-26 | 転がり軸受用シールの圧縮加硫成形用金型、及び転がり軸受用シールの製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11440226B2 (enExample) |

| EP (1) | EP3575640A4 (enExample) |

| JP (1) | JP6836152B2 (enExample) |

| CN (1) | CN110168261B (enExample) |

| WO (1) | WO2018138981A1 (enExample) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112400075A (zh) * | 2018-08-29 | 2021-02-23 | Nok株式会社 | 密封构件的制造方法和成型模具 |

| JP7478411B2 (ja) * | 2020-02-17 | 2024-05-07 | 内山工業株式会社 | 金型 |

| JP2022189011A (ja) * | 2021-06-10 | 2022-12-22 | 株式会社神戸製鋼所 | 金属樹脂複合体を製造するための金型、装置、および方法 |

| CN113910503B (zh) * | 2021-10-20 | 2025-04-29 | 厦门正新橡胶工业有限公司 | 一种轮胎的硫化模具 |

| JP7768821B2 (ja) * | 2022-04-11 | 2025-11-12 | 矢崎総業株式会社 | 成形品の製造方法 |

| WO2024176472A1 (ja) * | 2023-02-24 | 2024-08-29 | 株式会社ジェイテクト | 摺動部材、及び、転がり軸受 |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3501155A (en) * | 1967-05-22 | 1970-03-17 | Gen Motors Corp | Bi-directional seal |

| US3572732A (en) * | 1969-02-26 | 1971-03-30 | Mather Co | Double load area lip seal |

| US3895814A (en) * | 1971-08-10 | 1975-07-22 | Parker Hannifin Corp | Rotary shaft seal |

| CH567927A5 (enExample) * | 1974-08-21 | 1975-10-15 | Schiesser Ag | |

| DE2556992C2 (de) * | 1975-12-18 | 1980-04-24 | Goetze Ag, 5093 Burscheid | Wellendichtring |

| US4399998A (en) * | 1981-12-28 | 1983-08-23 | The Timken Company | Self-venting seal lip |

| US4770424A (en) * | 1985-12-19 | 1988-09-13 | The Timken Company | Compact labyrinth-type seal |

| FR2636691B1 (fr) * | 1988-09-20 | 1994-12-09 | Roulements Soc Nouvelle | Roulement avec joint d'etancheite |

| JP3242517B2 (ja) * | 1993-12-29 | 2001-12-25 | 東洋シール工業株式会社 | 軸受用密封板およびその製造方法 |

| US5921555A (en) * | 1997-04-10 | 1999-07-13 | Freudenberg-Nok General Partnership | Uni-directional seal for use on a shaft |

| US6409177B1 (en) * | 1999-08-23 | 2002-06-25 | Freudenberg-Nok General Partnership | Rotary shaft seal |

| JP4461518B2 (ja) * | 1999-08-27 | 2010-05-12 | 住友化学株式会社 | 熱可塑性樹脂成形体製造用金型および熱可塑性樹脂成形体の製造方法 |

| JP4419641B2 (ja) * | 2004-03-29 | 2010-02-24 | 日産自動車株式会社 | 車両用ヘッドランプの取付け構造 |

| US8657299B2 (en) * | 2004-07-15 | 2014-02-25 | John E. Rode | Mounting rings for shafts |

| US7563050B2 (en) * | 2004-07-15 | 2009-07-21 | Temper Corporation | Rings for mounting structures to shafts and methods of using such rings |

| WO2008059790A1 (en) * | 2006-11-14 | 2008-05-22 | Ntn Corporation | Sealed rolling bearing |

| JP5126999B2 (ja) * | 2008-03-13 | 2013-01-23 | 日本バルカー工業株式会社 | シール材 |

| US8596872B2 (en) * | 2009-10-13 | 2013-12-03 | Amsted Rail Company, Inc. | Roller bearing seal |

| JP2013007463A (ja) | 2011-06-27 | 2013-01-10 | Ntn Corp | シール付き軸受 |

| US9115762B2 (en) * | 2011-06-27 | 2015-08-25 | Ntn Corporation | Rolling bearing |

| KR102051171B1 (ko) * | 2012-06-04 | 2019-12-02 | 테네코 인코퍼레이티드 | 레이디얼 샤프트 시일 및 이것을 갖춘 어셈블리 |

| JP6522357B2 (ja) * | 2015-02-06 | 2019-05-29 | Ntn株式会社 | 転がり軸受 |

| WO2016143786A1 (ja) * | 2015-03-09 | 2016-09-15 | Ntn株式会社 | シール付軸受 |

| US10190637B2 (en) | 2015-03-09 | 2019-01-29 | Ntn Corporation | Sealed bearing assembly |

| JP2016166655A (ja) | 2015-03-10 | 2016-09-15 | Ntn株式会社 | シール付き転がり軸受 |

| JP2016166654A (ja) | 2015-03-10 | 2016-09-15 | Ntn株式会社 | シール付き転がり軸受 |

| JP6609460B2 (ja) * | 2015-11-13 | 2019-11-20 | 内山工業株式会社 | 成型金型及び密封装置の製造方法 |

| JP6789739B2 (ja) * | 2016-09-08 | 2020-11-25 | Ntn株式会社 | シール付軸受 |

-

2017

- 2017-01-26 JP JP2017012017A patent/JP6836152B2/ja active Active

- 2017-10-17 WO PCT/JP2017/037490 patent/WO2018138981A1/ja not_active Ceased

- 2017-10-17 EP EP17894047.4A patent/EP3575640A4/en active Pending

- 2017-10-17 US US16/479,140 patent/US11440226B2/en active Active

- 2017-10-17 CN CN201780082936.5A patent/CN110168261B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US20190351590A1 (en) | 2019-11-21 |

| CN110168261B (zh) | 2021-05-11 |

| EP3575640A1 (en) | 2019-12-04 |

| US11440226B2 (en) | 2022-09-13 |

| EP3575640A4 (en) | 2020-10-14 |

| JP2018119624A (ja) | 2018-08-02 |

| WO2018138981A1 (ja) | 2018-08-02 |

| CN110168261A (zh) | 2019-08-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6836152B2 (ja) | 転がり軸受用シールの圧縮加硫成形用金型、及び転がり軸受用シールの製造方法 | |

| US6660206B1 (en) | Method of manufacturing a sealing device | |

| US9714713B2 (en) | Seal ring with frictional load surface | |

| US4986553A (en) | Shaft seal | |

| CN105745477B (zh) | 密封装置的制造方法 | |

| CN107208796B (zh) | 环形密封件的制造方法 | |

| JP2009092223A (ja) | ユニバーサルジョイント用密封装置 | |

| JP6011777B2 (ja) | 密封装置 | |

| JP6566384B2 (ja) | 密封装置 | |

| US11668399B2 (en) | Rotary seal and method of making same | |

| JP3169130B2 (ja) | 密封装置の製造方法 | |

| US20200340588A1 (en) | Sealing device and method for making slinger | |

| US20200292082A1 (en) | Sealing device | |

| JP7121135B2 (ja) | 密封装置 | |

| WO2020009005A1 (ja) | 密封装置 | |

| JP2006275143A (ja) | 密封装置及びシール部材の製造方法 | |

| JP3367802B2 (ja) | シール部材の製造方法及び密封装置 | |

| US12442449B2 (en) | Bidirectional hydrodynamic rotary seal | |

| JP2021126857A (ja) | 金型 | |

| JP2011196461A (ja) | 転がり軸受用密封装置 | |

| JP6124052B2 (ja) | オイルシールとその製造方法 | |

| JP5702580B2 (ja) | オイルシール用金型 | |

| JPH0469487B2 (enExample) | ||

| JP2024056552A (ja) | 密封構造 | |

| JP2021025596A (ja) | 回転用シール |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190920 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190920 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200804 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200925 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20210106 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20210119 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6836152 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |