JP6550049B2 - 騒音低減繊維質層を内包するタイヤ - Google Patents

騒音低減繊維質層を内包するタイヤ Download PDFInfo

- Publication number

- JP6550049B2 JP6550049B2 JP2016533008A JP2016533008A JP6550049B2 JP 6550049 B2 JP6550049 B2 JP 6550049B2 JP 2016533008 A JP2016533008 A JP 2016533008A JP 2016533008 A JP2016533008 A JP 2016533008A JP 6550049 B2 JP6550049 B2 JP 6550049B2

- Authority

- JP

- Japan

- Prior art keywords

- overlay

- cord

- fold

- tire

- ply

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000835 fiber Substances 0.000 title description 22

- 229920001971 elastomer Polymers 0.000 claims description 30

- 239000011324 bead Substances 0.000 claims description 15

- 238000000034 method Methods 0.000 claims description 15

- 238000004804 winding Methods 0.000 claims description 14

- 238000003475 lamination Methods 0.000 claims description 9

- 239000004760 aramid Substances 0.000 description 34

- 229920003235 aromatic polyamide Polymers 0.000 description 34

- 239000003063 flame retardant Substances 0.000 description 19

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 description 18

- 229920000642 polymer Polymers 0.000 description 17

- 229920001778 nylon Polymers 0.000 description 16

- 239000004677 Nylon Substances 0.000 description 15

- 229920000728 polyester Polymers 0.000 description 13

- 239000000203 mixture Substances 0.000 description 12

- 125000003118 aryl group Chemical group 0.000 description 11

- 244000043261 Hevea brasiliensis Species 0.000 description 9

- 229920006231 aramid fiber Polymers 0.000 description 9

- 229920003052 natural elastomer Polymers 0.000 description 9

- 229920001194 natural rubber Polymers 0.000 description 9

- 150000004985 diamines Chemical class 0.000 description 8

- 229920001577 copolymer Polymers 0.000 description 7

- 238000002844 melting Methods 0.000 description 7

- 230000008018 melting Effects 0.000 description 7

- CBCKQZAAMUWICA-UHFFFAOYSA-N 1,4-phenylenediamine Chemical compound NC1=CC=C(N)C=C1 CBCKQZAAMUWICA-UHFFFAOYSA-N 0.000 description 6

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 6

- 239000000654 additive Substances 0.000 description 6

- -1 polyethylene Polymers 0.000 description 6

- 208000034699 Vitreous floaters Diseases 0.000 description 5

- 150000001805 chlorine compounds Chemical class 0.000 description 5

- 239000004744 fabric Substances 0.000 description 5

- LXEJRKJRKIFVNY-UHFFFAOYSA-N terephthaloyl chloride Chemical compound ClC(=O)C1=CC=C(C(Cl)=O)C=C1 LXEJRKJRKIFVNY-UHFFFAOYSA-N 0.000 description 5

- 239000004953 Aliphatic polyamide Substances 0.000 description 4

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 4

- 229920002302 Nylon 6,6 Polymers 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 4

- KKEYFWRCBNTPAC-UHFFFAOYSA-N Terephthalic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 description 4

- 229920003231 aliphatic polyamide Polymers 0.000 description 4

- 238000010348 incorporation Methods 0.000 description 4

- 238000006116 polymerization reaction Methods 0.000 description 4

- 239000010959 steel Substances 0.000 description 4

- 238000010998 test method Methods 0.000 description 4

- 229920000271 Kevlar® Polymers 0.000 description 3

- 229920002292 Nylon 6 Polymers 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 3

- 238000011156 evaluation Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 239000011112 polyethylene naphthalate Substances 0.000 description 3

- 238000004073 vulcanization Methods 0.000 description 3

- ZBMISJGHVWNWTE-UHFFFAOYSA-N 3-(4-aminophenoxy)aniline Chemical compound C1=CC(N)=CC=C1OC1=CC=CC(N)=C1 ZBMISJGHVWNWTE-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 229920000106 Liquid crystal polymer Polymers 0.000 description 2

- 229920000305 Nylon 6,10 Polymers 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 229920000297 Rayon Polymers 0.000 description 2

- 150000001408 amides Chemical class 0.000 description 2

- ADCOVFLJGNWWNZ-UHFFFAOYSA-N antimony trioxide Chemical compound O=[Sb]O[Sb]=O ADCOVFLJGNWWNZ-UHFFFAOYSA-N 0.000 description 2

- QMKYBPDZANOJGF-UHFFFAOYSA-N benzene-1,3,5-tricarboxylic acid Chemical compound OC(=O)C1=CC(C(O)=O)=CC(C(O)=O)=C1 QMKYBPDZANOJGF-UHFFFAOYSA-N 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- LYMBWJDBLCMHBO-UHFFFAOYSA-N cyclooctane;1,2,3,4,5,5-hexachlorocyclopenta-1,3-diene Chemical compound C1CCCCCCC1.ClC1=C(Cl)C(Cl)(Cl)C(Cl)=C1Cl.ClC1=C(Cl)C(Cl)(Cl)C(Cl)=C1Cl LYMBWJDBLCMHBO-UHFFFAOYSA-N 0.000 description 2

- WOZVHXUHUFLZGK-UHFFFAOYSA-N dimethyl terephthalate Chemical compound COC(=O)C1=CC=C(C(=O)OC)C=C1 WOZVHXUHUFLZGK-UHFFFAOYSA-N 0.000 description 2

- 229920001519 homopolymer Polymers 0.000 description 2

- QQVIHTHCMHWDBS-UHFFFAOYSA-N isophthalic acid Chemical compound OC(=O)C1=CC=CC(C(O)=O)=C1 QQVIHTHCMHWDBS-UHFFFAOYSA-N 0.000 description 2

- 150000003951 lactams Chemical class 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- BDJRBEYXGGNYIS-UHFFFAOYSA-N nonanedioic acid Chemical compound OC(=O)CCCCCCCC(O)=O BDJRBEYXGGNYIS-UHFFFAOYSA-N 0.000 description 2

- 210000000006 pectoral fin Anatomy 0.000 description 2

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- CYIDZMCFTVVTJO-UHFFFAOYSA-N pyromellitic acid Chemical compound OC(=O)C1=CC(C(O)=O)=C(C(O)=O)C=C1C(O)=O CYIDZMCFTVVTJO-UHFFFAOYSA-N 0.000 description 2

- 239000002964 rayon Substances 0.000 description 2

- CXMXRPHRNRROMY-UHFFFAOYSA-N sebacic acid Chemical compound OC(=O)CCCCCCCCC(O)=O CXMXRPHRNRROMY-UHFFFAOYSA-N 0.000 description 2

- NDRKXFLZSRHAJE-UHFFFAOYSA-N 1,2,3,4,5-pentabromo-6-(2,3,4-tribromophenyl)benzene Chemical group BrC1=C(Br)C(Br)=CC=C1C1=C(Br)C(Br)=C(Br)C(Br)=C1Br NDRKXFLZSRHAJE-UHFFFAOYSA-N 0.000 description 1

- RTBFRGCFXZNCOE-UHFFFAOYSA-N 1-methylsulfonylpiperidin-4-one Chemical compound CS(=O)(=O)N1CCC(=O)CC1 RTBFRGCFXZNCOE-UHFFFAOYSA-N 0.000 description 1

- ZZPLGBZOTXYEQS-UHFFFAOYSA-N 2,3-dichlorobenzene-1,4-dicarbonyl chloride Chemical compound ClC(=O)C1=CC=C(C(Cl)=O)C(Cl)=C1Cl ZZPLGBZOTXYEQS-UHFFFAOYSA-N 0.000 description 1

- XAFOTXWPFVZQAZ-UHFFFAOYSA-N 2-(4-aminophenyl)-3h-benzimidazol-5-amine Chemical compound C1=CC(N)=CC=C1C1=NC2=CC=C(N)C=C2N1 XAFOTXWPFVZQAZ-UHFFFAOYSA-N 0.000 description 1

- NGNBDVOYPDDBFK-UHFFFAOYSA-N 2-[2,4-di(pentan-2-yl)phenoxy]acetyl chloride Chemical class CCCC(C)C1=CC=C(OCC(Cl)=O)C(C(C)CCC)=C1 NGNBDVOYPDDBFK-UHFFFAOYSA-N 0.000 description 1

- VWPQCOZMXULHDM-UHFFFAOYSA-N 9-aminononanoic acid Chemical compound NCCCCCCCCC(O)=O VWPQCOZMXULHDM-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229920003368 Kevlar® 29 Polymers 0.000 description 1

- 241000254043 Melolonthinae Species 0.000 description 1

- 229920000784 Nomex Polymers 0.000 description 1

- 229920001007 Nylon 4 Polymers 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 229920000491 Polyphenylsulfone Polymers 0.000 description 1

- 229920002334 Spandex Polymers 0.000 description 1

- 229920001494 Technora Polymers 0.000 description 1

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 description 1

- 229920000561 Twaron Polymers 0.000 description 1

- 239000004699 Ultra-high molecular weight polyethylene Substances 0.000 description 1

- 229920013651 Zenite Polymers 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- ORLQHILJRHBSAY-UHFFFAOYSA-N [1-(hydroxymethyl)cyclohexyl]methanol Chemical compound OCC1(CO)CCCCC1 ORLQHILJRHBSAY-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- XECAHXYUAAWDEL-UHFFFAOYSA-N acrylonitrile butadiene styrene Chemical compound C=CC=C.C=CC#N.C=CC1=CC=CC=C1 XECAHXYUAAWDEL-UHFFFAOYSA-N 0.000 description 1

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 1

- 239000004676 acrylonitrile butadiene styrene Substances 0.000 description 1

- 150000008064 anhydrides Chemical class 0.000 description 1

- JFCQEDHGNNZCLN-UHFFFAOYSA-N anhydrous glutaric acid Natural products OC(=O)CCCC(O)=O JFCQEDHGNNZCLN-UHFFFAOYSA-N 0.000 description 1

- 229910000410 antimony oxide Inorganic materials 0.000 description 1

- 150000004984 aromatic diamines Chemical class 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- KVBYPTUGEKVEIJ-UHFFFAOYSA-N benzene-1,3-diol;formaldehyde Chemical compound O=C.OC1=CC=CC(O)=C1 KVBYPTUGEKVEIJ-UHFFFAOYSA-N 0.000 description 1

- 239000004305 biphenyl Substances 0.000 description 1

- 235000010290 biphenyl Nutrition 0.000 description 1

- 125000006267 biphenyl group Chemical group 0.000 description 1

- 239000006085 branching agent Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000006482 condensation reaction Methods 0.000 description 1

- USIUVYZYUHIAEV-UHFFFAOYSA-N diphenyl ether Chemical compound C=1C=CC=CC=1OC1=CC=CC=C1 USIUVYZYUHIAEV-UHFFFAOYSA-N 0.000 description 1

- 238000000578 dry spinning Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 125000004185 ester group Chemical group 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 239000011152 fibreglass Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- UQSXHKLRYXJYBZ-UHFFFAOYSA-N iron oxide Inorganic materials [Fe]=O UQSXHKLRYXJYBZ-UHFFFAOYSA-N 0.000 description 1

- 239000004761 kevlar Substances 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 125000005647 linker group Chemical group 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- RXOHFPCZGPKIRD-UHFFFAOYSA-N naphthalene-2,6-dicarboxylic acid Chemical compound C1=C(C(O)=O)C=CC2=CC(C(=O)O)=CC=C21 RXOHFPCZGPKIRD-UHFFFAOYSA-N 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000004763 nomex Substances 0.000 description 1

- VTRUBDSFZJNXHI-UHFFFAOYSA-N oxoantimony Chemical class [Sb]=O VTRUBDSFZJNXHI-UHFFFAOYSA-N 0.000 description 1

- WXZMFSXDPGVJKK-UHFFFAOYSA-N pentaerythritol Chemical compound OCC(CO)(CO)CO WXZMFSXDPGVJKK-UHFFFAOYSA-N 0.000 description 1

- ZUOUZKKEUPVFJK-UHFFFAOYSA-N phenylbenzene Natural products C1=CC=CC=C1C1=CC=CC=C1 ZUOUZKKEUPVFJK-UHFFFAOYSA-N 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920003366 poly(p-phenylene terephthalamide) Polymers 0.000 description 1

- 229920002492 poly(sulfone) Polymers 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1

- 229920001230 polyarylate Polymers 0.000 description 1

- 229920002577 polybenzoxazole Polymers 0.000 description 1

- 229920001707 polybutylene terephthalate Polymers 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 229920002530 polyetherether ketone Polymers 0.000 description 1

- 229920001601 polyetherimide Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 238000009987 spinning Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 239000012209 synthetic fiber Substances 0.000 description 1

- 239000004950 technora Substances 0.000 description 1

- MHSKRLJMQQNJNC-UHFFFAOYSA-N terephthalamide Chemical compound NC(=O)C1=CC=C(C(N)=O)C=C1 MHSKRLJMQQNJNC-UHFFFAOYSA-N 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- QXJQHYBHAIHNGG-UHFFFAOYSA-N trimethylolethane Chemical compound OCC(C)(CO)CO QXJQHYBHAIHNGG-UHFFFAOYSA-N 0.000 description 1

- 229920000785 ultra high molecular weight polyethylene Polymers 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

- 238000002166 wet spinning Methods 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

- PGNWIWKMXVDXHP-UHFFFAOYSA-L zinc;1,3-benzothiazole-2-thiolate Chemical compound [Zn+2].C1=CC=C2SC([S-])=NC2=C1.C1=CC=C2SC([S-])=NC2=C1 PGNWIWKMXVDXHP-UHFFFAOYSA-L 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

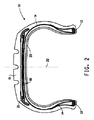

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/26—Folded plies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/30—Applying the layers; Guiding or stretching the layers during application

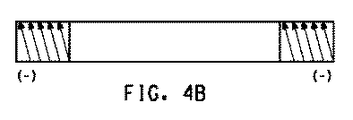

- B29D30/3028—Applying the layers; Guiding or stretching the layers during application by feeding a continuous band and winding it helically, i.e. the band is fed while being advanced along the drum axis, to form an annular element

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/70—Annular breakers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/1835—Rubber strips or cushions at the belt edges

- B60C9/185—Rubber strips or cushions at the belt edges between adjacent or radially below the belt plies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C9/2003—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel characterised by the materials of the belt cords

- B60C9/2009—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel characterised by the materials of the belt cords comprising plies of different materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C9/22—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel the plies being arranged with all cords disposed along the circumference of the tyre

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C2009/2012—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel with particular configuration of the belt cords in the respective belt layers

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Tires In General (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/084,699 US9370970B2 (en) | 2013-11-20 | 2013-11-20 | Tire containing noise reducing fibrous layers |

| US14/084,699 | 2013-11-20 | ||

| PCT/US2014/065442 WO2015077121A1 (en) | 2013-11-20 | 2014-11-13 | Tire containing noise reducing fibrous layers |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016537257A JP2016537257A (ja) | 2016-12-01 |

| JP2016537257A5 JP2016537257A5 (enExample) | 2017-12-21 |

| JP6550049B2 true JP6550049B2 (ja) | 2019-07-24 |

Family

ID=52282853

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016533008A Expired - Fee Related JP6550049B2 (ja) | 2013-11-20 | 2014-11-13 | 騒音低減繊維質層を内包するタイヤ |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9370970B2 (enExample) |

| EP (1) | EP3071425B1 (enExample) |

| JP (1) | JP6550049B2 (enExample) |

| CN (1) | CN105722694A (enExample) |

| WO (1) | WO2015077121A1 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5957430B2 (ja) * | 2013-10-24 | 2016-07-27 | 住友ゴム工業株式会社 | 空気入りタイヤ及びその製造方法 |

| JP6805164B2 (ja) * | 2015-04-22 | 2020-12-23 | テイジン・アラミド・ビー.ブイ.Teijin Aramid B.V. | 複数の非円形フィラメントを有するマルチフィラメントパラアラミド糸を有するコード |

| JP7155768B2 (ja) * | 2018-09-06 | 2022-10-19 | 横浜ゴム株式会社 | 空気入りタイヤ及び空気入りタイヤの製造方法 |

| KR102526920B1 (ko) * | 2021-03-11 | 2023-05-02 | 넥센타이어 주식회사 | 스틸벨트층이 보강되는 공기입 타이어 및 이의 제조방법 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3063966A (en) | 1958-02-05 | 1962-11-13 | Du Pont | Process of making wholly aromatic polyamides |

| US3094511A (en) | 1958-11-17 | 1963-06-18 | Du Pont | Wholly aromatic polyamides |

| US3227793A (en) | 1961-01-23 | 1966-01-04 | Celanese Corp | Spinning of a poly(polymethylene) terephthalamide |

| US3414645A (en) | 1964-06-19 | 1968-12-03 | Monsanto Co | Process for spinning wholly aromatic polyamide fibers |

| GB1090598A (en) | 1964-08-17 | 1967-11-08 | Hooker Chemical Corp | Polymers and coatings rendered flame retardant by the addition of halogenated cyclopentadiene diels-alder adducts |

| US3287324A (en) | 1965-05-07 | 1966-11-22 | Du Pont | Poly-meta-phenylene isophthalamides |

| US3354127A (en) | 1966-04-18 | 1967-11-21 | Du Pont | Aromatic copolyamides |

| US3819587A (en) | 1969-05-23 | 1974-06-25 | Du Pont | Wholly aromatic carbocyclic polycarbonamide fiber having orientation angle of less than about 45{20 |

| US3673143A (en) | 1970-06-24 | 1972-06-27 | Du Pont | Optically anisotropic spinning dopes of polycarbonamides |

| DE2115914A1 (de) * | 1971-04-01 | 1972-10-05 | Umroyal AG, 5100 Aachen | Fahrzeugluftreifen, insbesondere fur hohe und höchste Fahrzeuggeschwindigkei ten |

| US3869430A (en) | 1971-08-17 | 1975-03-04 | Du Pont | High modulus, high tenacity poly(p-phenylene terephthalamide) fiber |

| US3869429A (en) | 1971-08-17 | 1975-03-04 | Du Pont | High strength polyamide fibers and films |

| US3767756A (en) | 1972-06-30 | 1973-10-23 | Du Pont | Dry jet wet spinning process |

| PH15509A (en) | 1974-05-10 | 1983-02-03 | Du Pont | Improvements in an relating to synthetic polyesters |

| DE2518223C2 (de) * | 1975-04-24 | 1985-04-25 | Continental Gummi-Werke Ag, 3000 Hannover | Fahrzeugluftreifen |

| JPS53294A (en) | 1976-06-23 | 1978-01-05 | Teijin Ltd | Preparation of aromatic polyamide with high degree of polymerization |

| FR2386424A1 (fr) * | 1977-04-06 | 1978-11-03 | Uniroyal | Ceinture de renforcement pour enveloppe de pneumatique et enveloppe en comportant application |

| JPS54107003A (en) * | 1978-02-10 | 1979-08-22 | Asahi Chem Ind Co Ltd | Radial tire |

| FR2428533A1 (fr) * | 1978-06-14 | 1980-01-11 | Uniroyal | Ceinture de renforcement a longevite augmentee et enveloppe de bandage pneumatique en comportant application |

| JPS5853603B2 (ja) * | 1979-12-28 | 1983-11-30 | 横浜ゴム株式会社 | 空気入りタイヤ |

| JPS6112407A (ja) * | 1984-06-29 | 1986-01-20 | Yokohama Rubber Co Ltd:The | 空気入りラジアルタイヤ |

| JPS6112409A (ja) * | 1984-06-29 | 1986-01-20 | Yokohama Rubber Co Ltd:The | 空気入りラジアルタイヤ |

| JPS6436434A (en) * | 1987-07-31 | 1989-02-07 | Sumitomo Rubber Ind | Formation of belt reinforcement layer and its device |

| JP2660521B2 (ja) * | 1987-11-16 | 1997-10-08 | 株式会社ブリヂストン | 空気入りタイヤ |

| US5667743A (en) | 1996-05-21 | 1997-09-16 | E. I. Du Pont De Nemours And Company | Wet spinning process for aramid polymer containing salts |

| JP4060173B2 (ja) * | 2002-12-12 | 2008-03-12 | 横浜ゴム株式会社 | 空気入りタイヤ、および空気入りタイヤの製造方法 |

| EP2065226B1 (en) * | 2006-09-22 | 2011-09-07 | Sumitomo Rubber Industries, Ltd. | Radial tire for heavy load |

-

2013

- 2013-11-20 US US14/084,699 patent/US9370970B2/en not_active Expired - Fee Related

-

2014

- 2014-11-13 CN CN201480063636.9A patent/CN105722694A/zh active Pending

- 2014-11-13 WO PCT/US2014/065442 patent/WO2015077121A1/en not_active Ceased

- 2014-11-13 JP JP2016533008A patent/JP6550049B2/ja not_active Expired - Fee Related

- 2014-11-13 EP EP14824177.1A patent/EP3071425B1/en not_active Not-in-force

Also Published As

| Publication number | Publication date |

|---|---|

| EP3071425B1 (en) | 2019-08-28 |

| US9370970B2 (en) | 2016-06-21 |

| WO2015077121A1 (en) | 2015-05-28 |

| US20150136294A1 (en) | 2015-05-21 |

| CN105722694A (zh) | 2016-06-29 |

| EP3071425A1 (en) | 2016-09-28 |

| JP2016537257A (ja) | 2016-12-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8800257B2 (en) | Composite cord and method of making and support structure and tire containing same | |

| JP6338291B2 (ja) | タイヤまたはベルトなどの物体の補強のための複合層 | |

| EP3484730B1 (en) | Electrically conductive yarn | |

| US20100108218A1 (en) | Extensible non-load bearing cut resistant tire side-wall component cotaining elastomeric filament, tire containing said component, and processes for making same | |

| JP6550049B2 (ja) | 騒音低減繊維質層を内包するタイヤ | |

| US20150064438A1 (en) | Fibrous cord and method of making | |

| JP2012507440A (ja) | 非耐荷重性の切断抵抗性タイヤサイドウォールコンポーネント、そのコンポーネントを含むタイヤ、およびその製造方法 | |

| JP2012507438A (ja) | タイヤサイドウォール切断抵抗性テキスタイル編布、その布を含むタイヤ、およびその製造方法 | |

| US8375692B2 (en) | Composite cord having a metal core and method of making | |

| JP4664666B2 (ja) | ブレンド複合材繊維コードを有する空気入りタイヤ | |

| WO2014089151A1 (en) | Reinforcing structure comprising spun staple yarns | |

| US20120103498A1 (en) | Tire containing a heat and flame resistant fibrous barrier layer and method for protecting a tire | |

| KR102430309B1 (ko) | 파라-아라미드 입자를 포함하는 컷 저항성 코팅을 갖는 패브릭 | |

| JPH05179531A (ja) | 複層構造糸及びそれを用いた布帛 | |

| CN116710294A (zh) | 包括具有低吸湿含量的蓬乱纬向增强元件的轮胎织物 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171113 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20171113 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20181122 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20181121 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20190221 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190422 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20190606 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20190628 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6550049 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |