JP6192554B2 - Manufacturing method of vacuum insulation - Google Patents

Manufacturing method of vacuum insulation Download PDFInfo

- Publication number

- JP6192554B2 JP6192554B2 JP2014018160A JP2014018160A JP6192554B2 JP 6192554 B2 JP6192554 B2 JP 6192554B2 JP 2014018160 A JP2014018160 A JP 2014018160A JP 2014018160 A JP2014018160 A JP 2014018160A JP 6192554 B2 JP6192554 B2 JP 6192554B2

- Authority

- JP

- Japan

- Prior art keywords

- heat insulating

- fiber

- less

- core material

- fibers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000009413 insulation Methods 0.000 title description 30

- 238000004519 manufacturing process Methods 0.000 title description 8

- 239000000835 fiber Substances 0.000 claims description 139

- 239000011162 core material Substances 0.000 claims description 65

- 239000005022 packaging material Substances 0.000 claims description 27

- 239000003365 glass fiber Substances 0.000 claims description 19

- 238000007789 sealing Methods 0.000 claims description 8

- 230000006835 compression Effects 0.000 claims description 7

- 238000007906 compression Methods 0.000 claims description 7

- 230000007246 mechanism Effects 0.000 claims description 6

- 239000011810 insulating material Substances 0.000 description 62

- 238000000034 method Methods 0.000 description 16

- 239000010410 layer Substances 0.000 description 10

- 238000005259 measurement Methods 0.000 description 10

- 239000011230 binding agent Substances 0.000 description 7

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 6

- 230000004888 barrier function Effects 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 239000003463 adsorbent Substances 0.000 description 5

- 238000000691 measurement method Methods 0.000 description 5

- 238000012545 processing Methods 0.000 description 5

- 238000003466 welding Methods 0.000 description 5

- 238000001035 drying Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 239000012774 insulation material Substances 0.000 description 4

- 230000003287 optical effect Effects 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 3

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 3

- 239000006260 foam Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- -1 polypropylene Polymers 0.000 description 3

- 239000011241 protective layer Substances 0.000 description 3

- 239000000377 silicon dioxide Substances 0.000 description 3

- 238000012546 transfer Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- ODINCKMPIJJUCX-UHFFFAOYSA-N Calcium oxide Chemical compound [Ca]=O ODINCKMPIJJUCX-UHFFFAOYSA-N 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000003822 epoxy resin Substances 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- 229920006284 nylon film Polymers 0.000 description 2

- 238000000879 optical micrograph Methods 0.000 description 2

- 238000005325 percolation Methods 0.000 description 2

- 230000035699 permeability Effects 0.000 description 2

- 229920006255 plastic film Polymers 0.000 description 2

- 239000002985 plastic film Substances 0.000 description 2

- 229920000647 polyepoxide Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 230000008707 rearrangement Effects 0.000 description 2

- 238000001179 sorption measurement Methods 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 241000283014 Dama Species 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 229910021536 Zeolite Inorganic materials 0.000 description 1

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 239000000292 calcium oxide Substances 0.000 description 1

- BRPQOXSCLDDYGP-UHFFFAOYSA-N calcium oxide Chemical compound [O-2].[Ca+2] BRPQOXSCLDDYGP-UHFFFAOYSA-N 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- JNSGIVNNHKGGRU-JYRVWZFOSA-N diethoxyphosphinothioyl (2z)-2-(2-amino-1,3-thiazol-4-yl)-2-methoxyiminoacetate Chemical compound CCOP(=S)(OCC)OC(=O)C(=N/OC)\C1=CSC(N)=N1 JNSGIVNNHKGGRU-JYRVWZFOSA-N 0.000 description 1

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000012153 distilled water Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 229920006262 high density polyethylene film Polymers 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 229920000092 linear low density polyethylene Polymers 0.000 description 1

- 239000004707 linear low-density polyethylene Substances 0.000 description 1

- 239000011490 mineral wool Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000004745 nonwoven fabric Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

- 239000010457 zeolite Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L59/00—Thermal insulation in general

- F16L59/06—Arrangements using an air layer or vacuum

- F16L59/065—Arrangements using an air layer or vacuum using vacuum

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

- F25D23/06—Walls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2201/00—Insulation

- F25D2201/10—Insulation with respect to heat

- F25D2201/14—Insulation with respect to heat using subatmospheric pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2500/00—Problems to be solved

- F25D2500/02—Geometry problems

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Thermal Insulation (AREA)

Description

本発明は、真空断熱材の製造方法に関する。 The present invention relates to a manufacturing method of vacuum insulation material.

冷蔵庫などの断熱箱の断熱材として用いられている従来の真空断熱材としては、ガラス繊維の集合体で形成される芯材を、ガスバリア性を有する外包材で被覆し、外包材の内部が減圧されて密閉されたものがある(例えば、特許文献1参照)。 As a conventional vacuum heat insulating material used as a heat insulating material for a heat insulating box such as a refrigerator, a core material formed of an aggregate of glass fibers is covered with an outer packaging material having a gas barrier property, and the inside of the outer packaging material is decompressed. And sealed (see, for example, Patent Document 1).

このように外包材の内部を減圧した真空断熱材は、嵩張るガラス繊維の集合体を外包材で被覆し減圧密閉することによって厚さが薄くなるとともに、外包材内部の気体の対流と熱伝導の影響を小さくして断熱性能の向上を図るものである。一般に、断熱材の伝熱機構は、固体および気体成分の熱伝導、輻射、対流により引き起こされる。一方、外包材内部を減圧密閉された真空断熱材は、気体成分の熱伝導と対流に関してはその影響は小さい。また、常温以下の温度領域での使用においては、輻射の影響も殆どない。よって、常温以下の温度領域で使用される冷蔵庫等に適用する真空断熱材においては、固体成分の熱伝導を抑制することが重要となる。そこで、断熱性能に優れる真空断熱用芯材として、種々の形態をした繊維が報告されている。近年では激しい省エネルギー競争によって、薄くても断熱性能のより優れた真空断熱材、とりわけ芯材となる高い断熱性を有する繊維集合体が強く求められている。 In this way, the vacuum heat insulating material in which the inside of the outer packaging material is depressurized is thinned by covering the bulky glass fiber aggregate with the outer packaging material and sealing under reduced pressure, and the convection and heat conduction of the gas inside the outer packaging material are reduced. The effect is reduced to improve the heat insulation performance. In general, the heat transfer mechanism of a heat insulating material is caused by heat conduction, radiation, and convection of solid and gas components. On the other hand, the vacuum heat insulating material whose inside of the outer packaging material is sealed under reduced pressure has little effect on the heat conduction and convection of the gas component. Further, there is almost no influence of radiation when used in a temperature range below room temperature. Therefore, in a vacuum heat insulating material applied to a refrigerator or the like used in a temperature range below room temperature, it is important to suppress the heat conduction of the solid component. Therefore, various forms of fibers have been reported as vacuum insulation core materials having excellent heat insulation performance. In recent years, due to fierce energy-saving competition, there is a strong demand for a vacuum heat insulating material with excellent heat insulating performance even when it is thin, in particular, a fiber assembly having high heat insulating properties as a core material.

真空断熱材の熱伝導率を低減する方法として、真空断熱材を構成するガラス繊維を断熱方向に対して垂直方向に配向することによって、ガラス繊維による伝熱を抑制したものがある(例えば、特許文献2参照)。 As a method of reducing the thermal conductivity of the vacuum heat insulating material, there is one in which heat transfer by the glass fiber is suppressed by orienting the glass fiber constituting the vacuum heat insulating material in a direction perpendicular to the heat insulating direction (for example, patents) Reference 2).

また、バインダーを使用してガラス繊維を乾式法により加熱加圧成形し、ガラス繊維を伝熱方向に対して垂直に配向するだけでなく、長さが100μm以下の短い繊維を40〜70%含有させることにより、繊維を伝わる熱を途切れさせ、固体熱伝導率を低減したものがある(例えば、特許文献3参照)。 In addition, glass fibers are heated and pressed by a dry method using a binder, and the glass fibers are not only oriented perpendicular to the heat transfer direction, but also contain 40 to 70% of short fibers with a length of 100 μm or less. As a result, the heat transmitted through the fibers is interrupted to reduce the solid thermal conductivity (for example, see Patent Document 3).

また、バインダーを使用しない乾式法において、平均繊維径が2〜5μmのガラス繊維でなり、ショット(ダマ)の混入率が0.5質量%以下で、かつショットの平均粒径が150μm以下であって、500μm以上の繊維長を有するガラス繊維の割合が80%以上であるガラス繊維積層体を芯材とする断熱性に優れた真空断熱材がある(例えば、特許文献4参照)。 Further, in a dry method that does not use a binder, the glass fiber has an average fiber diameter of 2 to 5 μm, the shot (dama) mixing rate is 0.5 mass% or less, and the average particle diameter of the shot is 150 μm or less. In addition, there is a vacuum heat insulating material excellent in heat insulating properties using a glass fiber laminate in which the ratio of glass fibers having a fiber length of 500 μm or more is 80% or more (see, for example, Patent Document 4).

真空断熱材の熱伝導率を低減する方法として、真空断熱材を構成するガラス繊維を断熱方向に対して垂直方向に配向して積層するものがあるが、ガラス繊維を断熱方向に対して垂直方向に配向して積層しただけでは、ガラス繊維を伝わる熱が存在してしまうために固体熱伝導率が大きくなり、真空断熱材において初期熱伝導率の低減に限界があった。 As a method for reducing the thermal conductivity of the vacuum heat insulating material, there is a method in which the glass fibers constituting the vacuum heat insulating material are oriented and laminated in a direction perpendicular to the heat insulating direction, but the glass fibers are perpendicular to the heat insulating direction. If the layers are simply oriented and laminated, the heat transmitted through the glass fiber is present, so that the solid thermal conductivity is increased, and there is a limit to the reduction of the initial thermal conductivity in the vacuum heat insulating material.

また、バインダーを用いて加熱加圧成形によりガラス繊維を結着させる方法では、加熱するための動力費やバインダーの材料費が増加し、真空断熱材を安価に得られないだけでなく、経時的な熱伝導率悪化が大きいという課題があった。これは、真空断熱材にした際に、真空中でバインダーから低分子のガス成分が放出され、真空度が低下するためである。 In addition, the method of binding glass fibers by heat and pressure molding using a binder increases not only the power cost for heating and the material cost of the binder, but also the vacuum heat insulating material cannot be obtained at a low cost. There was a problem that the thermal conductivity was greatly deteriorated. This is because when a vacuum heat insulating material is used, a low molecular gas component is released from the binder in vacuum, and the degree of vacuum is lowered.

また、バインダーを使用しない乾式法では、ガラス繊維の長さ及び短繊維の重量割合をコントロールできても、真空断熱材にした状態での繊維角度のコントロールはできないという課題があった。 Moreover, in the dry method which does not use a binder, even if the length of the glass fiber and the weight ratio of the short fiber can be controlled, there is a problem that the fiber angle in a state where the vacuum heat insulating material is used cannot be controlled.

本発明は、前記課題を解決するためになされたもので、短繊維の重量割合、平均繊維角度及びその標準偏差をコントロールできて、断熱性能に優れる真空断熱材の製造方法を提供することを目的とする。 The present invention has been made in order to solve the above problems, the weight ratio of the short fibers, and can control the average fiber angle and its standard deviation, to provide a method for producing a vacuum insulation material having excellent heat insulating performance Objective.

本発明に係る真空断熱材の製造方法は、ガラス繊維の集合体を、荷重制御できる圧縮機構によって0.02〜0.07MPaの圧力で厚み方向に50〜1000回繰り返し圧縮することで、繊維長1.85mm以下の繊維の重量割合が11wt%以下である芯材を作成する工程と、前記芯材を外包材へ挿入し、前記外包材の内部を予め設定された真空度に減圧する工程と、前記外包材を減圧された状態で、開口部を密封する工程とを有するものである。

The method for producing a vacuum heat insulating material according to the present invention is a method of repeatedly compressing an aggregate of

本発明に係る真空断熱材において、芯材は繊維長1.85mm以下の繊維の重量割合がこの芯材の11wt%以下であるので、芯材の断熱方向への熱パス経路を短くし断熱性能を悪化させる因子である繊維長1.85mm以下の繊維の影響を最小限に抑えることができる。このため、高い断熱性能を得ることができる。

また、繊維長1.85mm以下の繊維の重量割合を芯材の11wt%以下にすることによって、繊維長1.85mm以上の繊維が芯材の断熱方向に対して垂直に配向しやすくなり、芯材の断熱方向に配向し断熱性能を悪化させる因子である繊維長1.85mm以下の繊維の影響を最小限に抑えることができる。このため、断熱性能に優れる真空断熱材を得ることができる。

そして、本発明の真空断熱材を冷蔵庫等の断熱箱に適用することによって、製品の断熱効果が上がり、製品の壁の厚みを薄くすることができ、製品の限られたスペースで内容積を大きくすることができる。

In the vacuum heat insulating material according to the present invention, since the weight ratio of the fiber having a fiber length of 1.85 mm or less is 11 wt% or less of the core material, the heat path path in the heat insulating direction of the core material is shortened and the heat insulating performance. The influence of a fiber having a fiber length of 1.85 mm or less, which is a factor that deteriorates the resistance, can be minimized. For this reason, high heat insulation performance can be obtained.

In addition, by setting the weight ratio of the fibers having a fiber length of 1.85 mm or less to 11 wt% or less of the core material, the fibers having a fiber length of 1.85 mm or more can be easily oriented perpendicular to the heat insulating direction of the core material. The influence of fibers having a fiber length of 1.85 mm or less, which is a factor that is oriented in the heat insulating direction of the material and deteriorates the heat insulating performance, can be minimized. For this reason, the vacuum heat insulating material excellent in heat insulation performance can be obtained.

And by applying the vacuum heat insulating material of the present invention to a heat insulation box such as a refrigerator, the heat insulation effect of the product is improved, the thickness of the product wall can be reduced, and the internal volume is increased in a limited space of the product. can do.

実施形態1.

本発明の実施形態1に係る真空断熱材は、芯材となる繊維集合体において、繊維長1.85mm以下の繊維(以下、これを「短繊維」という場合もある)の重量割合が、芯材の11wt%以下であり、好ましくは芯材の8wt%以下である。ここで、繊維長1.85mm以下の繊維(短繊維)の重量割合は、次の方法で測定された測定値を意味する。

The vacuum heat insulating material according to

(短繊維の重量割合測定方法)

秤量した繊維100mLをビーカーに入れ、蒸留水50mLを加え超音波洗浄機で5分間拡散させた。その後、繊維が2本以上接触している塊状の繊維を精密ピンセットで1分以内に取り除ける量を全て取り除き、精密ピンセットで摘み取ることのできない残った繊維(短繊維)を濾過して乾燥させた。ろ紙に残った短繊維を秤量し、初期繊維量で割ることで、その重量割合を求めた。

(Short fiber weight ratio measurement method)

100 mL of the weighed fiber was put in a beaker, 50 mL of distilled water was added, and the mixture was diffused with an ultrasonic cleaner for 5 minutes. Thereafter, all of the aggregated fibers in contact with two or more fibers were removed with precision tweezers within 1 minute, and the remaining fibers (short fibers) that could not be picked with precision tweezers were filtered and dried. The short fibers remaining on the filter paper were weighed and divided by the initial fiber amount to obtain the weight ratio.

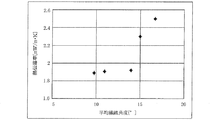

図1は本発明の実施形態1に係る真空断熱材の芯材の繊維長1.85mm以下の繊維の重量割合と熱伝導率との関係を示すグラフであり、縦軸に熱伝導率[mW/m・K]をとり、横軸に繊維長1.85mm以下の繊維の重量割合[wt%]をとったものである。

この結果から明らかなように、繊維長1.85mm以下の繊維の重量割合が芯材の11wt%以下の範囲において、熱伝導率は2.0mW/m・K以下でほぼ一定であった。これに対し、繊維長1.85mm以下の繊維の重量割合が芯材の11wt%を超えると、熱伝導率は2.0mW/m・K以上に増加する。

以上の結果より、熱伝導率2.0mW/m・K以下の真空断熱材を構成する繊維長1.85mm以下の繊維の重量割合は、芯材の11wt%以下である。

前記測定方法における短繊維の平均繊維長は、次の方法で求めた。

FIG. 1 is a graph showing the relationship between the weight ratio of fibers having a fiber length of 1.85 mm or less and the thermal conductivity of the core material of the vacuum heat insulating material according to

As is clear from this result, the thermal conductivity was almost constant at 2.0 mW / m · K or less in the range where the weight ratio of the fiber having a fiber length of 1.85 mm or less was 11 wt% or less of the core material. On the other hand, when the weight ratio of fibers having a fiber length of 1.85 mm or less exceeds 11 wt% of the core material, the thermal conductivity increases to 2.0 mW / m · K or more.

From the above results, the weight ratio of the fibers having a fiber length of 1.85 mm or less constituting the vacuum heat insulating material having a thermal conductivity of 2.0 mW / m · K or less is 11 wt% or less of the core material.

The average fiber length of the short fibers in the measurement method was determined by the following method.

(平均繊維長の測定方法)

水中に分散させた数mg程度の短繊維をシャーレ上に数滴滴下し、110℃の高温槽内で水分を蒸発させた。乾燥した繊維を光学顕微鏡(20〜100倍)で観察し、任意の1箇所の繊維20本についてその長さを0.01mm単位まで測定し、この測定を5箇所について行い、合計100本の繊維の長さの平均値をもって平均繊維長とした。

(Measurement method of average fiber length)

Several drops of several mg of short fibers dispersed in water were dropped on the petri dish, and the water was evaporated in a high-temperature bath at 110 ° C. The dried fiber was observed with an optical microscope (20 to 100 times), the length of 20 fibers at any one place was measured to the nearest 0.01 mm, this measurement was performed at 5 places, and a total of 100 fibers. The average value of the lengths was taken as the average fiber length.

図2は本発明の実施形態1に係る真空断熱材の芯材の平均繊維長の測定における光学顕微鏡写真である。

本測定法によって重量割合測定における短繊維の平均繊維長を測定した結果、平均繊維長は0.50mmであり、標準偏差σは0.45mmであることが分った。すなわち、熱伝導率が2.0mW/m・K以下の真空断熱材を構成する芯材は、平均短繊維長+3σである繊維長1.85mm以下の繊維の重量割合が芯材の11wt%以下である。標準偏差σは、データの分布の広がり幅(ばらつき)をみる一つの尺度である。平均短繊維長+3σで求められる繊維長1.85mmを最長とする繊維長の範囲内に、採取した短繊維の長さの全データの99.73%が分布する。

FIG. 2 is an optical micrograph in the measurement of the average fiber length of the core material of the vacuum heat insulating material according to

As a result of measuring the average fiber length of the short fibers in the weight ratio measurement by this measurement method, it was found that the average fiber length was 0.50 mm and the standard deviation σ was 0.45 mm. That is, the core material constituting the vacuum heat insulating material having a thermal conductivity of 2.0 mW / m · K or less has an average short fiber length + 3σ of fiber length of 1.85 mm or less, and the weight ratio of the core material is 11 wt% or less. It is. The standard deviation σ is one measure for looking at the spread width (variation) of the data distribution. 99.73% of the total length data of the collected short fibers is distributed within the range of the fiber length that is 1.85 mm long as the average short fiber length + 3σ.

本発明の実施形態1に係る真空断熱材の芯材となる繊維集合体において、芯材の断熱方向に対して垂直な面に対する繊維角度φの平均値は14°以下である。ここで、芯材の断熱方向に対して垂直な面に対する繊維角度φの平均値(平均繊維角度)は、次の方法で測定された測定値を意味する。

In the fiber assembly serving as the core material of the vacuum heat insulating material according to

(平均繊維角度の測定方法)

図3は本発明の実施形態1に係る真空断熱材の芯材の平均繊維角度の測定における光学顕微鏡写真であり、図中に測定例を示している。

すなわち、真空断熱材の状態での厚みを保持するため、真空断熱材の外側をエポキシ樹脂で固めた後、真空下で芯材内部にエポキシ樹脂を流し込み、硬化させた。硬化後、真空断熱材の中央部を断熱方向に沿う水平な面で切断し、切断面を研磨し、芯材の断熱方向に対して垂直な面を角度の基準となる水平面(0°)として光学顕微鏡で観察した。繊維断面を全て楕円であると仮定し、切断した断面の周囲幅1mm範囲を除いた任意の1箇所について、画面上の繊維全ての長軸の長さa[μm]、短軸の長さb[μm]、及び長軸と角度の基準となる水平面とのなす角度θ[°]を、それぞれ0.01μm、0.01μmおよび0.01°単位までそれぞれ測定し、測定結果を下式(1)に代入して繊維角度φ[°]を算出し、この測定を2箇所について行い、合計200本の繊維角度φの平均値をもって平均繊維角度とした。ここで、角度θは楕円の長軸と水平面とのなす角度であるのに対して、繊維角度φは楕円の長軸と水平面とのなす角度に、切断面とのなす角度を含めた角度である。

(Measurement method of average fiber angle)

FIG. 3 is an optical micrograph in the measurement of the average fiber angle of the core material of the vacuum heat insulating material according to

That is, in order to maintain the thickness of the vacuum heat insulating material, the outside of the vacuum heat insulating material was hardened with an epoxy resin, and then the epoxy resin was poured into the core material under vacuum to be cured. After curing, the central part of the vacuum heat insulating material is cut by a horizontal surface along the heat insulating direction, the cut surface is polished, and the surface perpendicular to the heat insulating direction of the core material is used as a horizontal plane (0 °) as a reference for the angle. Observed with an optical microscope. Assuming that the cross section of the fiber is all elliptical, the long axis length a [μm] and the short axis length b of all the fibers on the screen at any one location except the range of the peripheral width of 1 mm of the cut cross section. [μm] and the angle θ [°] between the major axis and the horizontal plane that is the reference of the angle are measured to 0.01 μm, 0.01 μm, and 0.01 ° units, respectively, and the measurement result is expressed by the following formula (1 The fiber angle φ [°] was calculated by substituting in (), and this measurement was performed at two locations. The average value of a total of 200 fiber angles φ was taken as the average fiber angle. Here, the angle θ is an angle between the major axis of the ellipse and the horizontal plane, whereas the fiber angle φ is an angle including the angle between the major axis of the ellipse and the horizontal plane and the angle formed with the cut surface. is there.

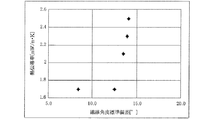

図4は本発明の実施形態1に係る真空断熱材の芯材の平均繊維角度と熱伝導率との関係を示すグラフであり、縦軸に熱伝導率[mW/m・K]をとり、横軸に平均繊維角度[°]をとったものである。

この結果から明らかなように、平均繊維角度が14°以下の範囲において、熱伝導率は2.0mW/m・K以下でほぼ一定であった。これに対し、平均繊維角度が14°を超えると、熱伝導率は2.0mW/m・K以上に増加することが分った。

以上の結果より、熱伝導率2.0mW/m・K以下の真空断熱材を構成する芯材の平均繊維角度は14°以下である。

FIG. 4 is a graph showing the relationship between the average fiber angle of the core material of the vacuum heat insulating material according to

As is apparent from the results, the thermal conductivity was almost constant at 2.0 mW / m · K or less in the range where the average fiber angle was 14 ° or less. In contrast, it has been found that when the average fiber angle exceeds 14 °, the thermal conductivity increases to 2.0 mW / m · K or more.

From the above results, the average fiber angle of the core material constituting the vacuum heat insulating material having a thermal conductivity of 2.0 mW / m · K or less is 14 ° or less.

図5は本発明の実施形態1に係る真空断熱材の芯材の繊維角度標準偏差と熱伝導率との関係を示すグラフであり、縦軸に熱伝導率[mW/m・K]をとり、横軸に繊維角度標準偏差[°]をとったものである。

この結果から明らかなように、繊維角度の標準偏差が12°以下の範囲において、熱伝導率は2.0mW/m・K以下でほぼ一定であった。これに対し、12°を超えると、2.0mW/m・K以上に増加することが分った。

以上の結果より、2.0mW/m・K以下の真空断熱材を構成する芯材の繊維角度の標準偏差は12°以下である。

FIG. 5 is a graph showing the relationship between the fiber angle standard deviation of the core material of the vacuum heat insulating material according to

As is clear from this result, in the range where the standard deviation of the fiber angle is 12 ° or less, the thermal conductivity was almost constant at 2.0 mW / m · K or less. On the other hand, when it exceeded 12 degrees, it turned out that it increases to 2.0 mW / m * K or more.

From the above results, the standard deviation of the fiber angle of the core material constituting the vacuum heat insulating material of 2.0 mW / m · K or less is 12 ° or less.

繊維長1.85mm以下の繊維の重量割合、平均繊維角度および繊維角度標準偏差と、熱伝導率との関係において、それぞれ変曲点を有することに関しては、パーコレーション理論によって説明できる。例えば、繊維長1.85mm以下の繊維の重量割合について考える。VIP(真空断熱材:Vacuum Insulation Panel)の断熱性能を悪化させる要因の一つとして、VIPの断熱方向に配向される繊維がある。繊維が短くなればなるほどVIPの断熱方向に配向される確率が高くなるため、短い繊維が少ないほうが断熱性能は高いと考えられる。しかしながら、断熱方向に配向した繊維が複数重なり、断熱方向への熱パス経路が繋がらなければ断熱性能への影響は少ない。 The relationship between the weight ratio of fibers having a fiber length of 1.85 mm or less, the average fiber angle and fiber angle standard deviation, and the thermal conductivity can be explained by percolation theory. For example, consider the weight ratio of fibers with a fiber length of 1.85 mm or less. One of the factors that deteriorate the heat insulation performance of VIP (Vacuum Insulation Panel) is fiber oriented in the heat insulation direction of VIP. The shorter the fibers, the higher the probability that they will be oriented in the heat insulating direction of VIP. Therefore, it is considered that the heat insulating performance is higher when there are fewer short fibers. However, if a plurality of fibers oriented in the heat insulation direction overlap and the heat path path in the heat insulation direction is not connected, the influence on the heat insulation performance is small.

本発明では、繊維長1.85mm以下の繊維を短繊維と定義しており、この短繊維が少ないほうが断熱性は高いと考えられる。実験の結果、短繊維の重量割合が芯材の11wt%以下においては、熱伝導率は一定であり、短繊維の重量割合が芯材の11wt%を超えると、熱伝導率が急増したことが判明した。このことは、繊維長1.85mm以下の繊維の重量割合が芯材の11wt%である点が、断熱方向に配向された繊維が複数重なり、断熱方向への熱パス経路の繋がりが急増する変曲点である(パーコレーションの臨界点である)ことを示唆している。

以上の理由から、繊維長1.85mm以下の繊維の重量割合と熱伝導率との関係において、変曲点を有すると考えられる。さらに、平均繊維角度および繊維角度標準偏差と、熱伝導率との関係において、それぞれ変曲点を有することに関しても、同様に考えることができる。

In the present invention, fibers having a fiber length of 1.85 mm or less are defined as short fibers, and it is considered that the heat insulation is higher when the number of short fibers is smaller. As a result of the experiment, when the weight ratio of the short fibers is 11 wt% or less of the core material, the thermal conductivity is constant, and when the weight ratio of the short fibers exceeds 11 wt% of the core material, the thermal conductivity increases rapidly. found. This is because the weight ratio of the fiber having a fiber length of 1.85 mm or less is 11 wt% of the core material, and a plurality of fibers oriented in the heat insulation direction overlap, and the connection of the heat path path in the heat insulation direction increases rapidly. This suggests that the point is a critical point (percolation critical point).

For the above reasons, it is considered that there is an inflection point in the relationship between the weight ratio of fibers having a fiber length of 1.85 mm or less and the thermal conductivity. Furthermore, regarding the relationship between the average fiber angle, the fiber angle standard deviation, and the thermal conductivity, it can be similarly considered that each has an inflection point.

図6は本発明の実施形態1に係る真空断熱材を示す断面図である。

図6において、真空断熱材1は、繊維集合体で構成される芯材2と、芯材2を被覆するガスバリア性の外包材3と、外包材3の内部の水分を吸着して経時劣化を抑制する水分吸着剤4とを備えている。外包材3の内部は、1〜3Pa(パスカル)の真空度に減圧された状態で、開口部が例えばヒートシールの溶着シール部5によって密封されている。

FIG. 6 is a cross-sectional view showing a vacuum heat insulating material according to

In FIG. 6, the vacuum

芯材2は、ガラス繊維、アルミナ繊維、シリカアルミナ繊維、シリカ繊維、ロックウール、炭化ケイ素繊維、又は不織布を使用でき、特に指定するものではない。

As the

外包材3は、少なくともガスバリア層および熱溶着層を有するものであり、必要に応じて表面保護層を設けてもよい。ガスバリア層としては、金属または金属酸化物、あるいはダイヤモンドライクカーボンを蒸着したプラスチックフィルムや金属箔を用いることができ、ガス透過を低減する目的で使用できるものであればよく、特に指定するものではない。

また、プラスチックフィルム上への金属酸化物蒸着の材料は、シリカ、アルミナを用いることができ、特に指定するものではない。

The

Further, silica or alumina can be used as a material for metal oxide vapor deposition on the plastic film, and is not particularly specified.

外包材3の熱溶着層は、外包材3を構成するフィルムの中で最もガス透過度が大きい部分であり、熱溶着層の性質は真空断熱材の経時断熱性能に大きく影響する。熱溶着層の厚さは、減圧封止工程における封止品質の安定性や、熱溶着部端面からのガス侵入の抑制や、ガスバリア層として金属箔を使用した場合における熱伝導による表面からのヒートリークを考慮すると、25μm〜60μmが適している。

The heat welding layer of the

熱溶着層の材料としては、無延伸ポリプロピレンフィルム、高密度ポリエチレンフィルム、直鎖状低密度ポリエチレンフィルムを用いることができ、特に指定するものではない。 As the material for the heat-welded layer, an unstretched polypropylene film, a high-density polyethylene film, or a linear low-density polyethylene film can be used, and is not particularly specified.

また、ガスバリア層の外側にさらに表面保護層を設けることも可能である。表面保護層としては、ポリエチレンテレフタレートフィルム、ポリプロピレンフィルム、ナイロンフィルムの延伸加工品が利用でき、さらに外側にナイロンフィルムを用いると、耐折り曲げ性、耐突き刺し性が向上する。 It is also possible to further provide a surface protective layer outside the gas barrier layer. As the surface protective layer, a stretched product of a polyethylene terephthalate film, a polypropylene film, or a nylon film can be used. Further, when a nylon film is used on the outer side, the bending resistance and the puncture resistance are improved.

また、外包材3の袋形状は、四方シール袋、ガゼット袋、三方シール袋、ピロー袋、センターテープシール袋があるが、特に指定するものではない。

The bag shape of the

水分吸着剤4は、例えば通気性の良い袋に挿入された酸化カルシウム(CaO)である。水分吸着剤4は、CaOのみに限定されず、例えばゼオライトのように、水分吸着性を有するものであればよく、特に限定されるものではない。 The moisture adsorbent 4 is, for example, calcium oxide (CaO) inserted into a bag having good air permeability. The moisture adsorbent 4 is not limited to CaO, and is not particularly limited as long as it has moisture adsorption properties such as zeolite.

次に、本発明の実施形態1に係る真空断熱材1の製造方法について説明する。

本実施形態の真空断熱材1に使用する芯材2は、例えばバインダーを使用しない乾式法によって製造したガラス繊維集合体で構成される。このガラス繊維集合体で構成される芯材2は、嵩密度が小さく真空断熱材1を製造する際のハンドリング性及び外包材3への挿入性が悪い。そのため、芯材2として取扱うためには加工により嵩密度を大きくする必要がある。

Next, the manufacturing method of the vacuum

The

図7は本発明の実施形態1に係る真空断熱材の製造方法を示す模式図である。

加工装置6は、芯材2を圧縮する圧縮機構7を有する。芯材2は、真空断熱材1として必要な幅と長さにそろえられた上で、加工装置6に設置される。このとき、芯材2の厚みは、真空断熱材1の厚みと比較し10倍以上の厚みを有している。

FIG. 7 is a schematic view showing a method for manufacturing a vacuum heat insulating material according to

The processing device 6 includes a compression mechanism 7 that compresses the

次に、圧縮機構7により芯材2を繰り返し圧縮する。圧縮するときの圧力は、0.02〜0.07MPaが好ましく、0.02〜0.04MPaであればより好ましい。圧縮回数は50〜1000回が好ましい。前記条件で圧縮することで、繊維長1.85mm以下の繊維の重量割合は圧縮前の状態を維持したまま、繊維が徐々にずれて再配置を繰り返し、芯材2の断熱方向に対して垂直な面に対する繊維角度φの平均値が14°以下であり、標準偏差は12°以下である芯材2が得られる。

Next, the

50〜1000回圧縮するときの圧力が0.07MPaを超えると、繊維が破断し、繊維長1.85mm以下の繊維の重量割合が芯材2の11wt%以上となり、断熱性能に優れた真空断熱材が得られない。その原因として、短繊維が、主体となる繊維の間を充填したり、主体となる繊維の間に絡みついたりして、繊維間に熱伝導が発生し、芯材の厚み方向に沿って熱伝導を引き起こすことによって、断熱性能を低下させているものと考えられる。

When the pressure when compressed 50 to 1000 times exceeds 0.07 MPa, the fiber breaks, the weight ratio of the fiber having a fiber length of 1.85 mm or less becomes 11 wt% or more of the

一方、50〜1000回圧縮するときの圧力が0.02MPaを下回ると、繊維がずれることによる再配置が起こりにくくなり、芯材2の断熱方向に対して垂直な面に対する繊維角度φの平均値を14°以下に制御することができず、断熱性能に優れた真空断熱材が得られない。また、嵩密度が増加せずハンドリング性及び外包材3への挿入性が改善されず、効率的に真空断熱材を製造できない。

On the other hand, when the pressure when compressed 50 to 1000 times is less than 0.02 MPa, rearrangement due to fiber displacement is less likely to occur, and the average value of the fiber angle φ with respect to the plane perpendicular to the heat insulating direction of the

次に、嵩密度が高く加工された芯材2を外包材3へ挿入し、水分除去のための乾燥工程を経た後、水分吸着剤4が挿入され、外包材3の内部が1〜3Pa(パスカル)の真空度に減圧された状態で開口部がヒートシールにより密封されることによって、真空断熱材1が得られる。なお、乾燥工程は、芯材2とこの芯材2を被覆する外包材3の水分を除去できる条件である、例えば100℃で2時間の加熱を行えばよいが、加熱条件はこれに限定されず、芯材2とこの芯材2を被覆する外包材3の水分を除去できる条件であればよい。

また、水分吸着剤4は、乾燥工程を経た後に挿入されることに限定されず、乾燥工程の前や、加工装置6で、芯材2とこの芯材2を被覆する外包材3を圧縮する前に挿入されていてもよい。

Next, the

Further, the moisture adsorbent 4 is not limited to being inserted after the drying process, but compresses the

本発明の実施形態1に係る真空断熱材1について、熱伝導率、繊維長1.85mm以下の繊維の重量割合、芯材2の断熱方向に対して垂直な面に対する繊維角度φの平均値及びその標準偏差について評価した。熱伝導率は、定常法により熱伝導率計で測定した。測定条件は、高温側37.7℃、低温側10℃、平均温度23.85℃で実施した。繊維長1.85mm以下の繊維の重量割合が芯材2の11wt%以下、芯材2の断熱方向に対して垂直な面に対する繊維角度φの平均値が14°以下、及び標準偏差が12°以下であれば、熱伝導率は2.0mW/m・K以下であった。以上の結果より、本実施形態の方法で加工した前記条件を満たす真空断熱材は、断熱性能に優れたものであることが分かった。

About the vacuum

実施形態2.

前記実施形態では、真空断熱材1及びその製造方法について説明してきたが、この真空断熱材1を使用することで、消費電力の小さな冷蔵庫の断熱箱を提供することができる。

図8は本発明の実施形態2に係る断熱箱(本実施形態では冷蔵庫の断熱箱を示す)を示す模式図であり、図中、前述の実施形態1のものに相当する部分には同一符号を付してある。

図8において、断熱箱8は、ABS樹脂で構成される内箱9と、鋼板で構成される外箱10と、内箱9と外箱10との間の空間の片面(内箱9側)に配設された真空断熱材1と、内箱9と外箱10との間の真空断熱材1以外の空間に発泡充填された発泡ウレタン断熱材11とを有している。なお、内箱9及び外箱10は、共通する面にそれぞれ開口部(図示せず)が形成されており、この開口部に開閉扉(図示せず)が設けられている。それ以外の部分は、一般的な冷蔵庫に用いられている断熱箱と違いがないため、図示及び説明を省略する。

Although the said

FIG. 8 is a schematic view showing a heat insulation box according to the second embodiment of the present invention (in this embodiment, a heat insulation box of a refrigerator). In the figure, parts corresponding to those of the first embodiment are denoted by the same reference numerals. Is attached.

In FIG. 8, the heat insulating box 8 includes an inner box 9 made of ABS resin, an

前記の冷蔵庫の断熱箱8において、真空断熱材1が配置される範囲は限定するものではなく、内箱9と外箱10との間に形成される空間の全範囲であっても、あるいは一部であってもよく、また前記開閉扉の内部に配置されてもよい。

In the heat insulating box 8 of the refrigerator, the range in which the vacuum

前記のように構成した冷蔵庫の断熱箱8は、本発明の真空断熱材1を発泡ウレタン断熱材11中に埋設して併用しているので、さらに断熱効果が上がり、消費電力の低減等による省エネ効果が得られる。

The refrigerator heat insulating box 8 configured as described above uses the vacuum

1 真空断熱材、2 芯材、3 外包材、4 水分吸着剤、5 溶着シール部、6 加工装置、7 圧縮機構、8 断熱箱、9 内箱、10 外箱、11 発泡ウレタン断熱材。

DESCRIPTION OF

Claims (1)

前記芯材を外包材へ挿入し、前記外包材の内部を予め設定された真空度に減圧する工程と、

前記外包材を減圧された状態で、開口部を密封する工程と

を有することを特徴とする真空断熱材の製造方法。 The weight ratio of fibers having a fiber length of 1.85 mm or less is 11 wt% by repeatedly compressing the aggregate of glass fibers 50 to 1000 times in the thickness direction at a pressure of 0.02 to 0.07 MPa by a compression mechanism capable of controlling the load. Creating a core material that is:

Inserting the core material into an outer packaging material, and depressurizing the interior of the outer packaging material to a preset vacuum degree;

And a step of sealing the opening in a state where the outer packaging material is depressurized.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014018160A JP6192554B2 (en) | 2014-02-03 | 2014-02-03 | Manufacturing method of vacuum insulation |

| CN201580006850.5A CN105992902B (en) | 2014-02-03 | 2015-01-08 | The manufacturing method of vacuum heat insulation materials |

| PCT/JP2015/050403 WO2015115149A1 (en) | 2014-02-03 | 2015-01-08 | Vacuum heat-insulating material, heat-insulating box using vacuum heat-insulating material, and method for manufacturing vacuum heat-insulating material |

| RU2016135626A RU2658725C1 (en) | 2014-02-03 | 2015-01-08 | Vacuum heat insulating material, heat-insulating box, which uses the heat-insulating material, and method of manufacturing of heat-insulating material |

| SG11201605643YA SG11201605643YA (en) | 2014-02-03 | 2015-01-08 | Vacuum heat insulating material, heat insulating box using vacuum heat insulating material, and manufacturing method of vacuum heat insulating material |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014018160A JP6192554B2 (en) | 2014-02-03 | 2014-02-03 | Manufacturing method of vacuum insulation |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015145696A JP2015145696A (en) | 2015-08-13 |

| JP2015145696A5 JP2015145696A5 (en) | 2016-07-07 |

| JP6192554B2 true JP6192554B2 (en) | 2017-09-06 |

Family

ID=53756727

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014018160A Active JP6192554B2 (en) | 2014-02-03 | 2014-02-03 | Manufacturing method of vacuum insulation |

Country Status (5)

| Country | Link |

|---|---|

| JP (1) | JP6192554B2 (en) |

| CN (1) | CN105992902B (en) |

| RU (1) | RU2658725C1 (en) |

| SG (1) | SG11201605643YA (en) |

| WO (1) | WO2015115149A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2017029727A1 (en) * | 2015-08-19 | 2018-04-05 | 三菱電機株式会社 | Vacuum insulation and insulation box |

| CN109690164A (en) * | 2016-09-08 | 2019-04-26 | 三菱电机株式会社 | Vacuumed insulation panel and hot box |

| EP3627030A4 (en) * | 2017-05-15 | 2020-04-15 | Panasonic Intellectual Property Management Co., Ltd. | Heat-insulating material and heat-insulating structure employing same |

| CN111656076A (en) * | 2018-01-31 | 2020-09-11 | 三菱电机株式会社 | Vacuum heat insulating material and heat insulating box |

| EP4414596A1 (en) * | 2021-10-08 | 2024-08-14 | Nitto Denko Corporation | Thermal insulation material and method for producing thermal insulation material |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1044290A (en) * | 1996-08-08 | 1998-02-17 | Mitsubishi Chem Corp | Vacuum heat insulation material |

| CN101311165B (en) * | 1998-07-02 | 2011-05-18 | 安万特第二分公司 | Novel antihistaminic piperidine derivatives and intermediates for the preparation thereof |

| TW593919B (en) * | 2002-05-31 | 2004-06-21 | Matsushita Refrigeration | Vacuum heat insulating material and method for producing the same, and refrigerator using the vacuum heat insulating material |

| JP3513143B2 (en) * | 2002-06-06 | 2004-03-31 | 松下冷機株式会社 | Vacuum insulation material and refrigerator using vacuum insulation material |

| JP2004011709A (en) * | 2002-06-05 | 2004-01-15 | Matsushita Refrig Co Ltd | Vacuum heat insulating material, its manufacturing method |

| JP2004308691A (en) * | 2003-04-02 | 2004-11-04 | Nisshinbo Ind Inc | Vacuum heat insulating material and manufacturing method thereof |

| JP3580315B1 (en) * | 2004-02-04 | 2004-10-20 | 松下電器産業株式会社 | Vacuum heat insulating material and method for manufacturing the same, heat insulating / cooling device equipped with the vacuum heat insulating material, and heat insulating board |

| JP4183657B2 (en) * | 2004-06-04 | 2008-11-19 | 日立アプライアンス株式会社 | refrigerator |

| JP2006017169A (en) * | 2004-06-30 | 2006-01-19 | Asahi Fiber Glass Co Ltd | Vacuum heat insulating material, core material for vacuum heat insulating material and its producing method |

| JP4713566B2 (en) * | 2007-12-28 | 2011-06-29 | シャープ株式会社 | Core material for vacuum heat insulating material, vacuum heat insulating material, and manufacturing method thereof |

| JP5169531B2 (en) * | 2008-06-24 | 2013-03-27 | 三菱電機株式会社 | Vacuum insulation |

| JP5548025B2 (en) * | 2010-05-10 | 2014-07-16 | 日立アプライアンス株式会社 | Vacuum heat insulating material and refrigerator using the same |

-

2014

- 2014-02-03 JP JP2014018160A patent/JP6192554B2/en active Active

-

2015

- 2015-01-08 WO PCT/JP2015/050403 patent/WO2015115149A1/en active Application Filing

- 2015-01-08 CN CN201580006850.5A patent/CN105992902B/en active Active

- 2015-01-08 SG SG11201605643YA patent/SG11201605643YA/en unknown

- 2015-01-08 RU RU2016135626A patent/RU2658725C1/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| WO2015115149A1 (en) | 2015-08-06 |

| CN105992902A (en) | 2016-10-05 |

| CN105992902B (en) | 2018-06-26 |

| JP2015145696A (en) | 2015-08-13 |

| RU2658725C1 (en) | 2018-06-22 |

| SG11201605643YA (en) | 2016-08-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6192554B2 (en) | Manufacturing method of vacuum insulation | |

| WO2003102460A1 (en) | Vacuum thermal insulating material, process for producing the same and refrigerator including the same | |

| WO2010087039A1 (en) | Vacuum insulation material and insulation box using the same | |

| JP2004308691A (en) | Vacuum heat insulating material and manufacturing method thereof | |

| WO2016143781A1 (en) | Vacuum insulated panel, core material, and refrigerator | |

| JP6014759B2 (en) | Vacuum insulation containing annealed binderless glass fiber | |

| JP2006125631A (en) | Vacuum insulation material and manufacturing method thereof | |

| JP6185270B2 (en) | Vacuum insulation | |

| JP2013512396A (en) | Core material for vacuum insulation panel and method for producing the same | |

| KR20130095506A (en) | A sealing member having good impact resistance and non-inflammability for vacuum insulation panel | |

| JP5695212B2 (en) | CORE MATERIAL FOR VACUUM INSULATION MATERIAL COMPRISING PHENOL RESIN CURED FOAM, VACUUM INSULATION MATERIAL USING SAME, AND METHOD FOR PRODUCING THE SAME | |

| JP6726842B2 (en) | Insulation | |

| JP2007138976A (en) | Vacuum heat insulating material and its manufacturing method | |

| JP6598715B2 (en) | Vacuum insulation panel and method for manufacturing the same, gas adsorption pack | |

| JP2015098907A (en) | Vacuum heat insulation material | |

| WO2019171566A1 (en) | Vacuum heat-insulation material and heat-insulating box | |

| JP6793571B2 (en) | Vacuum heat insulating material, equipment equipped with it, and manufacturing method of vacuum heat insulating material | |

| EP2985376B1 (en) | Core material for vacuum insulator, comprising organic synthetic fiber, and vacuum insulator containing same | |

| JPWO2019021359A1 (en) | Vacuum insulation material, insulation box, and method of manufacturing vacuum insulation material | |

| JP2016064845A (en) | Bag body and vacuum heat insulation material using the bag body | |

| WO2019150478A1 (en) | Vacuum insulation material and insulated box | |

| JP6184841B2 (en) | Vacuum insulation material and equipment using the same | |

| WO2021054395A1 (en) | Vacuum heat-insulating material | |

| KR101477343B1 (en) | Method for manufacturing vacuum insulation panel and vacuum insulation panel | |

| JP7154316B2 (en) | Vacuum insulation material and insulation box |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160519 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160519 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20160519 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20160628 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160719 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160908 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20161101 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20170131 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170426 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20170508 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170801 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170808 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6192554 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |