JP5726875B2 - 廃熱システム - Google Patents

廃熱システム Download PDFInfo

- Publication number

- JP5726875B2 JP5726875B2 JP2012524931A JP2012524931A JP5726875B2 JP 5726875 B2 JP5726875 B2 JP 5726875B2 JP 2012524931 A JP2012524931 A JP 2012524931A JP 2012524931 A JP2012524931 A JP 2012524931A JP 5726875 B2 JP5726875 B2 JP 5726875B2

- Authority

- JP

- Japan

- Prior art keywords

- preheating

- scrap

- exhaust gas

- burner

- scrap metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002918 waste heat Substances 0.000 title description 5

- 239000007789 gas Substances 0.000 claims description 62

- 239000003923 scrap metal Substances 0.000 claims description 32

- 238000002844 melting Methods 0.000 claims description 31

- 230000008018 melting Effects 0.000 claims description 31

- 238000012546 transfer Methods 0.000 claims description 10

- 238000004891 communication Methods 0.000 claims description 3

- 239000012530 fluid Substances 0.000 claims description 3

- 230000035515 penetration Effects 0.000 claims description 3

- 238000007599 discharging Methods 0.000 claims description 2

- 230000000153 supplemental effect Effects 0.000 claims description 2

- 238000010438 heat treatment Methods 0.000 description 9

- 238000000034 method Methods 0.000 description 8

- 229910052751 metal Inorganic materials 0.000 description 6

- 239000002184 metal Substances 0.000 description 6

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 4

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 4

- 239000000463 material Substances 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 2

- 239000000446 fuel Substances 0.000 description 2

- 239000003345 natural gas Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000001294 propane Substances 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000000567 combustion gas Substances 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

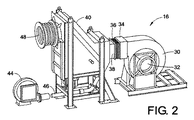

- 238000010586 diagram Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 238000010926 purge Methods 0.000 description 1

- 230000007723 transport mechanism Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS, OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D13/00—Apparatus for preheating charges; Arrangements for preheating charges

- F27D13/002—Preheating scrap

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21C—PROCESSING OF PIG-IRON, e.g. REFINING, MANUFACTURE OF WROUGHT-IRON OR STEEL; TREATMENT IN MOLTEN STATE OF FERROUS ALLOYS

- C21C5/00—Manufacture of carbon-steel, e.g. plain mild steel, medium carbon steel or cast steel or stainless steel

- C21C5/56—Manufacture of steel by other methods

- C21C5/562—Manufacture of steel by other methods starting from scrap

- C21C5/565—Preheating of scrap

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B1/00—Preliminary treatment of ores or scrap

- C22B1/005—Preliminary treatment of scrap

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B21/00—Obtaining aluminium

- C22B21/0007—Preliminary treatment of ores or scrap or any other metal source

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B21/00—Obtaining aluminium

- C22B21/0084—Obtaining aluminium melting and handling molten aluminium

- C22B21/0092—Remelting scrap, skimmings or any secondary source aluminium

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21C—PROCESSING OF PIG-IRON, e.g. REFINING, MANUFACTURE OF WROUGHT-IRON OR STEEL; TREATMENT IN MOLTEN STATE OF FERROUS ALLOYS

- C21C2100/00—Exhaust gas

- C21C2100/06—Energy from waste gas used in other processes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/20—Recycling

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Environmental & Geological Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Geology (AREA)

- General Engineering & Computer Science (AREA)

- Furnace Details (AREA)

- Waste-Gas Treatment And Other Accessory Devices For Furnaces (AREA)

- Manufacture And Refinement Of Metals (AREA)

Description

Claims (6)

- 溶融炉への送り出し前に屑金を予熱する予熱装入システムであって、前記システムは、 予熱コンベヤを有し、前記予熱コンベヤは、

チャンバと、

前記チャンバ内に屑金を導入するスクラップ入口と、

前記チャンバから屑金を排出するスクラップ出口と、

前記屑金を予熱するために高温排気ガスを前記チャンバ内に導入する入口ポートとを有し、

前記システムは、予熱ステーションを有し、前記予熱ステーションは、

バーナチャンバを有し、前記バーナチャンバは、

高温排気ガス源から高温排気ガスを受け入れる高温排気ガス入口ポートと、高温排気ガス出口ポートと、前記高温排気ガス入口ポートと前記高温排気ガス出口ポートの間の高温排気ガス流路中で前記高温排気ガスに補充的な熱を要求に応じて供給するよう構成されたバーナ装置を有し、

前記高温排気ガス出口ポートは、前記屑金を予熱するために前記高温排気ガスを前記予熱コンベヤに送るために前記予熱コンベヤの前記入口ポートと流体連通状態にある、予熱装入システム。 - 前記バーナ装置は、前記高温ガス出口ポートの方向に発火するよう位置決めされている、請求項1記載の予熱装入システム。

- 前記バーナ装置は、前記バーナチャンバ内への調節可能な侵入度を有する、請求項1又は2に記載の予熱装入システム。

- 前記バーナは、水平方向又は垂直方向のうちの少なくとも一方の方向で前記バーナチャンバ内に調節可能に設けられている、請求項1から3のいずれか一項に記載の予熱装入システム。

- 屑金溶融炉システムであって、屑金を溶融する溶融炉と、屑金を前記溶融炉に運搬するよう構成された移送コンベヤと、前記屑金を予熱するための請求項1から4のいずれか一項に記載の予熱装入システムとを有し、前記移送コンベヤは、前記予熱コンベヤのスクラップ入口に隣接し、前記予熱コンベヤのスクラップ出口は前記溶融炉に隣接している、屑金溶融炉システム。

- 前記スクラップ出口は、前記溶融炉の屑金取り入れ口に連結されている、請求項5記載の屑金溶融炉システム。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US23396709P | 2009-08-14 | 2009-08-14 | |

| US61/233,967 | 2009-08-14 | ||

| PCT/US2010/045607 WO2011020092A1 (en) | 2009-08-14 | 2010-08-16 | Waste heat system |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013501916A JP2013501916A (ja) | 2013-01-17 |

| JP2013501916A5 JP2013501916A5 (ja) | 2013-10-03 |

| JP5726875B2 true JP5726875B2 (ja) | 2015-06-03 |

Family

ID=42829466

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012524931A Active JP5726875B2 (ja) | 2009-08-14 | 2010-08-16 | 廃熱システム |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US9459047B2 (ja) |

| EP (1) | EP2464940B1 (ja) |

| JP (1) | JP5726875B2 (ja) |

| CA (1) | CA2771157C (ja) |

| ES (1) | ES2683341T3 (ja) |

| MX (1) | MX338568B (ja) |

| PL (1) | PL2464940T3 (ja) |

| WO (1) | WO2011020092A1 (ja) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5885758B2 (ja) * | 2011-12-27 | 2016-03-15 | キヤノン株式会社 | 情報信号生成方法 |

| CN106440774B (zh) * | 2016-08-18 | 2019-12-27 | 富通昭和线缆(天津)有限公司 | 一种铜杆生产用密闭式预热炉及铜杆制造方法 |

| DE102017124108A1 (de) * | 2017-10-17 | 2019-04-18 | Inteco Melting And Casting Technologies Gmbh | Schrottvorwärmeinrichtung für einen Schmelzofen und Verfahren zur Schrottvorwärmung |

| CN114322540A (zh) * | 2022-02-28 | 2022-04-12 | 山东宝阳干燥设备科技有限公司 | 一种磷酸铁锂回收料专用焙烧系统 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3645515A (en) * | 1970-10-12 | 1972-02-29 | Waagner Biro American | Metallurgical furnace installation and operating method |

| US3985497A (en) * | 1974-11-21 | 1976-10-12 | Melting Systems, Inc. | Scrap preheating system |

| US4010935A (en) * | 1975-12-22 | 1977-03-08 | Alumax Inc. | High efficiency aluminum scrap melter and process therefor |

| GB2083181A (en) * | 1980-09-01 | 1982-03-17 | British Steel Corp | Pre-heating furnace charges |

| CH661788A5 (de) | 1984-02-21 | 1987-08-14 | Gautschi Electro Fours Sa | Beschickungsvorrichtung fuer einen schmelzofen. |

| EP0225939B1 (de) * | 1985-12-20 | 1991-07-17 | MANNESMANN Aktiengesellschaft | Verfahren zum Einschmelzen von Schrott o.dgl. und Vorrichtung zur Durchführung des Verfahrens |

| JPS62225889A (ja) * | 1986-03-27 | 1987-10-03 | 日立プラント建設株式会社 | アルミスクラツプの予熱装置 |

| DE69018874D1 (de) * | 1989-05-29 | 1995-06-01 | Alcan Int Ltd | Verfahren und Anlage zum Schmelzen verunreinigter metallischer Abfälle. |

| TW221462B (ja) | 1991-06-28 | 1994-03-01 | Stein Atkinson Strody Ltd | |

| US6024912A (en) * | 1997-11-27 | 2000-02-15 | Empco (Canada) Ltd. | Apparatus and process system for preheating of steel scrap for melting metallurgical furnaces with concurrent flow of scrap and heating gases |

| CA2222401C (en) * | 1997-11-27 | 2002-09-17 | Robert Roy Wunsche | Apparatus and process system for preheating of steel scrap for melting metallurgical furnaces with concurrent flow of scrap and heating gases |

| JP2000292074A (ja) * | 1999-04-05 | 2000-10-20 | Nippon Steel Corp | スクラップの予熱装置 |

-

2010

- 2010-08-16 MX MX2012001966A patent/MX338568B/es active IP Right Grant

- 2010-08-16 ES ES10747122.9T patent/ES2683341T3/es active Active

- 2010-08-16 PL PL10747122T patent/PL2464940T3/pl unknown

- 2010-08-16 JP JP2012524931A patent/JP5726875B2/ja active Active

- 2010-08-16 WO PCT/US2010/045607 patent/WO2011020092A1/en active Application Filing

- 2010-08-16 US US13/390,367 patent/US9459047B2/en active Active

- 2010-08-16 EP EP10747122.9A patent/EP2464940B1/en not_active Not-in-force

- 2010-08-16 CA CA2771157A patent/CA2771157C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US9459047B2 (en) | 2016-10-04 |

| EP2464940A1 (en) | 2012-06-20 |

| MX338568B (es) | 2016-04-21 |

| MX2012001966A (es) | 2012-07-10 |

| JP2013501916A (ja) | 2013-01-17 |

| ES2683341T3 (es) | 2018-09-26 |

| EP2464940B1 (en) | 2018-05-23 |

| US20120217683A1 (en) | 2012-08-30 |

| WO2011020092A1 (en) | 2011-02-17 |

| CA2771157A1 (en) | 2011-02-17 |

| CA2771157C (en) | 2018-09-11 |

| PL2464940T3 (pl) | 2018-10-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109336364B (zh) | 玻璃窑炉 | |

| US4249895A (en) | Kiln | |

| JP5726875B2 (ja) | 廃熱システム | |

| CN207963507U (zh) | 一种煤基竖炉烟气余热回收系统 | |

| US20050274373A1 (en) | Method and apparatus for heating glass panels | |

| CN107120963A (zh) | 带式焙烧机冷却和回热风系统及其方法 | |

| CN104215078A (zh) | 一种带有余热回收装置的镁熔坨生产工艺及设备 | |

| JP7013265B2 (ja) | フライアッシュの加熱改質装置および加熱改質方法 | |

| RU2606671C2 (ru) | Устройство для транспортирования металлургического материала | |

| TW201412994A (zh) | 用於連續供應預熱金屬材料至熔爐供生產鋼之設備及相關程序 | |

| JPH05172465A (ja) | 連続焼成炉の温度制御装置 | |

| US4432791A (en) | Ceramic radiant tube heated aluminum melter and method of melting aluminium | |

| JPS5966687A (ja) | 溶融炉装入スクラツプの予熱方法および装置 | |

| RU2602573C2 (ru) | Устройство для предварительного нагрева транспортируемого скрапа | |

| US8377371B2 (en) | System and method for producing metallic iron | |

| JP5211943B2 (ja) | 加熱炉の排気設備 | |

| CN214172902U (zh) | 一种高效节能型隧道窑 | |

| CN102966942A (zh) | 不换向火焰蓄热式燃烧装置 | |

| CN110487065A (zh) | 链箅机预热二段热风供给系统及温度调节方法 | |

| JPH11281264A (ja) | インゴットの予熱装置を有する溶解炉 | |

| JPH11239862A (ja) | 取鍋の乾燥および加熱方法並びにその装置 | |

| CN209197469U (zh) | 高效保温材料制备用氧化窑炉系统 | |

| CN202166295U (zh) | 冬夏两用加热烤房 | |

| RU2390570C1 (ru) | Способ термообработки окатышей | |

| CN110986579A (zh) | 一种烧结窑炉 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130816 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130816 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140818 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20141118 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20141126 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20141218 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150119 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150302 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150401 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5726875 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |