JP5259603B2 - 改良型電解コンデンサ陽極の製造方法 - Google Patents

改良型電解コンデンサ陽極の製造方法 Download PDFInfo

- Publication number

- JP5259603B2 JP5259603B2 JP2009530540A JP2009530540A JP5259603B2 JP 5259603 B2 JP5259603 B2 JP 5259603B2 JP 2009530540 A JP2009530540 A JP 2009530540A JP 2009530540 A JP2009530540 A JP 2009530540A JP 5259603 B2 JP5259603 B2 JP 5259603B2

- Authority

- JP

- Japan

- Prior art keywords

- metal

- billet

- copper

- forming

- ductile metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G9/00—Electrolytic capacitors, rectifiers, detectors, switching devices, light-sensitive or temperature-sensitive devices; Processes of their manufacture

- H01G9/004—Details

- H01G9/04—Electrodes or formation of dielectric layers thereon

- H01G9/042—Electrodes or formation of dielectric layers thereon characterised by the material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G9/00—Electrolytic capacitors, rectifiers, detectors, switching devices, light-sensitive or temperature-sensitive devices; Processes of their manufacture

- H01G9/004—Details

- H01G9/04—Electrodes or formation of dielectric layers thereon

- H01G9/048—Electrodes or formation of dielectric layers thereon characterised by their structure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G9/00—Electrolytic capacitors, rectifiers, detectors, switching devices, light-sensitive or temperature-sensitive devices; Processes of their manufacture

- H01G9/004—Details

- H01G9/04—Electrodes or formation of dielectric layers thereon

- H01G9/048—Electrodes or formation of dielectric layers thereon characterised by their structure

- H01G9/055—Etched foil electrodes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12479—Porous [e.g., foamed, spongy, cracked, etc.]

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Fixed Capacitors And Capacitor Manufacturing Machines (AREA)

- Powder Metallurgy (AREA)

- Metal Extraction Processes (AREA)

- Extrusion Of Metal (AREA)

Description

(1)多数の個別フィラメントを用いる代わりに、連続タンタル板を用いてもよい。これにより、ビレットの組立が非常に簡単になり、完成品の品質がより安定する。

(2)さらに、フィラメントの数を大幅に減らすことによって、最終実装がより容易になる。ジェリーロール設計によって接続が強化されるため、等価直列抵抗(ESR)の改善が可能になる。

(3)さらに、タンタル成分の均質性により、非常に良好なCV/g値を得ることができる。

(4)プロセスは、断面の均一性と、高い表面対体積比を保証する。この要素は両方とも、高い静電容量のコンデンサを工業規模で確実に製造するために重要である。

(5)得られたワイヤを丸まった状態で用いることができる、すなわち巻くか、撚ってから巻いてもよい。さらに、より高い静電容量のコンデンサ用に、複数のストランドを、例えば編むか撚り合わせることによって組み立てることができる。

(6)ワイヤを巻く際、ワイヤは、商業市場で現在用いられるチップコンデンサの形状のアスペクト比をとることとする。

(7)プロセスは柔軟性があり、主なビレット設計を変更することによって、シース内の体積密度が要求するのであれば、要求に応じてタンタルの量を多くすることも少なくすることもできる。

(8)プロセスは、粉末またはフィラメントを使用するその他のプロセスに比して経済的である。

得られたビレットを、押出成形して、0.127ミリメートルの直径に伸線加工した。得られた押出成形および伸線加工ロッドを硝酸1対水1の溶液に浸漬して、銅を浸出させた。そして、得られたタンタルフィラメントを1500℃で20分間真空焼結した。得られたタンタルセグメントは、分割管のセグメントの形状を有し、その厚みは約1ミクロンであった。

Claims (5)

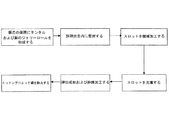

- バルブ金属と延性金属の交互層を組み合わせてビレットを形成し、前記ビレットを押出成形および伸線加工によって機械的に圧縮し、その後エッチングする多孔質電解電極の形成方法であって、前記バルブ金属の層は連続薄板を含み、且つ、前記機械的圧縮の前に前記ビレットにバルブ金属層及び延性金属層を貫いて1つ以上のスロットを形成し、前記延性金属を前記1つ以上のスロットに充填する方法。

- (a)前記バルブ金属としてタンタルを含み、延性金属として銅を含むこと、

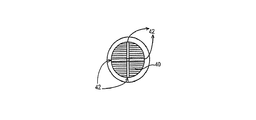

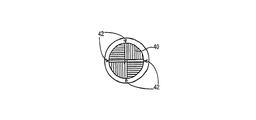

(b)前記ビレットの外面の周囲に等間隔で複数のスロットを形成すること、

(c)前記ビレットが円形断面を有し、前記ビレットの外面の周囲に等間隔かつ半径方向に前記スロットを形成すること、

(d)前記ビレットの周囲に約90°間隔で4つのスロットを形成すること、

(e)前記交互の薄板をコア金属の周囲にジェリーロール状に形成すること、

(f)前記交互の薄板を積層として形成すること、

(g)前記交互の薄板を、好ましくは銅である前記延性金属と同じ金属を含有するコア金属の周囲にジェリーロール状に形成すること、および

(h)タンタル板および銅板を銅芯の周囲にジェリーロール状に巻き付けて、前記ビレットを形成すること

のうち1つ以上の特徴を備える、請求項1に記載の方法。 - 前記交互の薄板を積層として形成し、バルブ金属と延性金属による前記積層をバルブ金属と延性金属の前記交互層から形成されるジェリーロールによって取り囲むことを含む、請求項1に記載の方法。

- バルブ金属と延性金属の連続薄板の交互層を組み合わせてパケットを形成するために積層として形成され、複数のパケットはビレットを形成するために単層又は多層の延性金属の薄板で分離されて形成され、前記ビレットを押出成形および伸線加工によって機械的に圧縮し、延性金属を除去するために圧縮して得られたビレットをエッチングする多孔質電解電極の形成方法。

- (a)前記バルブ金属としてタンタルを含み、前記延性金属として銅を含むこと、

(b)前記パケット状の前記延性金属の層および前記延性金属分離層が、同じ金属、好ましくは銅であること、

(c)複数のパケットを互いに対して異なる配向に配列するとともに、銅の薄板によって分離すること、および

(d)バルブ金属と延性金属による複数のパケットを、バルブ金属と延性金属の交互層から形成されるジェリーロールによって取り囲むこと

のうち1つ以上の特徴を備える、請求項4に記載の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US82703606P | 2006-09-26 | 2006-09-26 | |

| US60/827,036 | 2006-09-26 | ||

| PCT/US2007/079249 WO2008039707A1 (en) | 2006-09-26 | 2007-09-21 | Methods for fabrication of improved electrolytic capacitor anode |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010504858A JP2010504858A (ja) | 2010-02-18 |

| JP5259603B2 true JP5259603B2 (ja) | 2013-08-07 |

Family

ID=39230520

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009530540A Active JP5259603B2 (ja) | 2006-09-26 | 2007-09-21 | 改良型電解コンデンサ陽極の製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8858738B2 (ja) |

| EP (1) | EP2076911A4 (ja) |

| JP (1) | JP5259603B2 (ja) |

| CN (1) | CN101517675B (ja) |

| WO (1) | WO2008039707A1 (ja) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9978656B2 (en) * | 2011-11-22 | 2018-05-22 | Taiwan Semiconductor Manufacturing Company, Ltd. | Mechanisms for forming fine-pitch copper bump structures |

| US9031671B2 (en) | 2012-09-21 | 2015-05-12 | Composite Materials Technology, Inc. | Medical implantable lead and manufacture thereof |

| US9028584B2 (en) | 2012-10-11 | 2015-05-12 | Composite Materials Technology, Inc. | System and method for fabrication of 3-D parts |

| USRE48439E1 (en) | 2013-09-06 | 2021-02-16 | Greatbatch Ltd. | High voltage tantalum anode and method of manufacture |

| US9312075B1 (en) | 2013-09-06 | 2016-04-12 | Greatbatch Ltd. | High voltage tantalum anode and method of manufacture |

| US9633796B2 (en) | 2013-09-06 | 2017-04-25 | Greatbatch Ltd. | High voltage tantalum anode and method of manufacture |

| MX379158B (es) * | 2013-12-25 | 2025-03-11 | Ningxia Orient Tantalum Ind Co Ltd | Polvo de tantalo grado capacitor de alta capacitancia especifica con propiedades electricas mejoradas y proceso para hacer el mismo. |

| US9155605B1 (en) | 2014-07-10 | 2015-10-13 | Composite Materials Technology, Inc. | Biocompatible extremely fine tantalum filament scaffolding for bone and soft tissue prosthesis |

| US9498316B1 (en) | 2014-07-10 | 2016-11-22 | Composite Materials Technology, Inc. | Biocompatible extremely fine tantalum filament scaffolding for bone and soft tissue prosthesis |

| WO2016187143A1 (en) | 2015-05-15 | 2016-11-24 | Composite Materials Technology, Inc. | Improved high capacity rechargeable batteries |

| EP3895832B1 (en) | 2016-08-12 | 2022-12-28 | COMPOSITE MATERIALS TECHNOLOGY, Inc. | Electrolytic capacitor and method for improved electrolytic capacitor anodes |

| US10230110B2 (en) | 2016-09-01 | 2019-03-12 | Composite Materials Technology, Inc. | Nano-scale/nanostructured Si coating on valve metal substrate for LIB anodes |

Family Cites Families (48)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3218693A (en) * | 1962-07-03 | 1965-11-23 | Nat Res Corp | Process of making niobium stannide superconductors |

| US3277465A (en) * | 1963-02-25 | 1966-10-04 | Bronson M Potter | Electrically operated audible alarm |

| US3394213A (en) * | 1964-03-02 | 1968-07-23 | Roehr Prod Co Inc | Method of forming filaments |

| US3277564A (en) * | 1965-06-14 | 1966-10-11 | Roehr Prod Co Inc | Method of simultaneously forming a plurality of filaments |

| BE683279A (ja) * | 1965-06-28 | 1966-12-01 | ||

| US3379000A (en) * | 1965-09-15 | 1968-04-23 | Roehr Prod Co Inc | Metal filaments suitable for textiles |

| US3567407A (en) * | 1966-06-27 | 1971-03-02 | Whittaker Corp | Composite materials |

| US3540114A (en) * | 1967-11-21 | 1970-11-17 | Brunswick Corp | Method of forming fine filaments |

| US3800061A (en) * | 1969-03-05 | 1974-03-26 | Norton Co | Composite conductor containing superconductive wires |

| US3742369A (en) * | 1969-03-13 | 1973-06-26 | R Douglass | Capacitor with fibered valve metal anode |

| US3698863A (en) * | 1970-01-29 | 1972-10-17 | Brunswick Corp | Fibrous metal filaments |

| FR2154364B1 (ja) * | 1971-10-01 | 1975-06-06 | Snecma | |

| US3743986A (en) * | 1972-02-08 | 1973-07-03 | Atomic Energy Commission | Improved resistive envelope for a multifilament superconductor wire |

| CH586952A5 (ja) * | 1975-03-26 | 1977-04-15 | Bbc Brown Boveri & Cie | |

| JPS5235744A (en) * | 1975-09-17 | 1977-03-18 | Nippon Steel Corp | Method to manufacture hot extrusion billit for metal fibre |

| FR2334182A1 (fr) * | 1975-12-03 | 1977-07-01 | Furukawa Electric Co Ltd | Cable comportant un compose supraconducteur et procede de fabrication d'un tel cable |

| JPS5539144A (en) * | 1978-09-14 | 1980-03-18 | Nat Res Inst Metals | Method of fabricating nb3sn composite superconductor |

| US4502884A (en) * | 1983-10-27 | 1985-03-05 | Cabot Corporation | Method for producing fiber-shaped tantalum powder and the powder produced thereby |

| JPS6097514A (ja) * | 1983-10-31 | 1985-05-31 | 株式会社東芝 | 複合超電導線の製造方法 |

| DE3531770A1 (de) * | 1985-09-06 | 1987-03-19 | Kernforschungsz Karlsruhe | Multifilament-supraleiterdraehte, bestehend aus mit kupfer oder mit kupfer-legierung umgebenen filamenten aus nb(pfeil abwaerts)3(pfeil abwaerts)sn oder v(pfeil abwaerts)3(pfeil abwaerts)ga mit zusaetzen sowie verfahren zu deren herstellung |

| JPS62174354A (ja) * | 1986-01-25 | 1987-07-31 | Natl Res Inst For Metals | Ti添加Nb3Sn複合超電導線材の製造法 |

| JPH02106885A (ja) | 1988-10-14 | 1990-04-18 | Hitachi Cable Ltd | 超電導線の接続方法 |

| JP2848618B2 (ja) | 1989-01-25 | 1999-01-20 | 株式会社東芝 | 化合物系超電導線の接続方法 |

| JPH0713888B2 (ja) * | 1989-03-27 | 1995-02-15 | 工業技術院長 | 超電導線 |

| JPH033272A (ja) | 1989-05-30 | 1991-01-09 | Mitsubishi Electric Corp | 半導体装置 |

| US5174831A (en) * | 1989-06-08 | 1992-12-29 | Composite Materials Technology, Inc. | Superconductor and process of manufacture |

| US5034857A (en) * | 1989-10-06 | 1991-07-23 | Composite Materials Technology, Inc. | Porous electrolytic anode |

| JP2606393B2 (ja) | 1990-01-10 | 1997-04-30 | 日立電線株式会社 | 化合物系超電導線の接続方法 |

| US5541787A (en) * | 1990-11-09 | 1996-07-30 | Seagate Technology, Inc. | Head disc assembly with printed circuit cable connector adapted for automated assembly |

| US5223348A (en) * | 1991-05-20 | 1993-06-29 | Composite Materials Technology, Inc. | APC orientation superconductor and process of manufacture |

| US5217526A (en) * | 1991-05-31 | 1993-06-08 | Cabot Corporation | Fibrous tantalum and capacitors made therefrom |

| US5245514A (en) * | 1992-05-27 | 1993-09-14 | Cabot Corporation | Extruded capacitor electrode and method of making the same |

| US5284531A (en) | 1992-07-31 | 1994-02-08 | Cabot Corporation | Cylindrical metal fibers made from tantalum, columbium, and alloys thereof |

| US5299728A (en) * | 1992-10-28 | 1994-04-05 | General Electric Company | Method and apparatus for laminating foils into a superconducting tape for use in a superconducting magnet |

| JPH06251645A (ja) * | 1993-02-22 | 1994-09-09 | Sumitomo Electric Ind Ltd | Nb3X系超電導線用線材 |

| US5638253A (en) * | 1994-04-28 | 1997-06-10 | Rohm Co. Ltd. | Package-type solid electrolytic capacitor |

| US5534219A (en) * | 1994-05-27 | 1996-07-09 | Oxford Instruments Inc. | Method for producing multifilamentary niobium-tin superconductor |

| US5505790A (en) * | 1994-09-09 | 1996-04-09 | General Electric Company | Method for enhancing critical current of triniobium tin |

| US5540787A (en) * | 1995-06-14 | 1996-07-30 | General Electric Company | Method of forming triniobium tin superconductor |

| US5963417A (en) * | 1995-11-09 | 1999-10-05 | Wisconsin Alumni Research Foundation | Electrochemical capacitor |

| JPH09204828A (ja) * | 1996-01-29 | 1997-08-05 | Hitachi Cable Ltd | Nb3Al系超電導線材の製造方法 |

| US5869169A (en) * | 1996-09-27 | 1999-02-09 | Fed Corporation | Multilayer emitter element and display comprising same |

| US5869196A (en) * | 1996-12-20 | 1999-02-09 | Composite Material Technology, Inc. | Constrained filament electrolytic anode and process of fabrication |

| JPH11250747A (ja) | 1998-02-27 | 1999-09-17 | Kobe Steel Ltd | Nb3 Sn系超電導線の製造方法 |

| US6543123B1 (en) | 1999-04-20 | 2003-04-08 | Composite Materials Technology, Inc. | Process for making constrained filament niobium-based superconductor composite |

| EP1340235B1 (en) | 2000-11-30 | 2006-08-09 | Showa Denko K.K. | Powder for capacitor, sintered body thereof and capacitor using the sintered body |

| AU2003297192A1 (en) * | 2002-12-17 | 2004-07-22 | Composite Materials Technology, Inc. | Production of electrolytic capacitors and superconductors |

| JP2005097671A (ja) * | 2003-09-24 | 2005-04-14 | Hitachi Cable Ltd | Ti−Al系金属間化合物及びその製造方法 |

-

2007

- 2007-09-21 JP JP2009530540A patent/JP5259603B2/ja active Active

- 2007-09-21 US US11/859,687 patent/US8858738B2/en active Active

- 2007-09-21 CN CN2007800358240A patent/CN101517675B/zh active Active

- 2007-09-21 WO PCT/US2007/079249 patent/WO2008039707A1/en not_active Ceased

- 2007-09-21 EP EP07843025A patent/EP2076911A4/en not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010504858A (ja) | 2010-02-18 |

| EP2076911A1 (en) | 2009-07-08 |

| CN101517675B (zh) | 2012-09-05 |

| EP2076911A4 (en) | 2012-06-20 |

| US8858738B2 (en) | 2014-10-14 |

| CN101517675A (zh) | 2009-08-26 |

| US20080072407A1 (en) | 2008-03-27 |

| WO2008039707A1 (en) | 2008-04-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5259603B2 (ja) | 改良型電解コンデンサ陽極の製造方法 | |

| US5245514A (en) | Extruded capacitor electrode and method of making the same | |

| JP4741044B2 (ja) | 電解コンデンサ用アノードおよび製造方法 | |

| US20070214857A1 (en) | Valve metal ribbon type fibers for solid electrolytic capacitors | |

| USRE47560E1 (en) | Method for manufacturing a high voltage tantalum anode | |

| WO2009082631A1 (en) | Methods for fabrication of improved electrolytic capacitor anode | |

| EP1618574B1 (en) | Sintered body electrode and solid electrolytic capacitor using the electrode | |

| US9633796B2 (en) | High voltage tantalum anode and method of manufacture | |

| US8673025B1 (en) | Wet electrolytic capacitor and method for fabricating of improved electrolytic capacitor cathode | |

| JP2018519621A (ja) | 改良型高容量再充電可能電池 | |

| EP3895832B1 (en) | Electrolytic capacitor and method for improved electrolytic capacitor anodes | |

| JP2008153589A (ja) | 固体電解コンデンサ | |

| JPH08162372A (ja) | 電解コンデンサの製造方法 | |

| KR20040054356A (ko) | 고용량 탄탈 고체 전해커패시터 및 그 제조방법 | |

| JP4653643B2 (ja) | 固体電解コンデンサ用素子、固体電解コンデンサおよびその製造方法 | |

| HK1016421B (en) | Extruded capacitor electrode and method of making the same | |

| JP2009141044A (ja) | 固体電解コンデンサ素子およびその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100921 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120423 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120508 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120801 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120808 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120907 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130326 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130424 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160502 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5259603 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |