JP5259290B2 - 容器加圧装置 - Google Patents

容器加圧装置 Download PDFInfo

- Publication number

- JP5259290B2 JP5259290B2 JP2008196094A JP2008196094A JP5259290B2 JP 5259290 B2 JP5259290 B2 JP 5259290B2 JP 2008196094 A JP2008196094 A JP 2008196094A JP 2008196094 A JP2008196094 A JP 2008196094A JP 5259290 B2 JP5259290 B2 JP 5259290B2

- Authority

- JP

- Japan

- Prior art keywords

- air supply

- container

- air

- chamber

- supply nozzle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Filling Of Jars Or Cans And Processes For Cleaning And Sealing Jars (AREA)

- Basic Packing Technique (AREA)

Description

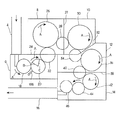

2c 容器の首部

2d 口部

54 支持部材(グリッパ)

62 給気ノズル(エア供給ノズル)

66 カム(昇降手段)

68 カムフォロア(昇降手段)

90 給気管(圧縮エア供給管)

94 ヒータ

106 結露防止手段(噴射ノズル)

Claims (6)

- 気体が供給される給気管と、この給気管から供給される気体を吹き出す給気ノズルとを備え、給気ノズルから樹脂製容器内に気体を吹き込んで容器内部を加圧する容器加圧装置において、

前記給気管および給気ノズルの結露を防止する結露防止手段を備えたことを特徴とする容器加圧装置。 - 前記結露防止手段として、前記給気管に供給される気体を加熱するヒータを設け、このヒータによって昇温させた気体を給気管へ供給し、給気ノズルから吹き出すことを特徴とする請求項1に記載の容器加圧装置。

- 前記給気ノズルに向けて無菌エアを吹き付ける噴射ノズルを設けたことを特徴とする請求項2に記載の容器加圧装置。

- 前記給気ノズルを加温する加温手段を設け、加温することで給気ノズルの結露を防止するようにしたことを特徴とする請求項1ないし請求項3のいずれかに記載の容器加圧装置。

- 前記ヒータによって昇温させた気体を、前記噴射ノズルから噴射することを特徴とする請求項3に記載の容器加圧装置。

- 前記給気管および給気ノズルを、内部雰囲気が外部よりも高温となるチャンバ内に設置して、チャンバ内で給気ノズルから樹脂製容器内に気体を吹き込んで容器内部を加圧することを特徴とする請求項1ないし請求項5のいずれかに記載の容器加圧装置。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008196094A JP5259290B2 (ja) | 2008-07-30 | 2008-07-30 | 容器加圧装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008196094A JP5259290B2 (ja) | 2008-07-30 | 2008-07-30 | 容器加圧装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010030645A JP2010030645A (ja) | 2010-02-12 |

| JP5259290B2 true JP5259290B2 (ja) | 2013-08-07 |

Family

ID=41735648

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008196094A Active JP5259290B2 (ja) | 2008-07-30 | 2008-07-30 | 容器加圧装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5259290B2 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3015417B1 (de) | 2014-10-29 | 2017-08-23 | INDAG Gesellschaft für Industriebedarf mbH & Co. Betriebs KG | Vorrichtung zum Einleiten eines Mediums in einen Behälter |

| JP6576076B2 (ja) * | 2015-03-31 | 2019-09-18 | 小林製薬株式会社 | 容器の製造方法 |

| JP6956495B2 (ja) * | 2017-02-28 | 2021-11-02 | サントリーホールディングス株式会社 | 充填方法及び充填設備 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0781926B2 (ja) * | 1985-09-27 | 1995-09-06 | 株式会社吉野工業所 | 合成樹脂製壜容器口筒の気密性検査方法及びその装置 |

| JPH068151B2 (ja) * | 1988-05-09 | 1994-02-02 | キッコーマン株式会社 | 変形プラスチックボトルの修正方法 |

| JPH06127530A (ja) * | 1992-10-19 | 1994-05-10 | Kunoole Shokuhin Kk | 軟質容器膨らまし整形装置 |

| JPH1111588A (ja) * | 1997-06-24 | 1999-01-19 | Lion Corp | 脆弱容器の充填前処理方法及びその装置 |

| JP3444174B2 (ja) * | 1998-01-21 | 2003-09-08 | 靜甲株式会社 | 容器処理装置 |

| JP2000326921A (ja) * | 1999-05-13 | 2000-11-28 | Hokkai Can Co Ltd | 不活性ガス充填装置 |

| JP2005082219A (ja) * | 2003-09-10 | 2005-03-31 | Nihon Tetra Pak Kk | 充填機 |

-

2008

- 2008-07-30 JP JP2008196094A patent/JP5259290B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010030645A (ja) | 2010-02-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10449708B2 (en) | Method and apparatus for sterilizing bottle | |

| CN104985797B (zh) | 饮料灌装方法及饮料灌装装置 | |

| US10137217B2 (en) | Method and apparatus for sterilizing preform | |

| CN105658526B (zh) | 饮料填充装置 | |

| CN112678278B (zh) | 无菌填充机以及无菌填充方法 | |

| JP2001507659A (ja) | ボトルを充填のために準備しかつボトルを充填するための方法および機械 | |

| CN110621609A (zh) | 无菌灌装机以及无菌灌装方法 | |

| CN113382951B (zh) | 容器杀菌装置、内容物填充系统、容器杀菌方法以及内容物填充方法 | |

| JP5259290B2 (ja) | 容器加圧装置 | |

| JP2020029310A (ja) | 炭酸飲料無菌充填システム | |

| WO2016175237A1 (ja) | 無菌容器の成形方法及び装置並びに無菌充填方法及び装置 | |

| JP6330876B2 (ja) | 無菌充填機及び無菌充填方法 | |

| JP6911964B2 (ja) | ボトルの殺菌方法及び装置 | |

| JP7428169B2 (ja) | 無菌充填機により密封された容器の洗浄方法及び無菌充填機 | |

| JP7193700B2 (ja) | 充填システムおよび充填方法 | |

| CN116615378A (zh) | 容器杀菌方法、容器杀菌装置及内容物填充系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110330 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20121227 Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20121227 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130108 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20121227 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130308 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130409 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130424 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160502 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5259290 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313117 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |