JP5154948B2 - コーティング流体パターンの画定方法 - Google Patents

コーティング流体パターンの画定方法 Download PDFInfo

- Publication number

- JP5154948B2 JP5154948B2 JP2007549378A JP2007549378A JP5154948B2 JP 5154948 B2 JP5154948 B2 JP 5154948B2 JP 2007549378 A JP2007549378 A JP 2007549378A JP 2007549378 A JP2007549378 A JP 2007549378A JP 5154948 B2 JP5154948 B2 JP 5154948B2

- Authority

- JP

- Japan

- Prior art keywords

- applicator roll

- coating fluid

- coating

- roll surface

- microspheres

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0839—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being unsupported at the line of contact between the coating roller and the work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/28—Processes for applying liquids or other fluent materials performed by transfer from the surfaces of elements carrying the liquid or other fluent material, e.g. brushes, pads, rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0817—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line characterised by means for removing partially liquid or other fluent material from the roller, e.g. scrapers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0826—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being a web or sheets

- B05C1/0834—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being a web or sheets the coating roller co-operating with other rollers, e.g. dosing, transfer rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/16—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length only at particular parts of the work

- B05C1/165—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length only at particular parts of the work using a roller or other rotating member which contacts the work along a generating line

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D3/00—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials

- B05D3/12—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials by mechanical means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D2252/00—Sheets

- B05D2252/02—Sheets of indefinite length

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D5/00—Processes for applying liquids or other fluent materials to surfaces to obtain special surface effects, finishes or structures

- B05D5/06—Processes for applying liquids or other fluent materials to surfaces to obtain special surface effects, finishes or structures to obtain multicolour or other optical effects

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/66—Coatings characterised by a special visual effect, e.g. patterned, textured

- D21H19/68—Coatings characterised by a special visual effect, e.g. patterned, textured uneven, broken, discontinuous

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H21/00—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties

- D21H21/50—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties characterised by form

- D21H21/52—Additives of definite length or shape

- D21H21/54—Additives of definite length or shape being spherical, e.g. microcapsules, beads

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H23/00—Processes or apparatus for adding material to the pulp or to the paper

- D21H23/02—Processes or apparatus for adding material to the pulp or to the paper characterised by the manner in which substances are added

- D21H23/22—Addition to the formed paper

- D21H23/52—Addition to the formed paper by contacting paper with a device carrying the material

- D21H23/56—Rolls

- D21H23/58—Details thereof, e.g. surface characteristics, peripheral speed

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Coating Apparatus (AREA)

- Manufacturing Of Printed Circuit Boards (AREA)

Description

Claims (2)

- 表面上にコーティング流体のパターンを形成する方法であって、

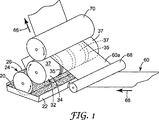

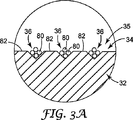

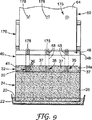

アプリケーターロール表面のトポグラフィーが、コーティング流体のミクロスフィアを少なくとも部分的に受け入れるように寸法設定された長手方向に延びる少なくとも1つの周方向らせん状溝部分と、長手方向に延びる少なくとも1つの周方向平滑表面部分とを含んでなる該アプリケーターロール表面に、該ミクロスフィアを含有する該コーティング流体を導入することと、

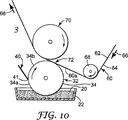

前記アプリケーターロール表面にドクターブレードを係合させて、前記アプリケーターロール表面の前記平滑表面部分から前記コーティング流体を除去するとともに、前記アプリケーターロール表面の前記らせん状溝部分により、該ドクターブレードを通過して前進する前記ミクロスフィアの量を制限し、前記ミクロスフィアを含有する前記コーティング流体のパターンを、該パターンが前記らせん状溝部分によって画定され、かつ前記ミクロスフィアを含有する前記コーティング流体の少なくとも1つのストライプを画定するべく該パターンが形成されるように、前記アプリケーターロール表面に残存させることと、

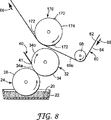

前記コーティング流体の前記パターンを、前記アプリケーターロール表面から、リバースキス方式で前記アプリケーターロール表面に係合する移動ウェブのコーティング面に転写することと、

を含む方法。 - コーティング面とその反対側の後面とを有する移動ウェブ上に、ミクロスフィアを含有するコーティング流体を塗布する方法であって、

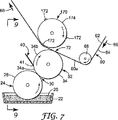

長手方向範囲を有する回転する供給ロール表面に、ミクロスフィアを含有するコーティング流体を塗布することと、

アプリケーターロール表面のトポグラフィーが、前記コーティング流体の前記ミクロスフィアを受け入れる形状を有する長手方向に延びる少なくとも1つの周方向らせん状溝部分と、長手方向に延びる少なくとも1つの周方向平滑表面部分とを含んでなる、長手方向範囲を有する回転する該アプリケーターロール表面に、前記コーティング流体を前記供給ロール表面から転写することと、

前記アプリケーターロール表面に直線状ドクターブレード縁を係合させて、前記アプリケーターロール表面の前記平滑表面部分から前記コーティング流体を除去するとともに、前記アプリケーターロール表面の前記らせん状溝部分により、該ドクターブレード縁を通過して前進する前記ミクロスフィアの量を制限し、前記ミクロスフィアを含有する前記コーティング流体のパターンを、該パターンが前記らせん状溝部分によって画定され、かつ前記ミクロスフィアを含有する前記コーティング流体の少なくとも1つのストライプを画定するべく該パターンが形成されるように、前記アプリケーターロール表面に残存させることと、

前記ミクロスフィアを含有する前記コーティング流体の前記ストライプを、前記アプリケーターロール表面から、リバースキス方式で前記アプリケーターロール表面に係合する移動ウェブのコーティング面に転写することと、

を含む方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/027,542 US7625605B2 (en) | 2004-12-30 | 2004-12-30 | Method for coating a surface with a pattern of coating fluid |

| US11/027,542 | 2004-12-30 | ||

| PCT/US2005/042946 WO2006073615A1 (en) | 2004-12-30 | 2005-11-29 | Method for defining a coating fluid pattern |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008526476A JP2008526476A (ja) | 2008-07-24 |

| JP2008526476A5 JP2008526476A5 (ja) | 2009-01-15 |

| JP5154948B2 true JP5154948B2 (ja) | 2013-02-27 |

Family

ID=36086903

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007549378A Expired - Fee Related JP5154948B2 (ja) | 2004-12-30 | 2005-11-29 | コーティング流体パターンの画定方法 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7625605B2 (ja) |

| EP (1) | EP1830969B1 (ja) |

| JP (1) | JP5154948B2 (ja) |

| KR (1) | KR101251680B1 (ja) |

| CN (1) | CN101094730B (ja) |

| AT (1) | ATE466666T1 (ja) |

| DE (1) | DE602005021154D1 (ja) |

| WO (1) | WO2006073615A1 (ja) |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007039949B3 (de) * | 2007-08-23 | 2008-12-04 | Flooring Technologies Ltd. | Vorrichtung zum Auftragen einer Suspension auf eine Trägerplatte |

| US7925192B2 (en) * | 2007-09-04 | 2011-04-12 | Ricoh Company, Ltd. | Developing roller, developing device, process cartridge, and image forming apparatus |

| CN101503869B (zh) * | 2008-02-05 | 2010-12-15 | 伟盟工业股份有限公司 | 生物可分解防水复合纸及其制造方法 |

| JP5347527B2 (ja) * | 2008-05-23 | 2013-11-20 | 株式会社リコー | 画像形成装置、泡塗布装置 |

| JP4820427B2 (ja) * | 2009-03-25 | 2011-11-24 | 富士機械工業株式会社 | 塗工装置 |

| US8728950B2 (en) * | 2009-06-18 | 2014-05-20 | Konica Minolta Holdings, Inc. | Coating method, and organic electroluminescence element |

| CN101722128B (zh) * | 2009-11-27 | 2011-12-21 | 东莞市华立实业股份有限公司 | 新型平板封边条背涂处理设备 |

| JP5596721B2 (ja) * | 2012-02-23 | 2014-09-24 | 尾池工業株式会社 | 導電性高分子樹脂フィルムの製造方法 |

| US9248054B2 (en) | 2012-11-27 | 2016-02-02 | The Procter & Gamble Company | Methods and apparatus for making elastic laminates |

| US9295590B2 (en) | 2012-11-27 | 2016-03-29 | The Procter & Gamble Company | Method and apparatus for applying an elastic material to a moving substrate in a curved path |

| US9265672B2 (en) | 2012-11-27 | 2016-02-23 | The Procter & Gamble Company | Methods and apparatus for applying adhesives in patterns to an advancing substrate |

| CN103143476B (zh) * | 2013-03-07 | 2016-03-02 | 金红叶纸业集团有限公司 | 涂布装置及涂布方法 |

| JP5971157B2 (ja) * | 2013-03-11 | 2016-08-17 | Jfeスチール株式会社 | 塗布装置および塗布方法 |

| IN2013MU01209A (ja) * | 2013-03-28 | 2015-04-10 | Tata Consultancy Services Ltd | |

| GB2531035A (en) * | 2014-10-08 | 2016-04-13 | British American Tobacco Investments Ltd | Adhesive transfer system |

| GB201509080D0 (en) | 2015-05-27 | 2015-07-08 | Landa Labs 2012 Ltd | Coating apparatus |

| SE539739C2 (en) * | 2015-09-17 | 2017-11-14 | Ikea Supply Ag | A method of and a selective strip coating apparatus for applying a coating to one face of a selected first sub-group of parallel strips |

| HUE071236T2 (hu) * | 2016-07-08 | 2025-08-28 | Lucart Spa | Papíranyag, berendezés és eljárás annak elõállítására |

| CN106216164A (zh) * | 2016-08-29 | 2016-12-14 | 贵州苗仁堂制药有限责任公司 | 一种涂布辊 |

| CN106216165A (zh) * | 2016-08-29 | 2016-12-14 | 贵州苗仁堂制药有限责任公司 | 巴布膏涂布成型机 |

| MX2019005656A (es) * | 2016-11-16 | 2019-07-04 | Essity Hygiene & Health Ab | Aparato y metodo para revestimiento de una trama de substrato absorbente. |

| CN107287567B (zh) * | 2017-07-11 | 2019-09-27 | 成都天府新区河川科技有限公司 | 微滴离子溅射工艺以及水轮机制备方法 |

| US11707548B2 (en) | 2018-10-09 | 2023-07-25 | The Procter & Gamble Company | Absorbent article comprising a lotion resistant polymeric filler composition |

| AU2019425686B2 (en) * | 2019-01-31 | 2025-03-27 | Dow Global Technologies Llc | Paint roller cover for multicolor paint, method of uniformly applying multicolor paint and method of quantifying uniformity of paint application |

| DE102019106642A1 (de) * | 2019-03-15 | 2020-09-17 | Homag Gmbh | Vorrichtung zum Abtragen von Schmelzklebstoff |

| CN111546699A (zh) * | 2020-04-26 | 2020-08-18 | 佛山市达肯包装机械有限公司 | 一种纸筒袋制筒机的纵向条胶机构 |

| CN112642641A (zh) * | 2020-12-28 | 2021-04-13 | 南京万博鼎成新材料科技有限公司 | 一种平板涂装留边装置 |

| WO2023057796A1 (en) * | 2021-10-07 | 2023-04-13 | Arcelormittal | Process and apparatus for manufacturing a steel strip for electrical applications |

| CN115946447A (zh) * | 2022-12-28 | 2023-04-11 | 汕头市远生实业有限公司 | 一种节能快干的上光油结构 |

| CN119702329B (zh) * | 2024-12-31 | 2025-11-11 | 浙江墙煌新材料有限公司 | 一种耐色光金属彩涂板及其辊涂加工系统 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3552353A (en) * | 1966-12-05 | 1971-01-05 | Raymond A Labombarde | Apparatus for applying high viscosity coatings |

| US3691140A (en) * | 1970-03-09 | 1972-09-12 | Spencer Ferguson Silver | Acrylate copolymer microspheres |

| GB1337345A (en) * | 1970-11-30 | 1973-11-14 | Fuji Photo Film Co Ltd | Producing capsule-coated sheets |

| US3857731A (en) * | 1973-04-06 | 1974-12-31 | Minnesota Mining & Mfg | Acrylate microsphere-surfaced sheet material |

| US4268597A (en) * | 1976-04-13 | 1981-05-19 | Philip A. Hunt Chemical Corp. | Method, apparatus and compositions for liquid development of electrostatic images |

| US4166152B1 (en) * | 1977-08-17 | 1999-05-18 | Minnesota Mining & Mfg | Tacky polymeric microspheres |

| EP0031646B1 (en) * | 1979-12-11 | 1984-10-24 | Crosfield Electronics Limited | Correction of gravure printing members |

| US4404243A (en) * | 1982-08-03 | 1983-09-13 | Reeves Bros., Inc. | Latent pressure-sensitive sheet material and method of making same using solvent-based pressure-sensitive adhesive |

| US4468418A (en) * | 1983-02-07 | 1984-08-28 | The Louis G. Freeman Company | Process for applying thermoplastic adhesive to flexible die-cut parts |

| US4495318A (en) * | 1984-03-21 | 1985-01-22 | International Cube Corporation | Low tack microsphere glue |

| US4839416A (en) * | 1987-06-09 | 1989-06-13 | Ampad Corporation | Low tack microsphere adhesive |

| US5045569A (en) * | 1988-11-30 | 1991-09-03 | Minnesota Mining And Manufacturing Company | Hollow acrylate polymer microspheres |

| JPH0312267A (ja) * | 1989-06-09 | 1991-01-21 | Nordson Kk | ホットメルト型粘着剤のパターンコーティング法 |

| US5340611A (en) * | 1989-07-25 | 1994-08-23 | J. M. Voith Gmbh | Process for coating travelling webs |

| DE3927365A1 (de) | 1989-08-19 | 1991-02-21 | Hans Amoser | Auftragswerk zum auftragen von beschichtungen |

| JP2616999B2 (ja) * | 1989-09-01 | 1997-06-04 | ユニ・チャーム株式会社 | 着用物品 |

| DE4029896A1 (de) * | 1989-12-02 | 1991-06-06 | Beiersdorf Ag | Traegerloses beidseitig klebendes selbstklebeband |

| US5571617A (en) * | 1993-04-23 | 1996-11-05 | Minnesota Mining And Manufacturing Company | Pressure sensitive adhesive comprising tacky surface active microspheres |

| US5868838A (en) * | 1994-08-17 | 1999-02-09 | Minnesota Mining & Manufacturing Company | Apparatus and method for applying coating materials to individual sheet members |

| US5447747A (en) * | 1994-08-22 | 1995-09-05 | Minnesota Mining And Manufacturing Company | Method and apparatus for smoothing gravure coatings in the manufacture of magnetic recording tape |

| DE19511050A1 (de) * | 1995-03-25 | 1996-09-26 | Voith Sulzer Papiermasch Gmbh | Verfahren und Vorrichtung zur Herstellung einer eine CF-Schicht aufweisenden Papierbahn |

| JPH11511377A (ja) | 1995-08-31 | 1999-10-05 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 送出ロール付リバースグラビアキスコーティング装置 |

| US5714237A (en) * | 1996-01-16 | 1998-02-03 | Minnesota Mining Manufacturing Company | Partially crosslinked microspheres |

| US5824748A (en) * | 1996-06-03 | 1998-10-20 | Minnesota Mining And Manufacturing Company | Composite pressure sensitive adhesive microspheres |

| US5756625A (en) * | 1996-10-11 | 1998-05-26 | Minnesota Mining And Manufacturing Company | Stabilized adhesive microspheres |

| JP3070565B2 (ja) * | 1998-01-21 | 2000-07-31 | 松下電器産業株式会社 | 塗布方法 |

| US6531027B1 (en) * | 1998-08-03 | 2003-03-11 | The Procter & Gamble Company | Adhesive printing process for disposable absorbent articles |

| US6296932B1 (en) * | 1998-12-14 | 2001-10-02 | 3M Innovative Properties Company | Microsphere adhesive coated article for use with coated papers |

| US6692819B1 (en) * | 1999-01-07 | 2004-02-17 | The Standard Register Company | Method of transparentizing a cellulose substrate |

| EP1262243B1 (en) * | 2001-06-02 | 2010-02-24 | The Procter & Gamble Company | Improved process for printing actives onto articles |

| US20030109630A1 (en) * | 2001-10-23 | 2003-06-12 | Smith Dawn E. | Microsphere adhesive formulations |

-

2004

- 2004-12-30 US US11/027,542 patent/US7625605B2/en not_active Expired - Fee Related

-

2005

- 2005-11-29 DE DE602005021154T patent/DE602005021154D1/de not_active Expired - Lifetime

- 2005-11-29 WO PCT/US2005/042946 patent/WO2006073615A1/en not_active Ceased

- 2005-11-29 JP JP2007549378A patent/JP5154948B2/ja not_active Expired - Fee Related

- 2005-11-29 EP EP05825813A patent/EP1830969B1/en not_active Expired - Lifetime

- 2005-11-29 AT AT05825813T patent/ATE466666T1/de not_active IP Right Cessation

- 2005-11-29 CN CN2005800456615A patent/CN101094730B/zh not_active Expired - Fee Related

- 2005-11-29 KR KR1020077017367A patent/KR101251680B1/ko not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008526476A (ja) | 2008-07-24 |

| DE602005021154D1 (de) | 2010-06-17 |

| EP1830969A1 (en) | 2007-09-12 |

| ATE466666T1 (de) | 2010-05-15 |

| US20060147637A1 (en) | 2006-07-06 |

| EP1830969B1 (en) | 2010-05-05 |

| KR20070097554A (ko) | 2007-10-04 |

| KR101251680B1 (ko) | 2013-04-05 |

| US7625605B2 (en) | 2009-12-01 |

| CN101094730A (zh) | 2007-12-26 |

| CN101094730B (zh) | 2011-12-28 |

| WO2006073615A1 (en) | 2006-07-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5154948B2 (ja) | コーティング流体パターンの画定方法 | |

| US20060147636A1 (en) | Method and apparatus of forming a coating fluid pattern | |

| EP0453427B1 (en) | Method for limitation of the width of coating in coating of paper or board and a device intended for carrying out the method | |

| CN106794484B (zh) | 浆液涂覆装置以及浆液涂覆方法 | |

| US3627564A (en) | Method for coating a continuous web | |

| US7144478B1 (en) | Pollution control method for cylindrical dryer used in paper machine | |

| JP2693441B2 (ja) | 被覆装置 | |

| EP0839584A2 (en) | Improved apparatus and method for applying a viscous liquid to a material surface | |

| NL8000747A (nl) | Rol voor het overbrengen van een fluidum, en werkwijze voor het vervaardigen daarvan. | |

| JP2005111299A (ja) | 塗工用ロッド及びその製造方法 | |

| EP1108538B1 (en) | Apparatus for coating a web | |

| JP4093330B2 (ja) | 帯状材料の連続塗装方法及び装置 | |

| CN206688959U (zh) | 一种可消除板材辊印的辊涂机 | |

| KR20010075378A (ko) | 초지기에 사용되는 원통상 드라이어의 오염방지방법 | |

| JPH0427462A (ja) | 塗布方法及び塗布装置 | |

| JPH073698A (ja) | 繊維性材料ウエブ上にカラー塗料を塗布する装置及びその方法 | |

| JP2003190855A (ja) | グラビア塗布装置 | |

| JP2000126673A (ja) | 塗布方法 | |

| JP2003170112A (ja) | 塗布方法及び装置 | |

| GB1600616A (en) | Coating sheet material with liquids | |

| JP4531924B2 (ja) | 穴開き薄板への粘性液の塗布方法およびその装置 | |

| JP2000102757A (ja) | コーター装置及びストライプ状塗膜の製造方法 | |

| RU2254937C2 (ru) | Способ и устройство для непрямого нанесения тонкослойного покрытия | |

| JPH0531439A (ja) | 塗布方法 | |

| JPH02293068A (ja) | 塗工装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081120 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081120 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110725 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110802 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20111101 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20111109 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120202 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20121106 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121206 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151214 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5154948 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |