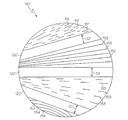

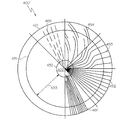

JP5089073B2 - 半径方向の偏った研磨パッド - Google Patents

半径方向の偏った研磨パッド Download PDFInfo

- Publication number

- JP5089073B2 JP5089073B2 JP2006109276A JP2006109276A JP5089073B2 JP 5089073 B2 JP5089073 B2 JP 5089073B2 JP 2006109276 A JP2006109276 A JP 2006109276A JP 2006109276 A JP2006109276 A JP 2006109276A JP 5089073 B2 JP5089073 B2 JP 5089073B2

- Authority

- JP

- Japan

- Prior art keywords

- polishing

- radial

- groove

- polishing pad

- microchannels

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/26—Lapping pads for working plane surfaces characterised by the shape of the lapping pad surface, e.g. grooved

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/18—Paper- or board-based structures for surface covering

- D21H27/20—Flexible structures being applied by the user, e.g. wallpaper

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/001—Release paper

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/30—Multi-ply

- D21H27/32—Multi-ply with materials applied between the sheets

- D21H27/34—Continuous materials, e.g. filaments, sheets, nets

- D21H27/36—Films made from synthetic macromolecular compounds

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Grinding-Machine Dressing And Accessory Apparatuses (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US67046605P | 2005-04-12 | 2005-04-12 | |

| US60/670,466 | 2005-04-12 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006289605A JP2006289605A (ja) | 2006-10-26 |

| JP2006289605A5 JP2006289605A5 (enExample) | 2009-05-07 |

| JP5089073B2 true JP5089073B2 (ja) | 2012-12-05 |

Family

ID=37054983

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006109276A Active JP5089073B2 (ja) | 2005-04-12 | 2006-04-12 | 半径方向の偏った研磨パッド |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7255633B2 (enExample) |

| JP (1) | JP5089073B2 (enExample) |

| KR (1) | KR101279819B1 (enExample) |

| CN (1) | CN100515685C (enExample) |

| DE (1) | DE102006016312B4 (enExample) |

| FR (1) | FR2884164B1 (enExample) |

| TW (1) | TWI372093B (enExample) |

Families Citing this family (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020068516A1 (en) * | 1999-12-13 | 2002-06-06 | Applied Materials, Inc | Apparatus and method for controlled delivery of slurry to a region of a polishing device |

| USD559066S1 (en) * | 2004-10-26 | 2008-01-08 | Jsr Corporation | Polishing pad |

| JP2008062367A (ja) * | 2006-09-11 | 2008-03-21 | Nec Electronics Corp | 研磨装置、研磨パッド、研磨方法 |

| TWI455795B (zh) * | 2007-10-18 | 2014-10-11 | Iv Technologies Co Ltd | 研磨墊及研磨方法 |

| US7927092B2 (en) * | 2007-12-31 | 2011-04-19 | Corning Incorporated | Apparatus for forming a slurry polishing pad |

| US9180570B2 (en) | 2008-03-14 | 2015-11-10 | Nexplanar Corporation | Grooved CMP pad |

| US9117870B2 (en) * | 2008-03-27 | 2015-08-25 | Lam Research Corporation | High throughput cleaner chamber |

| WO2009139401A1 (ja) * | 2008-05-16 | 2009-11-19 | 東レ株式会社 | 研磨パッド |

| TWI449597B (zh) * | 2008-07-09 | 2014-08-21 | Iv Technologies Co Ltd | 研磨墊及其製造方法 |

| TWI535527B (zh) * | 2009-07-20 | 2016-06-01 | 智勝科技股份有限公司 | 研磨方法、研磨墊與研磨系統 |

| JP5544124B2 (ja) * | 2009-08-18 | 2014-07-09 | 富士紡ホールディングス株式会社 | 研磨パッド |

| US8562272B2 (en) | 2010-02-16 | 2013-10-22 | Lam Research Corporation | Substrate load and unload mechanisms for high throughput |

| US8893642B2 (en) | 2010-03-24 | 2014-11-25 | Lam Research Corporation | Airflow management for low particulate count in a process tool |

| US8282698B2 (en) * | 2010-03-24 | 2012-10-09 | Lam Research Corporation | Reduction of particle contamination produced by moving mechanisms in a process tool |

| JP5839163B2 (ja) * | 2010-07-12 | 2016-01-06 | Jsr株式会社 | 化学機械研磨パッドおよび化学機械研磨方法 |

| US20140054266A1 (en) * | 2012-08-24 | 2014-02-27 | Wiechang Jin | Compositions and methods for selective polishing of platinum and ruthenium materials |

| US9522454B2 (en) * | 2012-12-17 | 2016-12-20 | Seagate Technology Llc | Method of patterning a lapping plate, and patterned lapping plates |

| WO2016106020A1 (en) * | 2014-12-22 | 2016-06-30 | 3M Innovative Properties Company | Abrasive articles with removable abrasive member and methods of separating and replacing thereof |

| US10875146B2 (en) * | 2016-03-24 | 2020-12-29 | Rohm And Haas Electronic Materials Cmp Holdings | Debris-removal groove for CMP polishing pad |

| WO2017165216A1 (en) * | 2016-03-24 | 2017-09-28 | Applied Materials, Inc. | Textured small pad for chemical mechanical polishing |

| US10625393B2 (en) | 2017-06-08 | 2020-04-21 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Chemical mechanical polishing pads having offset circumferential grooves for improved removal rate and polishing uniformity |

| US10861702B2 (en) | 2017-06-14 | 2020-12-08 | Rohm And Haas Electronic Materials Cmp Holdings | Controlled residence CMP polishing method |

| US10857648B2 (en) | 2017-06-14 | 2020-12-08 | Rohm And Haas Electronic Materials Cmp Holdings | Trapezoidal CMP groove pattern |

| US10586708B2 (en) | 2017-06-14 | 2020-03-10 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Uniform CMP polishing method |

| US10857647B2 (en) | 2017-06-14 | 2020-12-08 | Rohm And Haas Electronic Materials Cmp Holdings | High-rate CMP polishing method |

| US10777418B2 (en) * | 2017-06-14 | 2020-09-15 | Rohm And Haas Electronic Materials Cmp Holdings, I | Biased pulse CMP groove pattern |

| US10654146B2 (en) | 2018-01-23 | 2020-05-19 | Seagate Technology Llc | One or more charging members used in the manufacture of a lapping plate, and related apparatuses and methods of making |

| CN110039380B (zh) * | 2019-04-11 | 2020-12-01 | 上海理工大学 | 一种用于周期性微沟槽结构抛光的磁性复合流体抛光装置 |

| CN112720282B (zh) * | 2020-12-31 | 2022-04-08 | 湖北鼎汇微电子材料有限公司 | 一种抛光垫 |

| EP4382250A4 (en) * | 2021-08-04 | 2025-06-11 | Kuraray Co., Ltd. | POLISHING CUSHION |

| CN114770371B (zh) * | 2022-03-10 | 2023-08-25 | 宁波赢伟泰科新材料有限公司 | 一种高抛光液使用效率的抛光垫 |

| CN114918824B (zh) * | 2022-06-29 | 2024-08-20 | 万华化学集团电子材料有限公司 | 一种具有径向微沟槽的抛光垫 |

| US20240139906A1 (en) * | 2022-10-27 | 2024-05-02 | Applied Materials, Inc. | Control of carrier head sweep and platen shape |

| WO2024257742A1 (ja) * | 2023-06-12 | 2024-12-19 | 株式会社クラレ | 研磨パッド、研磨方法及び半導体の製造方法 |

| CN117325088A (zh) * | 2023-09-20 | 2024-01-02 | 咸宁南玻光电玻璃有限公司 | 抛光海绵、抛光设备及玻璃抛光方法 |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5081051A (en) * | 1990-09-12 | 1992-01-14 | Intel Corporation | Method for conditioning the surface of a polishing pad |

| US5216843A (en) * | 1992-09-24 | 1993-06-08 | Intel Corporation | Polishing pad conditioning apparatus for wafer planarization process |

| US5456627A (en) | 1993-12-20 | 1995-10-10 | Westech Systems, Inc. | Conditioner for a polishing pad and method therefor |

| US5785585A (en) * | 1995-09-18 | 1998-07-28 | International Business Machines Corporation | Polish pad conditioner with radial compensation |

| US5611943A (en) * | 1995-09-29 | 1997-03-18 | Intel Corporation | Method and apparatus for conditioning of chemical-mechanical polishing pads |

| JP3042593B2 (ja) * | 1995-10-25 | 2000-05-15 | 日本電気株式会社 | 研磨パッド |

| US5938507A (en) | 1995-10-27 | 1999-08-17 | Applied Materials, Inc. | Linear conditioner apparatus for a chemical mechanical polishing system |

| US5645469A (en) * | 1996-09-06 | 1997-07-08 | Advanced Micro Devices, Inc. | Polishing pad with radially extending tapered channels |

| US5885147A (en) * | 1997-05-12 | 1999-03-23 | Integrated Process Equipment Corp. | Apparatus for conditioning polishing pads |

| US5916010A (en) * | 1997-10-30 | 1999-06-29 | International Business Machines Corporation | CMP pad maintenance apparatus and method |

| US6027659A (en) * | 1997-12-03 | 2000-02-22 | Intel Corporation | Polishing pad conditioning surface having integral conditioning points |

| JP2001001253A (ja) * | 1999-06-21 | 2001-01-09 | Toray Ind Inc | 研磨布 |

| US6306008B1 (en) * | 1999-08-31 | 2001-10-23 | Micron Technology, Inc. | Apparatus and method for conditioning and monitoring media used for chemical-mechanical planarization |

| US6626743B1 (en) * | 2000-03-31 | 2003-09-30 | Lam Research Corporation | Method and apparatus for conditioning a polishing pad |

| WO2001091969A2 (en) | 2000-05-31 | 2001-12-06 | Philips Semiconductors, Inc. | Polishing methods and apparatus for semiconductor and integrated circuit manufacture |

| JP2002100592A (ja) * | 2000-09-20 | 2002-04-05 | Rodel Nitta Co | 研磨パッド |

| US6767427B2 (en) * | 2001-06-07 | 2004-07-27 | Lam Research Corporation | Apparatus and method for conditioning polishing pad in a chemical mechanical planarization process |

| JP2003145413A (ja) * | 2001-10-31 | 2003-05-20 | Applied Materials Inc | 研磨パッド |

| JP2003303793A (ja) * | 2002-04-12 | 2003-10-24 | Hitachi Ltd | 研磨装置および半導体装置の製造方法 |

| JP2004167605A (ja) * | 2002-11-15 | 2004-06-17 | Rodel Nitta Co | 研磨パッドおよび研磨装置 |

| US6976907B2 (en) * | 2003-01-10 | 2005-12-20 | Intel Corporation | Polishing pad conditioning |

| JPWO2005023487A1 (ja) * | 2003-08-29 | 2007-10-04 | 東邦エンジニアリング株式会社 | 研磨パッドおよびその製造方法と製造装置 |

| US7591713B2 (en) * | 2003-09-26 | 2009-09-22 | Shin-Etsu Handotai Co., Ltd. | Polishing pad, method for processing polishing pad, and method for producing substrate using it |

| US6843711B1 (en) * | 2003-12-11 | 2005-01-18 | Rohm And Haas Electronic Materials Cmp Holdings, Inc | Chemical mechanical polishing pad having a process-dependent groove configuration |

-

2006

- 2006-03-17 KR KR1020060025061A patent/KR101279819B1/ko active Active

- 2006-03-29 US US11/392,373 patent/US7255633B2/en active Active

- 2006-04-06 DE DE102006016312.5A patent/DE102006016312B4/de not_active Expired - Fee Related

- 2006-04-10 TW TW095112634A patent/TWI372093B/zh active

- 2006-04-11 CN CNB2006100747763A patent/CN100515685C/zh not_active Expired - Fee Related

- 2006-04-11 FR FR0651303A patent/FR2884164B1/fr not_active Expired - Fee Related

- 2006-04-12 JP JP2006109276A patent/JP5089073B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US7255633B2 (en) | 2007-08-14 |

| JP2006289605A (ja) | 2006-10-26 |

| KR20060108211A (ko) | 2006-10-17 |

| CN1846940A (zh) | 2006-10-18 |

| TW200642797A (en) | 2006-12-16 |

| KR101279819B1 (ko) | 2013-06-28 |

| CN100515685C (zh) | 2009-07-22 |

| US20060229002A1 (en) | 2006-10-12 |

| DE102006016312A1 (de) | 2006-10-19 |

| FR2884164B1 (fr) | 2014-04-11 |

| TWI372093B (en) | 2012-09-11 |

| DE102006016312B4 (de) | 2018-10-31 |

| FR2884164A1 (fr) | 2006-10-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5089073B2 (ja) | 半径方向の偏った研磨パッド | |

| KR101507611B1 (ko) | 화학적 기계적 연마를 위한 상호침투 망상조직 | |

| TWI788070B (zh) | 拋光物和用於製造化學機械拋光物的整合系統 | |

| EP1502703B1 (en) | Porous polyurethane polishing pads | |

| JP3072526B2 (ja) | 研磨パッドおよびその使用方法 | |

| KR101539462B1 (ko) | 화학적 기계적 연마를 위한 적층된-필라멘트 격자 | |

| US6354915B1 (en) | Polishing pads and methods relating thereto | |

| US7458885B1 (en) | Chemical mechanical polishing pad and methods of making and using same | |

| KR101601281B1 (ko) | 고속 연마 방법 | |

| US20070173187A1 (en) | Chemical mechanical polishing pad with micro-holes | |

| JP2004501789A (ja) | 溝付き研磨パッドおよび使用方法 | |

| US20220226963A1 (en) | Chemical mechanical planarization tools, and related pads for chemical mechanical planarization tools | |

| KR20070082575A (ko) | 화학 기계적 연마를 위한 3차원 네트워크 | |

| JP2007180550A (ja) | 改善された欠陥品率を有する多層研磨パッド及びその製造方法 | |

| US7226345B1 (en) | CMP pad with designed surface features | |

| JP2647046B2 (ja) | 研磨布および研磨方法 | |

| KR100500803B1 (ko) | 워크피스 연마 패드 및 워크피스 표면의 연마 방법 | |

| CN118123702A (zh) | 微层cmp抛光子垫 | |

| CN118123703A (zh) | 双层cmp抛光子垫 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090325 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090325 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110920 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20111219 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20111222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120605 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120809 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120828 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120911 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150921 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5089073 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |