JP4790900B2 - 掛け外し可能でかつ自動的に再位置決めするプッシャを備えるコンベヤ - Google Patents

掛け外し可能でかつ自動的に再位置決めするプッシャを備えるコンベヤ Download PDFInfo

- Publication number

- JP4790900B2 JP4790900B2 JP2000287148A JP2000287148A JP4790900B2 JP 4790900 B2 JP4790900 B2 JP 4790900B2 JP 2000287148 A JP2000287148 A JP 2000287148A JP 2000287148 A JP2000287148 A JP 2000287148A JP 4790900 B2 JP4790900 B2 JP 4790900B2

- Authority

- JP

- Japan

- Prior art keywords

- pusher

- conveyor

- lever

- drive chain

- carrying element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000007493 shaping process Methods 0.000 claims description 11

- 238000000465 moulding Methods 0.000 claims description 9

- 230000000712 assembly Effects 0.000 abstract 1

- 238000000429 assembly Methods 0.000 abstract 1

- 238000000034 method Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

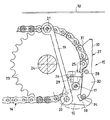

- B65G19/00—Conveyors comprising an impeller or a series of impellers carried by an endless traction element and arranged to move articles or materials over a supporting surface or underlying material, e.g. endless scraper conveyors

- B65G19/18—Details

- B65G19/22—Impellers, e.g. push-plates, scrapers; Guiding means therefor

- B65G19/24—Attachment of impellers to traction element

- B65G19/26—Attachment of impellers to traction element pivotal

- B65G19/265—Attachment of impellers to traction element pivotal for article conveyors, e.g. for container conveyors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2404/00—Parts for transporting or guiding the handled material

- B65H2404/30—Chains

- B65H2404/31—Chains with auxiliary handling means

- B65H2404/311—Blades, lugs, plates, paddles, fingers

Landscapes

- Mechanical Engineering (AREA)

- Engineering & Computer Science (AREA)

- Pusher Or Impeller Conveyors (AREA)

- Attitude Control For Articles On Conveyors (AREA)

- Paper (AREA)

- Special Conveying (AREA)

- Discharge Of Articles From Conveyors (AREA)

- Control And Other Processes For Unpacking Of Materials (AREA)

- Looms (AREA)

- Automatic Assembly (AREA)

- Insulated Conductors (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Advancing Webs (AREA)

- Feeding Of Articles By Means Other Than Belts Or Rollers (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT99A001961 | 1999-09-22 | ||

| ITMI99A001961 | 1999-09-22 | ||

| IT1999MI001961A IT1313365B1 (it) | 1999-09-22 | 1999-09-22 | Trasportatore a spintori ribaltabili a riposizionamento automatico |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2001146313A JP2001146313A (ja) | 2001-05-29 |

| JP2001146313A5 JP2001146313A5 (enExample) | 2007-09-20 |

| JP4790900B2 true JP4790900B2 (ja) | 2011-10-12 |

Family

ID=11383633

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000287148A Expired - Fee Related JP4790900B2 (ja) | 1999-09-22 | 2000-09-21 | 掛け外し可能でかつ自動的に再位置決めするプッシャを備えるコンベヤ |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US6378693B1 (enExample) |

| EP (1) | EP1086911B1 (enExample) |

| JP (1) | JP4790900B2 (enExample) |

| AT (1) | ATE265973T1 (enExample) |

| DE (1) | DE60010393T2 (enExample) |

| DK (1) | DK1086911T3 (enExample) |

| ES (1) | ES2220338T3 (enExample) |

| IT (1) | IT1313365B1 (enExample) |

| PT (1) | PT1086911E (enExample) |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1116676B1 (fr) * | 1999-12-29 | 2007-11-14 | Aries Packaging | Installation pour la constitution de lots d'articles |

| US6536582B1 (en) * | 2001-09-13 | 2003-03-25 | John Andrew Combs | Reversible shelf vertical conveyor |

| WO2004037647A2 (en) * | 2002-10-25 | 2004-05-06 | Kliklok Corporation | Carton feeding and forming machine with selectively actuated lugs and related methods |

| US7431147B2 (en) * | 2002-10-25 | 2008-10-07 | Kliklok Corporation | Carton feeding and forming machine with selectively actuated diverter and related methods |

| US20100200371A1 (en) * | 2002-10-25 | 2010-08-12 | Urs Reuteler | Conveyor with selectively actuated lugs and related methods |

| US7565964B2 (en) * | 2002-10-25 | 2009-07-28 | Kliklok Corporation | Random carton feeding and forming machine with selectively actuated lugs and related methods |

| EP1473174B1 (en) * | 2003-04-14 | 2013-09-18 | Bell and Howell, LLC | Envelope insert conveyor assembly |

| DE20308865U1 (de) * | 2003-06-06 | 2003-09-04 | Pfankuch Maschinen GmbH, 22926 Ahrensburg | Mitnehmer, insbesondere zur Verwendung in Zusammentrag- und Verpackungsmaschinen |

| DE202005002796U1 (de) * | 2005-02-22 | 2006-05-11 | Brückner Maschinenbau GmbH | Antriebssystem |

| US7731018B2 (en) * | 2005-03-08 | 2010-06-08 | Goss International Americas, Inc | Rotary gatherer with collapsible pins |

| DE102005016119A1 (de) * | 2005-04-08 | 2006-10-12 | Robert Bosch Gmbh | Zuführvorrichtung einer Verpackungsmaschine |

| US20090050449A1 (en) * | 2007-08-21 | 2009-02-26 | Ammeraal Beltech B.V. | Conveying system |

| US7779992B2 (en) * | 2007-12-20 | 2010-08-24 | Pflow Industries, Inc. | Shopping cart conveyor system with pivoting lug |

| US7931136B2 (en) * | 2008-03-31 | 2011-04-26 | Pflow Industries, Inc. | Jam sensor for shopping cart conveyor |

| US7954631B1 (en) * | 2008-09-23 | 2011-06-07 | Weaverline, LLC | Chain link conveyor for use in material handling equipment |

| FR2937897B1 (fr) * | 2008-11-03 | 2010-11-12 | Rapidex Sm | Dispositif d'equerrage pour une ligne de faconnage d'emballages |

| JP5597010B2 (ja) * | 2010-03-31 | 2014-10-01 | アンリツ産機システム株式会社 | バケットコンベア |

| EP2479122A1 (de) | 2011-01-24 | 2012-07-25 | Müller Martini Holding AG | Fördervorrichtung für Druckprodukte und Verfahren zum Verschwenken von Mitnehmern der Fördervorrichtung |

| DE102011075178A1 (de) * | 2011-05-03 | 2012-11-08 | Robert Bosch Gmbh | Elektromagnetisches Transfersystem |

| CH710023A1 (de) * | 2014-08-27 | 2016-02-29 | Ferag Ag | Förderanlage für den Transport von Gegenständen, insbesondere Waren, entlang einer vorgegebenen Strecke. |

| US9376091B2 (en) * | 2014-11-06 | 2016-06-28 | G. Thomas Ennis | Conveyor system |

| CN106081489A (zh) * | 2016-08-02 | 2016-11-09 | 河南省矿山起重机有限公司 | 一种单梁起重机行走轮加工装置的上料机构 |

| CN108116838A (zh) * | 2017-11-05 | 2018-06-05 | 安徽康乐机械科技有限公司 | 刮板输送机 |

| CN107852955B (zh) * | 2017-11-14 | 2020-12-15 | 六安栀子农业科技有限公司 | 一种无花果采摘运输装置 |

| KR102131509B1 (ko) * | 2018-09-27 | 2020-07-07 | 주식회사 포스코 | 판 적치용 받침부재 공급장치 및 이를 이용한 철판 적치방법 |

| CN113104508B (zh) * | 2021-05-07 | 2023-10-27 | 王立炜 | 一种包装机械的送料装置 |

| CN115465689B (zh) * | 2022-08-12 | 2025-02-25 | 科捷智能科技股份有限公司 | 容器自动装车装置 |

| ES2994370B2 (es) * | 2023-07-17 | 2025-09-25 | Boix Maquinaria Spain Slu | Sistema de arrastre de una lámina de cartón en una máquina formadora de cajas |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3232414A (en) * | 1963-03-29 | 1966-02-01 | Continental Can Co | Accelerating feed mechanism |

| US3876062A (en) * | 1973-08-27 | 1975-04-08 | Tokyo Automatic Mach Works | Pusher reversing mechanism |

| US4004680A (en) * | 1975-09-22 | 1977-01-25 | Warmann Bruno D | Conveyor pusher mechanism |

| US4044686A (en) * | 1975-10-30 | 1977-08-30 | Haverberg Auto Laundry Equipment Co. Inc. | Reduced length vehicle conveyor |

| FR2408996A1 (fr) * | 1977-11-18 | 1979-06-15 | Ponzo Rene | Perfectionnements aux dispositifs ramasseurs de vegetaux |

| FR2448849B1 (fr) * | 1979-02-16 | 1985-10-25 | Ponzo Barthelemy | Dispositif releveur ou rabatteur de tiges vegetales |

| GB2100212B (en) * | 1981-05-14 | 1984-06-27 | Baker Perkins Holdings Plc | Apparatus for collating articles to be wrapped into batches |

| US4776448A (en) * | 1987-09-30 | 1988-10-11 | Emhart Industries, Inc. | Glass container transfer mechanism |

| US5501318A (en) * | 1994-07-06 | 1996-03-26 | Riverwood International Corporation | Overhead pusher lug assembly for packaging machines |

| EP0729905A1 (de) * | 1995-03-02 | 1996-09-04 | Elpatronic Ag | Fördermittel und Verwendung desselben |

| IT1297163B1 (it) * | 1997-03-03 | 1999-08-03 | Azionaria Costruizioni Macchin | Convogliatore per l'avanzamento di organi di spinta. |

| US6161483A (en) * | 1998-07-17 | 2000-12-19 | Conveyor Technology Group | Accumulator mechanism for detaching trolleys from drive chains in power and free conveyor system |

-

1999

- 1999-09-22 IT IT1999MI001961A patent/IT1313365B1/it active

-

2000

- 2000-09-07 AT AT00203092T patent/ATE265973T1/de active

- 2000-09-07 PT PT00203092T patent/PT1086911E/pt unknown

- 2000-09-07 DK DK00203092T patent/DK1086911T3/da active

- 2000-09-07 ES ES00203092T patent/ES2220338T3/es not_active Expired - Lifetime

- 2000-09-07 DE DE60010393T patent/DE60010393T2/de not_active Expired - Lifetime

- 2000-09-07 EP EP00203092A patent/EP1086911B1/en not_active Expired - Lifetime

- 2000-09-18 US US09/663,200 patent/US6378693B1/en not_active Expired - Lifetime

- 2000-09-21 JP JP2000287148A patent/JP4790900B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ITMI991961A0 (it) | 1999-09-22 |

| ITMI991961A1 (it) | 2001-03-22 |

| PT1086911E (pt) | 2004-09-30 |

| US6378693B1 (en) | 2002-04-30 |

| IT1313365B1 (it) | 2002-07-23 |

| DE60010393D1 (de) | 2004-06-09 |

| EP1086911B1 (en) | 2004-05-06 |

| ES2220338T3 (es) | 2004-12-16 |

| ATE265973T1 (de) | 2004-05-15 |

| DK1086911T3 (da) | 2004-08-30 |

| EP1086911A1 (en) | 2001-03-28 |

| DE60010393T2 (de) | 2005-05-04 |

| JP2001146313A (ja) | 2001-05-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4790900B2 (ja) | 掛け外し可能でかつ自動的に再位置決めするプッシャを備えるコンベヤ | |

| EP1144279B1 (en) | Conveyor having an article-conveying surface with article-engagement characteristics that can be changed while the conveyor is running | |

| US20140245703A1 (en) | Bread conveying apparatus and bread slicing apparatus | |

| FR2710317A1 (fr) | Dispositif pour la formation de lots de produits en vue de leur conditionnement. | |

| US5628539A (en) | Robotic gripping device | |

| KR20200011086A (ko) | 브러쉬 롤러를 구비한 벨트 컨베이어 | |

| NL9100786A (nl) | Eirichtinrichting. | |

| US4863008A (en) | Apparatus for transferring objects to be processed such as eggs or the like | |

| JPS5818894B2 (ja) | カコウヘントリアツカイホウホウ オヨビ ソウチ | |

| JP2796581B2 (ja) | 高架コンベヤ用フツク | |

| US5791121A (en) | Apparatus for attachment of carrier sheet to containers | |

| US4739607A (en) | Conveyor | |

| US5535875A (en) | Conveyor systems | |

| KR101726426B1 (ko) | 롤러 컨베이어용 스토퍼 및 이를 포함하는 롤러 컨베이어 | |

| US20160213172A1 (en) | Shelf facing device | |

| US12389917B2 (en) | Carcass stabilizing system | |

| US5273268A (en) | Sheet member grasping device for supply apparatus | |

| JP5283942B2 (ja) | 搬送装置 | |

| JP2741851B2 (ja) | 仕分けコンベヤの搬送アーム | |

| JP3080180B2 (ja) | びん形状の容器のための洗浄機 | |

| JP2737741B2 (ja) | 塊状青果物の搬送装置 | |

| JP2003052345A (ja) | 農作物皮剥ぎ装置 | |

| JP2546540Y2 (ja) | 物品の切り出し装置 | |

| BE1012832A4 (fr) | Poussoir a mouvement de retour a effacement pour le transfert de produits a conditionner du transporteur d'alimentation a la grille de service de l'elevateur sur machines pour le conditionnement de ces produits sous film extensible. | |

| SU1245517A1 (ru) | Цепной конвейер дл накоплени изделий |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070808 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070808 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100713 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101013 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110621 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110721 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140729 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |