JP4603003B2 - ポリウレタン発泡体の劣化を最小化するための、芳香族二酸エステルジオールおよびそれらの置換カルバメート - Google Patents

ポリウレタン発泡体の劣化を最小化するための、芳香族二酸エステルジオールおよびそれらの置換カルバメート Download PDFInfo

- Publication number

- JP4603003B2 JP4603003B2 JP2007063564A JP2007063564A JP4603003B2 JP 4603003 B2 JP4603003 B2 JP 4603003B2 JP 2007063564 A JP2007063564 A JP 2007063564A JP 2007063564 A JP2007063564 A JP 2007063564A JP 4603003 B2 JP4603003 B2 JP 4603003B2

- Authority

- JP

- Japan

- Prior art keywords

- ester

- polyol

- foam

- aromatic diacid

- catalyst

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/42—Polycondensates having carboxylic or carbonic ester groups in the main chain

- C08G18/4205—Polycondensates having carboxylic or carbonic ester groups in the main chain containing cyclic groups

- C08G18/4208—Polycondensates having carboxylic or carbonic ester groups in the main chain containing cyclic groups containing aromatic groups

- C08G18/4211—Polycondensates having carboxylic or carbonic ester groups in the main chain containing cyclic groups containing aromatic groups derived from aromatic dicarboxylic acids and dialcohols

- C08G18/4213—Polycondensates having carboxylic or carbonic ester groups in the main chain containing cyclic groups containing aromatic groups derived from aromatic dicarboxylic acids and dialcohols from terephthalic acid and dialcohols

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L75/00—Compositions of polyureas or polyurethanes; Compositions of derivatives of such polymers

- C08L75/04—Polyurethanes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/08—Processes

- C08G18/16—Catalysts

- C08G18/18—Catalysts containing secondary or tertiary amines or salts thereof

- C08G18/1825—Catalysts containing secondary or tertiary amines or salts thereof having hydroxy or primary amino groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/08—Processes

- C08G18/16—Catalysts

- C08G18/18—Catalysts containing secondary or tertiary amines or salts thereof

- C08G18/1841—Catalysts containing secondary or tertiary amines or salts thereof having carbonyl groups which may be linked to one or more nitrogen or oxygen atoms

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/30—Low-molecular-weight compounds

- C08G18/34—Carboxylic acids; Esters thereof with monohydroxyl compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/4009—Two or more macromolecular compounds not provided for in one single group of groups C08G18/42 - C08G18/64

- C08G18/4018—Mixtures of compounds of group C08G18/42 with compounds of group C08G18/48

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/4009—Two or more macromolecular compounds not provided for in one single group of groups C08G18/42 - C08G18/64

- C08G18/4072—Mixtures of compounds of group C08G18/63 with other macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

- C08G18/74—Polyisocyanates or polyisothiocyanates cyclic

- C08G18/76—Polyisocyanates or polyisothiocyanates cyclic aromatic

- C08G18/7614—Polyisocyanates or polyisothiocyanates cyclic aromatic containing only one aromatic ring

- C08G18/7621—Polyisocyanates or polyisothiocyanates cyclic aromatic containing only one aromatic ring being toluene diisocyanate including isomer mixtures

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/04—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G2110/00—Foam properties

- C08G2110/0008—Foam properties flexible

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G2110/00—Foam properties

- C08G2110/0083—Foam properties prepared using water as the sole blowing agent

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L83/00—Compositions of macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon only; Compositions of derivatives of such polymers

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Polyurethanes Or Polyureas (AREA)

Description

当該技術分野で公知の種々のタイプのいずれかの発泡体も、本発明の方法を使用し、本発明に従って1種または2種以上の芳香族二酸エステルジオール(および/又はそれらの置換カルバメート)が加えられた典型的なポリウレタン調合物を使用して作られるであろう。例えば、本明細書に記載された優れた経時特徴を有する軟質ポリウレタン発泡体は、典型的には、下の表1内に示す量の成分を含む。表1に示す成分は、後で下に詳細が記載される。

本発明の組成物中の触媒は、非遊離性の第3級アミンを含む。本願で用いるように、“非遊離性第3級アミン”の語は、第1級アミン、第2級アミン、ヒドロキシル基、アミドもしくはウレア等のイソシアネート反応性基を含む第3級アミン、または(典型的には、120℃より上の)高沸点を有する第3級アミンをいう。いずれの場合でも、結果としていくらかあるいは全ての触媒が発泡体内に残留する。本願で用いるように、“発泡体に残留する”第3級アミン触媒への言及は、それが発泡体中のいかなる他の成分またはその出発材料と反応しているか否かによらず、いかなる形でも残留する触媒を含む。

ポリウレタンは、ポリオール(典型的には、ポリオールの混合物である)中のヒドロキシル基と、有機イソシアネートとの反応によって製造される。本発明の目的のためには、“ポリオール成分”の語は、エステルを含まないポリオールのみを含み、トレース量以外のエステルは存在しないという意味である。したがって、例えば、ポリエステルポリオールは、本発明に従う“ポリオール成分”の一部ではない。

重合時にポリウレタンマトリックス中にボイドを生成する発泡剤を含ませることによって、ポリウレタン発泡体の生成を補助してもよい。当該技術分野で公知のあらゆる発泡剤が使用されてもよい。好適な発泡剤は、発熱重合反応の間に蒸発する低沸点を有する化合物を含む。そうした発泡剤は一般的に不活性であり、したがって重合反応の間に分解または反応しない。不活性発泡剤の例は、二酸化炭素、クロロフルオロ炭素、水素化されたフルオロ炭素、水素化されたクロロフルオロ炭素、アセトン、およびシクロペンタン、イソペンタン、n−ペンタン、およびそれらの混合物等の低沸点炭化水素を含むが、これらに限られない。他の好適な発泡剤は、イソシアネート化合物と反応してガスを発生する化合物、例えば水を含む。

他の追加成分

顔料は、製造の間のポリウレタン発泡体をカラーコード化するために使用されてもよい、例えば生産物の等級を識別するため、または黄色化を隠すために使用されてもよい。顔料は、ポリウレタンの技術分野で公知のあらゆる好適な有機または無機顔料を含んでもよい。例えば、有機顔料または着色剤は、アゾ/ジアゾ染料、フタロシアニン、ジオキサジン、およびカーボンブラックを含むがこれらに限られない。無機顔料の例は、チタニウムジオキサイド、酸化鉄、または酸化クロムを含むがこれらに限られない。

遊離性対非遊離性触媒を使用した先行技術の処方

32オンス(951ml)紙コップ中の約302gの前混合物(表2の様に調製された)に第3級アミン触媒を加えることによって発泡体パッドを調製した。処方物を、2インチ(5.1cm)直径の攪拌パドルを付けたオーバーヘッド攪拌機で、約6,000RPM約10秒間混合した。

2)コポリマー化スチレンおよびアクリロニトリル、ベースポリオール分子量約4800を含むグラフト化ポリエーテルポリオール、MIミッドランドのダウケミカル社から入手可能。

3)シリコーン界面活性剤、エアープロダクツアンドケミカルズ社から入手可能。

発泡体パッドを、比較実施例2と同じ手順および同じ非遊離性の触媒が使用して作ったが、これらの例では芳香族二酸エステルジオールを、ポリオール前混合物に加えた。実施例3のために、標準および商業的に入手可能なポリエステルポリオール(PEP、NCワシントンのインビスタ社(Invista)から商標名TERATE(商標)2540で販売される)を加え、実施例4では、同じPEPを加えたが、より高い充填量レベル(2.0PPHP)であった。TERATE(商標)2540ポリオールは式(I)に従うテレフタル酸およびジエチレングリコールから誘導された芳香族二酸エステルジオールを含む。

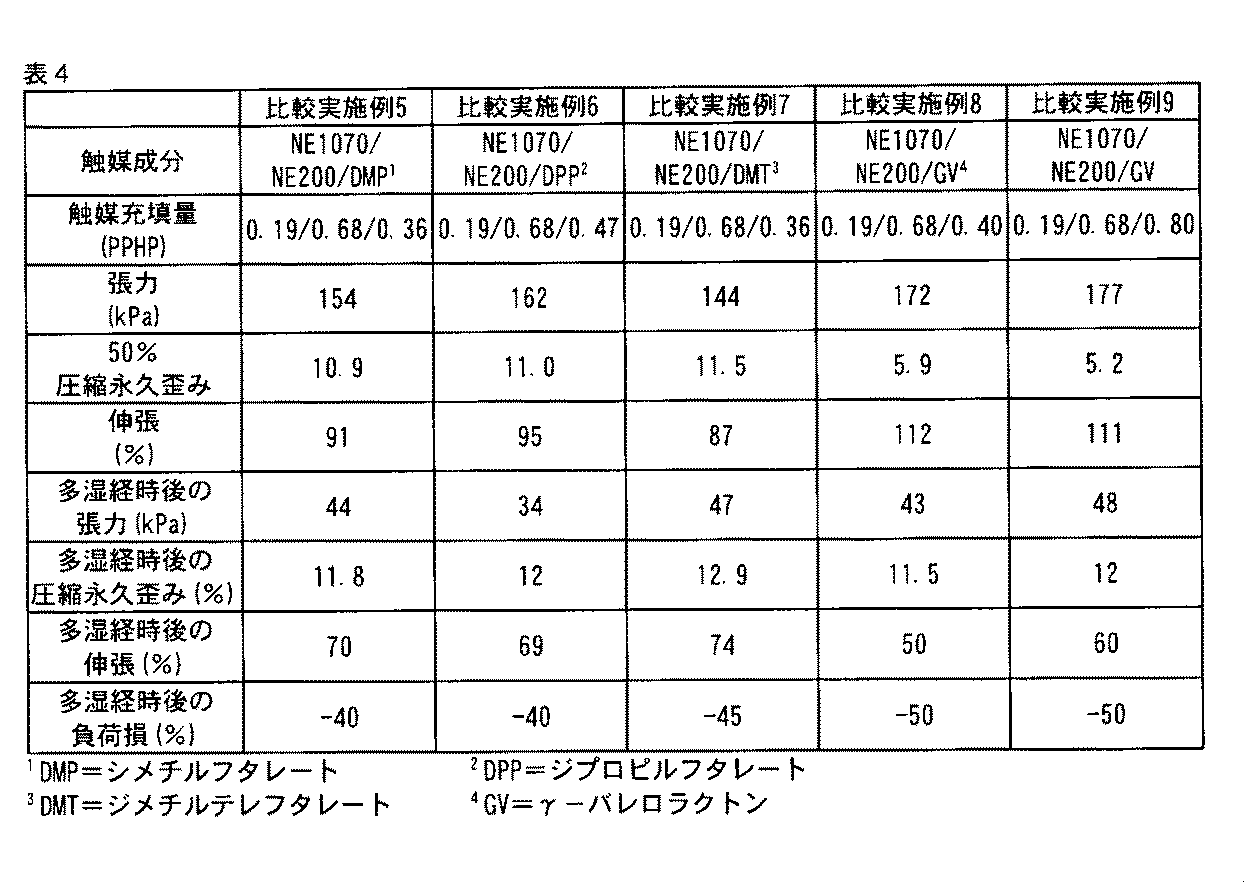

非遊離性触媒と組み合わせた他のエステル

本発明の芳香族二酸エステルジオール(および/又はそれらの置換カルバメート)の代わりに、種々の量の他のエステルを使用して、発泡体パッドを上記の様に調製した。発泡体パッドテストの結果が下の表4に示される。

Claims (10)

- 柔軟な成形されたポリウレタン発泡体の製造方法であって、当該方法は、(a)20〜100重量%のポリエーテルポリオールならびに0〜80重量%のグラフトおよび/またはポリ尿素改質コポリマーからなるエステルを含まないポリオール成分、(b)有機ポリイソシアネート、(c)イソシアネート反応性基を有する非遊離性の第3級アミンウレタン触媒、および(d)式(I)に従う芳香族二酸エステルジオールを含む柔軟なポリウレタン発泡体の反応混合物を型内で混合させることを含み、

- nが、1〜5の範囲にある、請求項1の方法。

- Zが、C 2 H 4 -O-C 2 H 4 である、請求項1の方法。

- nが1〜5の範囲内にあり、そしてZが(CH 2 ) 4 -O-(CH 2 ) 4 である請求項1の方法。

- 該型内の柔軟な発泡体反応混合物が、1種または2種以上の、発泡剤、架橋剤、追加のウレタン触媒、および界面活性剤を含む、請求項1の方法。

- 該エステルを含まない成分の少なくとも50重量%が、1種または2種以上のポリエーテルポリオールから成る、請求項1の方法。

- Zが、CH(CH 3 )CH 2 である、請求項1の方法。

- Aが、C 6 H 4 である、請求項1の方法。

- Zが、CH(CH 3 )CH 2 である、請求項2の方法。

- Aが、C 6 H 4 である、請求項2の方法。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/374,742 US7666919B2 (en) | 2006-03-14 | 2006-03-14 | Aromatic diacid ester diols and substituted carbamates thereof for minimizing deterioration of polyurethane foams |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007246904A JP2007246904A (ja) | 2007-09-27 |

| JP2007246904A5 JP2007246904A5 (ja) | 2010-09-24 |

| JP4603003B2 true JP4603003B2 (ja) | 2010-12-22 |

Family

ID=38134581

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007063564A Expired - Fee Related JP4603003B2 (ja) | 2006-03-14 | 2007-03-13 | ポリウレタン発泡体の劣化を最小化するための、芳香族二酸エステルジオールおよびそれらの置換カルバメート |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US7666919B2 (ja) |

| EP (1) | EP1834974A3 (ja) |

| JP (1) | JP4603003B2 (ja) |

| KR (1) | KR100885712B1 (ja) |

| CN (1) | CN101054432B (ja) |

| BR (1) | BRPI0700651A (ja) |

| MX (1) | MX2007002973A (ja) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009157450A1 (ja) * | 2008-06-25 | 2009-12-30 | 株式会社イノアックコーポレーション | フレームラミネーション用ポリウレタンフォーム |

| KR101699098B1 (ko) | 2009-04-09 | 2017-02-01 | 코베스트로 도이칠란드 아게 | 테레프탈산 및 올리고알킬 옥시드로부터의 폴리에스테르 폴리올 |

| WO2013143129A1 (en) | 2012-03-30 | 2013-10-03 | Air Products And Chemicals, Inc. | Polyurethane foam production process, pre-mix, formulation, and product |

| US10023681B2 (en) | 2012-10-24 | 2018-07-17 | Evonik Degussa Gmbh | Delay action catalyst for improving the stability of polyurethane systems having halogen containing blowing agents |

| WO2016178793A1 (en) | 2015-05-05 | 2016-11-10 | Air Products And Chemicals, Inc. | Delayed action gelling catalyst compositions and methods for making polyurethane polymers |

| US20170055600A1 (en) * | 2015-08-28 | 2017-03-02 | Damon Howard Hawkins | Anti-Slip Slip-On Slip-Over Roof Safety Shorts |

| JP7586887B2 (ja) * | 2019-07-12 | 2024-11-19 | ダウ グローバル テクノロジーズ エルエルシー | 改善された燃焼挙動を有するポリウレタン発泡体 |

| EP3954722A1 (en) | 2020-07-30 | 2022-02-16 | Evonik Operations GmbH | Process and composition for the production of flexible polyurethane foam |

| WO2025040451A1 (en) | 2023-08-18 | 2025-02-27 | Evonik Operations Gmbh | Hydrolysis resistance of polyurethane foams |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4007140A (en) | 1972-11-01 | 1977-02-08 | Imperial Chemical Industries Limited | Tertiary amines as catalysts in polyurethane manufacture |

| DE2513741C3 (de) * | 1974-03-30 | 1980-05-14 | Bridgestone Tire Co. Ltd., Tokio | Verfahren zur Herstellung eines flammfesten rauchbeständigen Polyurethan-Weichschaumstoffs |

| DE2937330A1 (de) * | 1979-09-14 | 1981-04-02 | Bayer Ag, 5090 Leverkusen | Verfahren zur herstellung von elastischen, flammkaschierbaren und hochfrequenzverschweissbaren polyurethanschaumstoffen |

| DE3001462A1 (de) * | 1980-01-17 | 1981-09-10 | Basf Ag, 6700 Ludwigshafen | Verfahren zur herstellung von urethan- und/oder isocyanuratgruppenhaltigen schaumstoffen |

| US4433170A (en) | 1981-07-20 | 1984-02-21 | Texaco Inc. | Novel bis(aminoethyl)ether derivatives useful as polyurethane catalysts |

| US4338408A (en) | 1981-07-20 | 1982-07-06 | Texaco Inc. | Polyurethanes using bis(aminoethyl)ether derivatives as catalysts |

| US4469823A (en) * | 1983-07-28 | 1984-09-04 | Texaco Inc. | Flexible polyurethane foams made using an aromatic polyester polyol |

| US4544679A (en) * | 1985-02-21 | 1985-10-01 | Mobay Chemical Corporation | Polyol blend and polyisocyanurate foam produced therefrom |

| CA2071030A1 (en) * | 1991-06-17 | 1992-12-18 | Kenneth P. Klapper | Thermoformable polyisocyanurate foam laminates for interior finishing applications |

| US5559161A (en) | 1994-02-18 | 1996-09-24 | Air Products And Chemicals, Inc. | Hydroxy-functional triamine catalyst compositions for the production of polyurethanes |

| US5508314A (en) | 1994-02-18 | 1996-04-16 | Air Products And Chemicals, Inc. | Hydroxyl group-containing blowing catalyst compositions for the production of polyurethanes |

| JP3360920B2 (ja) * | 1994-03-24 | 2003-01-07 | サカタインクス株式会社 | ポリウレタン樹脂、その製造方法およびそれを用いたラミネート用印刷インキ組成物 |

| JPH07278249A (ja) * | 1994-04-12 | 1995-10-24 | Sekisui Chem Co Ltd | 熱可塑性ポリウレタン |

| JP2619614B2 (ja) | 1994-12-07 | 1997-06-11 | 大同鋼板株式会社 | 断熱パネル及びその製造方法 |

| JPH08143638A (ja) * | 1994-11-17 | 1996-06-04 | Asahi Denka Kogyo Kk | ポリウレタンフォームの製造方法 |

| US5633293A (en) | 1995-11-30 | 1997-05-27 | Air Products And Chemicals, Inc. | Hydroxy-functional triamine catalyst compositions for polyurethane production |

| US6232356B1 (en) | 1997-05-05 | 2001-05-15 | Air Products And Chemicals, Inc. | Reactive catalyst compositions for improving water blown polyurethane foam performance |

| US5859079A (en) | 1997-05-21 | 1999-01-12 | Air Products And Chemicals, Inc. | Polyurethane catalyst compositions for improving foam performance |

| DE19909978A1 (de) * | 1999-03-06 | 2000-09-07 | Bayer Ag | Die Verwendung von hydrophilen Polyester-Polyurethan-Schaumstoffen bei der Herstellung von Verbundstoffen für die Fahrzeuginnenausstattung |

| AU5314400A (en) * | 1999-06-01 | 2000-12-18 | Solutia Inc. | Composition for use in flexible polyurethane foams |

| US6114403A (en) | 1999-06-09 | 2000-09-05 | Air Products And Chemicals, Inc. | Polyurethane catalyst compositions for improving rigid foam performance |

| US6784220B2 (en) * | 2000-05-19 | 2004-08-31 | Kao Corporation | Polyurethane foam |

| AU2002315173A1 (en) * | 2001-06-15 | 2003-01-02 | Stepan Company | Phthalate polyester polyol-based compositions and high dimensionally stable all water-blown spray polyurethane foam derived therefrom |

| US6818675B2 (en) * | 2002-08-06 | 2004-11-16 | General Electric Company | Process for preparing polyurethane foam |

| CA2441246A1 (en) * | 2002-09-23 | 2004-03-23 | Hilti Aktiengesellschaft | Two-component foam system for producing constructional foams and their use |

| WO2004094506A2 (en) * | 2003-04-23 | 2004-11-04 | Stepan Company | Liquid hardness agent for open cell foams |

| WO2004113410A1 (en) | 2003-06-13 | 2004-12-29 | Dow Global Technologies Inc. | Catalyst composition to get polyurethane product with good hydrolysis resistance |

| US6858654B1 (en) | 2003-10-27 | 2005-02-22 | Air Products And Chemicals, Inc. | Catalyst blends for producing low thermal desorption polyurethane foams |

| DE102004062540A1 (de) | 2004-12-24 | 2006-07-06 | Bayer Materialscience Ag | Polyurethan-Hartschaumstoffe, ein Verfahren zu ihrer Herstellung sowie ihre Verwendung |

-

2006

- 2006-03-14 US US11/374,742 patent/US7666919B2/en active Active

-

2007

- 2007-03-08 BR BRPI0700651-9A patent/BRPI0700651A/pt active Search and Examination

- 2007-03-12 MX MX2007002973A patent/MX2007002973A/es active IP Right Grant

- 2007-03-13 JP JP2007063564A patent/JP4603003B2/ja not_active Expired - Fee Related

- 2007-03-13 EP EP07005183A patent/EP1834974A3/en not_active Withdrawn

- 2007-03-13 KR KR1020070024514A patent/KR100885712B1/ko not_active Expired - Fee Related

- 2007-03-14 CN CN200710085758XA patent/CN101054432B/zh not_active Expired - Fee Related

- 2007-06-15 US US11/763,467 patent/US7615580B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US7615580B2 (en) | 2009-11-10 |

| BRPI0700651A (pt) | 2007-11-06 |

| US20070235691A1 (en) | 2007-10-11 |

| EP1834974A2 (en) | 2007-09-19 |

| MX2007002973A (es) | 2009-02-13 |

| EP1834974A3 (en) | 2008-01-02 |

| US7666919B2 (en) | 2010-02-23 |

| JP2007246904A (ja) | 2007-09-27 |

| CN101054432A (zh) | 2007-10-17 |

| KR20070093859A (ko) | 2007-09-19 |

| KR100885712B1 (ko) | 2009-02-26 |

| US20070219283A1 (en) | 2007-09-20 |

| CN101054432B (zh) | 2013-01-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4603003B2 (ja) | ポリウレタン発泡体の劣化を最小化するための、芳香族二酸エステルジオールおよびそれらの置換カルバメート | |

| KR100479534B1 (ko) | 폴리우레탄 제조용 산-블록화된 아민 촉매 | |

| CA2675153C (en) | Tertiary amines blocked with polymer acids | |

| US9309346B2 (en) | Polyurethane foams made with blowing catalyst compositions containing primary hydroxyl groups and high ethylenediamine backbones | |

| KR101886419B1 (ko) | 폴리우레탄 포움의 방출물을 감소시키는 방법 | |

| MX2008006557A (es) | Sistemas de poliuretano que contienen poliol de poliester que tienen estabilidad hidrolitica mejorada. | |

| JP5655261B2 (ja) | 軟質又は半硬質ポリウレタンフォーム製造用の触媒組成物、及びそれを用いた軟質及び半硬質ポリウレタンフォームの製造法 | |

| KR102621939B1 (ko) | 지연 작용 겔화 촉매 조성물 및 폴리우레탄 폴리머의 제조 방법 | |

| EP2591035A1 (en) | Additives for improving polyurethane foam performance | |

| JP5407208B2 (ja) | 軟質又は半硬質ポリウレタンフォーム製造用の触媒組成物、及びそれを用いた軟質又は半硬質ポリウレタンフォームの製造方法 | |

| MXPA06004207A (en) | Polyurethane foams made with blowing catalyst compositions containing primary hydroxyl groups and high ethylenediamine backbones |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20080213 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100212 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100216 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20100514 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20100519 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100810 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20100810 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100831 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100930 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131008 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |