JP4459313B2 - 押出ダイスの製造方法 - Google Patents

押出ダイスの製造方法 Download PDFInfo

- Publication number

- JP4459313B2 JP4459313B2 JP29452597A JP29452597A JP4459313B2 JP 4459313 B2 JP4459313 B2 JP 4459313B2 JP 29452597 A JP29452597 A JP 29452597A JP 29452597 A JP29452597 A JP 29452597A JP 4459313 B2 JP4459313 B2 JP 4459313B2

- Authority

- JP

- Japan

- Prior art keywords

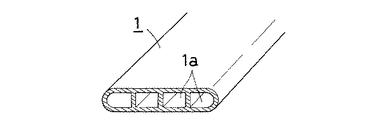

- core

- extrusion die

- die

- electric discharge

- mold

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Electrical Discharge Machining, Electrochemical Machining, And Combined Machining (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP29452597A JP4459313B2 (ja) | 1997-10-27 | 1997-10-27 | 押出ダイスの製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP29452597A JP4459313B2 (ja) | 1997-10-27 | 1997-10-27 | 押出ダイスの製造方法 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008121060A Division JP2008246580A (ja) | 2008-05-07 | 2008-05-07 | 押出ダイスの中子の製造方法および押出ダイスの中子 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH11123444A JPH11123444A (ja) | 1999-05-11 |

| JPH11123444A5 JPH11123444A5 (enExample) | 2005-06-30 |

| JP4459313B2 true JP4459313B2 (ja) | 2010-04-28 |

Family

ID=17808920

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP29452597A Expired - Lifetime JP4459313B2 (ja) | 1997-10-27 | 1997-10-27 | 押出ダイスの製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4459313B2 (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4892682B2 (ja) * | 2006-12-20 | 2012-03-07 | 国立大学法人 新潟大学 | ワイヤ放電加工の表面改質方法 |

| JP2010120020A (ja) * | 2008-11-17 | 2010-06-03 | Ykk Ap株式会社 | 押出形材の製造方法、押出形材の製造装置及び押出形材 |

| JP2009178770A (ja) * | 2009-05-08 | 2009-08-13 | Showa Denko Kk | 金型部材の加工方法、金型部材の製造方法、押出ダイス、押出材の製造方法及び押出材 |

| JP5002081B1 (ja) * | 2012-02-29 | 2012-08-15 | 株式会社 山一ハガネ | 金型の製造方法及び金型 |

| CN110842047A (zh) * | 2019-12-09 | 2020-02-28 | 苏州华泰模具制造有限公司 | 一种挤压模具加工方法 |

| CN113399943B (zh) * | 2021-06-15 | 2022-08-26 | 成都市联余精密机械有限公司 | 一种解决pet瓶胚合缝线粗的加工工艺 |

| CN115722871B (zh) * | 2021-08-31 | 2025-08-22 | 常熟市金华机械股份有限公司 | 一种球滑动管的加工方法 |

| CN117123635A (zh) * | 2023-07-21 | 2023-11-28 | 无锡华光汽车部件科技股份有限公司 | 一种多排联体孔散热铝管挤压模具的加工方法及挤压模具 |

| KR20250134308A (ko) * | 2024-03-04 | 2025-09-11 | 지성알미늄주식회사 | 열교환용 일체형 배관의 금형장치 및 이를 이용하여 제조된 열교환용 일체형 배관 |

-

1997

- 1997-10-27 JP JP29452597A patent/JP4459313B2/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| JPH11123444A (ja) | 1999-05-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4459313B2 (ja) | 押出ダイスの製造方法 | |

| EP0101096B1 (en) | Core and oil-well drill bits | |

| CN103111663B (zh) | 具有至少部分模制的本体的切削刀具及其制造方法 | |

| EP0523170A1 (en) | SAFETY RAZOR BLADE. | |

| JPH06315717A (ja) | 押出加工用ダイスおよび押出加工用ダイス装置 | |

| JP2008246580A (ja) | 押出ダイスの中子の製造方法および押出ダイスの中子 | |

| EP2094424A1 (en) | Diamond tool and method for manufacturing segment thereof | |

| KR100366529B1 (ko) | 미세구멍을 가진 압출재의 압출가공용 다이스 | |

| JP2602388B2 (ja) | 金属製中空押出材の押出用ダイス | |

| JPH0557337A (ja) | コンフオーム押出用ホローダイス | |

| JPH11123444A5 (enExample) | ||

| JP3745504B2 (ja) | ハニカム構造体押出用ダイスおよびその製造方法 | |

| CN104416229A (zh) | Pcd锯片及其制备方法 | |

| CN217343982U (zh) | 一种电极帽修磨整形刀具 | |

| CN114789292A (zh) | 一种电极帽修磨整形刀具 | |

| CN212121695U (zh) | 一种o型圈模具型腔车削加工的刀具 | |

| JPH0129841B2 (enExample) | ||

| JPH11123700A (ja) | 押出ダイスの製造方法 | |

| CN110405643B (zh) | 一种发泡陶瓷磨刷及其制备方法 | |

| CN210526140U (zh) | 嵌套式刀具及设备 | |

| JP4847167B2 (ja) | タイヤ用モールドの製造方法 | |

| JPH03169B2 (enExample) | ||

| JP2510764B2 (ja) | 超硬合金製ダイスの製造法 | |

| CN217121884U (zh) | 一种超薄刀具 | |

| CN222448600U (zh) | 一种开口电极加工用模具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20041021 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041021 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20070425 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071218 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080208 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20080311 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080502 |

|

| A911 | Transfer of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20080519 |

|

| A912 | Removal of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20080613 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100210 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130219 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130219 Year of fee payment: 3 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160219 Year of fee payment: 6 |

|

| EXPY | Cancellation because of completion of term |