JP4358729B2 - ショートアーク型放電灯 - Google Patents

ショートアーク型放電灯 Download PDFInfo

- Publication number

- JP4358729B2 JP4358729B2 JP2004370419A JP2004370419A JP4358729B2 JP 4358729 B2 JP4358729 B2 JP 4358729B2 JP 2004370419 A JP2004370419 A JP 2004370419A JP 2004370419 A JP2004370419 A JP 2004370419A JP 4358729 B2 JP4358729 B2 JP 4358729B2

- Authority

- JP

- Japan

- Prior art keywords

- lamp

- sealing

- arc tube

- mpa

- discharge lamp

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000005394 sealing glass Substances 0.000 claims description 42

- 238000007789 sealing Methods 0.000 claims description 36

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 claims description 5

- 229910052753 mercury Inorganic materials 0.000 claims description 5

- 239000011521 glass Substances 0.000 description 26

- 239000011888 foil Substances 0.000 description 18

- 229910052751 metal Inorganic materials 0.000 description 12

- 239000002184 metal Substances 0.000 description 12

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 8

- 238000012360 testing method Methods 0.000 description 8

- 238000010891 electric arc Methods 0.000 description 7

- 238000000034 method Methods 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 239000004020 conductor Substances 0.000 description 5

- 238000004880 explosion Methods 0.000 description 5

- 239000010453 quartz Substances 0.000 description 5

- 230000009172 bursting Effects 0.000 description 4

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 238000002474 experimental method Methods 0.000 description 3

- 230000002706 hydrostatic effect Effects 0.000 description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- WABPQHHGFIMREM-UHFFFAOYSA-N lead(0) Chemical compound [Pb] WABPQHHGFIMREM-UHFFFAOYSA-N 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 229910052750 molybdenum Inorganic materials 0.000 description 3

- 239000011733 molybdenum Substances 0.000 description 3

- 230000002265 prevention Effects 0.000 description 3

- 238000007667 floating Methods 0.000 description 2

- 239000004973 liquid crystal related substance Substances 0.000 description 2

- 239000004065 semiconductor Substances 0.000 description 2

- 239000000919 ceramic Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000000295 emission spectrum Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000003870 refractory metal Substances 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/02—Details

- H01J61/12—Selection of substances for gas fillings; Specified operating pressure or temperature

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/02—Details

- H01J61/30—Vessels; Containers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/02—Details

- H01J61/30—Vessels; Containers

- H01J61/33—Special shape of cross-section, e.g. for producing cool spot

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/84—Lamps with discharge constricted by high pressure

- H01J61/86—Lamps with discharge constricted by high pressure with discharge additionally constricted by close spacing of electrodes, e.g. for optical projection

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J9/00—Apparatus or processes specially adapted for the manufacture, installation, removal, maintenance of electric discharge tubes, discharge lamps, or parts thereof; Recovery of material from discharge tubes or lamps

- H01J9/24—Manufacture or joining of vessels, leading-in conductors or bases

- H01J9/245—Manufacture or joining of vessels, leading-in conductors or bases specially adapted for gas discharge tubes or lamps

- H01J9/247—Manufacture or joining of vessels, leading-in conductors or bases specially adapted for gas discharge tubes or lamps specially adapted for gas-discharge lamps

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J9/00—Apparatus or processes specially adapted for the manufacture, installation, removal, maintenance of electric discharge tubes, discharge lamps, or parts thereof; Recovery of material from discharge tubes or lamps

- H01J9/24—Manufacture or joining of vessels, leading-in conductors or bases

- H01J9/26—Sealing together parts of vessels

- H01J9/265—Sealing together parts of vessels specially adapted for gas-discharge tubes or lamps

- H01J9/266—Sealing together parts of vessels specially adapted for gas-discharge tubes or lamps specially adapted for gas-discharge lamps

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Discharge Lamps And Accessories Thereof (AREA)

- Vessels And Coating Films For Discharge Lamps (AREA)

Description

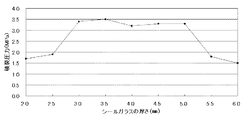

(2.0MPaにおけるaの平均値)=X×2.0(MPa)+Y

(3.0MPaにおけるaの平均値)=X×3.0(MPa)+Y

となる。切片bの方程式は、

(2.0MPaにおけるbの平均値)=X'×2.0(MPa)+Y'

(3.0MPaにおけるbの平均値)=X'×3.0(MPa)+Y'

となる。これらの方程式を解いて、X、Y、X'、Y'を求めることができる。

a=−0.38×P+1.79

b=−3.32×P+24.3

とすることができる。したがって、傾きaと、切片bと、内圧Pと、シール用ガラス部材の径Dと、発光管球面の端から封止部の先端までの距離L1との関係式は、

D=a×L1+b

=(−0.38×P+1.79)×L1+(−3.32×P+24.3)

と表すことができる。

D<(−0.38×P+1.79)×L1+(−3.32×P+24.3)

の範囲であれば、ランプは破裂しないといえる。ランプ投入電力が5〜25kWのランプに渡って、このことが確かめられたことにより、この範囲に入るすべてのランプに、この結果が適用できることは明らかである。

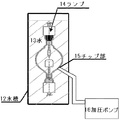

2 放電空間

3 陰極電極

4 陽極電極

5 電極支持棒

6 シールガラス

7 第1のシール用ガラス部材

8 第2のシール用ガラス部材

9 金属箔

10 ベース

11 リード線

12 水槽

13 水

14 ランプ

15 チップ部

16 加圧ポンプ

Claims (3)

- 発光管内の放電空間に陰極と陽極を配置し、前記放電空間内に希ガスと水銀を封入し、点灯時のランプ内圧力が2.0MPa〜3.0MPaとなるショートアーク型放電灯において、前記発光管球面の端から前記発光管をシール用ガラス部材で封止した封止部の先端までの長軸方向の間隔をL1(mm)とし、前記シール用ガラス部材の径をD(mm)とし、点灯時のランプ内圧力をP(MPa)として、D<(−0.38×P+1.79)×L1+(−3.32×P+24.3)の関係を満足するように、前記封止部付近を構成したことを特徴とするショートアーク型放電灯。

- 発光管球面端X1からランプ内部面の2つの異なる曲率の交点X2までの範囲L2において、前記シール用ガラス部材を封着するシールガラスの厚さtを3.0mm≦t≦5.0mmとしたことを特徴とする請求項1記載のショートアーク型放電灯。

- ランプ投入電力が5〜25kWであることを特徴とする請求項2記載のショートアーク型放電灯。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004370419A JP4358729B2 (ja) | 2004-12-22 | 2004-12-22 | ショートアーク型放電灯 |

| TW094140300A TWI368929B (en) | 2004-12-22 | 2005-11-16 | Short-arc discharge lamp |

| KR1020050114637A KR100914112B1 (ko) | 2004-12-22 | 2005-11-29 | 쇼트아크형 방전등 |

| CN2005101350338A CN1794412B (zh) | 2004-12-22 | 2005-12-21 | 短弧光型放电灯 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004370419A JP4358729B2 (ja) | 2004-12-22 | 2004-12-22 | ショートアーク型放電灯 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006179259A JP2006179259A (ja) | 2006-07-06 |

| JP4358729B2 true JP4358729B2 (ja) | 2009-11-04 |

Family

ID=36733161

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004370419A Expired - Lifetime JP4358729B2 (ja) | 2004-12-22 | 2004-12-22 | ショートアーク型放電灯 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP4358729B2 (ja) |

| KR (1) | KR100914112B1 (ja) |

| CN (1) | CN1794412B (ja) |

| TW (1) | TWI368929B (ja) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006032450B4 (de) * | 2006-07-13 | 2017-11-09 | Osram Gmbh | Hochdruckentladungslampe mit spezieller Dimensionierung von Halsbereichen des Entladungsgefäßes |

| JP2008269975A (ja) * | 2007-04-20 | 2008-11-06 | Orc Mfg Co Ltd | ランプおよび光源装置 |

| JP5528994B2 (ja) * | 2010-12-02 | 2014-06-25 | 株式会社小糸製作所 | 車輌用放電灯 |

| JP5800190B2 (ja) * | 2011-09-27 | 2015-10-28 | 岩崎電気株式会社 | ショートアーク型放電ランプ |

| JP5720756B2 (ja) * | 2013-10-28 | 2015-05-20 | ウシオ電機株式会社 | ダブルエンド型ショートアークフラッシュランプ |

| DE102014016601A1 (de) * | 2014-11-11 | 2016-05-12 | Schott Ag | Bauteil mit Bauteilverstärkung und Durchführung |

| CN106783522A (zh) * | 2016-12-15 | 2017-05-31 | 张念祖 | 一种高使用寿命的短弧汞氙灯 |

| JP7175228B2 (ja) * | 2019-03-27 | 2022-11-18 | 株式会社オーク製作所 | 放電ランプおよびその製造方法 |

| JP7626981B1 (ja) * | 2023-09-21 | 2025-02-05 | ウシオ電機株式会社 | ショートアーク型水銀ランプ |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2734007B2 (ja) * | 1988-10-07 | 1998-03-30 | ソニー株式会社 | 研磨装置および研磨方法 |

| JPH03151501A (ja) * | 1989-11-07 | 1991-06-27 | Mitsubishi Heavy Ind Ltd | ガスタービン翼冷却穴の検査方法 |

| JP3430887B2 (ja) * | 1997-10-31 | 2003-07-28 | ウシオ電機株式会社 | ショートアークランプ |

| JP3458756B2 (ja) * | 1999-03-29 | 2003-10-20 | ウシオ電機株式会社 | 放電ランプ |

| US6713957B2 (en) * | 2001-09-13 | 2004-03-30 | Ushiodenki Kabushiki Kaisha | Super-high pressure discharge lamp of the short arc type |

-

2004

- 2004-12-22 JP JP2004370419A patent/JP4358729B2/ja not_active Expired - Lifetime

-

2005

- 2005-11-16 TW TW094140300A patent/TWI368929B/zh active

- 2005-11-29 KR KR1020050114637A patent/KR100914112B1/ko not_active Expired - Lifetime

- 2005-12-21 CN CN2005101350338A patent/CN1794412B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| TWI368929B (en) | 2012-07-21 |

| JP2006179259A (ja) | 2006-07-06 |

| KR100914112B1 (ko) | 2009-08-27 |

| CN1794412A (zh) | 2006-06-28 |

| CN1794412B (zh) | 2010-06-23 |

| KR20060071865A (ko) | 2006-06-27 |

| TW200625382A (en) | 2006-07-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1639833A (zh) | 短弧光-高压放电灯 | |

| JP4358729B2 (ja) | ショートアーク型放電灯 | |

| KR100822583B1 (ko) | 고압 방전 램프 | |

| KR102190649B1 (ko) | 방전 램프 | |

| JP2005100958A (ja) | メタルハライドランプ及びその点灯方法 | |

| US6815893B2 (en) | Metal halide lamp having a long lifespan | |

| US7671536B2 (en) | Arc tube for discharge lamp device | |

| US5742125A (en) | High-pressure discharge lamp with torsionally wound electrode structure | |

| JPWO2000046836A1 (ja) | 高圧水銀蒸気放電ランプおよびランプユニット | |

| JP2008527677A (ja) | 高圧放電ランプ | |

| JP5800189B2 (ja) | ショートアーク型放電ランプ | |

| JP3399763B2 (ja) | 液晶バックライト用セラミック製高圧水銀放電ランプ | |

| JP4134927B2 (ja) | エキシマランプ | |

| JP4373356B2 (ja) | ショートアーク型放電灯 | |

| JP2009238671A (ja) | ショートアーク型放電ランプ | |

| US7443100B2 (en) | ARC tube discharge lamp with compression strain layer | |

| JP2001250504A (ja) | 高圧放電ランプ | |

| US7279838B2 (en) | Discharge tubes | |

| US4721887A (en) | Metal halide arc lamp having pinch seal with elongated space | |

| JP2010092865A (ja) | 片口金型ランプ | |

| JP3898490B2 (ja) | ショートアーク型放電灯 | |

| JP7149631B2 (ja) | 箔シール型ショートアーク水銀ランプ | |

| US7211954B2 (en) | Discharge tubes | |

| JP4606850B2 (ja) | メタルハライドランプ | |

| US20180061626A1 (en) | High-intensity discharge lamp |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070712 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090626 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090804 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090806 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120814 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4358729 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120814 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120814 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130814 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |