JP4339049B2 - 排ガス処理方法及び排ガス処理装置 - Google Patents

排ガス処理方法及び排ガス処理装置 Download PDFInfo

- Publication number

- JP4339049B2 JP4339049B2 JP2003306307A JP2003306307A JP4339049B2 JP 4339049 B2 JP4339049 B2 JP 4339049B2 JP 2003306307 A JP2003306307 A JP 2003306307A JP 2003306307 A JP2003306307 A JP 2003306307A JP 4339049 B2 JP4339049 B2 JP 4339049B2

- Authority

- JP

- Japan

- Prior art keywords

- exhaust gas

- voltage electrode

- low

- concentration

- low voltage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/02—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust

- F01N3/021—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/02—Plant or installations having external electricity supply

- B03C3/04—Plant or installations having external electricity supply dry type

- B03C3/06—Plant or installations having external electricity supply dry type characterised by presence of stationary tube electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/02—Plant or installations having external electricity supply

- B03C3/04—Plant or installations having external electricity supply dry type

- B03C3/14—Plant or installations having external electricity supply dry type characterised by the additional use of mechanical effects, e.g. gravity

- B03C3/155—Filtration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/40—Electrode constructions

- B03C3/41—Ionising-electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/40—Electrode constructions

- B03C3/45—Collecting-electrodes

- B03C3/49—Collecting-electrodes tubular

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/40—Electrode constructions

- B03C3/45—Collecting-electrodes

- B03C3/51—Catch- space electrodes, e.g. slotted-box form

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/40—Electrode constructions

- B03C3/60—Use of special materials other than liquids

- B03C3/62—Use of special materials other than liquids ceramics

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/40—Electrode constructions

- B03C3/60—Use of special materials other than liquids

- B03C3/64—Use of special materials other than liquids synthetic resins

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/01—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust by means of electric or electrostatic separators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/04—Ionising electrode being a wire

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/08—Ionising electrode being a rod

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/12—Cleaning the device by burning the trapped particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/30—Details of magnetic or electrostatic separation for use in or with vehicles

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/12—Improving ICE efficiencies

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Processes For Solid Components From Exhaust (AREA)

- Electrostatic Separation (AREA)

- Filtering Of Dispersed Particles In Gases (AREA)

Description

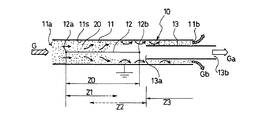

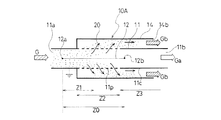

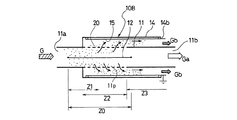

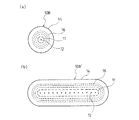

あるいは、上記目的を達成するための本発明の排ガス処理方法は、高電圧電極と該高電圧電極に対向して配置され、筒体で形成された低電圧電極とを備え、前記低電圧電極の少なくとも上流側部分の帯電部において、前記筒体の低電圧電極の中心付近に沿って長手方向に前記高電圧電極を配置し、かつ、前記帯電部の下流側の濃縮部において、前記低電圧電極を通気可能に形成し、更に、前記濃縮部の下流側の分流部を設け、前記濃縮部と前記分流部において、前記低電圧電極の外側に外筒を設けた排ガス処理装置の排気ガス処理方法であって、対向電極間に排ガスを流通させ、該対向電極間に高電圧を印加して排ガス中にコロナ放電を発生させ、該コロナ放電によって前記排ガス中の浮遊微粒子物質を帯電・凝集して、静電気力により低電圧電極に引き寄せることにより前記低電圧電極近傍に偏在させ、前記浮遊微粒子物質の濃度が相対的に高くなった高濃度排ガスを排ガス分流用の筒体である前記低電圧電極の外側に流し、前記浮遊微粒子物資の濃度が相対的に低くなった低濃度排ガスを前記低電圧電極の内側に流して分流することを特徴とする方法である。

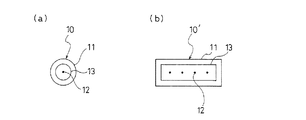

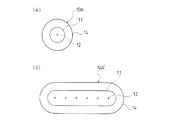

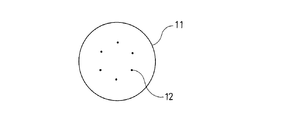

11 低電圧電極

12 高電圧電極

13 内筒

14 外筒

20 浮遊微粒子物質

G 排ガス

Ga 低濃度排ガス

Gb 高濃度排ガス

Z0 放電部

Z1 帯電部

Z2 濃縮部

Z3 分流部

Claims (7)

- 高電圧電極と、該高電圧電極に対向して配置され、かつ、筒体で形成された低電圧電極とを備え、該低電圧電極の少なくとも上流側部分の帯電部において、前記筒体の低電圧電極の中心付近に沿って長手方向に前記高電圧電極を配置した排ガス処理装置の排気ガス処理方法であって、対向電極間に排ガスを流通させ、放電部で該対向電極間に高電圧を印加して排ガス中にコロナ放電を発生させ、前記帯電部で該コロナ放電によって前記排ガス中の浮遊微粒子物質を帯電・凝集して、前記放電部の下流側の濃縮部で、前記低電圧電極近傍に偏在させ、前記濃縮部の下流の分流部において、前記低電圧電極の内側に設けた排ガス分流用の内筒の内側に前記低濃度排ガスが流れ、該内筒の外側に前記高濃度排ガスが流れるようにして、両電極間に流通させた排ガスを、前記低電圧電極近傍を流れる排ガスと前記低電圧電極の中心部を流れる排ガスとに分流させることを特徴とする排ガス処理方法。

- 高電圧電極と該高電圧電極に対向して配置され、筒体で形成された低電圧電極とを備え、前記低電圧電極の少なくとも上流側部分の帯電部において、前記筒体の低電圧電極の中心付近に沿って長手方向に前記高電圧電極を配置し、かつ、前記帯電部の下流側の濃縮部において、前記低電圧電極を通気可能に形成し、更に、前記濃縮部の下流側の分流部を設け、前記濃縮部と前記分流部において、前記低電圧電極の外側に外筒を設けた排ガス処理装置の排気ガス処理方法であって、対向電極間に排ガスを流通させ、該対向電極間に高電圧を印加して排ガス中にコロナ放電を発生させ、該コロナ放電によって前記排ガス中の浮遊微粒子物質を帯電・凝集して、静電気力により低電圧電極に引き寄せることにより前記低電圧電極近傍に偏在させ、前記浮遊微粒子物質の濃度が相対的に高くなった高濃度排ガスを排ガス分流用の筒体である前記低電圧電極の外側に流し、前記浮遊微粒子物資の濃度が相対的に低くなった低濃度排ガスを前記低電圧電極の内側に流して分流することを特徴とする排ガス処理方法。

- 前記高濃度排ガスをフィルタで浄化することを特徴とする請求項1又は2に記載の排ガス浄化方法。

- 高電圧電極と該高電圧電極に対向して配置された低電圧電極とを備え、対向電極間に排ガスを流通させ、該対向電極間に高電圧を印加して排ガス中にコロナ放電を形成し、浮遊微粒子物質を帯電させる帯電部と、該帯電部によって帯電された前記浮遊微粒子物質を前記低電圧電極近傍に偏在させる濃縮部と、前記対向電極間に流通させた排ガスを、前記浮遊微粒子物質の濃度が相対的に高くなった高濃度排ガスと、前記浮遊微粒子物資の濃度が相対的に低くなった低濃度排ガスとに分流する分流部とを有して構成し、更に、前記低電圧電極を筒体で形成し、該低電圧電極の少なくとも上流側部分の帯電部において、前記筒体の低電圧電極の中心付近に沿って長手方向に前記高電圧電極を配置すると共に、前記濃縮部の下流の分流部において、前記低電圧電極の内側に排ガス分流用の内筒を設け、該内筒はその内側に前記低濃度排ガスが流れ、該内筒の外側に前記高濃度排ガスが流れるように配置して、両電極間に流通させた排ガスを、前記低電圧電極近傍を流れる排ガスと前記低電圧電極の中心部を流れる排ガスとに分流させることを特徴とする排ガス処理装置。

- 高電圧電極と該高電圧電極に対向して配置された低電圧電極とを備え、対向電極間に排ガスを流通させ、該対向電極間に高電圧を印加して排ガス中にコロナ放電を形成し、浮遊微粒子物質を帯電させる帯電部と、該帯電部によって帯電された前記浮遊微粒子物質を前記低電圧電極近傍に偏在させる濃縮部と、前記浮遊微粒子物質の濃度が相対的に高くなった前記低電圧電極近傍の排ガスを、前記浮遊微粒子物質の濃度が相対的に高くなった高濃度排ガスと、前記浮遊微粒子物資の濃度が相対的に低くなった低濃度排ガスとに分流する分流部とを有して構成し、更に、前記低電圧電極を筒体で形成し、該低電圧電極の少なくとも上流側部分の帯電部において、前記筒体の低電圧電極の中心付近に沿って長手方向に前記高電圧電極を配置し、前記帯電部の下流側の前記濃縮部において、前記低電圧電極を通気可能に形成すると共に、前記濃縮部と前記分流部において、前記低電圧電極の外側に外筒を設け、前記低電圧電極の上流側から流入する排ガスを、前記低電圧電極の内側を流れる前記低濃度排ガスと、該低電圧電極の外側を流れる前記高濃度排ガスに分けるように構成したことを特徴とする排ガス処理装置。

- 前記高濃度排ガス中に含まれる浮遊微粒子物質を浄化するフィルタを設けたことを特徴とする請求項4又は5のいずれか1項に記載の排ガス浄化装置。

- 前記排ガスが内燃機関の排気ガスであることを特徴とする請求項4〜6のいずれか1項に記載の排ガス浄化装置。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003306307A JP4339049B2 (ja) | 2003-08-29 | 2003-08-29 | 排ガス処理方法及び排ガス処理装置 |

| PCT/JP2004/012262 WO2005021940A1 (ja) | 2003-08-29 | 2004-08-26 | 排ガス処理方法及び排ガス処理装置 |

| EP04772218A EP1669562A1 (en) | 2003-08-29 | 2004-08-26 | Exhaust gas processing method and exhaust gas processing system |

| US10/569,841 US20070000236A1 (en) | 2003-08-29 | 2004-08-26 | Exhaust gas processing method and exhaust gas processing system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003306307A JP4339049B2 (ja) | 2003-08-29 | 2003-08-29 | 排ガス処理方法及び排ガス処理装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005076497A JP2005076497A (ja) | 2005-03-24 |

| JP2005076497A5 JP2005076497A5 (ja) | 2006-03-23 |

| JP4339049B2 true JP4339049B2 (ja) | 2009-10-07 |

Family

ID=34269383

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003306307A Expired - Fee Related JP4339049B2 (ja) | 2003-08-29 | 2003-08-29 | 排ガス処理方法及び排ガス処理装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20070000236A1 (ja) |

| EP (1) | EP1669562A1 (ja) |

| JP (1) | JP4339049B2 (ja) |

| WO (1) | WO2005021940A1 (ja) |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE602006014805D1 (de) | 2005-03-18 | 2010-07-22 | Toyota Motor Co Ltd | Brennkraftmotorsteuervorrichtung und abgasreinigungsverfahren |

| JP4581130B2 (ja) * | 2005-08-19 | 2010-11-17 | いすゞ自動車株式会社 | 排気ガス処理方法及び排気ガス処理装置 |

| JP2007100635A (ja) * | 2005-10-06 | 2007-04-19 | Mitsubishi Heavy Ind Ltd | 排気ガス浄化装置 |

| FR2903726B1 (fr) * | 2006-07-12 | 2008-10-10 | Renault Sas | Dispositif et procede pour la capture et l'elimination des particules contenues dans les gaz d'echappement d'un moteur a combustion interne de vehicule automobile. |

| GR1005756B (el) * | 2006-09-20 | 2007-12-20 | (������� 30%) ��������� | Διαταξη επεξεργασιας αεριων |

| JP2009243419A (ja) | 2008-03-31 | 2009-10-22 | Denso Corp | 内燃機関の排気浄化装置 |

| US20100018850A1 (en) * | 2008-07-28 | 2010-01-28 | Caterpillar Inc. | System for removing particulate matter from exhaust streams |

| DE102008057960A1 (de) * | 2008-11-19 | 2010-05-20 | Emitec Gesellschaft Für Emissionstechnologie Mbh | Anordnung und Verfahren zur Reinigung eines Abgasstromes einer Verbrennungskraftmaschine durch die Abscheidung von Partikeln |

| DE102009025136A1 (de) * | 2009-06-17 | 2010-12-23 | Emitec Gesellschaft Für Emissionstechnologie Mbh | Vorrichtung und Verfahren zur Behandlung eines Partikel aufweisenden Abgases |

| US7959883B2 (en) * | 2009-08-28 | 2011-06-14 | Corning Incorporated | Engine exhaust gas reactors and methods |

| JP5705461B2 (ja) * | 2010-05-27 | 2015-04-22 | 富士電機株式会社 | 電気集塵装置 |

| JP5838373B2 (ja) * | 2010-09-27 | 2016-01-06 | パナソニックIpマネジメント株式会社 | 放電電極の製造方法、静電霧化装置、および、イオン発生装置 |

| JP5863087B2 (ja) * | 2010-11-16 | 2016-02-16 | 臼井国際産業株式会社 | 重油以下の低質燃料を使用する大排気量ディーゼルエンジン用排ガス処理装置 |

| JP5768423B2 (ja) * | 2011-03-17 | 2015-08-26 | 富士電機株式会社 | 電気集塵装置 |

| JP5761461B2 (ja) * | 2012-07-31 | 2015-08-12 | 富士電機株式会社 | 電気集塵装置 |

| ITAN20120152A1 (it) * | 2012-11-20 | 2014-05-21 | S C M Societa Costruzioni Metal Liche S R L | Filtro elettrostatico perfezionato. |

| US9808809B2 (en) | 2013-02-07 | 2017-11-07 | Mitsubishi Hitachi Power Systems Environmental Solutions, Ltd. | Dust collector, electrode selection method for dust collector, and dust collection method |

| US10071384B2 (en) | 2013-02-07 | 2018-09-11 | Mitsubishi Hitachi Power Systems Environmental Solutions, Ltd. | Dust collector, dust collection system, and dust collection method |

| JP6172714B2 (ja) * | 2013-05-09 | 2017-08-02 | 臼井国際産業株式会社 | 重油を使用する船舶用ディーゼルエンジンの排ガス処理装置 |

| DE102013113334A1 (de) * | 2013-12-02 | 2015-06-03 | Jochen Deichmann | Vorrichtung zum Reinigen von Gasen |

| JP2015202425A (ja) * | 2014-04-11 | 2015-11-16 | 国立大学法人金沢大学 | 微粒子捕集装置 |

| JP6268609B2 (ja) * | 2015-04-24 | 2018-01-31 | パナソニックIpマネジメント株式会社 | 溶媒分離装置及び熱処理装置 |

| CN105673139A (zh) * | 2016-03-21 | 2016-06-15 | 东北电力大学 | 基于介质阻挡放电等离子体的汽车尾气处理装置及处理方法 |

| JP6505050B2 (ja) * | 2016-06-02 | 2019-04-24 | パナソニック株式会社 | 溶媒分離方法及び装置 |

| FI20175319A1 (en) | 2017-04-06 | 2018-10-07 | Olfactomics Oy | Method and equipment for the analysis of biological samples |

| CN109236423A (zh) * | 2017-07-10 | 2019-01-18 | 东北林业大学 | 三段式低温等离子体木纤维柴油车尾气污染物净化器 |

| CN108554631B (zh) * | 2018-06-04 | 2023-08-22 | 江苏大学 | 基于介质阻挡放电的同轴多级ntp发生器 |

| EP3872322A4 (en) * | 2018-10-22 | 2021-12-22 | Shanghai Bixiufu Enterprise Management Co., Ltd. | SYSTEM AND PROCEDURE FOR END GAS OZONE CLEANING OF AN ENGINE |

| US20220250087A1 (en) * | 2018-10-22 | 2022-08-11 | Shanghai Bixiufu Enterprise Management Co., Ltd. | Engine exhaust dust removing system and method |

| JP2020195954A (ja) * | 2019-05-31 | 2020-12-10 | 臼井国際産業株式会社 | 電気集塵装置 |

| KR20210141740A (ko) * | 2019-11-05 | 2021-11-23 | 후지 덴키 가부시키가이샤 | 전기 집진기 |

| CN112879124A (zh) * | 2021-01-26 | 2021-06-01 | 东风汽车集团股份有限公司 | 汽车尾气颗粒物吸附装置 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4338784A (en) * | 1979-08-22 | 1982-07-13 | The Regents Of The University Of Minn. | Method of recycling collected exhaust particles |

| JPS57148017A (en) * | 1981-03-09 | 1982-09-13 | Toyota Central Res & Dev Lab Inc | Device for disposing of exhaust smoke of internal combustion engine |

| DE3622623A1 (de) * | 1986-07-05 | 1988-01-14 | Man Nutzfahrzeuge Gmbh | Verfahren und vorrichtung zum beseitigen von in einem abgasfilter einer brennkraftmaschine abgeschiedenem russ |

| CH675895A5 (ja) * | 1987-04-03 | 1990-11-15 | Daimler Benz Ag | |

| DE3723544A1 (de) * | 1987-07-16 | 1989-01-26 | Man Technologie Gmbh | Elektrostatischer filter zum reinigen von gasen |

| JPH05222915A (ja) * | 1992-02-10 | 1993-08-31 | Nippon Soken Inc | 内燃機関の排気ガス浄化装置 |

| US6038854A (en) * | 1996-08-19 | 2000-03-21 | The Regents Of The University Of California | Plasma regenerated particulate trap and NOx reduction system |

| JP2001041024A (ja) * | 1999-08-02 | 2001-02-13 | Isuzu Ceramics Res Inst Co Ltd | 電荷型のディーゼルパティキュレートフィルタ装置 |

| US6660061B2 (en) * | 2001-10-26 | 2003-12-09 | Battelle Memorial Institute | Vapor purification with self-cleaning filter |

-

2003

- 2003-08-29 JP JP2003306307A patent/JP4339049B2/ja not_active Expired - Fee Related

-

2004

- 2004-08-26 WO PCT/JP2004/012262 patent/WO2005021940A1/ja not_active Ceased

- 2004-08-26 US US10/569,841 patent/US20070000236A1/en not_active Abandoned

- 2004-08-26 EP EP04772218A patent/EP1669562A1/en not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| EP1669562A1 (en) | 2006-06-14 |

| WO2005021940A1 (ja) | 2005-03-10 |

| JP2005076497A (ja) | 2005-03-24 |

| US20070000236A1 (en) | 2007-01-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4339049B2 (ja) | 排ガス処理方法及び排ガス処理装置 | |

| RU2182850C1 (ru) | Устройство для очистки воздуха от пыли и аэрозолей | |

| US8991153B2 (en) | Self-regenerating particulate trap systems for emissions and methods thereof | |

| US8771600B2 (en) | Electrostatic filter and non-thermal plasma system for air pollution control of hydrocarbon combustion engines | |

| US20140020558A1 (en) | Apparatus and method for removal of particulate matter from a gas | |

| JP2008019853A (ja) | 内燃機関の排気処理装置 | |

| AU2012336492B2 (en) | Apparatus with conductive strip for dust removal | |

| EP0083845A1 (en) | Process and apparatus for reducing the environment pollution effect of exhaust and other gases | |

| CN103154453B (zh) | 用于减少内燃机的废气中的煤烟颗粒的方法和装置 | |

| US20060021503A1 (en) | Electrostatic precipitator particulate trap with impingement filtering element | |

| JP2006342730A (ja) | 内燃機関の排気処理装置 | |

| JP4896629B2 (ja) | 排気ガス処理装置 | |

| Hayashi et al. | Collection of diesel exhaust particles using electrostatic charging prior to DPF and regeneration of DPF using sliding discharge | |

| JP2002195618A (ja) | 厨房排気装置 | |

| JP4345568B2 (ja) | 排気処理装置用凝集器 | |

| US9333512B2 (en) | Electrostatic screen device and method for emission control | |

| RU2525539C1 (ru) | Электрофильтр | |

| CN209866326U (zh) | 一种高压静电积尘模块烟气排放净化装置 | |

| RU81655U1 (ru) | Устройство для очистки газов от аэрозольных частиц | |

| WO2024248645A1 (en) | Multi-stage filtration device | |

| JP2007255295A (ja) | 排気浄化装置 | |

| JP3027924U (ja) | 電気式集塵機能付エアーフィルタ | |

| HK40026359A (en) | Apparatus with conductive strip for dust removal | |

| JP2004332608A (ja) | Pm浄化リアクター | |

| JPH01299647A (ja) | 多重極電界型静電凝集装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060206 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060605 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090303 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090507 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090623 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090701 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313117 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313117 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130710 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |