JP3909401B2 - 積層型熱交換器 - Google Patents

積層型熱交換器 Download PDFInfo

- Publication number

- JP3909401B2 JP3909401B2 JP21604697A JP21604697A JP3909401B2 JP 3909401 B2 JP3909401 B2 JP 3909401B2 JP 21604697 A JP21604697 A JP 21604697A JP 21604697 A JP21604697 A JP 21604697A JP 3909401 B2 JP3909401 B2 JP 3909401B2

- Authority

- JP

- Japan

- Prior art keywords

- fluid

- recess

- flow path

- forming

- end plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000012530 fluid Substances 0.000 claims description 253

- 230000002093 peripheral effect Effects 0.000 claims description 24

- 230000015572 biosynthetic process Effects 0.000 claims description 18

- 238000005192 partition Methods 0.000 claims description 16

- 238000005304 joining Methods 0.000 claims description 9

- 238000000638 solvent extraction Methods 0.000 claims description 6

- 238000000034 method Methods 0.000 description 6

- 239000003507 refrigerant Substances 0.000 description 5

- 238000004891 communication Methods 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000005219 brazing Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 230000011218 segmentation Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D1/00—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators

- F28D1/02—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid

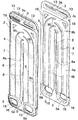

- F28D1/03—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with plate-like or laminated conduits

- F28D1/0308—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with plate-like or laminated conduits the conduits being formed by paired plates touching each other

- F28D1/0325—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with plate-like or laminated conduits the conduits being formed by paired plates touching each other the plates having lateral openings therein for circulation of the heat-exchange medium from one conduit to another

- F28D1/0333—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with plate-like or laminated conduits the conduits being formed by paired plates touching each other the plates having lateral openings therein for circulation of the heat-exchange medium from one conduit to another the plates having integrated connecting members

- F28D1/0341—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with plate-like or laminated conduits the conduits being formed by paired plates touching each other the plates having lateral openings therein for circulation of the heat-exchange medium from one conduit to another the plates having integrated connecting members with U-flow or serpentine-flow inside the conduits

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP21604697A JP3909401B2 (ja) | 1997-08-11 | 1997-08-11 | 積層型熱交換器 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP21604697A JP3909401B2 (ja) | 1997-08-11 | 1997-08-11 | 積層型熱交換器 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH1163881A JPH1163881A (ja) | 1999-03-05 |

| JPH1163881A5 JPH1163881A5 (enExample) | 2005-06-02 |

| JP3909401B2 true JP3909401B2 (ja) | 2007-04-25 |

Family

ID=16682437

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP21604697A Expired - Fee Related JP3909401B2 (ja) | 1997-08-11 | 1997-08-11 | 積層型熱交換器 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3909401B2 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100716029B1 (ko) * | 2000-11-20 | 2007-05-14 | 한라공조주식회사 | 적층형 열교환기 |

| KR20030080004A (ko) * | 2001-02-19 | 2003-10-10 | 쇼와 덴코 가부시키가이샤 | 열교환기 |

| KR100760589B1 (ko) * | 2001-06-12 | 2007-09-20 | 한라공조주식회사 | 열교환 플레이트 및 이 열교환 플레이트를 이용한 열교환기 |

| KR100819012B1 (ko) * | 2001-09-06 | 2008-04-02 | 한라공조주식회사 | 적층형 열교환기 |

| KR100858094B1 (ko) * | 2002-02-27 | 2008-09-10 | 한라공조주식회사 | 열교환 플레이트 및 이것을 이용한 적층형 열교환기 |

| KR101082469B1 (ko) | 2004-08-13 | 2011-11-10 | 한라공조주식회사 | 열교환기 |

| KR101385080B1 (ko) * | 2007-03-27 | 2014-04-14 | 한라비스테온공조 주식회사 | 증발기 |

| FR2967248B1 (fr) * | 2010-11-10 | 2015-01-23 | Valeo Systemes Thermiques | Echangeur de chaleur fluide/fluide |

| FR2978236B1 (fr) * | 2011-07-21 | 2015-08-21 | Valeo Systemes Thermiques | Echangeur thermique, tube plat et plaque correspondants |

| FR2993354B1 (fr) * | 2012-07-13 | 2018-07-13 | Delphi Automotive Systems Lux | Refroidisseur d'air de suralimentation |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2737987B2 (ja) * | 1989-03-09 | 1998-04-08 | アイシン精機株式会社 | 積層型蒸発器 |

| JPH06213532A (ja) * | 1993-01-20 | 1994-08-02 | Showa Alum Corp | 積層型熱交換器 |

| JPH07294160A (ja) * | 1994-04-28 | 1995-11-10 | Zexel Corp | 片タンク構造の積層型熱交換器 |

| JPH0933187A (ja) * | 1995-07-19 | 1997-02-07 | Showa Alum Corp | 積層型熱交換器 |

| JP3864288B2 (ja) * | 1996-12-06 | 2006-12-27 | 昭和電工株式会社 | 積層型蒸発器 |

-

1997

- 1997-08-11 JP JP21604697A patent/JP3909401B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH1163881A (ja) | 1999-03-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3172859B2 (ja) | 積層型熱交換器 | |

| JP3017272B2 (ja) | 熱交換器 | |

| JP2605035Y2 (ja) | 積層型熱交換器 | |

| AU2002217510B8 (en) | Layered heat exchangers | |

| JP2000097578A (ja) | 熱交換器、特に、排気ガス熱交換器 | |

| JPH04203895A (ja) | 熱交換器 | |

| JPH07280484A (ja) | 積層型熱交換器 | |

| JP3909401B2 (ja) | 積層型熱交換器 | |

| US6742577B2 (en) | Laminate type evaporator | |

| JP2001141379A (ja) | 複式熱交換器 | |

| JP2864173B2 (ja) | 熱交換器 | |

| JP4328425B2 (ja) | 積層型熱交換器 | |

| JPH10292995A (ja) | 積層型熱交換器 | |

| JPH0933187A (ja) | 積層型熱交換器 | |

| JP3151505B2 (ja) | 積層型熱交換器 | |

| JPH1163881A5 (enExample) | ||

| JP2874517B2 (ja) | 積層式熱交換器 | |

| JP2952593B1 (ja) | 積層型熱交換器 | |

| EP1310757B1 (en) | Stacked-type multi-flow heat exchangers | |

| JP2000055573A (ja) | 冷媒蒸発器 | |

| JPH1114281A (ja) | 熱交換器 | |

| JP7576944B2 (ja) | 熱交換器 | |

| JPH0721367B2 (ja) | 積層型熱交換器 | |

| JPH1047809A (ja) | 熱交換器 | |

| JP2572083Y2 (ja) | 蒸発器 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040809 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040809 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061129 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20061212 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20070109 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100202 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130202 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130202 Year of fee payment: 6 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| LAPS | Cancellation because of no payment of annual fees |