JP3662912B2 - 管状樹脂フィルムの製造装置 - Google Patents

管状樹脂フィルムの製造装置 Download PDFInfo

- Publication number

- JP3662912B2 JP3662912B2 JP2003331555A JP2003331555A JP3662912B2 JP 3662912 B2 JP3662912 B2 JP 3662912B2 JP 2003331555 A JP2003331555 A JP 2003331555A JP 2003331555 A JP2003331555 A JP 2003331555A JP 3662912 B2 JP3662912 B2 JP 3662912B2

- Authority

- JP

- Japan

- Prior art keywords

- resin film

- film

- tubular resin

- stretching

- tubular

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229920005989 resin Polymers 0.000 title claims description 265

- 239000011347 resin Substances 0.000 title claims description 265

- 238000004519 manufacturing process Methods 0.000 title claims description 60

- 239000011148 porous material Substances 0.000 claims description 29

- 238000009423 ventilation Methods 0.000 claims description 20

- 229920005992 thermoplastic resin Polymers 0.000 description 69

- 239000007789 gas Substances 0.000 description 56

- 238000005520 cutting process Methods 0.000 description 35

- 238000010438 heat treatment Methods 0.000 description 31

- 238000000034 method Methods 0.000 description 29

- 238000001125 extrusion Methods 0.000 description 25

- 238000007665 sagging Methods 0.000 description 19

- 230000037303 wrinkles Effects 0.000 description 19

- 230000000087 stabilizing effect Effects 0.000 description 18

- 239000000314 lubricant Substances 0.000 description 17

- 239000000463 material Substances 0.000 description 16

- 230000007246 mechanism Effects 0.000 description 16

- 238000002386 leaching Methods 0.000 description 15

- 239000004973 liquid crystal related substance Substances 0.000 description 12

- 229910052751 metal Inorganic materials 0.000 description 10

- 239000002184 metal Substances 0.000 description 10

- 238000004804 winding Methods 0.000 description 10

- 239000003963 antioxidant agent Substances 0.000 description 9

- 230000009477 glass transition Effects 0.000 description 8

- 238000012423 maintenance Methods 0.000 description 8

- 230000006641 stabilisation Effects 0.000 description 8

- 238000011105 stabilization Methods 0.000 description 8

- 239000000654 additive Substances 0.000 description 7

- 230000002265 prevention Effects 0.000 description 7

- 230000008569 process Effects 0.000 description 7

- 239000000126 substance Substances 0.000 description 7

- 125000004122 cyclic group Chemical group 0.000 description 6

- 229920000098 polyolefin Polymers 0.000 description 6

- 238000000926 separation method Methods 0.000 description 6

- 230000000996 additive effect Effects 0.000 description 5

- 238000001816 cooling Methods 0.000 description 5

- 235000014113 dietary fatty acids Nutrition 0.000 description 5

- 239000000194 fatty acid Substances 0.000 description 5

- 229930195729 fatty acid Natural products 0.000 description 5

- 150000004665 fatty acids Chemical class 0.000 description 5

- 238000003780 insertion Methods 0.000 description 5

- 230000037431 insertion Effects 0.000 description 5

- 238000000465 moulding Methods 0.000 description 5

- 239000002994 raw material Substances 0.000 description 5

- JFNLZVQOOSMTJK-KNVOCYPGSA-N norbornene Chemical compound C1[C@@H]2CC[C@H]1C=C2 JFNLZVQOOSMTJK-KNVOCYPGSA-N 0.000 description 4

- 239000002530 phenolic antioxidant Substances 0.000 description 4

- -1 polyethylene Polymers 0.000 description 4

- 239000000243 solution Substances 0.000 description 4

- 239000002904 solvent Substances 0.000 description 4

- 238000013022 venting Methods 0.000 description 4

- 239000004594 Masterbatch (MB) Substances 0.000 description 3

- BGYHLZZASRKEJE-UHFFFAOYSA-N [3-[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxy]-2,2-bis[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxymethyl]propyl] 3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoate Chemical compound CC(C)(C)C1=C(O)C(C(C)(C)C)=CC(CCC(=O)OCC(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)=C1 BGYHLZZASRKEJE-UHFFFAOYSA-N 0.000 description 3

- 230000003078 antioxidant effect Effects 0.000 description 3

- 238000005266 casting Methods 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- FTQWRYSLUYAIRQ-UHFFFAOYSA-N n-[(octadecanoylamino)methyl]octadecanamide Chemical compound CCCCCCCCCCCCCCCCCC(=O)NCNC(=O)CCCCCCCCCCCCCCCCC FTQWRYSLUYAIRQ-UHFFFAOYSA-N 0.000 description 3

- 230000003287 optical effect Effects 0.000 description 3

- 238000002834 transmittance Methods 0.000 description 3

- WKBPZYKAUNRMKP-UHFFFAOYSA-N 1-[2-(2,4-dichlorophenyl)pentyl]1,2,4-triazole Chemical compound C=1C=C(Cl)C=C(Cl)C=1C(CCC)CN1C=NC=N1 WKBPZYKAUNRMKP-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 229920000106 Liquid crystal polymer Polymers 0.000 description 2

- 241000282320 Panthera leo Species 0.000 description 2

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 2

- CGRTZESQZZGAAU-UHFFFAOYSA-N [2-[3-[1-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propanoyloxy]-2-methylpropan-2-yl]-2,4,8,10-tetraoxaspiro[5.5]undecan-9-yl]-2-methylpropyl] 3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propanoate Chemical compound CC(C)(C)C1=C(O)C(C)=CC(CCC(=O)OCC(C)(C)C2OCC3(CO2)COC(OC3)C(C)(C)COC(=O)CCC=2C=C(C(O)=C(C)C=2)C(C)(C)C)=C1 CGRTZESQZZGAAU-UHFFFAOYSA-N 0.000 description 2

- 230000002411 adverse Effects 0.000 description 2

- 101150059062 apln gene Proteins 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 150000002148 esters Chemical class 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000000178 monomer Substances 0.000 description 2

- UTOPWMOLSKOLTQ-UHFFFAOYSA-N octacosanoic acid Chemical compound CCCCCCCCCCCCCCCCCCCCCCCCCCCC(O)=O UTOPWMOLSKOLTQ-UHFFFAOYSA-N 0.000 description 2

- SSDSCDGVMJFTEQ-UHFFFAOYSA-N octadecyl 3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoate Chemical compound CCCCCCCCCCCCCCCCCCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 SSDSCDGVMJFTEQ-UHFFFAOYSA-N 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 229920000515 polycarbonate Polymers 0.000 description 2

- 239000004417 polycarbonate Substances 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- VNQNXQYZMPJLQX-UHFFFAOYSA-N 1,3,5-tris[(3,5-ditert-butyl-4-hydroxyphenyl)methyl]-1,3,5-triazinane-2,4,6-trione Chemical compound CC(C)(C)C1=C(O)C(C(C)(C)C)=CC(CN2C(N(CC=3C=C(C(O)=C(C=3)C(C)(C)C)C(C)(C)C)C(=O)N(CC=3C=C(C(O)=C(C=3)C(C)(C)C)C(C)(C)C)C2=O)=O)=C1 VNQNXQYZMPJLQX-UHFFFAOYSA-N 0.000 description 1

- XHSVWKJCURCWFU-UHFFFAOYSA-N 19-[3-(19-amino-19-oxononadecyl)phenyl]nonadecanamide Chemical compound NC(=O)CCCCCCCCCCCCCCCCCCC1=CC=CC(CCCCCCCCCCCCCCCCCCC(N)=O)=C1 XHSVWKJCURCWFU-UHFFFAOYSA-N 0.000 description 1

- VSAWBBYYMBQKIK-UHFFFAOYSA-N 4-[[3,5-bis[(3,5-ditert-butyl-4-hydroxyphenyl)methyl]-2,4,6-trimethylphenyl]methyl]-2,6-ditert-butylphenol Chemical compound CC1=C(CC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)C(C)=C(CC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)C(C)=C1CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 VSAWBBYYMBQKIK-UHFFFAOYSA-N 0.000 description 1

- 241000239290 Araneae Species 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- 239000004985 Discotic Liquid Crystal Substance Substances 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 229920000219 Ethylene vinyl alcohol Polymers 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 239000004988 Nematic liquid crystal Substances 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 229910001069 Ti alloy Inorganic materials 0.000 description 1

- 239000007983 Tris buffer Substances 0.000 description 1

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 239000007822 coupling agent Substances 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- ZJOLCKGSXLIVAA-UHFFFAOYSA-N ethene;octadecanamide Chemical compound C=C.CCCCCCCCCCCCCCCCCC(N)=O.CCCCCCCCCCCCCCCCCC(N)=O ZJOLCKGSXLIVAA-UHFFFAOYSA-N 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- FEEPBTVZSYQUDP-UHFFFAOYSA-N heptatriacontanediamide Chemical compound NC(=O)CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC(N)=O FEEPBTVZSYQUDP-UHFFFAOYSA-N 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 239000011256 inorganic filler Substances 0.000 description 1

- 229910003475 inorganic filler Inorganic materials 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 150000002596 lactones Chemical class 0.000 description 1

- 239000005001 laminate film Substances 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000005121 nitriding Methods 0.000 description 1

- 239000002736 nonionic surfactant Substances 0.000 description 1

- LYRFLYHAGKPMFH-UHFFFAOYSA-N octadecanamide Chemical compound CCCCCCCCCCCCCCCCCC(N)=O LYRFLYHAGKPMFH-UHFFFAOYSA-N 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 239000008188 pellet Substances 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 239000000088 plastic resin Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920001230 polyarylate Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920002959 polymer blend Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 238000006748 scratching Methods 0.000 description 1

- 230000002393 scratching effect Effects 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 229920006300 shrink film Polymers 0.000 description 1

- 229920002379 silicone rubber Polymers 0.000 description 1

- 239000004945 silicone rubber Substances 0.000 description 1

- 239000000344 soap Substances 0.000 description 1

- 239000007779 soft material Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

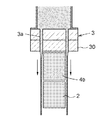

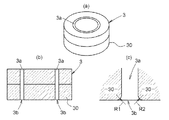

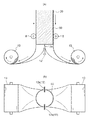

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/22—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of tubes

- B29C55/24—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of tubes radial

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/22—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of tubes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/09—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels

- B29C48/10—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels flexible, e.g. blown foils

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/90—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article

- B29C48/901—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article of hollow bodies

- B29C48/902—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article of hollow bodies internally

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/90—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article

- B29C48/908—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article characterised by calibrator surface, e.g. structure or holes for lubrication, cooling or venting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/22—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of tubes

- B29C55/26—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of tubes biaxial

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2793/00—Shaping techniques involving a cutting or machining operation

- B29C2793/009—Shaping techniques involving a cutting or machining operation after shaping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92009—Measured parameter

- B29C2948/92114—Dimensions

- B29C2948/92152—Thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92504—Controlled parameter

- B29C2948/92514—Pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92504—Controlled parameter

- B29C2948/92609—Dimensions

- B29C2948/92638—Length

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92504—Controlled parameter

- B29C2948/92609—Dimensions

- B29C2948/92647—Thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92504—Controlled parameter

- B29C2948/92704—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92819—Location or phase of control

- B29C2948/92923—Calibration, after-treatment or cooling zone

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/001—Combinations of extrusion moulding with other shaping operations

- B29C48/0018—Combinations of extrusion moulding with other shaping operations combined with shaping by orienting, stretching or shrinking, e.g. film blowing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/001—Combinations of extrusion moulding with other shaping operations

- B29C48/0019—Combinations of extrusion moulding with other shaping operations combined with shaping by flattening, folding or bending

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/911—Cooling

- B29C48/9135—Cooling of flat articles, e.g. using specially adapted supporting means

- B29C48/914—Cooling drums

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Shaping By String And By Release Of Stress In Plastics And The Like (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003331555A JP3662912B2 (ja) | 2003-01-31 | 2003-09-24 | 管状樹脂フィルムの製造装置 |

| US10/543,612 US7625194B2 (en) | 2003-01-31 | 2003-12-24 | Unit for production of tubular resin film |

| EP03786257A EP1595686B1 (en) | 2003-01-31 | 2003-12-24 | Unit for production of tubular resin film |

| KR1020057014071A KR101006419B1 (ko) | 2003-01-31 | 2003-12-24 | 튜브형 수지 필름의 제조 장치 |

| AU2003296075A AU2003296075A1 (en) | 2003-01-31 | 2003-12-24 | Unit for production of tubular resin film |

| CA2514919A CA2514919C (en) | 2003-01-31 | 2003-12-24 | Manufacturing apparatus for tubular resin film |

| PCT/JP2003/016534 WO2004067266A1 (ja) | 2003-01-31 | 2003-12-24 | 管状樹脂フィルムの製造装置 |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003024899 | 2003-01-31 | ||

| JP2003023208 | 2003-01-31 | ||

| JP2003050815 | 2003-02-27 | ||

| JP2003090375 | 2003-03-28 | ||

| JP2003331555A JP3662912B2 (ja) | 2003-01-31 | 2003-09-24 | 管状樹脂フィルムの製造装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004314589A JP2004314589A (ja) | 2004-11-11 |

| JP3662912B2 true JP3662912B2 (ja) | 2005-06-22 |

| JP2004314589A5 JP2004314589A5 (enExample) | 2005-07-28 |

Family

ID=32831157

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003331555A Expired - Fee Related JP3662912B2 (ja) | 2003-01-31 | 2003-09-24 | 管状樹脂フィルムの製造装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7625194B2 (enExample) |

| EP (1) | EP1595686B1 (enExample) |

| JP (1) | JP3662912B2 (enExample) |

| KR (1) | KR101006419B1 (enExample) |

| AU (1) | AU2003296075A1 (enExample) |

| CA (1) | CA2514919C (enExample) |

| WO (1) | WO2004067266A1 (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3710800B2 (ja) * | 2003-01-31 | 2005-10-26 | 住友ベークライト株式会社 | 管状樹脂フィルムの製造装置および製造方法 |

| US7780430B2 (en) | 2005-01-18 | 2010-08-24 | Sumitomo Bakelite Company, Ltd. | Mandrel, and apparatus and process for resin film production with mandrel |

| CA2620454A1 (en) | 2005-09-05 | 2007-03-15 | Sumitomo Bakelite Co., Ltd. | Device and method for cutting and winding a tubular resin film |

| DE102005060979A1 (de) | 2005-12-20 | 2007-06-28 | Kiefel Extrusion Gmbh | Verfahren und Vorrichtung zum Herstellen von Blasfolien aus thermoplastischen Kunststoffen |

| US8282384B1 (en) * | 2011-04-15 | 2012-10-09 | Thomas Michael R | Continuous curing and post curing apparatus |

| JP7336229B2 (ja) * | 2019-03-27 | 2023-08-31 | 住友重機械工業株式会社 | インフレーション成形装置 |

| US10870393B1 (en) * | 2019-10-04 | 2020-12-22 | Ford Global Technologies, Llc | Headliner for a vehicle |

| KR102339540B1 (ko) * | 2020-01-03 | 2021-12-16 | (주)믿음을 주는 나무 | 비닐봉투 제조장치 및 제조방법 |

| CN114873186A (zh) * | 2022-03-31 | 2022-08-09 | 江苏迪迈新材料有限公司 | 一种pc复合板生产系统 |

| US11680664B1 (en) | 2022-04-15 | 2023-06-20 | Zeus Company Inc. | Thin-walled heat shrink tubing |

| EP4623943A1 (en) | 2024-03-28 | 2025-10-01 | Zeus Company LLC | Non-crosslinked heat shrink tubing |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB868388A (en) * | 1957-06-11 | 1961-05-17 | Du Pont | Process for stretching thermoplastic tubing |

| US2987765A (en) * | 1960-07-07 | 1961-06-13 | Du Pont | Process and apparatus for forming tubes |

| US3246061A (en) * | 1962-08-17 | 1966-04-12 | Du Pont | Process for preparing biaxially oriented polypropylene film |

| US3412189A (en) * | 1962-10-31 | 1968-11-19 | Du Pont | Apparatus and process for use in the expansion of tubular film |

| GB1282062A (en) * | 1969-03-08 | 1972-07-19 | Showa Denko Kk | A method and apparatus for manufacturing a biaxially oriented cylindrical film |

| JPS4829542B1 (enExample) * | 1969-06-21 | 1973-09-11 | ||

| US3742105A (en) * | 1970-05-05 | 1973-06-26 | S Kuroda | Method for producing a seamless tubing |

| US3716320A (en) * | 1970-11-23 | 1973-02-13 | Du Pont | Apparatus for producing flat film from thermoplastic material |

| US3976733A (en) * | 1972-10-02 | 1976-08-24 | The Dow Chemical Company | Method for the preparation of plastic articles by extrusion and cooling by gas bearing |

| JPS5056453A (enExample) * | 1973-09-19 | 1975-05-17 | ||

| US3936265A (en) * | 1974-08-15 | 1976-02-03 | Continental Can Company, Inc. | Manufacturing clear plastic lids |

| US4251197A (en) * | 1979-09-12 | 1981-02-17 | Michio Sudo | Stretching apparatus of a flattened cylindrical film |

| JPS5979753A (ja) | 1982-10-29 | 1984-05-09 | 呉羽化学工業株式会社 | 熱収縮性複合フイルム及びその製造方法 |

| JPH028583A (ja) | 1988-06-27 | 1990-01-12 | Nippon Carbide Ind Co Inc | 軟質ホース |

| DE4003696C1 (enExample) * | 1990-02-07 | 1990-12-13 | Petzetakis, George Aristovoulos, Piraeus, Gr | |

| NL9400453A (nl) * | 1994-03-22 | 1995-11-01 | Wavin Bv | Werkwijze en inrichting voor het vervaardigen van biaxiaal georiënteerde buis uit thermoplastisch kunststofmateriaal. |

| NL9400738A (nl) * | 1994-05-04 | 1995-12-01 | Wavin Bv | Werkwijze en inrichting voor het vervaardigen van biaxiaal georiënteerde buis uit thermoplastisch kunststofmateriaal. |

| NL1001259C2 (nl) * | 1995-05-03 | 1996-11-05 | Wavin Bv | Werkwijze voor het behandelen van een geëxtrudeerd kunststof profiel en extrusie-installatie daarvoor. |

| NL1005282C2 (nl) * | 1997-02-14 | 1998-08-18 | Wavin Bv | Inrichting en werkwijze voor het vervaardigen van een hol kunststof profiel. |

| JPH1110713A (ja) * | 1997-06-19 | 1999-01-19 | Sekisui Chem Co Ltd | 熱可塑性樹脂管の製造方法及び製造装置 |

| JP2000263629A (ja) | 1999-03-18 | 2000-09-26 | Sekisui Chem Co Ltd | 合成樹脂管の押出成形方法 |

| JP2001096607A (ja) | 1999-09-30 | 2001-04-10 | Suzuki Kanshi Kk | 薄肉チューブの押出成形方法および装置 |

| US7780430B2 (en) * | 2005-01-18 | 2010-08-24 | Sumitomo Bakelite Company, Ltd. | Mandrel, and apparatus and process for resin film production with mandrel |

-

2003

- 2003-09-24 JP JP2003331555A patent/JP3662912B2/ja not_active Expired - Fee Related

- 2003-12-24 WO PCT/JP2003/016534 patent/WO2004067266A1/ja not_active Ceased

- 2003-12-24 US US10/543,612 patent/US7625194B2/en not_active Expired - Fee Related

- 2003-12-24 AU AU2003296075A patent/AU2003296075A1/en not_active Abandoned

- 2003-12-24 KR KR1020057014071A patent/KR101006419B1/ko not_active Expired - Fee Related

- 2003-12-24 CA CA2514919A patent/CA2514919C/en not_active Expired - Fee Related

- 2003-12-24 EP EP03786257A patent/EP1595686B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| AU2003296075A1 (en) | 2004-08-23 |

| KR20050106406A (ko) | 2005-11-09 |

| CA2514919C (en) | 2011-10-25 |

| WO2004067266A1 (ja) | 2004-08-12 |

| KR101006419B1 (ko) | 2011-01-06 |

| US20060269642A1 (en) | 2006-11-30 |

| JP2004314589A (ja) | 2004-11-11 |

| EP1595686A1 (en) | 2005-11-16 |

| EP1595686B1 (en) | 2012-08-01 |

| CA2514919A1 (en) | 2004-08-12 |

| EP1595686A4 (en) | 2010-12-08 |

| US7625194B2 (en) | 2009-12-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3710800B2 (ja) | 管状樹脂フィルムの製造装置および製造方法 | |

| US7749412B2 (en) | Wide optical film and method for producing the same | |

| JP3662912B2 (ja) | 管状樹脂フィルムの製造装置 | |

| JPWO2012102178A1 (ja) | 樹脂フィルムの製造方法及び製造装置 | |

| JP3846566B2 (ja) | 熱可塑性樹脂シートの製造方法 | |

| CN100475488C (zh) | 管状树脂薄膜的制造装置和制造方法 | |

| JP3948740B2 (ja) | マンドレル、マンドレルを用いた樹脂フィルムの製造装置及び製造方法 | |

| KR101645760B1 (ko) | 광학 필름의 제조 방법, 광학 필름 및 광학 필름의 제조 장치 | |

| JP5029145B2 (ja) | 光学フィルムの製造方法 | |

| JP2009092760A (ja) | 位相差フィルムの製造方法 | |

| JP2008170716A (ja) | 位相差フィルムの製造方法 | |

| JP2025021883A (ja) | 熱可塑性ポリマーフィルムの製造方法及び製造装置 | |

| JP2022077687A (ja) | 熱収縮性フィルム | |

| KR20230035894A (ko) | 폴리메틸메타크릴레이트(pmma) 블로운 필름 제조방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041222 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050216 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20050216 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20050304 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20050317 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20050324 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20090401 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100401 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110401 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120401 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130401 Year of fee payment: 8 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140401 Year of fee payment: 9 |

|

| LAPS | Cancellation because of no payment of annual fees |