JP2016540887A - 3次元印刷された熱間静水圧加圧成形用容器及びその製造方法 - Google Patents

3次元印刷された熱間静水圧加圧成形用容器及びその製造方法 Download PDFInfo

- Publication number

- JP2016540887A JP2016540887A JP2016523314A JP2016523314A JP2016540887A JP 2016540887 A JP2016540887 A JP 2016540887A JP 2016523314 A JP2016523314 A JP 2016523314A JP 2016523314 A JP2016523314 A JP 2016523314A JP 2016540887 A JP2016540887 A JP 2016540887A

- Authority

- JP

- Japan

- Prior art keywords

- container

- cavity

- coating

- powder

- isostatic pressing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

- B22F3/1208—Containers or coating used therefor

- B22F3/1258—Container manufacturing

- B22F3/1266—Container manufacturing by coating or sealing the surface of the preformed article, e.g. by melting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/60—Treatment of workpieces or articles after build-up

- B22F10/62—Treatment of workpieces or articles after build-up by chemical means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/60—Treatment of workpieces or articles after build-up

- B22F10/64—Treatment of workpieces or articles after build-up by thermal means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

- B22F3/1208—Containers or coating used therefor

- B22F3/1258—Container manufacturing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

- B22F3/14—Both compacting and sintering simultaneously

- B22F3/15—Hot isostatic pressing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F5/00—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product

- B22F5/10—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product of articles with cavities or holes, not otherwise provided for in the preceding subgroups

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/1601—Process or apparatus

- C23C18/1633—Process of electroless plating

- C23C18/1635—Composition of the substrate

- C23C18/1644—Composition of the substrate porous substrates

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D7/00—Electroplating characterised by the article coated

- C25D7/04—Tubes; Rings; Hollow bodies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/10—Formation of a green body

- B22F10/14—Formation of a green body by jetting of binder onto a bed of metal powder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

- B22F3/14—Both compacting and sintering simultaneously

- B22F3/15—Hot isostatic pressing

- B22F2003/153—Hot isostatic pressing apparatus specific to HIP

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/24—After-treatment of workpieces or articles

- B22F2003/241—Chemical after-treatment on the surface

- B22F2003/242—Coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2301/00—Metallic composition of the powder or its coating

- B22F2301/15—Nickel or cobalt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2301/00—Metallic composition of the powder or its coating

- B22F2301/35—Iron

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2302/00—Metal Compound, non-Metallic compound or non-metal composition of the powder or its coating

- B22F2302/20—Nitride

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2302/00—Metal Compound, non-Metallic compound or non-metal composition of the powder or its coating

- B22F2302/25—Oxide

- B22F2302/253—Aluminum oxide (Al2O3)

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y10/00—Processes of additive manufacturing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y80/00—Products made by additive manufacturing

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/31—Coating with metals

- C23C18/32—Coating with nickel, cobalt or mixtures thereof with phosphorus or boron

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/04—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the coating material

- C23C4/10—Oxides, borides, carbides, nitrides or silicides; Mixtures thereof

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/04—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the coating material

- C23C4/10—Oxides, borides, carbides, nitrides or silicides; Mixtures thereof

- C23C4/11—Oxides

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Electrochemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Powder Metallurgy (AREA)

- Electroplating Methods And Accessories (AREA)

Abstract

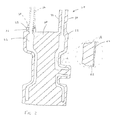

【選択図】図2

Description

Claims (20)

- 粉末材料を熱間静水圧加圧成形することにより物品(2)を形成するための容器(20)を製造する方法であって、

造形粉末を以て容器(20)を3次元印刷することから成り、当該容器は粉末材料を受容するための空洞(26)と外面のある外側部(22)を有しており、当該空洞は表面を有し、当該空洞(26)内に粉末材料がある状態で当該容器(20)を熱間静水圧加圧成形することにより、当該容器(20)に囲まれた当該物品(2)が作り出されるような形状と大きさをしている

ことを特徴とする方法。 - 当該物品(2)が内部通路(8)を有し、当該容器(20)を3次元印刷するステップが空洞(26)に隣接する中子(24)を形成することを含む、請求項1の方法。

- さらに、少なくとも1層のガスを通さない被覆(42)により外面の少なくとも一部を気密被覆するステップを含む、請求項1の方法。

- 前記気密被覆するステップが、電気めっきと無電解めっきから成る群から選択される少なくとも1つにより前記ガスを通さない被覆(42)を施すことを含む、請求項3の方法。

- 前記ガスを通さない被覆(42)がニッケルから成る、請求項3の方法。

- 前記ガスを通さない被覆(42)の厚さが60〜100ミクロンの範囲内にある、請求項3の方法。

- 当該気密被覆するステップが、当該被覆材から成る槽の中に前記容器(20)を浸すことにより前記ガスを通さない被覆(42)を施すことを含む、請求項3の方法。

- 当該気密被覆するステップが、プラズマ溶射付着により前記ガスを通さない被覆(42)を施すことを含む、請求項3の方法。

- 粉末材料と接触することになる前記空洞の表面の一部の不活性度を高めるステップをさらに含む、請求項1の方法。

- 前記不活性度を高めるステップが、前記空洞の表面を化学溶液及び懸濁液の少なくとも1つに接触させることを含む、請求項9の方法。

- 前記不活性度を高めるステップが、前記空洞の表面を所定の温度のガス又は複数のガスの組み合わせに曝すことを含む、請求項9の方法。

- 前記不活性度を高めるステップが、前記空洞の表面を不活性物質により被覆することを含む、請求項9の方法。

- 前記不活性物質として窒化ホウ素とアルミナから成る群から少なくとも1つが選択される、請求項12の方法。

- 前記造形粉末が鋼粉から成る請求項1の方法。

- 物品(2)を製造する方法であって、

造形粉末を以て熱間静水圧加圧成形用容器(20)を3次元印刷し、当該容器(20)は粉末材料を受容するための空洞(26)と外面のある外側部(22)を有し、当該空洞(26)は表面を有し、当該空洞(26)内に粉末材料がある状態で当該容器を熱間静水圧加圧成形することにより、当該容器(20)に囲まれた当該物品(2)が作り出されるような形状と大きさをしており、

当該粉末材料を当該空洞(26)の中に装填し、

当該空洞(26)内に当該粉末材料がある状態で当該容器(20)を熱間静水圧加圧成形する

ステップから成る方法。 - 前記物品(2)が内部通路(8)を有し、前記容器(20)を3次元印刷するステップは前記空洞(26)に隣接する中子(24)を形成することを含む、請求項15の方法。

- さらに、ガスを通さない被覆(42)の少なくとも1層により前記外面の少なくとも一部を気密被覆するステップを含む、請求項15の方法。

- 前記ガスを通さない被覆(42)がニッケルから成る、請求項17の方法。

- さらに、前記粉末材料と接触することになる前記空洞の表面の一部の不活性度を高めるステップを含む、請求項15の方法。

- 前記造形粉末が鋼粉から成る請求項1の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201361892078P | 2013-10-17 | 2013-10-17 | |

| US61/892,078 | 2013-10-17 | ||

| PCT/US2014/060572 WO2015057761A1 (en) | 2013-10-17 | 2014-10-15 | Three-dimensional printed hot isostatic pressing containers and processes for making same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2016540887A true JP2016540887A (ja) | 2016-12-28 |

Family

ID=52828629

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016523314A Pending JP2016540887A (ja) | 2013-10-17 | 2014-10-15 | 3次元印刷された熱間静水圧加圧成形用容器及びその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20160243621A1 (ja) |

| EP (1) | EP3057729A4 (ja) |

| JP (1) | JP2016540887A (ja) |

| WO (1) | WO2015057761A1 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023066788A (ja) * | 2021-10-29 | 2023-05-16 | 国立大学法人 東京大学 | 金属積層造形品の製造方法 |

| JP2023076470A (ja) * | 2017-05-19 | 2023-06-01 | ボディコート エイチ.アイ.ピー.リミテッド | コンポーネント |

| KR20230081817A (ko) | 2021-11-29 | 2023-06-08 | 한국생산기술연구원 | 캐닝 프리 열간 등방압 가압 분말야금 방법 |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101473900B1 (ko) * | 2013-12-18 | 2014-12-18 | 한국항공우주연구원 | 쾌속조형법을 이용한 메탈코어 제작 및 이를 이용한 열간 정수압 성형을 통한 정밀부품 제작 방법 및 이를 이용한 액체로켓 터보펌프 구동용 터빈 블리스크 |

| US10675685B2 (en) | 2014-01-14 | 2020-06-09 | Raytheon Technologies Corporation | Method for preventing powder depletion/contamination during consolidation process |

| US11434766B2 (en) * | 2015-03-05 | 2022-09-06 | General Electric Company | Process for producing a near net shape component with consolidation of a metallic powder |

| US20160279708A1 (en) * | 2015-03-26 | 2016-09-29 | Honeywell International Inc. | Net-shape or near-net shape powder metal components and methods for producing the same |

| US11117190B2 (en) * | 2016-04-07 | 2021-09-14 | Great Lakes Images & Engineering, Llc | Using thin-walled containers in powder metallurgy |

| GB2570618B (en) * | 2017-07-05 | 2021-05-19 | Bodycote H I P Ltd | Components |

| GB201721769D0 (en) * | 2017-12-22 | 2018-02-07 | Rolls Royce Power Eng Plc | A manufacturing method |

| EP3732019A1 (en) | 2017-12-31 | 2020-11-04 | Stratasys Ltd. | 3d printing of catalytic formulation for selective metal deposition |

| CN108220643B (zh) * | 2018-01-29 | 2019-06-28 | 华中科技大学 | 一种钨颗粒增强非晶基复合材料的制备方法 |

| GB201802405D0 (en) * | 2018-02-14 | 2018-03-28 | Rolls Royce Plc | Method of manufacturing an object |

| US10955059B2 (en) | 2018-02-27 | 2021-03-23 | Delta Faucet Company | Faucet including dual water outlets |

| WO2019192633A1 (de) * | 2018-04-06 | 2019-10-10 | Hermle Maschinenbau Gmbh | Verfahren zur herstellung eines bauteils, kapsel für heiss isostatisches pressen und bauteilanordnung |

| US11498125B2 (en) * | 2018-10-31 | 2022-11-15 | Hamilton Sundstrand Corporation | Method for fabricating components using hybrid additive manufacturing and consolidation process |

| US10844969B2 (en) | 2018-12-28 | 2020-11-24 | Delta Faucet Company | Faucet including a rotatable spout arm |

| US11186973B2 (en) | 2018-12-28 | 2021-11-30 | Delta Faucet Company | Cantilevered faucet spout |

| FR3095147B1 (fr) * | 2019-04-18 | 2022-07-08 | Safran Aircraft Engines | Procédé de fabrication d’une pièce de turbomachine |

| US11975389B2 (en) | 2019-11-14 | 2024-05-07 | Halliburton Energy Services, Inc. | Additive manufacturing of components with functionally graded properties |

| SE546938C2 (en) * | 2019-12-17 | 2025-03-11 | Kennametal Inc | A method forforming a densified green article by subjecting a green article, formed by additive manufacturing techniques, and a powder pressure transfer media to cold or warm isostatic pressing |

| CN112146439B (zh) * | 2020-09-25 | 2021-10-22 | 同济大学 | 一种高温高压气液联合烧结装置和烧结方法 |

| US12172214B2 (en) * | 2022-09-26 | 2024-12-24 | Ge Infrastructure Technology Llc | Hot isostatic pressing container with enhanced directional consolidation |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52147509A (en) * | 1976-06-01 | 1977-12-08 | Special Metals Corp | Process and apparatus for production of solidifying element |

| JPH09262841A (ja) * | 1996-03-26 | 1997-10-07 | Mitsuboshi:Kk | 中空樹脂成形品の製造法およびそれに用いる低融点金属製品の製造法 |

| JP2001522722A (ja) * | 1997-09-30 | 2001-11-20 | アメテック・スペシャリティ・メタル・プロダクツ・ディビジョン | ガス等静圧加工法 |

| US20080237933A1 (en) * | 2003-06-16 | 2008-10-02 | Rainer Hochsmann | Methods and systems for manufacturing the manufacture of layered three-dimensional forms |

Family Cites Families (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2751293A (en) * | 1951-07-31 | 1956-06-19 | Allied Prod Corp | Process of making perforated powdered metal article |

| US4212669A (en) * | 1978-08-03 | 1980-07-15 | Howmet Turbine Components Corporation | Method for the production of precision shapes |

| US5204055A (en) | 1989-12-08 | 1993-04-20 | Massachusetts Institute Of Technology | Three-dimensional printing techniques |

| US5387380A (en) * | 1989-12-08 | 1995-02-07 | Massachusetts Institute Of Technology | Three-dimensional printing techniques |

| US5775402A (en) | 1995-10-31 | 1998-07-07 | Massachusetts Institute Of Technology | Enhancement of thermal properties of tooling made by solid free form fabrication techniques |

| US5490882A (en) | 1992-11-30 | 1996-02-13 | Massachusetts Institute Of Technology | Process for removing loose powder particles from interior passages of a body |

| US5814161A (en) | 1992-11-30 | 1998-09-29 | Massachusetts Institute Of Technology | Ceramic mold finishing techniques for removing powder |

| US6146567A (en) | 1993-02-18 | 2000-11-14 | Massachusetts Institute Of Technology | Three dimensional printing methods |

| US6176874B1 (en) | 1993-10-18 | 2001-01-23 | Masschusetts Institute Of Technology | Vascularized tissue regeneration matrices formed by solid free form fabrication techniques |

| US6280771B1 (en) | 1997-02-20 | 2001-08-28 | Therics, Inc. | Dosage forms exhibiting multi-phasic release kinetics and methods of manufacture thereof |

| US5490962A (en) | 1993-10-18 | 1996-02-13 | Massachusetts Institute Of Technology | Preparation of medical devices by solid free-form fabrication methods |

| US5518680A (en) | 1993-10-18 | 1996-05-21 | Massachusetts Institute Of Technology | Tissue regeneration matrices by solid free form fabrication techniques |

| US5660621A (en) | 1995-12-29 | 1997-08-26 | Massachusetts Institute Of Technology | Binder composition for use in three dimensional printing |

| US6596224B1 (en) | 1996-05-24 | 2003-07-22 | Massachusetts Institute Of Technology | Jetting layers of powder and the formation of fine powder beds thereby |

| ATE421318T1 (de) | 1997-02-20 | 2009-02-15 | Massachusetts Inst Technology | Darreichungsform, welche rasche dispersionseigenschaften entfaltet, anwendungsverfahren sowie verfahren zur herstellung derselben |

| US5940674A (en) | 1997-04-09 | 1999-08-17 | Massachusetts Institute Of Technology | Three-dimensional product manufacture using masks |

| US6070973A (en) | 1997-05-15 | 2000-06-06 | Massachusetts Institute Of Technology | Non-resonant and decoupled droplet generator |

| US6508980B1 (en) | 1997-09-26 | 2003-01-21 | Massachusetts Institute Of Technology | Metal and ceramic containing parts produced from powder using binders derived from salt |

| US6397722B1 (en) | 1997-10-07 | 2002-06-04 | George D. Eddington | Variable torque accommodating, pressure fluid driven, transmissionless engine |

| US6197575B1 (en) | 1998-03-18 | 2001-03-06 | Massachusetts Institute Of Technology | Vascularized perfused microtissue/micro-organ arrays |

| US5939011A (en) * | 1998-04-06 | 1999-08-17 | Ford Global Technologies, Inc. | Method for producing a mandrel for use in hot isostatic pressed powder metallurgy rapid tool making |

| JP2002527144A (ja) | 1998-10-12 | 2002-08-27 | セリックス, インコーポレイテッド | 組織再生のための複合体およびその製造方法 |

| US6042780A (en) | 1998-12-15 | 2000-03-28 | Huang; Xiaodi | Method for manufacturing high performance components |

| CA2408956C (en) | 2000-05-18 | 2011-07-12 | Therics, Inc. | Method and form of a drug delivery device,such as encapsulating a toxic core within a non-toxic region in an oral dosage form |

| US6397922B1 (en) | 2000-05-24 | 2002-06-04 | Massachusetts Institute Of Technology | Molds for casting with customized internal structure to collapse upon cooling and to facilitate control of heat transfer |

| US6945638B2 (en) | 2001-10-29 | 2005-09-20 | Therics, Inc. | Method and system for controlling the temperature of a dispensed liquid |

| JP4551089B2 (ja) | 2001-10-29 | 2010-09-22 | マサチューセッツ インスティテュート オブ テクノロジー | 三次元印刷により製造されたゼロ次放出プロフィール投薬形態のような徐放投薬形態を製造するためのシステム |

| JP4845340B2 (ja) | 2001-10-29 | 2011-12-28 | マサチューセッツ インスティテュート オブ テクノロジー | 三次元プリント投薬形態のような物品の一軸圧縮のためのシステムおよび方法 |

| WO2003092633A2 (en) | 2002-05-06 | 2003-11-13 | Massachusetts Institute Of Technology | Diffusion-controlled dosage form and method of fabrication including three dimensional printing |

| GB0307523D0 (en) * | 2003-04-01 | 2003-05-07 | Rolls Royce Plc | Hip manufacture of a hollow component |

| US7077334B2 (en) | 2003-04-10 | 2006-07-18 | Massachusetts Institute Of Technology | Positive pressure drop-on-demand printing |

| US7250134B2 (en) | 2003-11-26 | 2007-07-31 | Massachusetts Institute Of Technology | Infiltrating a powder metal skeleton by a similar alloy with depressed melting point exploiting a persistent liquid phase at equilibrium, suitable for fabricating steel parts |

| JP2007537007A (ja) | 2004-05-12 | 2007-12-20 | マサチューセッツ インスティテュート オブ テクノロジー | 溶剤蒸気膜形成を含んだ立体印刷法等の製法 |

| EP2236229B1 (en) * | 2009-04-02 | 2015-07-15 | Sandvik Intellectual Property AB | Method for manufacturing a powder based article |

| US20110052441A1 (en) * | 2009-08-27 | 2011-03-03 | General Electric Company | Method and device for hot isostatic pressing of alloyed materials |

| EP2551040A1 (en) * | 2011-07-25 | 2013-01-30 | EADS Deutschland GmbH | Method of manufacturing a component by hot isostatic pressing |

-

2014

- 2014-10-15 EP EP14853308.6A patent/EP3057729A4/en not_active Withdrawn

- 2014-10-15 WO PCT/US2014/060572 patent/WO2015057761A1/en not_active Ceased

- 2014-10-15 JP JP2016523314A patent/JP2016540887A/ja active Pending

- 2014-10-15 US US15/029,097 patent/US20160243621A1/en not_active Abandoned

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52147509A (en) * | 1976-06-01 | 1977-12-08 | Special Metals Corp | Process and apparatus for production of solidifying element |

| JPH09262841A (ja) * | 1996-03-26 | 1997-10-07 | Mitsuboshi:Kk | 中空樹脂成形品の製造法およびそれに用いる低融点金属製品の製造法 |

| JP2001522722A (ja) * | 1997-09-30 | 2001-11-20 | アメテック・スペシャリティ・メタル・プロダクツ・ディビジョン | ガス等静圧加工法 |

| US20080237933A1 (en) * | 2003-06-16 | 2008-10-02 | Rainer Hochsmann | Methods and systems for manufacturing the manufacture of layered three-dimensional forms |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023076470A (ja) * | 2017-05-19 | 2023-06-01 | ボディコート エイチ.アイ.ピー.リミテッド | コンポーネント |

| JP2023066788A (ja) * | 2021-10-29 | 2023-05-16 | 国立大学法人 東京大学 | 金属積層造形品の製造方法 |

| JP7640432B2 (ja) | 2021-10-29 | 2025-03-05 | 国立大学法人 東京大学 | 金属積層造形品の製造方法 |

| KR20230081817A (ko) | 2021-11-29 | 2023-06-08 | 한국생산기술연구원 | 캐닝 프리 열간 등방압 가압 분말야금 방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20160243621A1 (en) | 2016-08-25 |

| WO2015057761A1 (en) | 2015-04-23 |

| EP3057729A1 (en) | 2016-08-24 |

| EP3057729A4 (en) | 2017-10-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2016540887A (ja) | 3次元印刷された熱間静水圧加圧成形用容器及びその製造方法 | |

| US6354362B1 (en) | Method and apparatus for infiltrating preformed components and component assemblies | |

| EP2910324B1 (en) | Method for manufacturing a three-dimensional object using powders | |

| KR102297842B1 (ko) | 서멧 또는 초경합금 분말을 제조하는 방법 | |

| CN109689196B (zh) | 用于添加剂合成的具有复合颗粒的多材料粉末 | |

| US9205492B2 (en) | Method for manufacturing a powder based article | |

| US6048432A (en) | Method for producing complex-shaped objects from laminae | |

| CN106862570A (zh) | 一种多喷头协同控制金属粉末3d成型方法 | |

| US20160158843A1 (en) | Method of achieving full density binder jet printed metallic articles | |

| US11117190B2 (en) | Using thin-walled containers in powder metallurgy | |

| JP2018501398A (ja) | 3次元印刷物の熱処理中の空洞の変形を抑制する方法 | |

| WO2016030654A1 (en) | A mould for use in a hot isostatic press | |

| CN112789130A (zh) | 生产反模板的方法以及使用此类的反模板制造具有复杂形状部件的方法 | |

| KR20230121370A (ko) | 3차원 성형체 및 그 제조 방법 | |

| JP2017514993A (ja) | 酸洗い可能な金属コンポーネントの製造方法 | |

| CN104972114A (zh) | 一种具有特殊功能层复杂零件的热等静压一体化成形方法 | |

| CN111690925B (zh) | 一种钛及钛合金表面硬化以及表面功能化处理工艺 | |

| JPH04224603A (ja) | 任意の複雑な形をした部品を製作する方法と装置 | |

| CN107671294A (zh) | 制作热等静压包套以及使用该包套来生产预成型件的热等静压工艺 | |

| RU2319580C2 (ru) | Способ изготовления тонкостенных изделий или изделий с внутренней полостью из композита на основе карбида | |

| EP3646970B1 (en) | Method for fabricating components using hybrid additive manufacturing and consolidation process | |

| JP4016106B2 (ja) | ポーラス金属材料及びその製造方法 | |

| JP7138826B1 (ja) | 封孔処理された金属複合体および金型並びに封孔処理された金属複合体の製造方法 | |

| WO2025179138A1 (en) | Method for densifying articles | |

| JPH07179907A (ja) | 通気性・通水性を有する金属素材の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160520 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170410 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170523 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170731 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20171213 |