JP2014513434A - 除去プロファイルを生成するための研磨パラメータの選択 - Google Patents

除去プロファイルを生成するための研磨パラメータの選択 Download PDFInfo

- Publication number

- JP2014513434A JP2014513434A JP2014508469A JP2014508469A JP2014513434A JP 2014513434 A JP2014513434 A JP 2014513434A JP 2014508469 A JP2014508469 A JP 2014508469A JP 2014508469 A JP2014508469 A JP 2014508469A JP 2014513434 A JP2014513434 A JP 2014513434A

- Authority

- JP

- Japan

- Prior art keywords

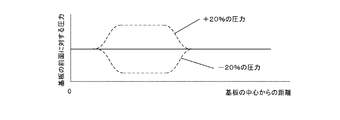

- substrate

- profile

- pressure

- removal

- polishing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

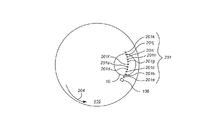

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/005—Control means for lapping machines or devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

- B24B37/042—Lapping machines or devices; Accessories designed for working plane surfaces operating processes therefor

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/18—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form

- G05B19/182—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form characterised by the machine tool function, e.g. thread cutting, cam making, tool direction control

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05D—SYSTEMS FOR CONTROLLING OR REGULATING NON-ELECTRIC VARIABLES

- G05D16/00—Control of fluid pressure

- G05D16/20—Control of fluid pressure characterised by the use of electric means

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/45—Nc applications

- G05B2219/45232—CMP chemical mechanical polishing of wafer

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- General Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- Fluid Mechanics (AREA)

- Human Computer Interaction (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/098,257 US8774958B2 (en) | 2011-04-29 | 2011-04-29 | Selection of polishing parameters to generate removal profile |

| US13/098,257 | 2011-04-29 | ||

| PCT/US2012/034702 WO2012148859A2 (en) | 2011-04-29 | 2012-04-23 | Selection of polishing parameters to generate removal profile |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2014513434A true JP2014513434A (ja) | 2014-05-29 |

| JP2014513434A5 JP2014513434A5 (enExample) | 2015-09-17 |

Family

ID=47068573

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014508469A Pending JP2014513434A (ja) | 2011-04-29 | 2012-04-23 | 除去プロファイルを生成するための研磨パラメータの選択 |

Country Status (5)

| Country | Link |

|---|---|

| US (3) | US8774958B2 (enExample) |

| JP (1) | JP2014513434A (enExample) |

| KR (2) | KR101834711B1 (enExample) |

| TW (2) | TWI637813B (enExample) |

| WO (1) | WO2012148859A2 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014061587A (ja) * | 2012-08-28 | 2014-04-10 | Ebara Corp | 弾性膜及び基板保持装置 |

| KR20170028369A (ko) * | 2014-06-27 | 2017-03-13 | 어플라이드 머티어리얼스, 인코포레이티드 | 다중 구역 화학 기계적 평탄화 연마 헤드를 위한 구성가능한 압력 설계 |

| JP2022517729A (ja) * | 2018-12-26 | 2022-03-10 | アプライド マテリアルズ インコーポレイテッド | プレストン行列ジェネレータ |

| JP2022551429A (ja) * | 2019-09-27 | 2022-12-09 | コーニング インコーポレイテッド | 平坦さ機能要件を満たすフォトマスクブランクを仕上げるための目標トポグラフィマップの生成提供装置、システムおよび方法 |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8774958B2 (en) * | 2011-04-29 | 2014-07-08 | Applied Materials, Inc. | Selection of polishing parameters to generate removal profile |

| JP5900196B2 (ja) * | 2012-07-05 | 2016-04-06 | 株式会社Sumco | ウェーハの片面研磨方法およびウェーハの片面研磨装置 |

| US20150160368A1 (en) * | 2012-07-10 | 2015-06-11 | Statoil Petroleum As | Anisotropy parameter estimation |

| US9248544B2 (en) * | 2012-07-18 | 2016-02-02 | Applied Materials, Inc. | Endpoint detection during polishing using integrated differential intensity |

| JP6266493B2 (ja) * | 2014-03-20 | 2018-01-24 | 株式会社荏原製作所 | 研磨装置及び研磨方法 |

| TWI658899B (zh) * | 2014-03-31 | 2019-05-11 | Ebara Corporation | 研磨裝置及研磨方法 |

| WO2018005039A1 (en) * | 2016-06-30 | 2018-01-04 | Applied Materials, Inc. | Chemical mechanical polishing automated recipe generation |

| TWI789385B (zh) | 2017-04-21 | 2023-01-11 | 美商應用材料股份有限公司 | 使用神經網路來監測的拋光裝置 |

| TWI783037B (zh) * | 2017-09-25 | 2022-11-11 | 美商應用材料股份有限公司 | 使用機器學習方式以產生製程控制參數的半導體製造 |

| TWI794293B (zh) | 2017-09-25 | 2023-03-01 | 美商應用材料股份有限公司 | 使用製程控制參數矩陣的半導體製造 |

| JP7068831B2 (ja) * | 2018-01-18 | 2022-05-17 | 株式会社荏原製作所 | 研磨装置 |

| KR102594342B1 (ko) * | 2018-03-12 | 2023-10-26 | 도쿄엘렉트론가부시키가이샤 | 기판의 휨 수정 방법, 컴퓨터 기억 매체 및 기판 휨 수정 장치 |

| TWI845444B (zh) | 2018-04-03 | 2024-06-11 | 美商應用材料股份有限公司 | 針對墊子厚度使用機器學習及補償的拋光裝置、拋光系統、方法及電腦儲存媒體 |

| US12017322B2 (en) * | 2018-08-14 | 2024-06-25 | Taiwan Semiconductor Manufacturing Co., Ltd. | Chemical mechanical polishing method |

| WO2020067914A1 (en) | 2018-09-26 | 2020-04-02 | Applied Materials, Inc. | Compensation for substrate doping in edge reconstruction for in-situ electromagnetic inductive monitoring |

| EP3640972A1 (en) * | 2018-10-18 | 2020-04-22 | ASML Netherlands B.V. | System and method for facilitating chemical mechanical polishing |

| TWI850338B (zh) * | 2019-02-28 | 2024-08-01 | 美商應用材料股份有限公司 | 拋光墊、化學機械拋光系統、及控制拋光墊的背襯層的剛度的方法 |

| US11282755B2 (en) | 2019-08-27 | 2022-03-22 | Applied Materials, Inc. | Asymmetry correction via oriented wafer loading |

| US12440942B2 (en) | 2021-03-03 | 2025-10-14 | Applied Materials, Inc. | Pressure signals with different frequencies during friction monitoring to provide spatial resolution |

| WO2022187105A1 (en) * | 2021-03-05 | 2022-09-09 | Applied Materials, Inc. | Control of processing parameters for substrate polishing with substrate precession |

| WO2022187146A1 (en) | 2021-03-05 | 2022-09-09 | Applied Materials, Inc. | Control of processing parameters during substrate polishing using cost function or expected future parameter changes |

| CN113159121B (zh) * | 2021-03-16 | 2022-07-19 | 华中科技大学 | 基于先验知识模型的机器人磨抛去除量预测方法及设备 |

| US20220362903A1 (en) * | 2021-05-12 | 2022-11-17 | Taiwan Semiconductor Manufacturing Co., Ltd. | Multiple polishing heads with cross-zone pressure element distributions for cmp |

| US20250114896A1 (en) * | 2023-10-05 | 2025-04-10 | Applied Materials, Inc. | Individually rotatable platens and control of carrier head sweep |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006043873A (ja) * | 2004-07-09 | 2006-02-16 | Ebara Corp | 研磨プロファイル又は研磨量の予測方法、研磨方法及び研磨装置、プログラム、記憶媒体 |

| JP2008503356A (ja) * | 2004-06-21 | 2008-02-07 | 株式会社荏原製作所 | 研磨装置および研磨方法 |

| WO2008032753A1 (fr) * | 2006-09-12 | 2008-03-20 | Ebara Corporation | Appareil de polissage et procédé de polissage |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6439964B1 (en) * | 1999-10-12 | 2002-08-27 | Applied Materials, Inc. | Method of controlling a polishing machine |

| US6544103B1 (en) * | 2000-11-28 | 2003-04-08 | Speedfam-Ipec Corporation | Method to determine optimum geometry of a multizone carrier |

| US6540591B1 (en) * | 2001-04-18 | 2003-04-01 | Alexander J. Pasadyn | Method and apparatus for post-polish thickness and uniformity control |

| US7698012B2 (en) | 2001-06-19 | 2010-04-13 | Applied Materials, Inc. | Dynamic metrology schemes and sampling schemes for advanced process control in semiconductor processing |

| US7160739B2 (en) | 2001-06-19 | 2007-01-09 | Applied Materials, Inc. | Feedback control of a chemical mechanical polishing device providing manipulation of removal rate profiles |

| US6857947B2 (en) | 2002-01-17 | 2005-02-22 | Asm Nutool, Inc | Advanced chemical mechanical polishing system with smart endpoint detection |

| US20050070205A1 (en) | 2003-09-30 | 2005-03-31 | Speedfam-Ipec Corporation | Integrated pressure control system for workpiece carrier |

| US6932671B1 (en) * | 2004-05-05 | 2005-08-23 | Novellus Systems, Inc. | Method for controlling a chemical mechanical polishing (CMP) operation |

| US7150673B2 (en) * | 2004-07-09 | 2006-12-19 | Ebara Corporation | Method for estimating polishing profile or polishing amount, polishing method and polishing apparatus |

| US7115017B1 (en) | 2006-03-31 | 2006-10-03 | Novellus Systems, Inc. | Methods for controlling the pressures of adjustable pressure zones of a work piece carrier during chemical mechanical planarization |

| US7699688B2 (en) | 2006-11-22 | 2010-04-20 | Applied Materials, Inc. | Carrier ring for carrier head |

| US8774958B2 (en) * | 2011-04-29 | 2014-07-08 | Applied Materials, Inc. | Selection of polishing parameters to generate removal profile |

-

2011

- 2011-04-29 US US13/098,257 patent/US8774958B2/en active Active

-

2012

- 2012-04-23 WO PCT/US2012/034702 patent/WO2012148859A2/en not_active Ceased

- 2012-04-23 KR KR1020177015865A patent/KR101834711B1/ko active Active

- 2012-04-23 JP JP2014508469A patent/JP2014513434A/ja active Pending

- 2012-04-23 KR KR1020137031787A patent/KR101831309B1/ko active Active

- 2012-04-24 TW TW101114548A patent/TWI637813B/zh active

- 2012-04-24 TW TW106120666A patent/TWI668078B/zh active

-

2014

- 2014-06-02 US US14/293,776 patent/US9213340B2/en active Active

-

2015

- 2015-12-14 US US14/968,546 patent/US10493590B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008503356A (ja) * | 2004-06-21 | 2008-02-07 | 株式会社荏原製作所 | 研磨装置および研磨方法 |

| JP2006043873A (ja) * | 2004-07-09 | 2006-02-16 | Ebara Corp | 研磨プロファイル又は研磨量の予測方法、研磨方法及び研磨装置、プログラム、記憶媒体 |

| WO2008032753A1 (fr) * | 2006-09-12 | 2008-03-20 | Ebara Corporation | Appareil de polissage et procédé de polissage |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014061587A (ja) * | 2012-08-28 | 2014-04-10 | Ebara Corp | 弾性膜及び基板保持装置 |

| KR20170028369A (ko) * | 2014-06-27 | 2017-03-13 | 어플라이드 머티어리얼스, 인코포레이티드 | 다중 구역 화학 기계적 평탄화 연마 헤드를 위한 구성가능한 압력 설계 |

| JP2017520922A (ja) * | 2014-06-27 | 2017-07-27 | アプライド マテリアルズ インコーポレイテッドApplied Materials,Incorporated | マルチゾーン化学機械平坦化研磨ヘッドのための設定可能な圧力設計 |

| KR102309223B1 (ko) | 2014-06-27 | 2021-10-06 | 어플라이드 머티어리얼스, 인코포레이티드 | 다중 구역 화학 기계적 평탄화 연마 헤드를 위한 구성가능한 압력 설계 |

| JP2022517729A (ja) * | 2018-12-26 | 2022-03-10 | アプライド マテリアルズ インコーポレイテッド | プレストン行列ジェネレータ |

| US11989492B2 (en) | 2018-12-26 | 2024-05-21 | Applied Materials, Inc. | Preston matrix generator |

| JP7558173B2 (ja) | 2018-12-26 | 2024-09-30 | アプライド マテリアルズ インコーポレイテッド | プレストン行列ジェネレータ |

| JP2022551429A (ja) * | 2019-09-27 | 2022-12-09 | コーニング インコーポレイテッド | 平坦さ機能要件を満たすフォトマスクブランクを仕上げるための目標トポグラフィマップの生成提供装置、システムおよび方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US10493590B2 (en) | 2019-12-03 |

| WO2012148859A3 (en) | 2013-03-21 |

| KR20170071609A (ko) | 2017-06-23 |

| US20160096251A1 (en) | 2016-04-07 |

| WO2012148859A2 (en) | 2012-11-01 |

| KR101831309B1 (ko) | 2018-02-22 |

| US9213340B2 (en) | 2015-12-15 |

| TW201736043A (zh) | 2017-10-16 |

| KR101834711B1 (ko) | 2018-03-05 |

| US8774958B2 (en) | 2014-07-08 |

| US20120277897A1 (en) | 2012-11-01 |

| TWI637813B (zh) | 2018-10-11 |

| KR20140028045A (ko) | 2014-03-07 |

| TW201313392A (zh) | 2013-04-01 |

| US20140277670A1 (en) | 2014-09-18 |

| TWI668078B (zh) | 2019-08-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2014513434A (ja) | 除去プロファイルを生成するための研磨パラメータの選択 | |

| KR102741434B1 (ko) | 분광 모니터링을 위한 기계 학습 시스템을 위한 훈련 스펙트럼 생성 | |

| JP6580042B2 (ja) | 基板研磨中の研磨速度の制限的調整 | |

| KR102733621B1 (ko) | 압전 압력 제어를 갖는 연마 캐리어 헤드 | |

| JP6562916B2 (ja) | 予測フィルタを用いた基板研磨中の研磨速度の調整 | |

| CN109844923B (zh) | 用于化学机械抛光的实时轮廓控制 | |

| JP7686015B2 (ja) | コスト関数または予想される将来のパラメータ変化を使用した、基板研磨中の処理パラメータの制御 | |

| KR102904061B1 (ko) | 기판 세차운동을 이용한 기판 연마를 위한 처리 파라미터들의 제어 | |

| US9289875B2 (en) | Feed forward and feed-back techniques for in-situ process control | |

| JP7558173B2 (ja) | プレストン行列ジェネレータ | |

| KR102108709B1 (ko) | 폴리싱 엔드포인트 검출에서의 데이터 시퀀스들을 위한 사용자 입력 함수들 | |

| US20240139906A1 (en) | Control of carrier head sweep and platen shape |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150423 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150423 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150728 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160516 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160524 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160823 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160920 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20170523 |