JP2013538677A - 粗芳香族ニトロ化合物の後処理からの廃水を精製する方法 - Google Patents

粗芳香族ニトロ化合物の後処理からの廃水を精製する方法 Download PDFInfo

- Publication number

- JP2013538677A JP2013538677A JP2013523614A JP2013523614A JP2013538677A JP 2013538677 A JP2013538677 A JP 2013538677A JP 2013523614 A JP2013523614 A JP 2013523614A JP 2013523614 A JP2013523614 A JP 2013523614A JP 2013538677 A JP2013538677 A JP 2013538677A

- Authority

- JP

- Japan

- Prior art keywords

- aqueous phase

- phase

- ammonia

- wastewater

- phases

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 75

- 239000002351 wastewater Substances 0.000 title claims abstract description 72

- -1 aromatic nitro compounds Chemical class 0.000 title claims abstract description 25

- 239000008346 aqueous phase Substances 0.000 claims abstract description 98

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 claims abstract description 96

- 229910021529 ammonia Inorganic materials 0.000 claims abstract description 48

- 238000005406 washing Methods 0.000 claims abstract description 30

- 239000012074 organic phase Substances 0.000 claims abstract description 25

- 238000004065 wastewater treatment Methods 0.000 claims abstract description 18

- 238000006396 nitration reaction Methods 0.000 claims abstract description 15

- 150000002894 organic compounds Chemical class 0.000 claims abstract description 10

- 238000000746 purification Methods 0.000 claims abstract description 10

- 150000001491 aromatic compounds Chemical class 0.000 claims abstract description 8

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 claims description 102

- LQNUZADURLCDLV-UHFFFAOYSA-N nitrobenzene Chemical compound [O-][N+](=O)C1=CC=CC=C1 LQNUZADURLCDLV-UHFFFAOYSA-N 0.000 claims description 76

- 238000004821 distillation Methods 0.000 claims description 23

- 239000002585 base Substances 0.000 claims description 20

- 239000012071 phase Substances 0.000 claims description 19

- 125000003118 aryl group Chemical group 0.000 claims description 15

- 239000006200 vaporizer Substances 0.000 claims description 14

- 238000010525 oxidative degradation reaction Methods 0.000 claims description 5

- 238000005979 thermal decomposition reaction Methods 0.000 claims description 4

- 150000008044 alkali metal hydroxides Chemical class 0.000 claims description 3

- 238000000197 pyrolysis Methods 0.000 claims description 3

- 238000006864 oxidative decomposition reaction Methods 0.000 abstract description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 28

- 239000000047 product Substances 0.000 description 18

- 238000000926 separation method Methods 0.000 description 14

- 239000007788 liquid Substances 0.000 description 13

- 239000002253 acid Substances 0.000 description 12

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 10

- 239000007789 gas Substances 0.000 description 10

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 9

- 238000006243 chemical reaction Methods 0.000 description 8

- 239000000203 mixture Substances 0.000 description 8

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 6

- 150000003839 salts Chemical class 0.000 description 6

- 239000007858 starting material Substances 0.000 description 6

- IQUPABOKLQSFBK-UHFFFAOYSA-N 2-nitrophenol Chemical compound OC1=CC=CC=C1[N+]([O-])=O IQUPABOKLQSFBK-UHFFFAOYSA-N 0.000 description 5

- 239000007864 aqueous solution Substances 0.000 description 5

- 239000011261 inert gas Substances 0.000 description 5

- 229910052757 nitrogen Inorganic materials 0.000 description 5

- 238000012856 packing Methods 0.000 description 5

- 241000894006 Bacteria Species 0.000 description 4

- NHNBFGGVMKEFGY-UHFFFAOYSA-N Nitrate Chemical compound [O-][N+]([O-])=O NHNBFGGVMKEFGY-UHFFFAOYSA-N 0.000 description 4

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 description 4

- 238000004140 cleaning Methods 0.000 description 4

- 238000005949 ozonolysis reaction Methods 0.000 description 4

- 238000005191 phase separation Methods 0.000 description 4

- 150000002989 phenols Chemical class 0.000 description 4

- 238000010992 reflux Methods 0.000 description 4

- WMFOQBRAJBCJND-UHFFFAOYSA-M Lithium hydroxide Chemical compound [Li+].[OH-] WMFOQBRAJBCJND-UHFFFAOYSA-M 0.000 description 3

- IOVCWXUNBOPUCH-UHFFFAOYSA-M Nitrite anion Chemical compound [O-]N=O IOVCWXUNBOPUCH-UHFFFAOYSA-M 0.000 description 3

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 description 3

- 230000015556 catabolic process Effects 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 238000006731 degradation reaction Methods 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- RBXVOQPAMPBADW-UHFFFAOYSA-N nitrous acid;phenol Chemical class ON=O.OC1=CC=CC=C1 RBXVOQPAMPBADW-UHFFFAOYSA-N 0.000 description 3

- WDCYWAQPCXBPJA-UHFFFAOYSA-N 1,3-dinitrobenzene Chemical compound [O-][N+](=O)C1=CC=CC([N+]([O-])=O)=C1 WDCYWAQPCXBPJA-UHFFFAOYSA-N 0.000 description 2

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- 229910002651 NO3 Inorganic materials 0.000 description 2

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 2

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 239000003513 alkali Substances 0.000 description 2

- 230000001651 autotrophic effect Effects 0.000 description 2

- 239000007795 chemical reaction product Substances 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 238000009833 condensation Methods 0.000 description 2

- 230000005494 condensation Effects 0.000 description 2

- 238000010924 continuous production Methods 0.000 description 2

- 238000005265 energy consumption Methods 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 239000011552 falling film Substances 0.000 description 2

- 150000002823 nitrates Chemical class 0.000 description 2

- 230000000802 nitrating effect Effects 0.000 description 2

- 229910017604 nitric acid Inorganic materials 0.000 description 2

- 230000001546 nitrifying effect Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- CPRMKOQKXYSDML-UHFFFAOYSA-M rubidium hydroxide Chemical compound [OH-].[Rb+] CPRMKOQKXYSDML-UHFFFAOYSA-M 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000009834 vaporization Methods 0.000 description 2

- 230000008016 vaporization Effects 0.000 description 2

- FVHAWXWFPBPFOS-UHFFFAOYSA-N 1,2-dimethyl-3-nitrobenzene Chemical group CC1=CC=CC([N+]([O-])=O)=C1C FVHAWXWFPBPFOS-UHFFFAOYSA-N 0.000 description 1

- DYSXLQBUUOPLBB-UHFFFAOYSA-N 2,3-dinitrotoluene Chemical compound CC1=CC=CC([N+]([O-])=O)=C1[N+]([O-])=O DYSXLQBUUOPLBB-UHFFFAOYSA-N 0.000 description 1

- QTTRFLVOJXBHKS-UHFFFAOYSA-N 6-nitro-7-oxabicyclo[4.1.0]hepta-2,4-dien-1-ol Chemical compound [N+](=O)([O-])C12C(C=CC=C1)(O)O2 QTTRFLVOJXBHKS-UHFFFAOYSA-N 0.000 description 1

- 241000251468 Actinopterygii Species 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 229910000288 alkali metal carbonate Inorganic materials 0.000 description 1

- 150000008041 alkali metal carbonates Chemical class 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 239000002518 antifoaming agent Substances 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000001580 bacterial effect Effects 0.000 description 1

- 239000010796 biological waste Substances 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 230000003139 buffering effect Effects 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000012043 crude product Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 239000013530 defoamer Substances 0.000 description 1

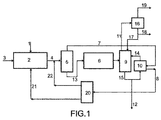

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 244000005700 microbiome Species 0.000 description 1

- 150000002828 nitro derivatives Chemical class 0.000 description 1

- VLZLOWPYUQHHCG-UHFFFAOYSA-N nitromethylbenzene Chemical compound [O-][N+](=O)CC1=CC=CC=C1 VLZLOWPYUQHHCG-UHFFFAOYSA-N 0.000 description 1

- 150000002897 organic nitrogen compounds Chemical class 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 230000020477 pH reduction Effects 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 229910052701 rubidium Inorganic materials 0.000 description 1

- IGLNJRXAVVLDKE-UHFFFAOYSA-N rubidium atom Chemical compound [Rb] IGLNJRXAVVLDKE-UHFFFAOYSA-N 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 229910000029 sodium carbonate Inorganic materials 0.000 description 1

- 239000002689 soil Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 238000010626 work up procedure Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/02—Treatment of water, waste water, or sewage by heating

- C02F1/04—Treatment of water, waste water, or sewage by heating by distillation or evaporation

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/02—Treatment of water, waste water, or sewage by heating

- C02F1/025—Thermal hydrolysis

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/20—Treatment of water, waste water, or sewage by degassing, i.e. liberation of dissolved gases

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/72—Treatment of water, waste water, or sewage by oxidation

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F9/00—Multistage treatment of water, waste water or sewage

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/72—Treatment of water, waste water, or sewage by oxidation

- C02F1/78—Treatment of water, waste water, or sewage by oxidation with ozone

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2101/00—Nature of the contaminant

- C02F2101/30—Organic compounds

- C02F2101/38—Organic compounds containing nitrogen

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2103/00—Nature of the water, waste water, sewage or sludge to be treated

- C02F2103/34—Nature of the water, waste water, sewage or sludge to be treated from industrial activities not provided for in groups C02F2103/12 - C02F2103/32

- C02F2103/36—Nature of the water, waste water, sewage or sludge to be treated from industrial activities not provided for in groups C02F2103/12 - C02F2103/32 from the manufacture of organic compounds

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2209/00—Controlling or monitoring parameters in water treatment

- C02F2209/02—Temperature

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2209/00—Controlling or monitoring parameters in water treatment

- C02F2209/03—Pressure

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2209/00—Controlling or monitoring parameters in water treatment

- C02F2209/06—Controlling or monitoring parameters in water treatment pH

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2209/00—Controlling or monitoring parameters in water treatment

- C02F2209/14—NH3-N

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Water Supply & Treatment (AREA)

- Organic Chemistry (AREA)

- Hydrology & Water Resources (AREA)

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Biodiversity & Conservation Biology (AREA)

- Microbiology (AREA)

- Physical Water Treatments (AREA)

- Heat Treatment Of Water, Waste Water Or Sewage (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Activated Sludge Processes (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP10172647.9 | 2010-08-12 | ||

| EP10172647A EP2418176A1 (de) | 2010-08-12 | 2010-08-12 | Verfahren zur Aufreinigung von Abwässern aus der Aufarbeitung vom rohem Mononitrobenzol |

| PCT/EP2011/063835 WO2012025393A1 (de) | 2010-08-12 | 2011-08-11 | Verfahren zur aufreinigung von abwässern aus der aufarbeitung von rohen aromatischen nitroverbindungen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2013538677A true JP2013538677A (ja) | 2013-10-17 |

| JP2013538677A5 JP2013538677A5 (enExample) | 2014-09-25 |

Family

ID=43128210

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013523614A Ceased JP2013538677A (ja) | 2010-08-12 | 2011-08-11 | 粗芳香族ニトロ化合物の後処理からの廃水を精製する方法 |

Country Status (7)

| Country | Link |

|---|---|

| EP (2) | EP2418176A1 (enExample) |

| JP (1) | JP2013538677A (enExample) |

| KR (1) | KR20130097749A (enExample) |

| CN (1) | CN103080012A (enExample) |

| BR (1) | BR112013002247A2 (enExample) |

| PT (1) | PT2603461E (enExample) |

| WO (1) | WO2012025393A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170021851A (ko) * | 2014-06-24 | 2017-02-28 | 코베스트로 도이칠란트 아게 | 니트로벤젠의 제조 방법 |

| JP2022532856A (ja) * | 2019-04-29 | 2022-07-20 | ゼロ ディスチャージ, エルエルシー | ゼロ排出の水処理装置および方法 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8933262B2 (en) | 2011-05-24 | 2015-01-13 | Basf Se | Process for preparing polyisocyanates from biomass |

| US8697921B2 (en) | 2011-08-09 | 2014-04-15 | Basf Se | Process for purifying wastewaters from the workup of crude aromatic nitro compounds |

| ES2570530T3 (es) * | 2012-04-25 | 2016-05-18 | Basf Se | Método para lavar dinitrotolueno |

| CN102826702A (zh) * | 2012-08-30 | 2012-12-19 | 宁夏宝塔石化集团有限公司 | 一种从苯醇烷基化反应工艺水中去除少量苯或甲苯的方法 |

| CN105246833B (zh) * | 2013-04-18 | 2018-02-06 | 科思创德国股份公司 | 后处理来自硝基苯制备的废水的方法 |

| WO2014170250A1 (de) | 2013-04-18 | 2014-10-23 | Bayer Materialscience Ag | Verfahren zur aufarbeitung von abwasser aus der nitro-benzolherstellung |

| CN110143631A (zh) * | 2019-06-11 | 2019-08-20 | 聊城煤泗新材料科技有限公司 | 一种节能型废水汽提回收轻质油工艺及其应用 |

| CN110440140B (zh) * | 2019-09-10 | 2024-07-16 | 浙江伟博化工科技有限公司 | 一种增塑剂dinp塔式气体系统 |

| CN111285421A (zh) * | 2020-01-16 | 2020-06-16 | 董国亮 | 一种甲醇制烯烃污水汽提塔系统 |

| CN111689541A (zh) * | 2020-07-17 | 2020-09-22 | 四川北方红光特种化工有限公司 | 硝基酚钠盐废水安全浓缩工艺及浓缩系统 |

| CN115594357B (zh) * | 2022-11-08 | 2024-04-19 | 煤炭科学技术研究院有限公司 | 一种酰化废水分级处理方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004230338A (ja) * | 2003-01-31 | 2004-08-19 | Nippon Steel Corp | 廃水からのアンモニア性窒素化合物の除去方法 |

| JP2005296949A (ja) * | 2004-04-10 | 2005-10-27 | Bayer Materialscience Ag | 芳香族ニトロ化合物を含有する廃水の後処理法 |

| JP2009528917A (ja) * | 2006-03-07 | 2009-08-13 | ビーエーエスエフ ソシエタス・ヨーロピア | ニトロ化用の酸でトルエンをニトロ化してジニトロトルエンを製造する工程からでるプロセス排水中のジニトロトルエンを蒸留的に除去する方法 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4241229A (en) * | 1979-08-08 | 1980-12-23 | American Cyanamid Company | Recovery of nitrated aromatic compounds from nitration wash liquors |

| DE3900932A1 (de) | 1989-01-14 | 1990-07-26 | Basf Ag | Verfahren zur reinigung von nitroaromaten enthaltenden abwaessern |

| DE69026590T2 (de) | 1990-01-04 | 1996-10-31 | Nrm Int Tech | Nitrierungsverfahren |

| DE19815844A1 (de) | 1998-04-08 | 1999-10-14 | Basf Ag | Verfahren zum Abbau von aromatischen Nitroverbindungen in Abwässern |

| US6288289B1 (en) * | 2000-01-27 | 2001-09-11 | Noram Engineering And Constructors Ltd. | Integrated effluent treatment process for nitroaromatic manufacture |

| CN1208123C (zh) | 2000-03-02 | 2005-06-29 | 陶氏环球技术公司 | 管式反应器、在管式反应器中进行液/液多相反应的方法、和一种在管式反应器中环-硝化芳烃化合物的方法 |

| DE10329304A1 (de) * | 2003-06-30 | 2005-02-03 | Bayer Materialscience Ag | Verfahren zur Aufarbeitung des bei der Herstellung von Dinitrotoluol anfallenden Abwassers |

| CN100509664C (zh) * | 2007-04-28 | 2009-07-08 | 黄继国 | 一种适合缺水地区垃圾填埋场渗滤液的处理方法 |

| WO2009027416A1 (de) | 2007-08-30 | 2009-03-05 | Basf Se | Verfahren zur aufarbeitung von abwässern aus der nitrierung |

| CN100522849C (zh) * | 2007-10-30 | 2009-08-05 | 云南亚太环境工程设计研究有限公司 | 一种深度处理氨氮污水的方法 |

| CN101514044A (zh) * | 2009-03-17 | 2009-08-26 | 南京师范大学 | 一种三相流化处理低浓度硝基苯废水的方法 |

-

2010

- 2010-08-12 EP EP10172647A patent/EP2418176A1/de not_active Withdrawn

-

2011

- 2011-08-11 WO PCT/EP2011/063835 patent/WO2012025393A1/de not_active Ceased

- 2011-08-11 KR KR1020137006008A patent/KR20130097749A/ko not_active Withdrawn

- 2011-08-11 PT PT117415901T patent/PT2603461E/pt unknown

- 2011-08-11 JP JP2013523614A patent/JP2013538677A/ja not_active Ceased

- 2011-08-11 BR BR112013002247A patent/BR112013002247A2/pt not_active Application Discontinuation

- 2011-08-11 CN CN2011800392943A patent/CN103080012A/zh active Pending

- 2011-08-11 EP EP11741590.1A patent/EP2603461B1/de active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004230338A (ja) * | 2003-01-31 | 2004-08-19 | Nippon Steel Corp | 廃水からのアンモニア性窒素化合物の除去方法 |

| JP2005296949A (ja) * | 2004-04-10 | 2005-10-27 | Bayer Materialscience Ag | 芳香族ニトロ化合物を含有する廃水の後処理法 |

| JP2009528917A (ja) * | 2006-03-07 | 2009-08-13 | ビーエーエスエフ ソシエタス・ヨーロピア | ニトロ化用の酸でトルエンをニトロ化してジニトロトルエンを製造する工程からでるプロセス排水中のジニトロトルエンを蒸留的に除去する方法 |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170021851A (ko) * | 2014-06-24 | 2017-02-28 | 코베스트로 도이칠란트 아게 | 니트로벤젠의 제조 방법 |

| JP2017525666A (ja) * | 2014-06-24 | 2017-09-07 | コベストロ、ドイチュラント、アクチエンゲゼルシャフトCovestro Deutschland Ag | ニトロベンゼンの製造方法 |

| KR102414963B1 (ko) | 2014-06-24 | 2022-07-01 | 코베스트로 도이칠란트 아게 | 니트로벤젠의 제조 방법 |

| JP2022532856A (ja) * | 2019-04-29 | 2022-07-20 | ゼロ ディスチャージ, エルエルシー | ゼロ排出の水処理装置および方法 |

| JP7587849B2 (ja) | 2019-04-29 | 2024-11-21 | ゼロ ディスチャージ, エルエルシー | ゼロ排出の水処理装置および方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103080012A (zh) | 2013-05-01 |

| PT2603461E (pt) | 2014-11-07 |

| EP2418176A1 (de) | 2012-02-15 |

| EP2603461A1 (de) | 2013-06-19 |

| KR20130097749A (ko) | 2013-09-03 |

| WO2012025393A1 (de) | 2012-03-01 |

| BR112013002247A2 (pt) | 2016-05-24 |

| EP2603461B1 (de) | 2014-10-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2013538677A (ja) | 粗芳香族ニトロ化合物の後処理からの廃水を精製する方法 | |

| RU2511380C2 (ru) | Способ и установка для регенерации отработанной серной кислоты из процессов нитрования | |

| CN107106961B (zh) | 用于连续生产二硝基甲苯的方法中的废气净化 | |

| JP4901883B2 (ja) | ニトロ化用の酸でトルエンをニトロ化してジニトロトルエンを製造する工程からでるプロセス排水中のジニトロトルエンを蒸留的に除去する方法 | |

| CN105263865B (zh) | 后处理来自硝基苯制备的废水的方法 | |

| US20120205308A1 (en) | Process for purifying wastewaters from the workup of crude aromatic nitro compounds | |

| CN105246833B (zh) | 后处理来自硝基苯制备的废水的方法 | |

| CN103748041B (zh) | 纯化来自粗芳族硝基化合物再加工的废水的方法 | |

| US8697921B2 (en) | Process for purifying wastewaters from the workup of crude aromatic nitro compounds | |

| US20130041188A1 (en) | Process for purifying wastewaters from the workup of crude aromatic nitro compounds | |

| CN107750244B (zh) | 一种纯化来自硝化过程的硝化芳香族化合物的方法 | |

| JPH03103316A (ja) | 硝酸の回収方法 | |

| KR20220052985A (ko) | 산화 처리를 통한 폐수 중 포름알데히드의 제거 | |

| JP7603911B2 (ja) | プロセス流のための蒸発システム | |

| JPH11319801A (ja) | 廃水の処理方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140805 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140805 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20150422 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150428 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150727 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20151215 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20160426 |