JP2013500173A - 予備処理指標及び持続的指標を有する研磨物品 - Google Patents

予備処理指標及び持続的指標を有する研磨物品 Download PDFInfo

- Publication number

- JP2013500173A JP2013500173A JP2012522849A JP2012522849A JP2013500173A JP 2013500173 A JP2013500173 A JP 2013500173A JP 2012522849 A JP2012522849 A JP 2012522849A JP 2012522849 A JP2012522849 A JP 2012522849A JP 2013500173 A JP2013500173 A JP 2013500173A

- Authority

- JP

- Japan

- Prior art keywords

- abrasive

- abrasive article

- composites

- coating

- article

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000002085 persistent effect Effects 0.000 title claims abstract description 22

- 238000002203 pretreatment Methods 0.000 title abstract description 9

- 239000002131 composite material Substances 0.000 claims abstract description 46

- 239000002245 particle Substances 0.000 claims abstract description 16

- 239000011230 binding agent Substances 0.000 claims abstract description 8

- 238000005498 polishing Methods 0.000 claims description 29

- 238000000576 coating method Methods 0.000 claims description 26

- 239000011248 coating agent Substances 0.000 claims description 22

- 238000007639 printing Methods 0.000 description 8

- 238000004519 manufacturing process Methods 0.000 description 7

- 238000000227 grinding Methods 0.000 description 6

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 5

- 238000007781 pre-processing Methods 0.000 description 5

- 239000002002 slurry Substances 0.000 description 5

- 241000238366 Cephalopoda Species 0.000 description 3

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 3

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 239000006061 abrasive grain Substances 0.000 description 3

- 239000000654 additive Substances 0.000 description 3

- 239000003086 colorant Substances 0.000 description 3

- 229910003460 diamond Inorganic materials 0.000 description 3

- 239000010432 diamond Substances 0.000 description 3

- 239000010687 lubricating oil Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- 230000007704 transition Effects 0.000 description 3

- SVTBMSDMJJWYQN-UHFFFAOYSA-N 2-methylpentane-2,4-diol Chemical compound CC(O)CC(C)(C)O SVTBMSDMJJWYQN-UHFFFAOYSA-N 0.000 description 2

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 2

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 2

- SIKJAQJRHWYJAI-UHFFFAOYSA-N Indole Chemical compound C1=CC=C2NC=CC2=C1 SIKJAQJRHWYJAI-UHFFFAOYSA-N 0.000 description 2

- 239000007864 aqueous solution Substances 0.000 description 2

- 239000004327 boric acid Substances 0.000 description 2

- -1 boric acid amine Chemical class 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000000314 lubricant Substances 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 239000000049 pigment Substances 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 238000007790 scraping Methods 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- ZGZUKKMFYTUYHA-HNNXBMFYSA-N (2s)-2-amino-3-(4-phenylmethoxyphenyl)propane-1-thiol Chemical class C1=CC(C[C@@H](CS)N)=CC=C1OCC1=CC=CC=C1 ZGZUKKMFYTUYHA-HNNXBMFYSA-N 0.000 description 1

- CWKFSQSYSQVXIW-UHFFFAOYSA-N 1,3,5-triethyltriazinane Chemical compound CCC1CN(CC)NN(CC)C1 CWKFSQSYSQVXIW-UHFFFAOYSA-N 0.000 description 1

- HXKKHQJGJAFBHI-UHFFFAOYSA-N 1-aminopropan-2-ol Chemical compound CC(O)CN HXKKHQJGJAFBHI-UHFFFAOYSA-N 0.000 description 1

- HZAXFHJVJLSVMW-UHFFFAOYSA-N 2-Aminoethan-1-ol Chemical compound NCCO HZAXFHJVJLSVMW-UHFFFAOYSA-N 0.000 description 1

- KRXFTOUYGXMRRU-UHFFFAOYSA-N 3h-1,3-benzothiazole-2-thione;sodium Chemical compound [Na].C1=CC=C2SC(=S)NC2=C1 KRXFTOUYGXMRRU-UHFFFAOYSA-N 0.000 description 1

- 229910017107 AlOx Inorganic materials 0.000 description 1

- MRABAEUHTLLEML-UHFFFAOYSA-N Butyl lactate Chemical compound CCCCOC(=O)C(C)O MRABAEUHTLLEML-UHFFFAOYSA-N 0.000 description 1

- 241000233866 Fungi Species 0.000 description 1

- 229920002873 Polyethylenimine Polymers 0.000 description 1

- GSEJCLTVZPLZKY-UHFFFAOYSA-N Triethanolamine Chemical compound OCCN(CCO)CCO GSEJCLTVZPLZKY-UHFFFAOYSA-N 0.000 description 1

- 239000003082 abrasive agent Substances 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 150000001408 amides Chemical class 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- QRUDEWIWKLJBPS-UHFFFAOYSA-N benzotriazole Chemical compound C1=CC=C2N[N][N]C2=C1 QRUDEWIWKLJBPS-UHFFFAOYSA-N 0.000 description 1

- 239000012964 benzotriazole Substances 0.000 description 1

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- CETPSERCERDGAM-UHFFFAOYSA-N ceric oxide Chemical compound O=[Ce]=O CETPSERCERDGAM-UHFFFAOYSA-N 0.000 description 1

- 229910000422 cerium(IV) oxide Inorganic materials 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 239000007822 coupling agent Substances 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- ZBCBWPMODOFKDW-UHFFFAOYSA-N diethanolamine Chemical compound OCCNCCO ZBCBWPMODOFKDW-UHFFFAOYSA-N 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000003995 emulsifying agent Substances 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229940051250 hexylene glycol Drugs 0.000 description 1

- PZOUSPYUWWUPPK-UHFFFAOYSA-N indole Natural products CC1=CC=CC2=C1C=CN2 PZOUSPYUWWUPPK-UHFFFAOYSA-N 0.000 description 1

- RKJUIXBNRJVNHR-UHFFFAOYSA-N indolenine Natural products C1=CC=C2CC=NC2=C1 RKJUIXBNRJVNHR-UHFFFAOYSA-N 0.000 description 1

- 239000003112 inhibitor Substances 0.000 description 1

- 229940102253 isopropanolamine Drugs 0.000 description 1

- 239000003350 kerosene Substances 0.000 description 1

- 150000002576 ketones Chemical class 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 239000002480 mineral oil Substances 0.000 description 1

- 235000010446 mineral oil Nutrition 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229940017144 n-butyl lactate Drugs 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- 239000010665 pine oil Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000012925 reference material Substances 0.000 description 1

- XNRNJIIJLOFJEK-UHFFFAOYSA-N sodium;1-oxidopyridine-2-thione Chemical compound [Na+].[O-]N1C=CC=CC1=S XNRNJIIJLOFJEK-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

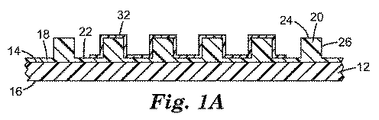

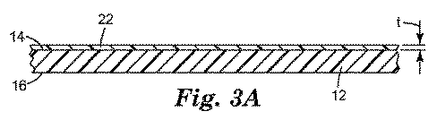

- B24D11/00—Constructional features of flexible abrasive materials; Special features in the manufacture of such materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

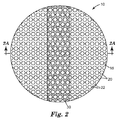

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/24—Lapping pads for working plane surfaces characterised by the composition or properties of the pad materials

- B24B37/245—Pads with fixed abrasives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/26—Lapping pads for working plane surfaces characterised by the shape of the lapping pad surface, e.g. grooved

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Polishing Bodies And Polishing Tools (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/509,707 | 2009-07-27 | ||

| US12/509,707 US20110021114A1 (en) | 2009-07-27 | 2009-07-27 | Abrasive article with preconditioning and persistent indicators |

| PCT/US2010/041275 WO2011016941A2 (en) | 2009-07-27 | 2010-07-08 | Abrasive article with preconditioning and persistent indicators |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2013500173A true JP2013500173A (ja) | 2013-01-07 |

| JP2013500173A5 JP2013500173A5 (enExample) | 2013-04-18 |

Family

ID=43497737

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012522849A Pending JP2013500173A (ja) | 2009-07-27 | 2010-07-08 | 予備処理指標及び持続的指標を有する研磨物品 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20110021114A1 (enExample) |

| EP (1) | EP2459345A2 (enExample) |

| JP (1) | JP2013500173A (enExample) |

| CN (1) | CN102470515A (enExample) |

| WO (1) | WO2011016941A2 (enExample) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8118644B2 (en) * | 2008-10-16 | 2012-02-21 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Chemical mechanical polishing pad having integral identification feature |

| CN103962974B (zh) * | 2013-01-31 | 2017-08-04 | 盖茨优霓塔传动系统(苏州)有限公司 | 磨轮 |

| JP6623153B2 (ja) | 2013-11-12 | 2019-12-18 | スリーエム イノベイティブ プロパティズ カンパニー | 構造化研磨物品並びにその使用方法 |

| US9491997B2 (en) * | 2013-12-02 | 2016-11-15 | Soft Lines International, Ltd. | Drum assembly, cosmetic device with drum assembly, and battery compartment for cosmetic device |

| CN106376234B (zh) | 2014-05-02 | 2019-11-05 | 3M创新有限公司 | 间断的结构化磨料制品以及抛光工件的方法 |

| US10259102B2 (en) * | 2014-10-21 | 2019-04-16 | 3M Innovative Properties Company | Abrasive preforms, method of making an abrasive article, and bonded abrasive article |

| JP6584507B2 (ja) * | 2014-11-07 | 2019-10-02 | スリーエム イノベイティブ プロパティズ カンパニー | 可撓性研磨物品およびその製造方法 |

| CN106853610B (zh) * | 2015-12-08 | 2019-11-01 | 中芯国际集成电路制造(北京)有限公司 | 抛光垫及其监测方法和监测系统 |

| WO2017187320A1 (en) * | 2016-04-29 | 2017-11-02 | 3M Innovative Properties Company | Cleaning articles including scouring bodies that form printed instructions |

| WO2019082148A1 (en) * | 2017-10-26 | 2019-05-02 | 3M Innovative Properties Company | SOFT ABRASIVE ARTICLE WITH IMAGE LAYER |

| EP3898092A1 (en) * | 2018-12-18 | 2021-10-27 | 3M Innovative Properties Company | Camouflage for abrasive articles |

| US12479067B2 (en) * | 2018-12-18 | 2025-11-25 | 3M Innovative Properties Company | Patterned abrasive substrate and method |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5537133U (enExample) * | 1978-08-30 | 1980-03-10 | ||

| JPS6376470U (enExample) * | 1986-06-03 | 1988-05-20 | ||

| JP2002264025A (ja) * | 2001-03-14 | 2002-09-18 | Dainippon Printing Co Ltd | 研磨フィルム |

| JP2003181768A (ja) * | 2001-12-19 | 2003-07-02 | Dainippon Printing Co Ltd | 識別表示を有する研磨シート |

| JP2004208886A (ja) * | 2002-12-27 | 2004-07-29 | Kenji Nakamura | 美容用研磨・艶出しシート |

| JP2004535306A (ja) * | 2001-07-20 | 2004-11-25 | スリーエム イノベイティブ プロパティズ カンパニー | 摩耗インジケータを有する固定研磨物品 |

| JP2009241196A (ja) * | 2008-03-31 | 2009-10-22 | Asahi Diamond Industrial Co Ltd | 工具及び砥粒層チップ |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5137542A (en) * | 1990-08-08 | 1992-08-11 | Minnesota Mining And Manufacturing Company | Abrasive printed with an electrically conductive ink |

| US5709598A (en) * | 1993-06-02 | 1998-01-20 | Dai Nippon Printing Co., Ltd. | Abrasive tape and method of producing the same |

| JPH09510405A (ja) * | 1994-09-08 | 1997-10-21 | ストルエルス アクチェ セルスカプ | 回転可能な研削/研磨ディスクの上に置くための研削/研磨用カバーシート |

| US6287184B1 (en) * | 1999-10-01 | 2001-09-11 | 3M Innovative Properties Company | Marked abrasive article |

| KR100516142B1 (ko) * | 2003-12-02 | 2005-09-21 | 김기환 | 홀로그램 기능을 가지며 기능성을 향상시킨 연마도구 |

-

2009

- 2009-07-27 US US12/509,707 patent/US20110021114A1/en not_active Abandoned

-

2010

- 2010-07-08 JP JP2012522849A patent/JP2013500173A/ja active Pending

- 2010-07-08 WO PCT/US2010/041275 patent/WO2011016941A2/en not_active Ceased

- 2010-07-08 CN CN2010800321360A patent/CN102470515A/zh active Pending

- 2010-07-08 EP EP10806804A patent/EP2459345A2/en not_active Withdrawn

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5537133U (enExample) * | 1978-08-30 | 1980-03-10 | ||

| JPS6376470U (enExample) * | 1986-06-03 | 1988-05-20 | ||

| JP2002264025A (ja) * | 2001-03-14 | 2002-09-18 | Dainippon Printing Co Ltd | 研磨フィルム |

| JP2004535306A (ja) * | 2001-07-20 | 2004-11-25 | スリーエム イノベイティブ プロパティズ カンパニー | 摩耗インジケータを有する固定研磨物品 |

| JP2003181768A (ja) * | 2001-12-19 | 2003-07-02 | Dainippon Printing Co Ltd | 識別表示を有する研磨シート |

| JP2004208886A (ja) * | 2002-12-27 | 2004-07-29 | Kenji Nakamura | 美容用研磨・艶出しシート |

| JP2009241196A (ja) * | 2008-03-31 | 2009-10-22 | Asahi Diamond Industrial Co Ltd | 工具及び砥粒層チップ |

Also Published As

| Publication number | Publication date |

|---|---|

| US20110021114A1 (en) | 2011-01-27 |

| WO2011016941A2 (en) | 2011-02-10 |

| WO2011016941A3 (en) | 2011-04-28 |

| EP2459345A2 (en) | 2012-06-06 |

| CN102470515A (zh) | 2012-05-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2013500173A (ja) | 予備処理指標及び持続的指標を有する研磨物品 | |

| US5993298A (en) | Lapping apparatus and process with controlled liquid flow across the lapping surface | |

| US5967882A (en) | Lapping apparatus and process with two opposed lapping platens | |

| US5910041A (en) | Lapping apparatus and process with raised edge on platen | |

| JP6620125B2 (ja) | バッキング層および研磨層を有する印刷による化学機械研磨パッド | |

| US6120352A (en) | Lapping apparatus and lapping method using abrasive sheets | |

| US6048254A (en) | Lapping apparatus and process with annular abrasive area | |

| US6769969B1 (en) | Raised island abrasive, method of use and lapping apparatus | |

| US20190262974A1 (en) | System for making abrasive article | |

| US20020077037A1 (en) | Fixed abrasive articles | |

| US20050032469A1 (en) | Raised island abrasive, lapping apparatus and method of use | |

| CN201026588Y (zh) | 磁流变效应曲面研磨抛光装置 | |

| US9149904B1 (en) | Platen for wafer polishing having diamond-ceramic composites | |

| DE602004015666D1 (de) | Schleifmaschine mit Schleifscheiben, die in einer Hin- und Herbewegung quer zum Werkstück bewegt werden | |

| JP2007268658A (ja) | 研磨シート及び研磨方法 | |

| CN202462224U (zh) | 整理盘、研磨垫整理器及研磨装置 | |

| JP2005088153A (ja) | ダイヤモンドラップ定盤による硬脆材料の平面研削加工法 | |

| CN207669004U (zh) | 磁力钝化研磨机 | |

| CN204771885U (zh) | 多穴式自动定位微调的防氧化磨床 | |

| US20070238397A1 (en) | Finishing process | |

| KR20170073854A (ko) | 연마 장치의 연마 디스크 | |

| KR102713740B1 (ko) | 정합가능 연마 용품 | |

| CN109590917B (zh) | 一种基于立体结构技术的磨具 | |

| CN115666849A (zh) | 实验室盘式研磨设备、方法、替换磨盘和磨盘的应用 | |

| CN219685059U (zh) | 研磨装置和研磨系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130226 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130226 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140204 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140708 |