JP2012530814A - キャストフィルム、微孔膜及びこれらの調製方法 - Google Patents

キャストフィルム、微孔膜及びこれらの調製方法 Download PDFInfo

- Publication number

- JP2012530814A JP2012530814A JP2012516446A JP2012516446A JP2012530814A JP 2012530814 A JP2012530814 A JP 2012530814A JP 2012516446 A JP2012516446 A JP 2012516446A JP 2012516446 A JP2012516446 A JP 2012516446A JP 2012530814 A JP2012530814 A JP 2012530814A

- Authority

- JP

- Japan

- Prior art keywords

- film

- temperature

- cast

- films

- stretched

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 126

- 239000012982 microporous membrane Substances 0.000 title claims description 51

- 238000001816 cooling Methods 0.000 claims abstract description 126

- 230000000877 morphologic effect Effects 0.000 claims abstract description 25

- 238000007664 blowing Methods 0.000 claims abstract description 4

- 239000010410 layer Substances 0.000 claims description 202

- 239000004743 Polypropylene Substances 0.000 claims description 182

- 229920001155 polypropylene Polymers 0.000 claims description 182

- 239000013078 crystal Substances 0.000 claims description 118

- 239000012528 membrane Substances 0.000 claims description 93

- 229920001903 high density polyethylene Polymers 0.000 claims description 90

- 239000004700 high-density polyethylene Substances 0.000 claims description 90

- 238000000137 annealing Methods 0.000 claims description 78

- -1 polypropylene Polymers 0.000 claims description 54

- 239000002356 single layer Substances 0.000 claims description 32

- 239000004698 Polyethylene Substances 0.000 claims description 28

- 229920000573 polyethylene Polymers 0.000 claims description 28

- 238000002844 melting Methods 0.000 claims description 24

- 230000008018 melting Effects 0.000 claims description 24

- 239000012071 phase Substances 0.000 description 72

- 239000011148 porous material Substances 0.000 description 66

- 239000002243 precursor Substances 0.000 description 60

- 239000000203 mixture Substances 0.000 description 54

- 238000004736 wide-angle X-ray diffraction Methods 0.000 description 47

- 238000002425 crystallisation Methods 0.000 description 41

- 230000008025 crystallization Effects 0.000 description 41

- 238000012360 testing method Methods 0.000 description 37

- 238000005033 Fourier transform infrared spectroscopy Methods 0.000 description 30

- 229920005989 resin Polymers 0.000 description 29

- 239000011347 resin Substances 0.000 description 29

- 238000010521 absorption reaction Methods 0.000 description 26

- 238000010622 cold drawing Methods 0.000 description 26

- 230000000694 effects Effects 0.000 description 26

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 24

- 230000015572 biosynthetic process Effects 0.000 description 21

- 239000007789 gas Substances 0.000 description 21

- 230000005540 biological transmission Effects 0.000 description 20

- 238000005259 measurement Methods 0.000 description 19

- 229920000642 polymer Polymers 0.000 description 19

- 230000008569 process Effects 0.000 description 19

- 238000001878 scanning electron micrograph Methods 0.000 description 19

- 238000000235 small-angle X-ray scattering Methods 0.000 description 17

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 16

- 238000009826 distribution Methods 0.000 description 16

- 230000007423 decrease Effects 0.000 description 15

- 238000012545 processing Methods 0.000 description 15

- 238000001228 spectrum Methods 0.000 description 15

- 210000004027 cell Anatomy 0.000 description 13

- 238000004519 manufacturing process Methods 0.000 description 13

- 230000008859 change Effects 0.000 description 12

- 239000000463 material Substances 0.000 description 12

- 238000002360 preparation method Methods 0.000 description 12

- 238000001464 small-angle X-ray scattering data Methods 0.000 description 11

- 230000004044 response Effects 0.000 description 10

- 238000011156 evaluation Methods 0.000 description 9

- 230000035699 permeability Effects 0.000 description 9

- 230000005855 radiation Effects 0.000 description 9

- 238000000926 separation method Methods 0.000 description 9

- PBKONEOXTCPAFI-UHFFFAOYSA-N 1,2,4-trichlorobenzene Chemical compound ClC1=CC=C(Cl)C(Cl)=C1 PBKONEOXTCPAFI-UHFFFAOYSA-N 0.000 description 8

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 8

- 238000010438 heat treatment Methods 0.000 description 8

- 238000000465 moulding Methods 0.000 description 8

- 229920006262 high density polyethylene film Polymers 0.000 description 7

- 230000006872 improvement Effects 0.000 description 7

- 239000000155 melt Substances 0.000 description 7

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 7

- 229910052753 mercury Inorganic materials 0.000 description 7

- 229910052757 nitrogen Inorganic materials 0.000 description 7

- 238000009864 tensile test Methods 0.000 description 7

- 229930040373 Paraformaldehyde Natural products 0.000 description 6

- 239000000470 constituent Substances 0.000 description 6

- 238000001125 extrusion Methods 0.000 description 6

- 229920000092 linear low density polyethylene Polymers 0.000 description 6

- 239000004707 linear low-density polyethylene Substances 0.000 description 6

- 210000001724 microfibril Anatomy 0.000 description 6

- 229920006324 polyoxymethylene Polymers 0.000 description 6

- 238000001757 thermogravimetry curve Methods 0.000 description 6

- 238000002834 transmittance Methods 0.000 description 6

- 101100453790 Drosophila melanogaster Kebab gene Proteins 0.000 description 5

- 238000004458 analytical method Methods 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- 230000007613 environmental effect Effects 0.000 description 5

- 238000005530 etching Methods 0.000 description 5

- 235000015231 kebab Nutrition 0.000 description 5

- 239000007788 liquid Substances 0.000 description 5

- 238000002156 mixing Methods 0.000 description 5

- 230000006911 nucleation Effects 0.000 description 5

- 238000010899 nucleation Methods 0.000 description 5

- 229920003023 plastic Polymers 0.000 description 5

- 239000004033 plastic Substances 0.000 description 5

- 230000002829 reductive effect Effects 0.000 description 5

- 229920006126 semicrystalline polymer Polymers 0.000 description 5

- 239000000243 solution Substances 0.000 description 5

- 239000002904 solvent Substances 0.000 description 5

- 238000005482 strain hardening Methods 0.000 description 5

- 238000002076 thermal analysis method Methods 0.000 description 5

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 4

- 239000010949 copper Substances 0.000 description 4

- 230000003247 decreasing effect Effects 0.000 description 4

- 230000001419 dependent effect Effects 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- 239000012286 potassium permanganate Substances 0.000 description 4

- 230000009467 reduction Effects 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 3

- 238000002441 X-ray diffraction Methods 0.000 description 3

- 238000009825 accumulation Methods 0.000 description 3

- 230000001154 acute effect Effects 0.000 description 3

- 238000004364 calculation method Methods 0.000 description 3

- 238000005266 casting Methods 0.000 description 3

- 230000015556 catabolic process Effects 0.000 description 3

- 229910052802 copper Inorganic materials 0.000 description 3

- 230000006378 damage Effects 0.000 description 3

- 238000006731 degradation reaction Methods 0.000 description 3

- 238000000113 differential scanning calorimetry Methods 0.000 description 3

- 238000002474 experimental method Methods 0.000 description 3

- 238000000605 extraction Methods 0.000 description 3

- 230000004927 fusion Effects 0.000 description 3

- 229910002804 graphite Inorganic materials 0.000 description 3

- 239000010439 graphite Substances 0.000 description 3

- 239000001307 helium Substances 0.000 description 3

- 229910052734 helium Inorganic materials 0.000 description 3

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 3

- 239000013628 high molecular weight specie Substances 0.000 description 3

- 238000001000 micrograph Methods 0.000 description 3

- 239000012299 nitrogen atmosphere Substances 0.000 description 3

- 229920006254 polymer film Polymers 0.000 description 3

- 238000002459 porosimetry Methods 0.000 description 3

- PFNQVRZLDWYSCW-UHFFFAOYSA-N (fluoren-9-ylideneamino) n-naphthalen-1-ylcarbamate Chemical compound C12=CC=CC=C2C2=CC=CC=C2C1=NOC(=O)NC1=CC=CC2=CC=CC=C12 PFNQVRZLDWYSCW-UHFFFAOYSA-N 0.000 description 2

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 2

- 101000620653 Homo sapiens Serine/threonine-protein phosphatase 5 Proteins 0.000 description 2

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 2

- 102100022346 Serine/threonine-protein phosphatase 5 Human genes 0.000 description 2

- 229920003350 Spectratech® Polymers 0.000 description 2

- 239000002099 adlayer Substances 0.000 description 2

- 239000002156 adsorbate Substances 0.000 description 2

- 230000002902 bimodal effect Effects 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 238000012937 correction Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 229910001873 dinitrogen Inorganic materials 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000000445 field-emission scanning electron microscopy Methods 0.000 description 2

- 238000013467 fragmentation Methods 0.000 description 2

- 238000006062 fragmentation reaction Methods 0.000 description 2

- 238000009775 high-speed stirring Methods 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 229910052744 lithium Inorganic materials 0.000 description 2

- 229920001684 low density polyethylene Polymers 0.000 description 2

- 239000004702 low-density polyethylene Substances 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 239000011259 mixed solution Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 235000011007 phosphoric acid Nutrition 0.000 description 2

- 239000004014 plasticizer Substances 0.000 description 2

- 229920002959 polymer blend Polymers 0.000 description 2

- 230000000171 quenching effect Effects 0.000 description 2

- 230000035484 reaction time Effects 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 0 *c1*c(O)*(*)c([O+])c1* Chemical compound *c1*c(O)*(*)c([O+])c1* 0.000 description 1

- 241001312296 Umbrina canariensis Species 0.000 description 1

- 229920006125 amorphous polymer Polymers 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 206010061592 cardiac fibrillation Diseases 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000001427 coherent effect Effects 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000002600 fibrillogenic effect Effects 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 238000005243 fluidization Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 230000017525 heat dissipation Effects 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 150000002605 large molecules Chemical class 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 229920002521 macromolecule Polymers 0.000 description 1

- 238000000386 microscopy Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 238000005453 pelletization Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 229920005597 polymer membrane Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 239000010734 process oil Substances 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000001953 recrystallisation Methods 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 238000009987 spinning Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 238000010561 standard procedure Methods 0.000 description 1

- 210000001519 tissue Anatomy 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- ZSDSQXJSNMTJDA-UHFFFAOYSA-N trifluralin Chemical compound CCCN(CCC)C1=C([N+]([O-])=O)C=C(C(F)(F)F)C=C1[N+]([O-])=O ZSDSQXJSNMTJDA-UHFFFAOYSA-N 0.000 description 1

- 238000000831 two-dimensional small-angle X-ray scattering data Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/005—Shaping by stretching, e.g. drawing through a die; Apparatus therefor characterised by the choice of materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D67/00—Processes specially adapted for manufacturing semi-permeable membranes for separation processes or apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D67/00—Processes specially adapted for manufacturing semi-permeable membranes for separation processes or apparatus

- B01D67/0002—Organic membrane manufacture

- B01D67/002—Organic membrane manufacture from melts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D67/00—Processes specially adapted for manufacturing semi-permeable membranes for separation processes or apparatus

- B01D67/0002—Organic membrane manufacture

- B01D67/0023—Organic membrane manufacture by inducing porosity into non porous precursor membranes

- B01D67/0025—Organic membrane manufacture by inducing porosity into non porous precursor membranes by mechanical treatment, e.g. pore-stretching

- B01D67/0027—Organic membrane manufacture by inducing porosity into non porous precursor membranes by mechanical treatment, e.g. pore-stretching by stretching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D69/00—Semi-permeable membranes for separation processes or apparatus characterised by their form, structure or properties; Manufacturing processes specially adapted therefor

- B01D69/12—Composite membranes; Ultra-thin membranes

- B01D69/1212—Coextruded layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D69/00—Semi-permeable membranes for separation processes or apparatus characterised by their form, structure or properties; Manufacturing processes specially adapted therefor

- B01D69/12—Composite membranes; Ultra-thin membranes

- B01D69/1216—Three or more layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D71/00—Semi-permeable membranes for separation processes or apparatus characterised by the material; Manufacturing processes specially adapted therefor

- B01D71/06—Organic material

- B01D71/26—Polyalkenes

- B01D71/261—Polyethylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D71/00—Semi-permeable membranes for separation processes or apparatus characterised by the material; Manufacturing processes specially adapted therefor

- B01D71/06—Organic material

- B01D71/26—Polyalkenes

- B01D71/262—Polypropylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/07—Flat, e.g. panels

- B29C48/08—Flat, e.g. panels flexible, e.g. films

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/911—Cooling

- B29C48/9135—Cooling of flat articles, e.g. using specially adapted supporting means

- B29C48/915—Cooling of flat articles, e.g. using specially adapted supporting means with means for improving the adhesion to the supporting means

- B29C48/917—Cooling of flat articles, e.g. using specially adapted supporting means with means for improving the adhesion to the supporting means by applying pressurised gas to the surface of the flat article

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D7/00—Producing flat articles, e.g. films or sheets

- B29D7/01—Films or sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2323/00—Details relating to membrane preparation

- B01D2323/08—Specific temperatures applied

- B01D2323/081—Heating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2323/00—Details relating to membrane preparation

- B01D2323/08—Specific temperatures applied

- B01D2323/082—Cooling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/09—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels

- B29C48/10—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels flexible, e.g. blown foils

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/911—Cooling

- B29C48/9135—Cooling of flat articles, e.g. using specially adapted supporting means

- B29C48/914—Cooling drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/02—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets

- B29C55/023—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets using multilayered plates or sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2023/00—Use of polyalkenes or derivatives thereof as moulding material

- B29K2023/04—Polymers of ethylene

- B29K2023/06—PE, i.e. polyethylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2023/00—Use of polyalkenes or derivatives thereof as moulding material

- B29K2023/10—Polymers of propylene

- B29K2023/12—PP, i.e. polypropylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/04—Condition, form or state of moulded material or of the material to be shaped cellular or porous

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

- Y10T428/249953—Composite having voids in a component [e.g., porous, cellular, etc.]

- Y10T428/249978—Voids specified as micro

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Shaping By String And By Release Of Stress In Plastics And The Like (AREA)

- Manufacture Of Porous Articles, And Recovery And Treatment Of Waste Products (AREA)

- Laminated Bodies (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US21958109P | 2009-06-23 | 2009-06-23 | |

| US61/219,581 | 2009-06-23 | ||

| US28804209P | 2009-12-18 | 2009-12-18 | |

| US61/288,042 | 2009-12-18 | ||

| PCT/CA2010/000952 WO2010148492A1 (en) | 2009-06-23 | 2010-06-18 | Cast films, microporous membranes, and method of preparation thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2012530814A true JP2012530814A (ja) | 2012-12-06 |

| JP2012530814A5 JP2012530814A5 (OSRAM) | 2013-08-08 |

Family

ID=43385827

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012516446A Ceased JP2012530814A (ja) | 2009-06-23 | 2010-06-18 | キャストフィルム、微孔膜及びこれらの調製方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20120276367A1 (OSRAM) |

| JP (1) | JP2012530814A (OSRAM) |

| KR (1) | KR20120104142A (OSRAM) |

| CN (1) | CN102869490A (OSRAM) |

| CA (1) | CA2802583A1 (OSRAM) |

| WO (1) | WO2010148492A1 (OSRAM) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102825805B (zh) * | 2012-09-12 | 2015-09-09 | 成都芝田高分子材料有限公司 | 聚丙烯微孔膜制备方法 |

| CN103647036B (zh) * | 2013-12-10 | 2016-01-06 | 深圳市星源材质科技股份有限公司 | 一种高强度微孔锂离子电池隔膜的制备方法及电池隔膜 |

| US9492332B2 (en) | 2014-05-13 | 2016-11-15 | Clopay Plastic Products Company, Inc. | Breathable and microporous thin thermoplastic film |

| JP7245650B2 (ja) | 2015-07-10 | 2023-03-24 | ベリー グローバル,インコーポレイテッド | 微孔質通気性フィルムおよび微孔質通気性フィルムの形成方法 |

| CN105181733A (zh) * | 2015-08-06 | 2015-12-23 | 江苏安瑞达新材料有限公司 | 一种利用dsc模拟聚烯烃流延基膜退火处理的方法 |

| MX2018005624A (es) | 2015-11-05 | 2018-09-05 | Berry Global Inc | Peliculas polimericas y metodos para fabricar peliculas polimericas. |

| US11472085B2 (en) | 2016-02-17 | 2022-10-18 | Berry Plastics Corporation | Gas-permeable barrier film and method of making the gas-permeable barrier film |

| US11584111B2 (en) | 2018-11-05 | 2023-02-21 | Windmoeller & Hoelscher Kg | Breathable thermoplastic film with reduced shrinkage |

| JP7275574B2 (ja) * | 2018-12-27 | 2023-05-18 | Ube株式会社 | ポリオレフィン微多孔膜及び蓄電デバイス |

| CN110204816B (zh) * | 2019-06-22 | 2022-03-15 | 天津登峰卫生用品材料有限公司 | 一种可撕包膜及其制备方法 |

| US20240170803A1 (en) * | 2022-11-21 | 2024-05-23 | Ii-Vi Delaware, Inc. | Electrochemical Device Separator |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02294340A (ja) * | 1989-05-09 | 1990-12-05 | Toray Ind Inc | ポリプロピレンフイルム |

| JPH03166234A (ja) * | 1989-11-24 | 1991-07-18 | Toray Ind Inc | 白色不透明化ポリオレフィンフイルム |

| JPH07304110A (ja) * | 1994-05-12 | 1995-11-21 | Ube Ind Ltd | 積層多孔質フイルム及びその製法 |

| JPH08230032A (ja) * | 1995-02-24 | 1996-09-10 | Toray Ind Inc | ポリエステルフィルムおよびその製造方法 |

| JPH1050286A (ja) * | 1996-08-06 | 1998-02-20 | Ube Ind Ltd | 電池用セパレータの製造法 |

| JP2002273780A (ja) * | 2001-03-21 | 2002-09-25 | Daiya Plastic Kk | 熱可塑性樹脂フィルムの冷却方法 |

| JP2003220675A (ja) * | 2001-11-19 | 2003-08-05 | Mitsui Kagaku Platech Co Ltd | ポリオレフィン系ストレッチフィルム及びその製造方法 |

| JP2006027133A (ja) * | 2004-07-16 | 2006-02-02 | Tohcello Co Ltd | 樹脂フィルムの製造方法及び樹脂フィルム成形用エッジピンニング装置 |

| JP2010137509A (ja) * | 2008-12-15 | 2010-06-24 | Asahi Kasei E-Materials Corp | 積層微多孔性フィルム及びその製造方法 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4276179A (en) * | 1979-06-01 | 1981-06-30 | Celanese Corporation | Removing halogenated hydrocarbons from aqueous media by utilizing a polyolefinic microporous adsorbent |

| DE3564078D1 (en) * | 1984-11-09 | 1988-09-08 | Terumo Corp | Flat permeable membrane and method for manufacture thereof |

| BR9206560A (pt) * | 1991-10-01 | 1995-03-28 | Minnesota Mining & Mfg | Fita compósita, e, processo para a fabricacão de fita adesiva sensível a pressão por processamento por fusão |

| US6090898A (en) * | 1997-02-26 | 2000-07-18 | Toray Industries, Inc. | Polyester film and a production process thereof |

| KR100371398B1 (ko) * | 1998-12-08 | 2003-05-12 | 주식회사 엘지화학 | 폴리올레핀블렌드로제조된통기성필름과그의제조방법및2차전지의격리막 |

| US6331343B1 (en) * | 1999-05-07 | 2001-12-18 | 3M Innovative Properties Company | Films having a fibrillated surface and method of making |

| US6479007B1 (en) * | 1999-09-16 | 2002-11-12 | University Technology Corporation | Apparatus and method for controlling pore size in polymeric membranes and thin films |

| US6809168B2 (en) * | 1999-12-10 | 2004-10-26 | Exxonmobil Chemical Patents Inc. | Articles formed from propylene diene copolymers |

| JP3952720B2 (ja) * | 2001-10-01 | 2007-08-01 | 富士フイルム株式会社 | 溶液製膜方法及び溶液製膜装置 |

| KR100961660B1 (ko) * | 2005-12-21 | 2010-06-09 | 에스케이에너지 주식회사 | 반결정고분자 미세다공막 및 그 제조방법 |

| US20070264578A1 (en) * | 2006-05-15 | 2007-11-15 | Tonen Chemical Corporation | Microporous polyolefin membrane, its production method and battery separator |

-

2010

- 2010-06-18 WO PCT/CA2010/000952 patent/WO2010148492A1/en not_active Ceased

- 2010-06-18 KR KR20127001845A patent/KR20120104142A/ko not_active Withdrawn

- 2010-06-18 US US13/379,272 patent/US20120276367A1/en not_active Abandoned

- 2010-06-18 CA CA2802583A patent/CA2802583A1/en not_active Abandoned

- 2010-06-18 JP JP2012516446A patent/JP2012530814A/ja not_active Ceased

- 2010-06-18 CN CN2010800373882A patent/CN102869490A/zh active Pending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02294340A (ja) * | 1989-05-09 | 1990-12-05 | Toray Ind Inc | ポリプロピレンフイルム |

| JPH03166234A (ja) * | 1989-11-24 | 1991-07-18 | Toray Ind Inc | 白色不透明化ポリオレフィンフイルム |

| JPH07304110A (ja) * | 1994-05-12 | 1995-11-21 | Ube Ind Ltd | 積層多孔質フイルム及びその製法 |

| JPH08230032A (ja) * | 1995-02-24 | 1996-09-10 | Toray Ind Inc | ポリエステルフィルムおよびその製造方法 |

| JPH1050286A (ja) * | 1996-08-06 | 1998-02-20 | Ube Ind Ltd | 電池用セパレータの製造法 |

| JP2002273780A (ja) * | 2001-03-21 | 2002-09-25 | Daiya Plastic Kk | 熱可塑性樹脂フィルムの冷却方法 |

| JP2003220675A (ja) * | 2001-11-19 | 2003-08-05 | Mitsui Kagaku Platech Co Ltd | ポリオレフィン系ストレッチフィルム及びその製造方法 |

| JP2006027133A (ja) * | 2004-07-16 | 2006-02-02 | Tohcello Co Ltd | 樹脂フィルムの製造方法及び樹脂フィルム成形用エッジピンニング装置 |

| JP2010137509A (ja) * | 2008-12-15 | 2010-06-24 | Asahi Kasei E-Materials Corp | 積層微多孔性フィルム及びその製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| JPN6014033830; Seyed H. Tabatabaei et al: 'Microporous membranes obtained from polypropylene blend films by stretching' Journal of Membrane Science Volume 325, Issue 2, 20081201, Pages 772-782, Elsevier * |

Also Published As

| Publication number | Publication date |

|---|---|

| US20120276367A1 (en) | 2012-11-01 |

| CN102869490A (zh) | 2013-01-09 |

| KR20120104142A (ko) | 2012-09-20 |

| WO2010148492A1 (en) | 2010-12-29 |

| CA2802583A1 (en) | 2010-12-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2012530814A (ja) | キャストフィルム、微孔膜及びこれらの調製方法 | |

| Tabatabaei et al. | Microporous membranes obtained from PP/HDPE multilayer films by stretching | |

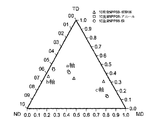

| Tabatabaei et al. | Microporous membranes obtained from polypropylene blend films by stretching | |

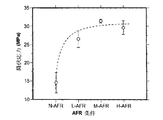

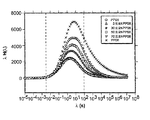

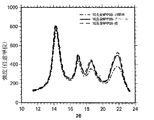

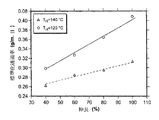

| Tabatabaei et al. | Effect of processing on the crystalline orientation, morphology, and mechanical properties of polypropylene cast films and microporous membrane formation | |

| Sadeghi et al. | Study of polypropylene morphology obtained from blown and cast film processes: initial morphology requirements for making porous membrane by stretching | |

| Wu et al. | Pore formation mechanism of β nucleated polypropylene stretched membranes | |

| Sadeghi et al. | Analysis of row nucleated lamellar morphology of polypropylene obtained from the cast film process: Effect of melt rheology and process conditions | |

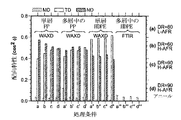

| Saffar et al. | The impact of new crystalline lamellae formation during annealing on the properties of polypropylene based films and membranes | |

| JP2022058637A (ja) | 高強度セパレータ | |

| Wu et al. | Influence of lamellar structure on double yield behavior and pore size distribution in β nucleated polypropylene stretched membranes | |

| KR20150002649A (ko) | 폴리에틸렌 미다공막 및 그 제조방법 | |

| Yang et al. | Deformation and pore formation mechanism of β nucleated polypropylene with different supermolecular structures | |

| Kang et al. | Understanding in the morphology and tensile behavior of isotactic polypropylene cast films with different stereo-defect distribution | |

| JP6962019B2 (ja) | 微多孔性フィルム用ポリプロピレン樹脂組成物およびその用途 | |

| Chen et al. | Influence of cocrystallization behavior on structure and properties of HDPE/LLDPE microporous membrane | |

| Wang et al. | Competition of shearing and cavitation effects on the deformation behavior of isotactic polypropylene during stretching | |

| JP2006124652A (ja) | ポリオレフィン製微多孔膜 | |

| Ma et al. | The supramolecular organization of PVDF lamellae formed in diphenyl ketone dilutions via thermally induced phase separation | |

| JP6879217B2 (ja) | ポリオレフィン微多孔膜とその製造方法、積層ポリオレフィン微多孔膜、ロール及びポリオレフィン微多孔膜の評価方法 | |

| Ding et al. | Influence of oriented β‐lamellae on deformation and pore formation in β‐nucleated polypropylene | |

| Wu et al. | Influence of lamellar structure on the stress–strain behavior of β nucleated polypropylene under tensile loading at elevated temperatures | |

| Ye et al. | Fractionated crystallization, polymorphism and crystal transformation of poly (butylene adipate) confined in electrospun immiscible blend fibers with polystyrene | |

| Lin et al. | Novel polypropylene-based microporous membranes via spherulitic deformation | |

| WO2022202095A1 (ja) | ポリオレフィン微多孔膜、電池用セパレータ及び二次電池 | |

| JP2022082461A (ja) | ポリオレフィン微多孔膜、電池用セパレータ、及び二次電池 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20120821 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120928 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20120928 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130618 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130618 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140725 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140819 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20141114 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20141121 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141127 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150526 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20150929 |