JP2010510885A - レーザ加工 - Google Patents

レーザ加工 Download PDFInfo

- Publication number

- JP2010510885A JP2010510885A JP2009537562A JP2009537562A JP2010510885A JP 2010510885 A JP2010510885 A JP 2010510885A JP 2009537562 A JP2009537562 A JP 2009537562A JP 2009537562 A JP2009537562 A JP 2009537562A JP 2010510885 A JP2010510885 A JP 2010510885A

- Authority

- JP

- Japan

- Prior art keywords

- laser

- substrate

- pulses

- processing

- pulse

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000758 substrate Substances 0.000 claims abstract description 32

- 238000000034 method Methods 0.000 claims abstract description 25

- 238000003754 machining Methods 0.000 claims description 6

- 239000004065 semiconductor Substances 0.000 claims description 5

- 238000005553 drilling Methods 0.000 claims description 2

- 238000009499 grossing Methods 0.000 claims description 2

- 239000000463 material Substances 0.000 description 5

- 238000005520 cutting process Methods 0.000 description 3

- 230000003993 interaction Effects 0.000 description 3

- 230000002238 attenuated effect Effects 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000005459 micromachining Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/062—Shaping the laser beam, e.g. by masks or multi-focusing by direct control of the laser beam

- B23K26/0622—Shaping the laser beam, e.g. by masks or multi-focusing by direct control of the laser beam by shaping pulses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/08—Devices involving relative movement between laser beam and workpiece

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/352—Working by laser beam, e.g. welding, cutting or boring for surface treatment

- B23K26/3568—Modifying rugosity

- B23K26/3576—Diminishing rugosity, e.g. grinding; Polishing; Smoothing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/50—Inorganic material, e.g. metals, not provided for in B23K2103/02 – B23K2103/26

- B23K2103/56—Inorganic material, e.g. metals, not provided for in B23K2103/02 – B23K2103/26 semiconducting

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

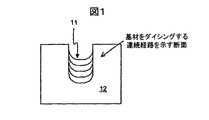

- Dicing (AREA)

- Laser Beam Processing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0623642A GB2444037A (en) | 2006-11-27 | 2006-11-27 | Laser Machining |

| PCT/EP2007/010291 WO2008064863A1 (en) | 2006-11-27 | 2007-11-27 | Laser machining |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010510885A true JP2010510885A (ja) | 2010-04-08 |

| JP2010510885A5 JP2010510885A5 (enExample) | 2011-01-13 |

Family

ID=37636595

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009537562A Pending JP2010510885A (ja) | 2006-11-27 | 2007-11-27 | レーザ加工 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7947575B2 (enExample) |

| EP (1) | EP2097209B1 (enExample) |

| JP (1) | JP2010510885A (enExample) |

| KR (1) | KR101260752B1 (enExample) |

| CN (1) | CN101657292B (enExample) |

| GB (1) | GB2444037A (enExample) |

| TW (1) | TWI448345B (enExample) |

| WO (1) | WO2008064863A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014500147A (ja) * | 2010-10-22 | 2014-01-09 | エレクトロ サイエンティフィック インダストリーズ インコーポレーテッド | ビームディザリング及びスカイビングのためのレーザ加工システム並びに方法 |

| JP2016505390A (ja) * | 2012-12-20 | 2016-02-25 | エレクトロ サイエンティフィック インダストリーズ インコーポレーテッド | レーザ微細加工によりイメージを形成する方法 |

| US10391585B2 (en) | 2009-05-28 | 2019-08-27 | Electro Scientific Industries, Inc | Acousto-optic deflector applications in laser processing of dielectric or other materials |

Families Citing this family (50)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2444037A (en) * | 2006-11-27 | 2008-05-28 | Xsil Technology Ltd | Laser Machining |

| US8536054B2 (en) * | 2008-01-18 | 2013-09-17 | Miasole | Laser polishing of a solar cell substrate |

| US8546172B2 (en) | 2008-01-18 | 2013-10-01 | Miasole | Laser polishing of a back contact of a solar cell |

| US8586398B2 (en) * | 2008-01-18 | 2013-11-19 | Miasole | Sodium-incorporation in solar cell substrates and contacts |

| US20100252959A1 (en) * | 2009-03-27 | 2010-10-07 | Electro Scientific Industries, Inc. | Method for improved brittle materials processing |

| US8319146B2 (en) * | 2009-05-05 | 2012-11-27 | General Electric Company | Method and apparatus for laser cutting a trench |

| DE102009044316B4 (de) | 2009-10-22 | 2015-04-30 | Ewag Ag | Verfahren zur Herstellung einer Fläche und/oder einer Kante an einem Rohling sowie Laserbearbeitungsvorrichtung zur Durchführung des Verfahrens |

| JP5620669B2 (ja) * | 2009-10-26 | 2014-11-05 | 東芝機械株式会社 | レーザダイシング方法およびレーザダイシング装置 |

| JP4961468B2 (ja) * | 2009-10-29 | 2012-06-27 | 三星ダイヤモンド工業株式会社 | レーザー加工方法、被加工物の分割方法およびレーザー加工装置 |

| EP2584064B1 (en) * | 2009-12-17 | 2015-07-29 | BYD Company Limited | Surface metallizing method, method for preparing plastic article and plastic article made therefrom |

| US9435035B2 (en) | 2010-01-15 | 2016-09-06 | Byd Company Limited | Metalized plastic articles and methods thereof |

| JP5452247B2 (ja) * | 2010-01-21 | 2014-03-26 | 東芝機械株式会社 | レーザダイシング装置 |

| CN102071424B (zh) | 2010-02-26 | 2012-05-09 | 比亚迪股份有限公司 | 一种塑料制品的制备方法及一种塑料制品 |

| US7977213B1 (en) * | 2010-03-31 | 2011-07-12 | Electro Scientific Industries, Inc. | Use of laser energy transparent stop layer to achieve minimal debris generation in laser scribing a multilayer patterned workpiece |

| US8383984B2 (en) | 2010-04-02 | 2013-02-26 | Electro Scientific Industries, Inc. | Method and apparatus for laser singulation of brittle materials |

| TW201134596A (en) * | 2010-04-15 | 2011-10-16 | Epileds Technologies Inc | Laser processing method |

| US8804102B2 (en) * | 2010-05-19 | 2014-08-12 | Materials Solutions | Laser scan speed calibration |

| JP2012000640A (ja) * | 2010-06-17 | 2012-01-05 | Omron Corp | レーザ加工装置およびレーザ加工方法 |

| JP5981094B2 (ja) | 2010-06-24 | 2016-08-31 | 東芝機械株式会社 | ダイシング方法 |

| CN102071411B (zh) | 2010-08-19 | 2012-05-30 | 比亚迪股份有限公司 | 一种塑料制品的制备方法及一种塑料制品 |

| CN102637639A (zh) * | 2011-02-12 | 2012-08-15 | 安徽三安光电有限公司 | 一种劈裂半导体芯片或其封装基板的方法 |

| JP5140198B1 (ja) | 2011-07-27 | 2013-02-06 | 東芝機械株式会社 | レーザダイシング方法 |

| CN102489884A (zh) * | 2011-12-02 | 2012-06-13 | 深圳光韵达光电科技股份有限公司 | 一种激光切割圆孔或椭圆孔的方法 |

| CN103212859A (zh) * | 2012-01-19 | 2013-07-24 | 昆山思拓机器有限公司 | 一种激光切割厚材料的方法 |

| US9266192B2 (en) | 2012-05-29 | 2016-02-23 | Electro Scientific Industries, Inc. | Method and apparatus for processing workpieces |

| JP2014011358A (ja) | 2012-06-29 | 2014-01-20 | Toshiba Mach Co Ltd | レーザダイシング方法 |

| KR101213958B1 (ko) * | 2012-10-12 | 2012-12-20 | 주식회사 엘티에스 | 레이저를 이용한 내장형 안테나 제조방법 |

| EP3336195B1 (en) | 2012-12-20 | 2020-02-26 | 3M Innovative Properties Company | Method of differentiating microbial colonies in an image |

| US20140268134A1 (en) * | 2013-03-15 | 2014-09-18 | Electro Scientific Industries, Inc. | Laser sampling methods for reducing thermal effects |

| KR101999336B1 (ko) * | 2013-04-09 | 2019-07-11 | 엘지디스플레이 주식회사 | 액정표시장치 및 그 제조 방법 |

| US10851884B2 (en) | 2014-03-14 | 2020-12-01 | ZPE Licensing Inc. | Super charger components |

| US11041558B2 (en) | 2014-03-14 | 2021-06-22 | ZPE Licensing Inc. | Super charger components |

| DE102014210611A1 (de) * | 2014-06-04 | 2015-12-17 | Trumpf Werkzeugmaschinen Gmbh + Co. Kg | Verfahren zum Markieren eines DataMatrix-Codes auf einem Werkstück mittels eines Laserstrahls |

| US10328529B2 (en) | 2015-08-26 | 2019-06-25 | Electro Scientific Industries, Inc | Laser scan sequencing and direction with respect to gas flow |

| US10794663B2 (en) * | 2017-05-11 | 2020-10-06 | ZPE Licensing Inc. | Laser induced friction surface on firearm |

| US10640837B2 (en) * | 2017-09-27 | 2020-05-05 | Faurecia Interior Systems, Inc. | Vehicle interior panel with laser-formed tear seam |

| CN109048047B (zh) * | 2018-07-09 | 2020-09-25 | 江苏峰钛激光科技有限公司 | 一种硬脆材料的激光打标方法 |

| DE102018120763A1 (de) * | 2018-08-24 | 2020-02-27 | Jenoptik Automatisierungstechnik Gmbh | Verfahren zur Herstellung wenigstens eines Schlitzes in ein flächenhaftes Werkstück mittels Laserstrahl |

| CN109262147A (zh) * | 2018-09-29 | 2019-01-25 | 北京工业大学 | 一种陶瓷增强金属基复合材料脉冲激光刻蚀加工方法 |

| CN109530928B (zh) * | 2018-12-27 | 2021-03-05 | 北京中科镭特电子有限公司 | 一种激光加工芯片的方法及装置 |

| CN109530929B (zh) * | 2018-12-27 | 2021-03-19 | 北京中科镭特电子有限公司 | 一种激光加工芯片的方法 |

| CN110681988A (zh) * | 2019-09-17 | 2020-01-14 | 北京兆维电子(集团)有限责任公司 | 一种激光加工方法及系统 |

| CN111992545B (zh) * | 2020-08-28 | 2023-09-08 | 格力电器(武汉)有限公司 | 一种热水器内胆下环缝氧化皮清洗装置及清洗方法 |

| KR102311246B1 (ko) * | 2021-01-28 | 2021-10-14 | 이노덴 주식회사 | 유동형 어버트먼트 및 이를 구비한 임플란트 |

| US12368053B2 (en) * | 2022-01-06 | 2025-07-22 | Taiwan Semiconductor Manufacturing Co., Ltd. | Method for laser drilling process for an integrated circuit package |

| US12209619B2 (en) | 2022-04-20 | 2025-01-28 | ZPE Licensing Inc. | Electromagnetic clutch |

| US12384009B2 (en) | 2022-11-15 | 2025-08-12 | ZPE Licensing Inc. | Socket with laser induced friction surfaces |

| CN117718611A (zh) * | 2024-01-22 | 2024-03-19 | 华中科技大学 | 一种间隔脉冲与扫描轨迹的协同激光制孔方法及系统 |

| CN118559190B (zh) * | 2024-07-31 | 2025-03-07 | 北京镭科光电科技有限公司 | 一种提升分布密度的焦点平移方法及相应的激光加工装置 |

| CN119347171A (zh) * | 2024-10-28 | 2025-01-24 | 河北工程大学 | 一种脉冲激光打孔方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52111663A (en) * | 1976-03-16 | 1977-09-19 | Nippon Electric Co | Method of producing hybrid integrated circuit substrate |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IL121890A (en) | 1997-10-06 | 2000-11-21 | Dov Zahavi | Laser assisted polishing |

| US6010497A (en) | 1998-01-07 | 2000-01-04 | Lasersight Technologies, Inc. | Method and apparatus for controlling scanning of an ablating laser beam |

| JP2002522191A (ja) * | 1998-08-12 | 2002-07-23 | ライ、ミン | 表面切除用パルスレーザービームを走査する方法 |

| US6231566B1 (en) | 1998-08-12 | 2001-05-15 | Katana Research, Inc. | Method for scanning a pulsed laser beam for surface ablation |

| KR100829876B1 (ko) * | 2000-10-26 | 2008-05-16 | 엑스에스아이엘 테크놀러지 리미티드 | 레이저 기계가공의 제어 |

| AU2003224098A1 (en) * | 2002-04-19 | 2003-11-03 | Xsil Technology Limited | Laser machining |

| US7804043B2 (en) * | 2004-06-15 | 2010-09-28 | Laserfacturing Inc. | Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser |

| US20060039419A1 (en) * | 2004-08-16 | 2006-02-23 | Tan Deshi | Method and apparatus for laser trimming of resistors using ultrafast laser pulse from ultrafast laser oscillator operating in picosecond and femtosecond pulse widths |

| US7528342B2 (en) * | 2005-02-03 | 2009-05-05 | Laserfacturing, Inc. | Method and apparatus for via drilling and selective material removal using an ultrafast pulse laser |

| GB2444037A (en) * | 2006-11-27 | 2008-05-28 | Xsil Technology Ltd | Laser Machining |

| CN105583526B (zh) * | 2008-03-21 | 2018-08-17 | Imra美国公司 | 基于激光的材料加工方法和系统 |

-

2006

- 2006-11-27 GB GB0623642A patent/GB2444037A/en not_active Withdrawn

-

2007

- 2007-11-27 JP JP2009537562A patent/JP2010510885A/ja active Pending

- 2007-11-27 US US12/515,926 patent/US7947575B2/en not_active Expired - Fee Related

- 2007-11-27 CN CN200780049577.XA patent/CN101657292B/zh not_active Expired - Fee Related

- 2007-11-27 EP EP07846853.5A patent/EP2097209B1/en not_active Not-in-force

- 2007-11-27 KR KR1020097012900A patent/KR101260752B1/ko not_active Expired - Fee Related

- 2007-11-27 WO PCT/EP2007/010291 patent/WO2008064863A1/en not_active Ceased

- 2007-11-28 TW TW096145175A patent/TWI448345B/zh not_active IP Right Cessation

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52111663A (en) * | 1976-03-16 | 1977-09-19 | Nippon Electric Co | Method of producing hybrid integrated circuit substrate |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10391585B2 (en) | 2009-05-28 | 2019-08-27 | Electro Scientific Industries, Inc | Acousto-optic deflector applications in laser processing of dielectric or other materials |

| US11738405B2 (en) | 2009-05-28 | 2023-08-29 | Electro Scientific Industries, Inc. | Acousto-optic deflector applications in laser processing of dielectric or other materials |

| JP2014500147A (ja) * | 2010-10-22 | 2014-01-09 | エレクトロ サイエンティフィック インダストリーズ インコーポレーテッド | ビームディザリング及びスカイビングのためのレーザ加工システム並びに方法 |

| JP2016505390A (ja) * | 2012-12-20 | 2016-02-25 | エレクトロ サイエンティフィック インダストリーズ インコーポレーテッド | レーザ微細加工によりイメージを形成する方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2008064863A1 (en) | 2008-06-05 |

| EP2097209B1 (en) | 2014-04-09 |

| TWI448345B (zh) | 2014-08-11 |

| US20100099239A1 (en) | 2010-04-22 |

| GB2444037A (en) | 2008-05-28 |

| KR101260752B1 (ko) | 2013-05-06 |

| CN101657292A (zh) | 2010-02-24 |

| CN101657292B (zh) | 2016-03-16 |

| EP2097209A1 (en) | 2009-09-09 |

| TW200922727A (en) | 2009-06-01 |

| GB0623642D0 (en) | 2007-01-03 |

| KR20090104003A (ko) | 2009-10-05 |

| US7947575B2 (en) | 2011-05-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010510885A (ja) | レーザ加工 | |

| JP6416901B2 (ja) | 平坦なワークピースを複数の部分に分割する方法及び装置 | |

| EP1341638B1 (en) | Laser machining of semiconductor materials | |

| US7134943B2 (en) | Wafer processing method | |

| KR101786844B1 (ko) | 웨이퍼 절단 방법 및 장치 | |

| US7134942B2 (en) | Wafer processing method | |

| KR101809783B1 (ko) | 반도체 기판을 방사상으로 그루빙하는 방법 | |

| US20100252540A1 (en) | Method and apparatus for brittle materials processing | |

| US20100147813A1 (en) | Method for laser processing glass with a chamfered edge | |

| JP2012146878A (ja) | レーザ加工方法 | |

| JP2004343008A (ja) | レーザ光線を利用した被加工物分割方法 | |

| EP3639966B1 (en) | Material cutting using laser pulses | |

| WO2012096094A1 (ja) | レーザ加工方法 | |

| US12304001B2 (en) | Optimised laser cutting | |

| WO2000075983B1 (en) | A method for dicing wafers with laser scribing | |

| KR20190087288A (ko) | 피가공물의 레이저 가공 방법 | |

| KR20180034551A (ko) | 기체 흐름에 대한 레이저 스캔 시퀀싱 및 방향 | |

| JP2015107491A (ja) | レーザー加工方法 | |

| IES20010945A2 (en) | Laser machining of semiconductor material | |

| JP2019201061A (ja) | 被加工物の加工方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101118 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101118 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120829 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120925 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121108 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130219 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130517 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130524 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130618 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130625 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130718 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140219 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140701 |