JP2005297364A - 無機質成形体の製造方法 - Google Patents

無機質成形体の製造方法 Download PDFInfo

- Publication number

- JP2005297364A JP2005297364A JP2004117158A JP2004117158A JP2005297364A JP 2005297364 A JP2005297364 A JP 2005297364A JP 2004117158 A JP2004117158 A JP 2004117158A JP 2004117158 A JP2004117158 A JP 2004117158A JP 2005297364 A JP2005297364 A JP 2005297364A

- Authority

- JP

- Japan

- Prior art keywords

- curing

- inorganic

- molded body

- water

- molding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 41

- 238000000465 moulding Methods 0.000 claims abstract description 36

- 239000000203 mixture Substances 0.000 claims abstract description 32

- 239000000126 substance Substances 0.000 claims abstract description 32

- 229920000036 polyvinylpyrrolidone Polymers 0.000 claims abstract description 20

- 239000001267 polyvinylpyrrolidone Substances 0.000 claims abstract description 20

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 claims abstract description 20

- 239000000839 emulsion Substances 0.000 claims abstract description 17

- 239000000463 material Substances 0.000 claims abstract description 16

- 239000007864 aqueous solution Substances 0.000 claims abstract description 15

- 239000003995 emulsifying agent Substances 0.000 claims abstract description 14

- 239000012779 reinforcing material Substances 0.000 claims abstract description 10

- 239000000243 solution Substances 0.000 claims abstract description 3

- 239000011248 coating agent Substances 0.000 claims description 5

- 238000000576 coating method Methods 0.000 claims description 5

- ARFDIYMUJAUTDK-UHFFFAOYSA-N 1-hydroxypentyl 2-methylpropanoate Chemical compound CCCCC(O)OC(=O)C(C)C ARFDIYMUJAUTDK-UHFFFAOYSA-N 0.000 claims 1

- DAFHKNAQFPVRKR-UHFFFAOYSA-N (3-hydroxy-2,2,4-trimethylpentyl) 2-methylpropanoate Chemical compound CC(C)C(O)C(C)(C)COC(=O)C(C)C DAFHKNAQFPVRKR-UHFFFAOYSA-N 0.000 abstract description 13

- 238000001723 curing Methods 0.000 description 35

- 238000011156 evaluation Methods 0.000 description 10

- 239000004568 cement Substances 0.000 description 9

- 238000000034 method Methods 0.000 description 9

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 6

- MYRTYDVEIRVNKP-UHFFFAOYSA-N 1,2-Divinylbenzene Chemical compound C=CC1=CC=CC=C1C=C MYRTYDVEIRVNKP-UHFFFAOYSA-N 0.000 description 4

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- 239000000835 fiber Substances 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 238000001125 extrusion Methods 0.000 description 3

- 239000000178 monomer Substances 0.000 description 3

- 238000005498 polishing Methods 0.000 description 3

- -1 rate Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000002344 surface layer Substances 0.000 description 3

- 239000004094 surface-active agent Substances 0.000 description 3

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 3

- 229920002554 vinyl polymer Polymers 0.000 description 3

- ZORQXIQZAOLNGE-UHFFFAOYSA-N 1,1-difluorocyclohexane Chemical compound FC1(F)CCCCC1 ZORQXIQZAOLNGE-UHFFFAOYSA-N 0.000 description 2

- VBICKXHEKHSIBG-UHFFFAOYSA-N 1-monostearoylglycerol Chemical compound CCCCCCCCCCCCCCCCCC(=O)OCC(O)CO VBICKXHEKHSIBG-UHFFFAOYSA-N 0.000 description 2

- VVQNEPGJFQJSBK-UHFFFAOYSA-N Methyl methacrylate Chemical compound COC(=O)C(C)=C VVQNEPGJFQJSBK-UHFFFAOYSA-N 0.000 description 2

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 239000011398 Portland cement Substances 0.000 description 2

- OKKRPWIIYQTPQF-UHFFFAOYSA-N Trimethylolpropane trimethacrylate Chemical compound CC(=C)C(=O)OCC(CC)(COC(=O)C(C)=C)COC(=O)C(C)=C OKKRPWIIYQTPQF-UHFFFAOYSA-N 0.000 description 2

- 239000002390 adhesive tape Substances 0.000 description 2

- 239000004566 building material Substances 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 238000006703 hydration reaction Methods 0.000 description 2

- 239000011396 hydraulic cement Substances 0.000 description 2

- 229910010272 inorganic material Inorganic materials 0.000 description 2

- 239000011147 inorganic material Substances 0.000 description 2

- 239000003350 kerosene Substances 0.000 description 2

- 238000011068 loading method Methods 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 238000007790 scraping Methods 0.000 description 2

- 239000001593 sorbitan monooleate Substances 0.000 description 2

- 235000011069 sorbitan monooleate Nutrition 0.000 description 2

- 229940035049 sorbitan monooleate Drugs 0.000 description 2

- 238000003756 stirring Methods 0.000 description 2

- 229920006337 unsaturated polyester resin Polymers 0.000 description 2

- JNYAEWCLZODPBN-JGWLITMVSA-N (2r,3r,4s)-2-[(1r)-1,2-dihydroxyethyl]oxolane-3,4-diol Chemical compound OC[C@@H](O)[C@H]1OC[C@H](O)[C@H]1O JNYAEWCLZODPBN-JGWLITMVSA-N 0.000 description 1

- PHDVPEOLXYBNJY-KTKRTIGZSA-N 2-(2-hydroxyethoxy)ethyl (z)-octadec-9-enoate Chemical compound CCCCCCCC\C=C/CCCCCCCC(=O)OCCOCCO PHDVPEOLXYBNJY-KTKRTIGZSA-N 0.000 description 1

- PWVUXRBUUYZMKM-UHFFFAOYSA-N 2-(2-hydroxyethoxy)ethyl octadecanoate Chemical compound CCCCCCCCCCCCCCCCCC(=O)OCCOCCO PWVUXRBUUYZMKM-UHFFFAOYSA-N 0.000 description 1

- 229920002972 Acrylic fiber Polymers 0.000 description 1

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- HVUMOYIDDBPOLL-XWVZOOPGSA-N Sorbitan monostearate Chemical compound CCCCCCCCCCCCCCCCCC(=O)OC[C@@H](O)[C@H]1OC[C@H](O)[C@H]1O HVUMOYIDDBPOLL-XWVZOOPGSA-N 0.000 description 1

- 229920002978 Vinylon Polymers 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000003945 anionic surfactant Substances 0.000 description 1

- 229920006231 aramid fiber Polymers 0.000 description 1

- 239000011400 blast furnace cement Substances 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 239000003093 cationic surfactant Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000010881 fly ash Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- YQEMORVAKMFKLG-UHFFFAOYSA-N glycerine monostearate Natural products CCCCCCCCCCCCCCCCCC(=O)OC(CO)CO YQEMORVAKMFKLG-UHFFFAOYSA-N 0.000 description 1

- SVUQHVRAGMNPLW-UHFFFAOYSA-N glycerol monostearate Natural products CCCCCCCCCCCCCCCCC(=O)OCC(O)CO SVUQHVRAGMNPLW-UHFFFAOYSA-N 0.000 description 1

- 238000013007 heat curing Methods 0.000 description 1

- 230000036571 hydration Effects 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 1

- 239000006082 mold release agent Substances 0.000 description 1

- 239000002736 nonionic surfactant Substances 0.000 description 1

- 150000001451 organic peroxides Chemical class 0.000 description 1

- 229910001562 pearlite Inorganic materials 0.000 description 1

- JRKICGRDRMAZLK-UHFFFAOYSA-L peroxydisulfate Chemical compound [O-]S(=O)(=O)OOS([O-])(=O)=O JRKICGRDRMAZLK-UHFFFAOYSA-L 0.000 description 1

- 238000007517 polishing process Methods 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 239000003505 polymerization initiator Substances 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000012783 reinforcing fiber Substances 0.000 description 1

- 229910021487 silica fume Inorganic materials 0.000 description 1

- 239000001587 sorbitan monostearate Substances 0.000 description 1

- 235000011076 sorbitan monostearate Nutrition 0.000 description 1

- 229940035048 sorbitan monostearate Drugs 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 239000012209 synthetic fiber Substances 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

Landscapes

- Devices For Post-Treatments, Processing, Supply, Discharge, And Other Processes (AREA)

Abstract

【解決手段】無機質成形用組成物を成形した養生前成形体の表面に、2,2,4−トリメチル−1,3−ペンタンジオールモノイソブチレート又はポリビニルピロリドン水溶液を塗布した後、養生硬化する。シーラーとして2,2,4−トリメチル−1,3−ペンタンジオールモノイソブチレート又はポリビニルピロリドン水溶液を用いることで、養生硬化時の成形体表面からの水や油性物質の揮散を充分に抑制し、ドライアウトの発生を防止することができる。

【選択図】なし

Description

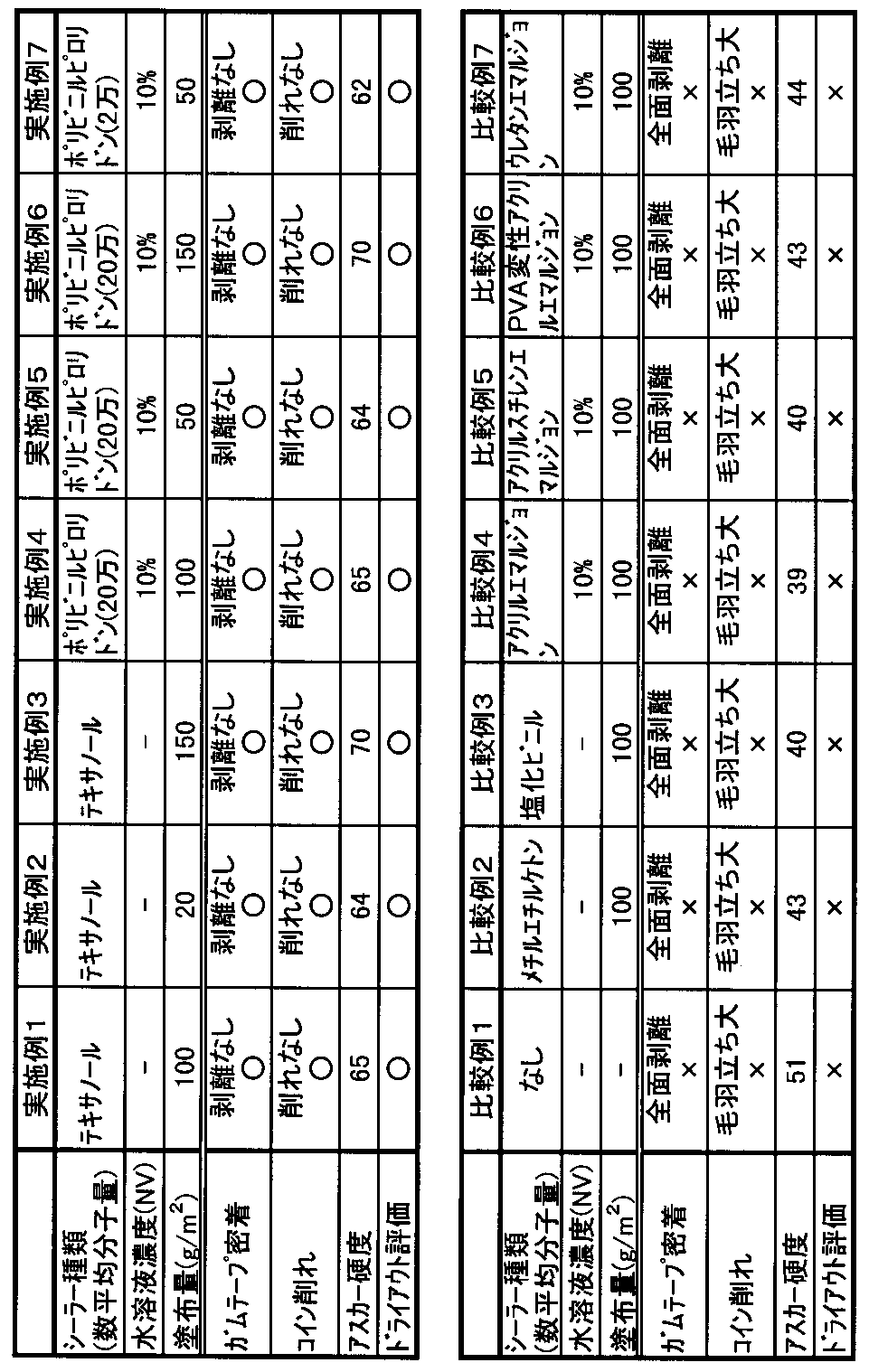

○〜△:ガムテープ密着の評価が「剥離なし」又はコイン削れ評価が「削れなし」であり、且つD型アスカー硬度が50以上

△:ガムテープ密着の評価が「一部剥離」、コイン削れ評価が「毛羽立ち小」であり、且つD型アスカー硬度が50以上

×:ガムテープ密着の評価が「全部剥離」又はコイン削れ評価が「毛羽立ち大」

Claims (3)

- 水、油性物質及び乳化剤を含むW/Oエマルジョン、水硬性硬化材、補強材を含有する無機質成形用組成物を成形した養生前成形体の表面に、2,2,4−トリメチル−1,3−ペンタンジオールモノイソブチレートを塗布した後、養生硬化することを特徴とする無機質成形体の製造方法。

- 水、油性物質及び乳化剤を含むW/Oエマルジョン、水硬性硬化材、補強材を含有する無機質成形用組成物を成形した養生前成形体の表面に、ポリビニルピロリドン水溶液を塗布した後、養生硬化することを特徴とする無機質成形体の製造方法。

- 上記ポリビニルピロリドン水溶液中のポリビニルピロリドンが、数平均分子量20000以上であることを特徴とする請求項2に記載の無機質成形体の製造方法。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004117158A JP4109647B2 (ja) | 2004-04-12 | 2004-04-12 | 無機質成形体の製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004117158A JP4109647B2 (ja) | 2004-04-12 | 2004-04-12 | 無機質成形体の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005297364A true JP2005297364A (ja) | 2005-10-27 |

| JP4109647B2 JP4109647B2 (ja) | 2008-07-02 |

Family

ID=35329503

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004117158A Expired - Fee Related JP4109647B2 (ja) | 2004-04-12 | 2004-04-12 | 無機質成形体の製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4109647B2 (ja) |

-

2004

- 2004-04-12 JP JP2004117158A patent/JP4109647B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP4109647B2 (ja) | 2008-07-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7695657B2 (en) | Method for manufacturing articles in the form of slabs with a siliceous binder and slabs thus obtained | |

| JPH0366126B2 (ja) | ||

| JPH03205376A (ja) | タンディッシュ用軽量耐火性組成物 | |

| JP4109647B2 (ja) | 無機質成形体の製造方法 | |

| JP4347913B2 (ja) | 裏打ちされた衛生製品及びその製造法 | |

| JP2009518274A (ja) | ジオポリマー性粒子、繊維、成形物品および製造方法 | |

| JPS6131434A (ja) | 無機成形体改質用エマルジヨン及びその製造法 | |

| JP4701453B2 (ja) | 無機質成形体の製造方法 | |

| US20220298078A1 (en) | Article made of conglomerate material, composite assembly comprising such article and method for manufacturing the article made of conglomerate material | |

| JP3858012B2 (ja) | セメント複合材 | |

| JP6983098B2 (ja) | 鋳型用骨材及びその製造方法 | |

| JP2006199558A (ja) | 無機質成形体の製造方法 | |

| JP3417700B2 (ja) | 厚付け化粧模様形成用軽量体組成物 | |

| JP2016175256A (ja) | 無機質板の製造方法 | |

| JP4625336B2 (ja) | 無機質成形体の製造方法 | |

| JP7317527B2 (ja) | コンクリート版の水分の蒸発を抑制する施工方法 | |

| SU1523245A1 (ru) | Состав разделительного покрыти дл модельной оснастки | |

| JP4820096B2 (ja) | ポリマー複合セメント板の製造方法 | |

| JP2007119295A (ja) | セメント系硬化材塗工品とその製造方法 | |

| JPH05339043A (ja) | 樹皮状及び木板状シート成形用組成物 | |

| IL37168A (en) | Method of manufacturing materials or articles of reinforced or filled polyester resins | |

| JP2767375B2 (ja) | モルタル組成物 | |

| CN109414847A (zh) | 胶泥组合物作为一次性铸造型芯的涂层的用途及相关涂覆的型芯 | |

| JPH0229003B2 (ja) | ||

| JP2000043020A (ja) | 水硬性無機質成形体の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20050822 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20050824 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051102 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060904 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070403 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070604 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080311 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080404 |

|

| FPAY | Renewal fee payment (prs date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110411 Year of fee payment: 3 |

|

| R150 | Certificate of patent (=grant) or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| FPAY | Renewal fee payment (prs date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110411 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (prs date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110411 Year of fee payment: 3 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| FPAY | Renewal fee payment (prs date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110411 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |