JP2004221511A - 電磁波シールド性パネル部材及びその製造方法 - Google Patents

電磁波シールド性パネル部材及びその製造方法 Download PDFInfo

- Publication number

- JP2004221511A JP2004221511A JP2003043373A JP2003043373A JP2004221511A JP 2004221511 A JP2004221511 A JP 2004221511A JP 2003043373 A JP2003043373 A JP 2003043373A JP 2003043373 A JP2003043373 A JP 2003043373A JP 2004221511 A JP2004221511 A JP 2004221511A

- Authority

- JP

- Japan

- Prior art keywords

- adhesive

- transparent plate

- laminated

- printed

- electromagnetic wave

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 7

- 239000000853 adhesive Substances 0.000 claims abstract description 30

- 230000001070 adhesive effect Effects 0.000 claims abstract description 30

- 238000007639 printing Methods 0.000 claims abstract description 25

- 239000004020 conductor Substances 0.000 claims abstract description 23

- 238000003825 pressing Methods 0.000 claims abstract description 4

- 238000000034 method Methods 0.000 claims description 7

- 229920001187 thermosetting polymer Polymers 0.000 claims description 7

- 230000003287 optical effect Effects 0.000 claims description 4

- 238000002834 transmittance Methods 0.000 claims description 4

- 230000001678 irradiating effect Effects 0.000 claims description 3

- 238000005304 joining Methods 0.000 claims 1

- 230000005855 radiation Effects 0.000 abstract 1

- 239000010410 layer Substances 0.000 description 10

- 239000000463 material Substances 0.000 description 10

- 239000011347 resin Substances 0.000 description 9

- 229920005989 resin Polymers 0.000 description 9

- 230000000052 comparative effect Effects 0.000 description 5

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 239000004744 fabric Substances 0.000 description 3

- 238000010030 laminating Methods 0.000 description 3

- 229920000178 Acrylic resin Polymers 0.000 description 2

- 239000004925 Acrylic resin Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000007731 hot pressing Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 238000004381 surface treatment Methods 0.000 description 2

- 229920000742 Cotton Polymers 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 238000009125 cardiac resynchronization therapy Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

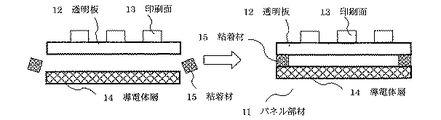

- 238000010586 diagram Methods 0.000 description 1

- 230000009982 effect on human Effects 0.000 description 1

- 239000003822 epoxy resin Substances 0.000 description 1

- 239000007849 furan resin Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000009940 knitting Methods 0.000 description 1

- 238000007644 letterpress printing Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- -1 polyethylene terephthalate Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 239000009719 polyimide resin Substances 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 description 1

- 229920006337 unsaturated polyester resin Polymers 0.000 description 1

Images

Landscapes

- Laminated Bodies (AREA)

- Shielding Devices Or Components To Electric Or Magnetic Fields (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003043373A JP2004221511A (ja) | 2003-01-15 | 2003-01-15 | 電磁波シールド性パネル部材及びその製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003043373A JP2004221511A (ja) | 2003-01-15 | 2003-01-15 | 電磁波シールド性パネル部材及びその製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004221511A true JP2004221511A (ja) | 2004-08-05 |

| JP2004221511A5 JP2004221511A5 (enExample) | 2005-12-02 |

Family

ID=32905413

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003043373A Pending JP2004221511A (ja) | 2003-01-15 | 2003-01-15 | 電磁波シールド性パネル部材及びその製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2004221511A (enExample) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5893765A (ja) * | 1981-11-30 | 1983-06-03 | Toobi:Kk | 紫外線硬化性接着剤および紫外線硬化性ラベル |

| JPH0214599A (ja) * | 1988-07-01 | 1990-01-18 | Tomoegawa Paper Co Ltd | 電磁波シールド用シート |

| JPH0373807U (enExample) * | 1989-11-20 | 1991-07-25 | ||

| JPH0658536U (ja) * | 1993-01-21 | 1994-08-12 | 松下電器産業株式会社 | メンブレンスイッチ |

| JPH10217397A (ja) * | 1997-02-06 | 1998-08-18 | Lintec Corp | 電磁波シールド性化粧シート |

| JPH11103192A (ja) * | 1997-04-10 | 1999-04-13 | Sumitomo Chem Co Ltd | プラズマディスプレイ用前面板およびこれを配置してなるプラズマディスプレイ |

| JP2000286593A (ja) * | 1999-03-31 | 2000-10-13 | Asahi Glass Co Ltd | 電磁波遮蔽積層体の製造方法 |

| JP2001038354A (ja) * | 1999-07-30 | 2001-02-13 | Daicen Membrane Systems Ltd | 膜分離装置 |

| JP2002229457A (ja) * | 2000-12-21 | 2002-08-14 | Sonoco Development Inc | 電子ビーム硬化被膜による印刷ラベル |

-

2003

- 2003-01-15 JP JP2003043373A patent/JP2004221511A/ja active Pending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5893765A (ja) * | 1981-11-30 | 1983-06-03 | Toobi:Kk | 紫外線硬化性接着剤および紫外線硬化性ラベル |

| JPH0214599A (ja) * | 1988-07-01 | 1990-01-18 | Tomoegawa Paper Co Ltd | 電磁波シールド用シート |

| JPH0373807U (enExample) * | 1989-11-20 | 1991-07-25 | ||

| JPH0658536U (ja) * | 1993-01-21 | 1994-08-12 | 松下電器産業株式会社 | メンブレンスイッチ |

| JPH10217397A (ja) * | 1997-02-06 | 1998-08-18 | Lintec Corp | 電磁波シールド性化粧シート |

| JPH11103192A (ja) * | 1997-04-10 | 1999-04-13 | Sumitomo Chem Co Ltd | プラズマディスプレイ用前面板およびこれを配置してなるプラズマディスプレイ |

| JP2000286593A (ja) * | 1999-03-31 | 2000-10-13 | Asahi Glass Co Ltd | 電磁波遮蔽積層体の製造方法 |

| JP2001038354A (ja) * | 1999-07-30 | 2001-02-13 | Daicen Membrane Systems Ltd | 膜分離装置 |

| JP2002229457A (ja) * | 2000-12-21 | 2002-08-14 | Sonoco Development Inc | 電子ビーム硬化被膜による印刷ラベル |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI637296B (zh) | 附觸碰感測器之顯示裝置及其製造方法 | |

| TWI389799B (zh) | Mating device and fitting method | |

| JPWO2008029709A1 (ja) | ディスプレイ用フィルター及びその製造方法並びにディスプレイの製造方法 | |

| JP2007534023A (ja) | 電子インク表示装置及びその製造方法 | |

| CN104345962A (zh) | 便携式电子产品、触摸屏及触摸屏制备方法 | |

| CN109795190B (zh) | 光学部件及具备触摸传感器的产品的生产方法、光学部件 | |

| TWI270341B (en) | Electronic assembly unit with conductive film, conductive film and method of making the same thereof | |

| JP2004221511A (ja) | 電磁波シールド性パネル部材及びその製造方法 | |

| JP4192329B2 (ja) | 電磁波遮蔽積層体の製造方法 | |

| JP4135122B2 (ja) | 電磁波シールドフィルタの製造方法 | |

| JP4875475B2 (ja) | 樹脂凸版 | |

| JP2014035493A (ja) | カバーフィルム、カバーフィルムの製造方法及び表示装置 | |

| JP5070063B2 (ja) | 液晶表示装置用表面保護板の製造方法および液晶表示装置の製造方法 | |

| CN109849456A (zh) | 一种用于军用窗口的电磁屏蔽玻璃生产工艺 | |

| JP2021061392A (ja) | Pctフィルムを絶縁層とするフレキシブルプリント回路基板及びその製造方法 | |

| JP2006039231A (ja) | 光電気配線混載基板の製造方法 | |

| JP2003307615A (ja) | 透明樹脂を基材とする光学フィルター | |

| WO2015097966A1 (ja) | 携帯端末及びその製造方法 | |

| JP2000036686A (ja) | 電磁シールド部材 | |

| WO2015097960A1 (ja) | 携帯端末及びその製造方法 | |

| JP2008277498A (ja) | 電磁波シールドシート及び光学フィルタ | |

| JP2001156489A (ja) | 電磁波シールド材およびその製造方法 | |

| JP2681512B2 (ja) | 電磁波シールドウインドーの製造方法 | |

| JP2001134198A (ja) | 電磁波シールド性光透過窓材及び表示装置 | |

| US9317062B2 (en) | Touch display device using light to debond touch module from display module |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050907 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050907 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20050907 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20050909 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20081023 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20081118 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090116 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20090116 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20090130 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090804 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091001 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100330 |