JP2004025301A - ハンダを基板上に小出しする方法と装置 - Google Patents

ハンダを基板上に小出しする方法と装置 Download PDFInfo

- Publication number

- JP2004025301A JP2004025301A JP2003057944A JP2003057944A JP2004025301A JP 2004025301 A JP2004025301 A JP 2004025301A JP 2003057944 A JP2003057944 A JP 2003057944A JP 2003057944 A JP2003057944 A JP 2003057944A JP 2004025301 A JP2004025301 A JP 2004025301A

- Authority

- JP

- Japan

- Prior art keywords

- solder

- substrate

- mixing chamber

- soldering wire

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

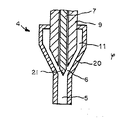

- B23K3/00—Tools, devices, or special appurtenances for soldering, e.g. brazing, or unsoldering, not specially adapted for particular methods

- B23K3/06—Solder feeding devices; Solder melting pans

- B23K3/0607—Solder feeding devices

- B23K3/063—Solder feeding devices for wire feeding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

- B23K1/012—Soldering with the use of hot gas

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/74—Apparatus for manufacturing arrangements for connecting or disconnecting semiconductor or solid-state bodies

- H01L24/741—Apparatus for manufacturing means for bonding, e.g. connectors

- H01L24/743—Apparatus for manufacturing layer connectors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/36—Electric or electronic devices

- B23K2101/40—Semiconductor devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/74—Apparatus for manufacturing arrangements for connecting or disconnecting semiconductor or solid-state bodies and for methods related thereto

- H01L2224/741—Apparatus for manufacturing means for bonding, e.g. connectors

- H01L2224/743—Apparatus for manufacturing layer connectors

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Die Bonding (AREA)

- Electric Connection Of Electric Components To Printed Circuits (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP02005422A EP1342525A1 (de) | 2002-03-08 | 2002-03-08 | Verfahren und Einrichtung zum Auftragen von Lot auf ein Substrat |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004025301A true JP2004025301A (ja) | 2004-01-29 |

| JP2004025301A5 JP2004025301A5 (enExample) | 2006-05-18 |

Family

ID=27741159

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003057944A Pending JP2004025301A (ja) | 2002-03-08 | 2003-03-05 | ハンダを基板上に小出しする方法と装置 |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1342525A1 (enExample) |

| JP (1) | JP2004025301A (enExample) |

| AT (1) | ATE340048T1 (enExample) |

| DE (1) | DE50305098D1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6811074B2 (en) * | 2002-03-08 | 2004-11-02 | Esec Trading Sa | Method and apparatus for dispensing solder on a substrate |

| JP2007294952A (ja) * | 2006-04-21 | 2007-11-08 | Internatl Business Mach Corp <Ibm> | はんだを射出成形するための充填ヘッド |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102024201352B4 (de) * | 2024-02-14 | 2025-12-04 | Volkswagen Aktiengesellschaft | Schutzgas-Lötbrenner mit Spritzschutzmanschette |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3734550A1 (de) * | 1987-10-13 | 1989-04-27 | Franz Ummen | Hochfrequenzbeheizter lotinjektor |

| US4934309A (en) * | 1988-04-15 | 1990-06-19 | International Business Machines Corporation | Solder deposition system |

| DE3913143C2 (de) * | 1989-04-21 | 1996-09-05 | U T S Uhrentechnik Schwarzwald | Löt- oder Schweißvorrichtung |

| EP0752294B1 (de) * | 1995-07-01 | 2000-06-21 | Esec Sa | Verfahren und Einrichtung zum Austragen von flüssigem Lot |

| JPH09232746A (ja) * | 1996-02-27 | 1997-09-05 | Omron Corp | 半田付け装置および半田付け方法 |

| JP3590319B2 (ja) * | 2000-03-10 | 2004-11-17 | 株式会社ジャパンユニックス | ガス噴射式はんだ付け方法及び装置 |

-

2002

- 2002-03-08 EP EP02005422A patent/EP1342525A1/de not_active Withdrawn

-

2003

- 2003-03-05 AT AT03100535T patent/ATE340048T1/de not_active IP Right Cessation

- 2003-03-05 JP JP2003057944A patent/JP2004025301A/ja active Pending

- 2003-03-05 DE DE50305098T patent/DE50305098D1/de not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6811074B2 (en) * | 2002-03-08 | 2004-11-02 | Esec Trading Sa | Method and apparatus for dispensing solder on a substrate |

| JP2007294952A (ja) * | 2006-04-21 | 2007-11-08 | Internatl Business Mach Corp <Ibm> | はんだを射出成形するための充填ヘッド |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1342525A1 (de) | 2003-09-10 |

| DE50305098D1 (de) | 2006-11-02 |

| ATE340048T1 (de) | 2006-10-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6811074B2 (en) | Method and apparatus for dispensing solder on a substrate | |

| TWI381465B (zh) | 用於安裝半導體晶片的銲料滴涂 | |

| US6427898B2 (en) | Solder bump forming method and apparatus | |

| TWI745840B (zh) | 接合裝置 | |

| US20040035907A1 (en) | Apparatus and method for dispensing solder | |

| JP2004025301A (ja) | ハンダを基板上に小出しする方法と装置 | |

| US20130119113A1 (en) | System for dispensing soft solder for mounting semiconductor chips using multiple solder wires | |

| US20160256949A1 (en) | Apparatus For Dispensing Flux-Free Solder On A Substrate | |

| JP3807487B2 (ja) | 半導体素子の装着装置 | |

| JPH03253045A (ja) | ワイヤボンディング装置 | |

| JP2000022323A (ja) | プリント基板のはんだ付け方法および噴流はんだ槽 | |

| JP2974714B2 (ja) | バンプ電極形成方法及びそのための装置 | |

| JP2000340936A (ja) | はんだ材塗布方法、マルチチップモジュールの製造方法およびマルチチップモジュール | |

| JPH0923057A (ja) | 半田付け装置 | |

| JPH08306847A (ja) | 整形済icのハンダコーティング装置 | |

| JPH0737916A (ja) | 液状物質の塗布方法 | |

| JPH03273651A (ja) | 半導体装置への樹脂被覆ボンディング細線の接合方法 | |

| CN1012968B (zh) | 提高带涂层铜线钎焊性能的热涂法 | |

| JPH05147952A (ja) | 光学素子の成形方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060228 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060301 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060228 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080819 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20081106 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20081119 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081210 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20090127 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20090127 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090818 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100209 |