EP3708714B1 - Securing device for securing a civil engineering element and civil engineering method - Google Patents

Securing device for securing a civil engineering element and civil engineering method Download PDFInfo

- Publication number

- EP3708714B1 EP3708714B1 EP19162495.6A EP19162495A EP3708714B1 EP 3708714 B1 EP3708714 B1 EP 3708714B1 EP 19162495 A EP19162495 A EP 19162495A EP 3708714 B1 EP3708714 B1 EP 3708714B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- securing

- construction machine

- civil engineering

- pile

- connecting link

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000012407 engineering method Methods 0.000 title claims description 8

- 238000010276 construction Methods 0.000 claims description 33

- 238000001514 detection method Methods 0.000 claims description 12

- 238000012360 testing method Methods 0.000 claims description 4

- 238000003780 insertion Methods 0.000 description 6

- 230000037431 insertion Effects 0.000 description 6

- 239000000463 material Substances 0.000 description 4

- 230000006378 damage Effects 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000010292 electrical insulation Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 238000004873 anchoring Methods 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 239000000872 buffer Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000012777 electrically insulating material Substances 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 238000005303 weighing Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D7/00—Methods or apparatus for placing sheet pile bulkheads, piles, mouldpipes, or other moulds

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D13/00—Accessories for placing or removing piles or bulkheads, e.g. noise attenuating chambers

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D13/00—Accessories for placing or removing piles or bulkheads, e.g. noise attenuating chambers

- E02D13/02—Accessories for placing or removing piles or bulkheads, e.g. noise attenuating chambers specially adapted for placing or removing bulkheads

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D13/00—Accessories for placing or removing piles or bulkheads, e.g. noise attenuating chambers

- E02D13/10—Follow-blocks of pile-drivers or like devices

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D15/00—Handling building or like materials for hydraulic engineering or foundations

- E02D15/08—Sinking workpieces into water or soil inasmuch as not provided for elsewhere

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D7/00—Methods or apparatus for placing sheet pile bulkheads, piles, mouldpipes, or other moulds

- E02D7/02—Placing by driving

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D7/00—Methods or apparatus for placing sheet pile bulkheads, piles, mouldpipes, or other moulds

- E02D7/02—Placing by driving

- E02D7/06—Power-driven drivers

- E02D7/14—Components for drivers inasmuch as not specially for a specific driver construction

- E02D7/16—Scaffolds or supports for drivers

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D7/00—Methods or apparatus for placing sheet pile bulkheads, piles, mouldpipes, or other moulds

- E02D7/18—Placing by vibrating

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D9/00—Removing sheet piles bulkheads, piles, mould-pipes or other moulds or parts thereof

- E02D9/02—Removing sheet piles bulkheads, piles, mould-pipes or other moulds or parts thereof by withdrawing

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D2600/00—Miscellaneous

- E02D2600/10—Miscellaneous comprising sensor means

Definitions

- the invention relates to a securing device for securing a civil engineering element on a construction machine, in particular a pile-driven material on a pile-driving device, with a connecting device on the construction machine and a flexible securing element, in particular a securing chain, a first end of the flexible securing element being attached to the construction machine and a second end is provided with a connecting member which can be passed through a securing eye on the civil engineering element and can be releasably attached to the construction machine with the connecting device, according to the preamble of claim 1.

- the invention also relates to a civil engineering method in which a civil engineering element on a construction machine, in particular a pile-driven material on a ramming device, is fixed by means of a flexible securing element, in particular a securing chain, a first end of the flexible securing element being attached to the construction machine and a second end is provided with a connecting member which is guided through a securing eye on the civil engineering element and is releasably fastened to the construction machine with a connecting device for securing the position of the civil engineering element on the construction machine, according to the preamble of claim 10.

- a generic safety device is based on DE 3 602 609 A1 emerged.

- a sheet pile can be loosely attached to a vibration device by means of chain anchoring.

- a safety chain is passed through a through hole or a safety eye at an upper end area of the screed.

- the safety chain is attached to the vibration device at one end. After passing through, the loose end is attached to the vibration device by means of a plug connection.

- the vibrating device can then be driven upwards along a mast, the sheet pile being held by the chain anchorage and being pulled upward, with an upper end of the sheet pile entering a receiving slot of the vibrating device between two clamping jaws. Then the sheet pile can be clamped on the vibration device between the two clamping jaws. Then the clamped sheet pile pile can be driven or rammed vertically into the ground by means of the vibration device.

- the known pile-driving device can also be used, the safety chain having to be guided through the safety eye on the sheet pile before pulling the sheet pile, in order to additionally secure the sheet pile to the driving or vibrating device.

- the upper end of the plank is then clamped in again and pulled out of the ground by means of the vibration device.

- the safety chain serves as an additional mechanical positional safeguard so that the screed does not fall to the ground in an uncontrolled manner if the hydraulic tensioning device fails.

- the screed is placed back on the ground with the help of the safety chain after releasing the clamping jaws.

- a similar arrangement of a piling device is from U.S. 5,332,047 known.

- a pile-shaped pile is driven into the ground, a safety chain also being arranged between the pile and the pile driver.

- the safety chain serves as an additional mechanical positional safeguard for the pile, which is usually a steel part up to 10 m or more long and weighing several 100 kg.

- the safety chain serves as an additional mechanical positional safeguard for the pile, which is usually a steel part up to 10 m or more long and weighing several 100 kg.

- With hydraulic clamping devices malfunctions, incorrect operation or damage to the hydraulic system can lead to an unexpected loosening or reduction of the hydraulic clamping force.

- Without the presence of an additional mechanical position security by the Safety chain there is a risk that the pile will fall from a vertical position to the ground and cause property damage and personal injury. Numerous fatal accidents have been documented.

- Another generic safety device is from the EP 3 228 392 A1 known.

- From the US 2002/063 245 A1 shows a pulling device for piles in which the piles are connected with a chain with a pull yoke.

- the invention is based on the object of specifying a safety device and a civil engineering method with which a particularly high level of work safety is ensured.

- the object is achieved on the one hand by a safety device with the features of claim 1 and on the other hand by a civil engineering method with the features of claim 10.

- a safety device with the features of claim 1

- a civil engineering method with the features of claim 10.

- the securing device is characterized in that a detector unit is provided on the connecting device, which is designed to detect attachment of the connecting link to the connecting device, and that a signal can be generated and emitted by the detector unit when attachment of the connecting link is detected.

- a basic idea of the invention is to verify correct closing of the flexible securing element on the connecting device.

- a detector unit is arranged on the connecting device, which detects the picking up and fastening of the connecting link to the connecting device.

- the detector unit emits a signal, in particular an electrical signal, when the connecting link has been correctly fastened.

- the detector unit can also emit a signal if the connecting link has not been fastened or not fastened correctly.

- the signal can be displayed directly to a machine operator, for example in a control station.

- a corresponding warning device which is operated optically and / or acoustically in particular, can also be actuated by the signal.

- the signal can also be fed to a corresponding control unit of the construction machine The control unit then intervenes accordingly in the further operating sequence.

- further operation of the construction machine can be stopped or at least restricted, for example in such a way that the ramming material cannot be clamped to the ramming device or the ram drive unit cannot be started until the connecting link has been correctly attached.

- a preferred development of the invention consists in that at least one locking bolt is provided on the connecting device, by means of which the connecting member can be locked in the connecting device.

- the at least one locking bolt thus represents a mechanical blocking of the connecting link in the connecting device.

- the detector device can alternatively or additionally detect the position of the locking bolt.

- the locking bolt is adjustably mounted between a retracted position for receiving or releasing the connecting member in the connecting device and a locking position in which the connecting member is locked in the connecting device.

- the locking bolt In the retracted position, the locking bolt can be held in place with a slight force by locking. This allows simple insertion of the connecting link into the connecting device and subsequent locking by moving the locking bolt into the locking position.

- the locking bolt can also be held in the locking position in a spring-tensioned manner.

- the lock can be operated by hand or preferably by an activatable actuator, such as a hydraulic actuator cylinder.

- a particularly expedient variant embodiment of the invention can be seen in the fact that the position of the connecting member in the locking position can be detected by the detector unit. This can be done alone or in addition to detecting the position of the locking bolt. This achieves a particularly high level of detection reliability.

- a particularly efficient variant embodiment of the invention results from the fact that the detector unit has at least one proximity sensor.

- a proximity sensor is a robust and generally inexpensive sensor element.

- the detector unit can be designed in a particularly economical and reliable manner.

- the proximity sensor can detect when the connecting link is in the connecting device. At the same time, the same or another proximity sensor can also be used to determine the position of the locking bolt in order to increase the detection reliability.

- the flexible securing element is electrically conductive and that an electrical energy source is provided with which between a fastening element, to which the first end of the flexible securing element is attached, and the connecting device through the flexible securing element Test current can be conducted, which can be detected by the detector unit.

- the electrical energy source can in particular be a current or voltage source, by means of which a test current is generated continuously or at certain times. If the flexible fuse element is correctly connected to the connecting device, a test current is conducted from the fastening element at one end of the flexible fuse element to its other end on the connecting device.

- This safety arrangement can be provided in addition to or instead of the detection arrangement described above.

- the flexible safety element can be, for example, a steel cable or a chain made of metallic or electrically conductive chain links. When a rope is used, it can also be provided or formed with a correspondingly electrically conductive material only on its outside or inside.

- the fastening element and the connecting device are electrically isolated from the construction machine. This avoids leakage currents.

- the electrical insulation can take place by means of appropriate electrically insulating materials. It when the fastening element and the connecting device are fastened to the construction machine via rubber buffers is particularly advantageous. This not only provides electrical insulation, but acoustic insulation and thus a reduction in sound radiation is also achieved.

- the invention also comprises a construction machine, in particular a pile driving device for driving a pile into the ground, the previously described safety device being provided.

- the ramming device has a ram drive unit which is used to drive the pile, in particular a pile, a girder or a sheet pile, into the ground by means of vibrations or pulses.

- the ram drive unit can be a vibrator with rotatable unbalance elements or a ram hammer with a linearly reversing impulse element.

- the vibrator can have one or more pairs of rotatable unbalance elements, which are mounted so as to be adjustable in relation to one another in a known manner in order to generate a directed unbalance.

- the pile driving unit can be a pile hammer.

- the ramming movement can trigger impact pulses in which the reversely driven pulse element hits a striking surface.

- the pulse element can also be driven in a reversing manner without impact contact, so that a targeted vibration movement is generated and transmitted to the pile.

- the construction machine can have a mobile carrier device on which a mast is arranged.

- the ram drive unit can be mounted vertically adjustable along the mast.

- the carrier device can in particular have a crawler chassis on which a rotatable superstructure with a boom for a rope suspension or a vertical mast with a slide guide, in particular a telescopic leader, is mounted.

- the civil engineering method according to the invention is characterized in that a connection device of a detector unit is provided, with which fastening of the connecting link to the connecting device is detected, and that a signal is generated and emitted by the detector unit when fastening and / or no fastening of the connecting link is detected is.

- the civil engineering method can in particular be carried out with the safety device described above.

- the advantages described here can be achieved.

- a preferred variant of the method of the invention consists in that the construction machine is a pile-driving device with which a pile-driven material is driven into the ground as a civil engineering element or pulled out of it.

- the pile can be a pile, a girder, a pipe, a sheet pile, etc.

- a large number of such underground construction elements can be driven in, so that a so-called sheet pile wall is formed in the ground.

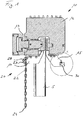

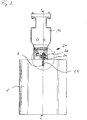

- FIG Figures 1 to 3 The basic structure of a securing device 20 according to the invention on a construction machine 10 is shown in FIG Figures 1 to 3 shown.

- the construction machine 10 which is only partially shown, has a ram drive unit 12, which can have imbalances that can be driven in rotation in a basically known manner.

- a hydraulic clamping device 13 is arranged on a lower region of the ram drive unit 12, with which a civil engineering element 5, which in the illustrated embodiment is a sheet pile wall, can be firmly clamped between two clamping jaws.

- a first insertion flank 14 and a second insertion flank 15 are arranged at the lower end of the ram drive unit 12, which together form an approximately V-shaped receiving slot.

- a securing device 20 according to the invention is provided for additionally securing the position of the civil engineering element 5.

- the securing device 20 comprises a flexible securing element 22, which is designed as a chain in the illustrated embodiment.

- a first end of the chain is fastened to the first insertion flank 14 and thus to the construction machine 10 by means of a plate-shaped fastening element 28.

- An insulating layer 29 can be arranged between the fastening element 28 and the first insertion flank 14, with which the fastening element 28 and thus the flexible securing element 22 is electrically insulated from the construction machine 10.

- a connecting member 24 is attached, which is designed as an approximately T-shaped toggle.

- the connecting member 24 can be pushed through a through hole or a securing eyelet 7 on the plank-shaped civil engineering element 5 and guided to a connecting device 30 on the second insertion flank 15, as illustrated in FIG Figures 2 and 3 is shown.

- the connecting member 24 can be introduced or pushed into a suitable slot-shaped receptacle 32 on the box-shaped connecting device 30, wherein the connecting member 24 can be locked in the connecting device 30.

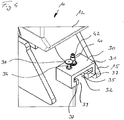

- the box-shaped connector 30 in a receiving state is in the Figures 4 and 5 shown.

- a block-like housing 31 has a slot-like receptacle 32 for receiving the connecting member 24.

- the receptacle 32 is open on one side which faces away from the clamped civil engineering element 5.

- a slot 33 is made on an underside of the housing 31, the slot width of which is smaller than the receiving area of the receptacle 32 located above it.

- Two lateral, rail-like supports 35 are formed, which serve to place the toggle-shaped connecting member 24 on.

- the supports 35 can be designed with an upwardly projecting shoulder 37.

- a proximity sensor 42 is introduced as a detector unit 40 into a corresponding receiving bore.

- the proximity sensor 42 is designed to detect the presence of the connecting link 24 in the receptacle 32 of the connecting device 30.

- a vertically displaceable locking bolt 34 with an upper actuating plate 36 protrudes from a receiving bore on the upper side of the housing 31.

- the locking bolt 34 with the actuating plate 36 is designed for mechanical operation by hand or by means of an actuating tool.

- an active device (not shown), in particular an actuator such as a pneumatic or hydraulic actuator cylinder, can be provided.

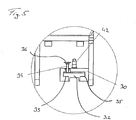

- Fig. 6 the state of the securing device 20 is shown in which the T-shaped connecting link 24 of the chain-shaped flexible securing element 22 is inserted into the receptacle 32 of the connecting device 30.

- the locking bolt 34 is adjusted downward from a retracted position into a locking position. In this position, both the presence of the connecting link 24 in the connecting device 30 and an adjustment of the locking bolt 34 into the locking position can be determined by the detector unit 40 with the proximity sensor 42.

- the detector unit 40 can send a signal to a control unit, which signals that the connecting member 24 is correctly attached in the connecting device 30 and that the civil engineering element 5 is thus correctly secured by the flexible securing element 22.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- Civil Engineering (AREA)

- Placing Or Removing Of Piles Or Sheet Piles, Or Accessories Thereof (AREA)

Description

Die Erfindung betrifft eine Sicherungsvorrichtung zum Sichern eines Tiefbauelementes an einer Baumaschine, insbesondere eines Rammgutes an einer Rammvorrichtung, mit einer Verbindungseinrichtung an der Baumaschine und einem flexiblen Sicherungselement, insbesondere einer Sicherungskette, wobei ein erstes Ende des flexiblen Sicherungselementes an der Baumaschine angebracht und ein zweites Ende mit einem Verbindungsglied versehen ist, welches durch eine Sicherungsöse an dem Tiefbauelement durchführbar und mit der Verbindungseinrichtung an der Baumaschine lösbar befestigbar ist, gemäß dem Oberbegriff des Anspruchs 1.The invention relates to a securing device for securing a civil engineering element on a construction machine, in particular a pile-driven material on a pile-driving device, with a connecting device on the construction machine and a flexible securing element, in particular a securing chain, a first end of the flexible securing element being attached to the construction machine and a second end is provided with a connecting member which can be passed through a securing eye on the civil engineering element and can be releasably attached to the construction machine with the connecting device, according to the preamble of claim 1.

Die Erfindung betrifft weiterhin ein Tiefbauverfahren, bei dem ein Tiefbauelement an einer Baumaschinen, insbesondere ein Rammgut an einer Rammvorrichtung, mittels eines flexiblen Sicherungselementes, insbesondere einer Sicherungskette, fixiert wird, wobei ein erstes Ende des flexiblen Sicherungselementes an der Baumaschine angebracht ist und ein zweites Ende mit einem Verbindungsglied versehen ist, welches durch eine Sicherungsöse an dem Tiefbauelement geführt und mit einer Verbindungseinrichtung an der Baumaschine zur Lagesicherung des Tiefbauelementes an der Baumaschine lösbar befestigt wird, gemäß dem Oberbegriff des Anspruchs 10.The invention also relates to a civil engineering method in which a civil engineering element on a construction machine, in particular a pile-driven material on a ramming device, is fixed by means of a flexible securing element, in particular a securing chain, a first end of the flexible securing element being attached to the construction machine and a second end is provided with a connecting member which is guided through a securing eye on the civil engineering element and is releasably fastened to the construction machine with a connecting device for securing the position of the civil engineering element on the construction machine, according to the preamble of claim 10.

Eine gattungsgemäße Sicherungsvorrichtung geht aus der

Anschließend kann die Vibrationseinrichtung entlang eines Mastes nach oben gefahren werden, wobei die Spundwandbohle durch die Kettenverankerung gehalten und nach oben gezogen wird, wobei ein oberes Ende der Spundwandbohle in einen Aufnahmeschlitz der Vibrationseinrichtung zwischen zwei Spannbacken eintritt. Anschließend kann die Spundwandbohle an der Vibrationseinrichtung zwischen den zwei Spannbacken eingespannt werden. Sodann kann die eingespannte Spundwandbohle vertikal mittels der Vibrationseinrichtung in den Boden eingetrieben oder eingerammt werden.The vibrating device can then be driven upwards along a mast, the sheet pile being held by the chain anchorage and being pulled upward, with an upper end of the sheet pile entering a receiving slot of the vibrating device between two clamping jaws. Then the sheet pile can be clamped on the vibration device between the two clamping jaws. Then the clamped sheet pile pile can be driven or rammed vertically into the ground by means of the vibration device.

Nach dem Abschluss einer Tiefbaumaßnahme ist es häufig erforderlich oder gewünscht, die Spundwandbohlen wieder aus dem Boden zu entfernen. Hierzu kann ebenfalls die bekannte Rammvorrichtung eingesetzt werden, wobei vor dem Ziehen der Spundwandbohle die Sicherungskette wieder durch die Sicherungsöse an der Spundwandbohle zu führen ist, um so die Spundwandbohle zusätzlich an der Ramm- oder Vibrationseinrichtung zu sichern. Anschließend wird das obere Ende der Bohle wieder eingespannt und mittels der Vibrationseinrichtung rüttelnd aus dem Boden gezogen. Die Sicherungskette dient dabei als eine zusätzliche mechanische Lagesicherung, damit die Bohle etwa bei einem Versagen der hydraulischen Spanneinrichtung nicht unkontrolliert zu Boden stürzt. Außerdem wird die Bohle mit Hilfe der Sicherungskette nach dem Lösen der Klemmbacken wieder auf dem Boden abgelegt.After civil engineering work has been completed, it is often necessary or desirable to remove the sheet piles from the ground. For this purpose, the known pile-driving device can also be used, the safety chain having to be guided through the safety eye on the sheet pile before pulling the sheet pile, in order to additionally secure the sheet pile to the driving or vibrating device. The upper end of the plank is then clamped in again and pulled out of the ground by means of the vibration device. The safety chain serves as an additional mechanical positional safeguard so that the screed does not fall to the ground in an uncontrolled manner if the hydraulic tensioning device fails. In addition, the screed is placed back on the ground with the help of the safety chain after releasing the clamping jaws.

Eine ähnliche Anordnung einer Rammvorrichtung ist aus der

Die Sicherungskette dient als eine zusätzliche mechanische Lagesicherung des Rammgutes, welches in der Regel ein bis zu 10 m oder mehr langes Stahlteil mit einem Gewicht von mehreren 100 kg ist. Bei hydraulischen Spanneinrichtungen kann es bei Fehlfunktionen, Fehlbedienungen oder Beschädigungen des hydraulischen Systems zu einem unerwarteten Lösen oder Verringern der hydraulischen Spannkraft kommen. Ohne das Vorhandensein einer zusätzlichen mechanischen Lagesicherung durch die Sicherungskette besteht die Gefahr, dass das Rammgut aus einer vertikalen Position zu Boden stürzt und dabei zu einem Sach- und Personenschaden führen kann. Es sind zahlreiche tödliche Unfälle dokumentiert.The safety chain serves as an additional mechanical positional safeguard for the pile, which is usually a steel part up to 10 m or more long and weighing several 100 kg. With hydraulic clamping devices, malfunctions, incorrect operation or damage to the hydraulic system can lead to an unexpected loosening or reduction of the hydraulic clamping force. Without the presence of an additional mechanical position security by the Safety chain, there is a risk that the pile will fall from a vertical position to the ground and cause property damage and personal injury. Numerous fatal accidents have been documented.

In der Praxis kann es vorkommen, dass Baustellenpersonal das Anbringen der Sicherungskette vergisst oder diese nicht korrekt befestigt ist. Dies stellt eine erhebliche Gefährdung der Arbeitssicherheit dar.In practice it can happen that construction site personnel forgets to attach the safety chain or that it is not correctly attached. This represents a considerable risk to occupational safety.

Eine weitere gattungsgemäße Sicherungsvorrichtung ist aus der

Aus der

Der Erfindung liegt die Aufgabe zugrunde, eine Sicherungsvorrichtung und ein Tiefbauverfahren anzugeben, mit welchen eine besonders hohe Arbeitssicherheit gewährleistet wird.The invention is based on the object of specifying a safety device and a civil engineering method with which a particularly high level of work safety is ensured.

Die Aufgabe wird nach der Erfindung zum einen durch eine Sicherungsvorrichtung mit den Merkmalen des Anspruchs 1 und zum anderen durch ein Tiefbauverfahren mit den Merkmalen des Anspruchs 10 gelöst. Bevorzugte Ausführungsformen der Erfindung sind in abhängigen Ansprüchen angegeben.According to the invention, the object is achieved on the one hand by a safety device with the features of claim 1 and on the other hand by a civil engineering method with the features of claim 10. Preferred embodiments of the invention are given in the dependent claims.

Die erfindungsgemäße Sicherungsvorrichtung ist dadurch gekennzeichnet, dass an der Verbindungseinrichtung eine Detektoreinheit vorgesehen ist, welche ausgebildet ist, ein Befestigen des Verbindungsglieds an der Verbindungseinrichtung zu erfassen, und dass durch die Detektoreinheit ein Signal erzeugbar und abgebbar ist, wenn ein Befestigen des Verbindungsglieds erfasst ist.The securing device according to the invention is characterized in that a detector unit is provided on the connecting device, which is designed to detect attachment of the connecting link to the connecting device, and that a signal can be generated and emitted by the detector unit when attachment of the connecting link is detected.

Eine Grundidee der Erfindung liegt darin, ein korrektes Schließen des flexiblen Sicherungselementes an der Verbindungseinrichtung zu verifizieren. Hierzu ist an der Verbindungeinrichtung eine Detektoreinheit angeordnet, welche ein Aufnehmen und Befestigen des Verbindungsgliedes an der Verbindungeinrichtung erfasst. Hierbei gibt die Detektoreinheit ein Signal, insbesondere ein elektrisches Signal ab, wenn ein korrektes Befestigen des Verbindungsgliedes erfolgt ist. Ergänzend oder alternativ kann die Detektoreinheit auch ein Signal abgeben, wenn kein oder kein korrektes Befestigen des Verbindungsgliedes durchgeführt wurde.A basic idea of the invention is to verify correct closing of the flexible securing element on the connecting device. For this purpose, a detector unit is arranged on the connecting device, which detects the picking up and fastening of the connecting link to the connecting device. Here, the detector unit emits a signal, in particular an electrical signal, when the connecting link has been correctly fastened. In addition or as an alternative, the detector unit can also emit a signal if the connecting link has not been fastened or not fastened correctly.

Das Signal kann unmittelbar einem Maschinenbediener etwa in einem Bedienstand angezeigt werden. Durch das Signal kann auch eine entsprechende Warneinrichtung betätigt werden, welche insbesondere optisch und/oder akustisch betrieben ist. Das Signal kann auch einer entsprechenden Steuereinheit der Baumaschine zugeleitet werden, wobei durch die Steuereinheit dann in den weiteren Betriebsablauf entsprechend eingegriffen wird. Insbesondere kann ein weiterer Betrieb der Baumaschine gestoppt oder zumindest eingeschränkt werden, beispielsweise dahingehend, dass eine Einspannung des Rammgutes an der Rammvorrichtung nicht gelöst oder eine Bewegung der Rammantriebseinheit nicht gestartet werden kann, bis ein korrektes Befestigen des Verbindungsgliedes erfolgt ist.The signal can be displayed directly to a machine operator, for example in a control station. A corresponding warning device, which is operated optically and / or acoustically in particular, can also be actuated by the signal. The signal can also be fed to a corresponding control unit of the construction machine The control unit then intervenes accordingly in the further operating sequence. In particular, further operation of the construction machine can be stopped or at least restricted, for example in such a way that the ramming material cannot be clamped to the ramming device or the ram drive unit cannot be started until the connecting link has been correctly attached.

Eine bevorzugte Weiterbildung der Erfindung besteht darin, dass an der Verbindungseinrichtung mindestens ein Riegelbolzen vorgesehen ist, durch welchen das Verbindungsglied in der Verbindungseinrichtung verriegelbar ist. Der mindestens eine Riegelbolzen stellt somit eine mechanische Blockierung des Verbindungsgliedes in der Verbindungseinrichtung dar. Die Detektoreinrichtung kann alternativ oder ergänzend die Stellung des Riegelbolzens erfassen.A preferred development of the invention consists in that at least one locking bolt is provided on the connecting device, by means of which the connecting member can be locked in the connecting device. The at least one locking bolt thus represents a mechanical blocking of the connecting link in the connecting device. The detector device can alternatively or additionally detect the position of the locking bolt.

Dabei ist es nach einer Weiterbildung der Erfindung besonders bevorzugt, dass der Riegelbolzen verstellbar zwischen einer Rückzugsposition zum Aufnehmen oder Lösen des Verbindungsgliedes in der Verbindungseinrichtung und einer Verriegelungsposition verstellbar gelagert ist, in welcher das Verbindungsglied in der Verbindungseinrichtung verriegelt ist. In der Rückzugsposition kann der Riegelbolzen durch eine Verrastung mit leichter Kraft gehalten sein. Dies erlaubt ein einfaches Einführen des Verbindungsgliedes in die Verbindungseinrichtung und ein anschließendes Verriegeln durch Bewegen des Riegelbolzens in die Verriegelungsposition. Alternativ kann der Riegelbolzen auch federgespannt in der Verriegelungsposition gehalten sein. Zum Einführen des Verbindungsgliedes wird der Riegelbolzen kurzfristig entgegen der Federspannung rückgezogen, wobei dieser dann nach Einführung des Verbindungsgliedes in ein entsprechendes Schloss der Verbindungseinrichtung wieder durch die Federkraft in die Verriegelungsposition gedrückt wird. Die Verriegelung kann von Hand oder vorzugsweise durch ein aktivierbares Stellorgan, etwa einen hydraulischen Stellzylinder, betätigt werden.According to a development of the invention, it is particularly preferred that the locking bolt is adjustably mounted between a retracted position for receiving or releasing the connecting member in the connecting device and a locking position in which the connecting member is locked in the connecting device. In the retracted position, the locking bolt can be held in place with a slight force by locking. This allows simple insertion of the connecting link into the connecting device and subsequent locking by moving the locking bolt into the locking position. Alternatively, the locking bolt can also be held in the locking position in a spring-tensioned manner. To insert the connecting link, the locking bolt is briefly withdrawn against the spring tension, which is then pushed back into the locking position by the spring force after the connecting link has been inserted into a corresponding lock of the connecting device. The lock can be operated by hand or preferably by an activatable actuator, such as a hydraulic actuator cylinder.

Eine besonders zweckmäßige Ausführungsvariante der Erfindung kann darin gesehen werden, dass durch die Detektoreinheit die Lage des Verbindungsgliedes in der Verriegelungsposition erfassbar ist. Dies kann alleine oder in Ergänzung zu einer Erfassung der Position des Riegelbolzens erfolgen. Hierdurch wird eine besonders hohe Erfassungssicherheit erreicht.A particularly expedient variant embodiment of the invention can be seen in the fact that the position of the connecting member in the locking position can be detected by the detector unit. This can be done alone or in addition to detecting the position of the locking bolt. This achieves a particularly high level of detection reliability.

Eine besonders effiziente Ausgestaltungsvariante der Erfindung ergibt sich dadurch, dass die Detektoreinheit mindestens einen Näherungssensor aufweist. Ein Näherungssensor ist ein robustes und insgesamt kostengünstiges Sensorelement. Hierdurch kann die Detektoreinheit in besonders wirtschaftlicher und zuverlässiger Weise ausgeführt werden.A particularly efficient variant embodiment of the invention results from the fact that the detector unit has at least one proximity sensor. A proximity sensor is a robust and generally inexpensive sensor element. As a result, the detector unit can be designed in a particularly economical and reliable manner.

Besonders vorteilhaft ist es dabei, dass durch den Näherungssensor erfassbar ist, wenn sich das Verbindungsglied in der Verbindungseinrichtung befindet. Gleichzeitig kann durch den gleichen oder einen weiteren Näherungssensor auch die Stellung des Riegelbolzens zur Erhöhung der Erfassungssicherheit ermittelt werden.It is particularly advantageous that the proximity sensor can detect when the connecting link is in the connecting device. At the same time, the same or another proximity sensor can also be used to determine the position of the locking bolt in order to increase the detection reliability.

Gemäß einer weiteren Ausführungsform der Erfindung ist es bevorzugt, dass das flexible Sicherungselement elektrisch leitend ist und dass eine elektrische Energiequelle vorgesehen ist, mit welcher zwischen einem Befestigungselement, an welchem das erste Ende des flexiblen Sicherungselementes angebracht ist, und der Verbindungseinrichtung durch das flexible Sicherungselement ein Prüfstrom leitbar ist, welcher von der Detektoreinheit erfassbar ist. Die elektrische Energiequelle kann insbesondere eine Strom- oder Spannungsquelle sein, durch welche ein Prüfstrom kontinuierlich oder zu bestimmten Zeitpunkten erzeugt wird. Ist das flexible Sicherungselement korrekt an der Verbindungseinrichtung angeschlossen, so wird ein Prüfstrom von dem Befestigungselement an dem einen Ende des flexiblen Sicherungselementes zu dessen anderen Ende an der Verbindungseinrichtung geleitet. Diese Sicherheitsanordnung kann ergänzend oder anstelle der zuvor beschriebenen Detektionsanordnung vorgesehen sein. Das flexible Sicherungselement kann beispielsweise ein Stahlseil oder eine Kette aus metallischen oder elektrisch leitenden Kettengliedern sein. Bei der Verwendung eines Seiles kann dieses auch nur an seiner Außen- oder Innenseite mit einem entsprechend elektrisch leitenden Material versehen oder gebildet sein.According to a further embodiment of the invention, it is preferred that the flexible securing element is electrically conductive and that an electrical energy source is provided with which between a fastening element, to which the first end of the flexible securing element is attached, and the connecting device through the flexible securing element Test current can be conducted, which can be detected by the detector unit. The electrical energy source can in particular be a current or voltage source, by means of which a test current is generated continuously or at certain times. If the flexible fuse element is correctly connected to the connecting device, a test current is conducted from the fastening element at one end of the flexible fuse element to its other end on the connecting device. This safety arrangement can be provided in addition to or instead of the detection arrangement described above. The flexible safety element can be, for example, a steel cable or a chain made of metallic or electrically conductive chain links. When a rope is used, it can also be provided or formed with a correspondingly electrically conductive material only on its outside or inside.

Besonders zweckmäßig ist es dabei, dass das Befestigungselement und die Verbindungseinrichtung gegenüber der Baumaschine elektrisch isoliert sind. Hierdurch werden Verlustströme vermieden. Die elektrische Isolierung kann durch entsprechende elektrisch isolierende Materialien erfolgen. Besonders vorteilhaft ist es, wenn das Befestigungselement und die Verbindungseinrichtung über Gummipuffer an der Baumaschine befestigt sind. Hierdurch wird nicht nur eine elektrische Isolierung, sondern auch eine akustische Isolation und damit eine Reduzierung der Schallabstrahlung erreicht.It is particularly useful here that the fastening element and the connecting device are electrically isolated from the construction machine. This avoids leakage currents. The electrical insulation can take place by means of appropriate electrically insulating materials. It when the fastening element and the connecting device are fastened to the construction machine via rubber buffers is particularly advantageous. This not only provides electrical insulation, but acoustic insulation and thus a reduction in sound radiation is also achieved.

Die Erfindung umfasst auch eine Baumaschine, insbesondere eine Rammvorrichtung zum Eintreiben eines Rammguts in den Boden, wobei die zuvor beschriebene Sicherungsvorrichtung vorgesehen ist.The invention also comprises a construction machine, in particular a pile driving device for driving a pile into the ground, the previously described safety device being provided.

Die Rammvorrichtung weist dabei eine Rammantriebseinheit auf, welche dazu dient, das Rammgut, insbesondere einen Pfahl, einen Träger oder eine Spundwandbohle, mittels Schwingungen oder Impulsen in einen Boden einzutreiben. Die Rammantriebseinheit kann dabei ein Rüttler mit rotierbaren Unwuchtelementen oder ein Rammhammer mit einem linear reversierend antreibbaren Impulselement sein. Der Rüttler kann dabei ein oder mehrere Paare von rotierbaren Unwuchtelementen aufweisen, welche in bekannter Weise zum Erzeugen einer gerichteten Unwucht zueinander verstellbar gelagert sind. Alternativ kann die Rammantriebseinheit ein Rammhammer sein. Dabei kann die Rammbewegung Schlagimpulse auslösen, bei welchen das reversierend angetriebene Impulselement auf eine Schlagfläche auftrifft. Alternativ kann das Impulselement auch ohne einen Schlagkontakt reversierend angetrieben sein, so dass eine gezielte Vibrationsbewegung erzeugt und auf das Rammgut übertragen wird.The ramming device has a ram drive unit which is used to drive the pile, in particular a pile, a girder or a sheet pile, into the ground by means of vibrations or pulses. The ram drive unit can be a vibrator with rotatable unbalance elements or a ram hammer with a linearly reversing impulse element. The vibrator can have one or more pairs of rotatable unbalance elements, which are mounted so as to be adjustable in relation to one another in a known manner in order to generate a directed unbalance. Alternatively, the pile driving unit can be a pile hammer. The ramming movement can trigger impact pulses in which the reversely driven pulse element hits a striking surface. Alternatively, the pulse element can also be driven in a reversing manner without impact contact, so that a targeted vibration movement is generated and transmitted to the pile.

Die Baumaschine kann ein mobiles Trägergerät aufweisen, an welchem ein Mast angeordnet ist. Entlang des Mastes kann die Rammantriebseinheit vertikal verstellbar gelagert sein. Das Trägergerät kann insbesondere ein Raupenfahrwerk aufweisen, an welchem ein drehbarer Oberwagen mit einem Ausleger für eine Seilaufhängung oder einem vertikalen Mast mit einer Schlittenführung, insbesondere einem Teleskopmäkler, gelagert ist.The construction machine can have a mobile carrier device on which a mast is arranged. The ram drive unit can be mounted vertically adjustable along the mast. The carrier device can in particular have a crawler chassis on which a rotatable superstructure with a boom for a rope suspension or a vertical mast with a slide guide, in particular a telescopic leader, is mounted.

Das erfindungsgemäße Tiefbauverfahren ist dadurch gekennzeichnet, dass eine Verbindungseinrichtung einer Detektoreinheit vorgesehen ist, mit welcher ein Befestigen des Verbindungsgliedes an der Verbindungseinrichtung erfasst wird, und dass durch die Detektoreinheit ein Signal erzeugt und abgegeben wird, wenn ein Befestigen und/oder kein Befestigen des Verbindungsgliedes erfasst ist.The civil engineering method according to the invention is characterized in that a connection device of a detector unit is provided, with which fastening of the connecting link to the connecting device is detected, and that a signal is generated and emitted by the detector unit when fastening and / or no fastening of the connecting link is detected is.

Das Tiefbauverfahren kann insbesondere mit der zuvor beschriebenen Sicherheitsvorrichtung ausgeführt werden. Es können die dabei beschriebenen Vorteile erzielt werden.The civil engineering method can in particular be carried out with the safety device described above. The advantages described here can be achieved.

Eine bevorzugte Verfahrensvariante der Erfindung besteht darin, dass die Baumaschine eine Rammvorrichtung ist, mit welcher ein Rammgut als Tiefbauelement in den Boden eingetrieben oder aus ihm gezogen wird. Das Rammgut kann ein Pfahl, ein Träger, ein Rohr, eine Spundwandbohle etc. sein. Insbesondere beim Eintreiben einer Spundwandbohle können eine Vielzahl solcher Tiefbauelemente eingetrieben werden, so dass im Boden eine sogenannte Spundwand gebildet wird.A preferred variant of the method of the invention consists in that the construction machine is a pile-driving device with which a pile-driven material is driven into the ground as a civil engineering element or pulled out of it. The pile can be a pile, a girder, a pipe, a sheet pile, etc. In particular when driving in a sheet pile wall, a large number of such underground construction elements can be driven in, so that a so-called sheet pile wall is formed in the ground.

Die Erfindung wird nachfolgend anhand von bevorzugten Ausführungsbeispielen weiter beschrieben, welche schematisch in den Zeichnungen dargestellt sind. In den Zeichnungen zeigen:

- Fig. 1

- eine Querschnittsansicht durch einen Teil einer Baumaschine mit einer erfindungsgemäßen Sicherungsvorrichtung in einem offenen Zustand;

- Fig. 2

- eine Vorderansicht der Sicherungsvorrichtung von

Fig. 1 in einem geschlossenen Zustand; - Fig. 3

- eine Querschnittsansicht der Sicherungsvorrichtung von

Fig. 2 entlang der Linie A-A; - Fig. 4

- eine vergrößerte Detailansicht einer Verbindungseinrichtung der Sicherungsvorrichtung nach

Fig. 3 in perspektivischer Darstellung; - Fig. 5

- die Verbindungseinrichtung gemäß

Fig. 4 in Vorderansicht, und - Fig. 6

- eine Vorderansicht der Verbindungseinrichtung von

Fig. 5 mit aufgenommenem Verbindungsglied.

- Fig. 1

- a cross-sectional view through part of a construction machine with a safety device according to the invention in an open state;

- Fig. 2

- a front view of the safety device of

Fig. 1 in a closed state; - Fig. 3

- a cross-sectional view of the securing device of FIG

Fig. 2 along the line AA; - Fig. 4

- an enlarged detailed view of a connecting device of the securing device according to FIG

Fig. 3 in perspective view; - Fig. 5

- the connecting device according to

Fig. 4 in front view, and - Fig. 6

- FIG. 3 is a front view of the connector of FIG

Fig. 5 with incorporated connecting link.

Der grundsätzliche Aufbau einer erfindungsgemäßen Sicherungsvorrichtung 20 an einer Baumaschine 10 ist in den

Zum Einführen des bohlenförmigen Tiefbauelementes 5 in die Spanneinrichtung 13 sind am unteren Ende der Rammantriebseinheit 12 eine erste Einführflanke 14 und eine zweite Einführflanke 15 angeordnet, welche gemeinsam einen etwa V-förmigen Aufnahmeschlitz bilden. Für eine zusätzliche Lagesicherung des Tiefbauelementes 5 ist eine erfindungsgemäße Sicherungsvorrichtung 20 vorgesehen.To introduce the plank-shaped civil engineering element 5 into the

Die Sicherungsvorrichtung 20 umfasst ein flexibles Sicherungselement 22, welches im dargestellten Ausführungsbeispiel als eine Kette ausgebildet ist. Ein erstes Ende der Kette ist mittels eines plattenförmigen Befestigungselements 28 an der ersten Einführflanke 14 und damit an der Baumaschine 10 befestigt. Zwischen dem Befestigungselement 28 und der ersten Einführflanke 14 kann eine Isolierschicht 29 angeordnet sein, mit welcher das Befestigungselement 28 und damit das flexible Sicherungselement 22 elektrisch gegenüber der Baumaschine 10 isoliert ist.The securing

Am zweiten Ende des flexiblen Sicherungselementes 22 ist ein Verbindungsglied 24 angebracht, welches als ein etwa T-förmiger Knebel ausgebildet ist. Das Verbindungsglied 24 kann durch ein Durchgangsloch oder eine Sicherungsöse 7 an dem bohlenförmigen Tiefbauelement 5 hindurchgesteckt und zu einer Verbindungseinrichtung 30 an der zweiten Einführflanke 15 geführt werden, wie anschaulich in den

Weiterhin ist an einer Unterseite des Gehäuses 31 ein Schlitz 33 eingebracht, welcher in seiner Schlitzbreite kleiner als der darüberliegende Aufnahmebereich der Aufnahme 32 ausgebildet ist. Dabei sind zwei seitliche, schienenartige Auflagen 35 gebildet, welche zum Auflegen des knebelförmigen Verbindungsgliedes 24 dienen. Zur offenen Seite hin können die Auflagen 35 mit einer nach oben vorstehenden Schulter 37 ausgebildet sein.Furthermore, a

An einer Oberseite des Gehäuses 31 ist als eine Detektoreinheit 40 ein Näherungssensor 42 in eine entsprechende Aufnahmebohrung eingebracht. Der Näherungssensor 42 ist dazu ausgebildet, ein Vorhandensein des Verbindungsgliedes 24 in der Aufnahme 32 der Verbindungseinrichtung 30 zu erfassen. Des Weiteren ragt aus einer Aufnahmebohrung an der Oberseite des Gehäuses 31 ein vertikal verschiebbarer Riegelbolzen 34 mit einem oberen Betätigungsteller 36 hervor. Der Riegelbolzen 34 mit dem Betätigungsteller 36 ist für eine mechanische Bedienung von Hand oder mittels eines Betätigungswerkzeuges ausgebildet. Zur Betätigung kann aber auch eine nicht dargestellte aktive Einrichtung, insbesondere ein Stellorgan, wie ein pneumatischer oder hydraulischer Stellzylinder, vorgesehen sein.On an upper side of the

In

Durch die Detektoreinheit 40 kann in diesem Zustand ein Signal an eine Steuereinheit abgegeben werden, mit welchem signalisiert wird, dass das Verbindungsglied 24 korrekt in der Verbindungseinrichtung 30 angebracht und damit das Tiefbauelement 5 durch das flexible Sicherungselement 22 korrekt gesichert ist.In this state, the detector unit 40 can send a signal to a control unit, which signals that the connecting

Claims (11)

- Securing means for securing a civil engineering element (5) to a construction machine (10), in particular a pile to a pile driver with a connecting means (30) at the construction machine (10) and a flexible securing element (22), in particular a securing chain, wherein a first end of the flexible securing element (22) is attached to the construction machine (10) and a second end is provided with a connecting link (24) which can pass through a securing lug (7) on the civil engineering element (5) and can be releasably fastened to the construction machine (10) by the connecting means (30),

characterised in that

a detection unit (40) is provided on the connecting means (30), which detection unit is designed for identifying a fastening of the connecting link (24) to the connecting means (30), and

in that the detection unit (40) can generate and output a signal if a fastening of the connecting link (24) is identified. - Securing means according to claim 1,

characterised in that

at least one locking bolt (34) is provided on the connecting means (30), by means of which bolt the connecting link (24) can be locked in the connecting means (30). - Securing means according to claim 2,

characterised in that

the locking bolt (34) is adjustably mounted between a retracted position for receiving or releasing the connecting link (24) in the connecting means (30), and a latching position in which the connecting link (24) is locked in the connecting means (30). - Securing means according to any of claims 1 to 3,

characterised in that

the detection unit (40) can identify the position of the connecting link (24) in the locking position. - Securing means according to any of claims 1 to 4,

characterised in that

the detection unit (40) comprises at least one proximity sensor (42). - Securing means according to claim 5,

characterised in that

the proximity sensor (42) can identify if the connecting link (24) is located in the connecting means (30). - Securing means according to any of claims 1 to 6,

characterised in that

the flexible securing element (22) is electrically conductive, and

in that an electrical energy source is provided, by means of which a test current can be conducted between a fastening element (28), to which the first end of the flexible securing element is attached (22), and the connection means (30) through the flexible securing element (22), which current can be identified by the detection unit (40). - Securing means according to claim 7,

characterised in that

the fastening element (28) and the connecting means (30) are electrically insulated with respect to the construction machine (10). - Construction machine, in particular pile driver for driving and/or drawing a pile in / out of the ground,

characterised in that

a securing means (20) according to any of claims 1 to 8 is provided. - Civil engineering method, in particular using a securing means (20) according to any of claims 1 to 9,

in which a civil engineering element (5) is fixed to a construction machine (10), in particular a pile to a pile driver, by means of a flexible securing element (22), in particular a securing chain, wherein a first end of the flexible securing element (22) is attached to the construction machine (10) and a second end is provided with a connecting link (24) which is passed through a securing lug (7) on the civil engineering element (5) and is releasably fastened to the construction machine (10) by a connecting means (30) in order to secure the position of the civil engineering element (5) on the construction machine (10),

characterised in that

a detection unit (40) is provided on the connecting means (30), which detection unit identifies a fastening of the connecting link (24) to the connecting means (30), and

in that the detection unit (40) generates and outputs a signal when a fastening and/or a lack of fastening of the connecting link (24) is identified. - Civil engineering method according to claim 10,

characterised in that

the construction machine (10) is a pile driver, by means of which a pile, as the civil engineering element (5), is driven into the ground or drawn out of the ground.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP19162495.6A EP3708714B1 (en) | 2019-03-13 | 2019-03-13 | Securing device for securing a civil engineering element and civil engineering method |

| AU2020201592A AU2020201592B2 (en) | 2019-03-13 | 2020-03-04 | Securing means for securing a civil engineering element, and civil engineering method |

| US16/815,143 US11174613B2 (en) | 2019-03-13 | 2020-03-11 | Securing means for securing a civil engineering element, and civil engineering method |

| CN202010176770.7A CN111691422B (en) | 2019-03-13 | 2020-03-13 | Fixing device for fixing civil engineering elements and civil engineering method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP19162495.6A EP3708714B1 (en) | 2019-03-13 | 2019-03-13 | Securing device for securing a civil engineering element and civil engineering method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3708714A1 EP3708714A1 (en) | 2020-09-16 |

| EP3708714B1 true EP3708714B1 (en) | 2021-01-13 |

Family

ID=65801981

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19162495.6A Active EP3708714B1 (en) | 2019-03-13 | 2019-03-13 | Securing device for securing a civil engineering element and civil engineering method |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US11174613B2 (en) |

| EP (1) | EP3708714B1 (en) |

| CN (1) | CN111691422B (en) |

| AU (1) | AU2020201592B2 (en) |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3602609A1 (en) | 1986-01-29 | 1987-07-30 | Sebastian Hofmann | Device for holding and inserting a structural section in a clamping device |

| US5353482A (en) | 1993-03-31 | 1994-10-11 | Ziaylek Theodore Jun | Releasable latching apparatus with an electrical engagement monitoring means |

| EP0870653A1 (en) | 1997-04-11 | 1998-10-14 | TAKATA (EUROPE) VEHICLE SAFETY TECHNOLOGY GmbH | Belt buckle |

| DE69812493T2 (en) | 1997-07-25 | 2004-02-19 | Trw Inc., Lyndhurst | Method and device for displaying the locked or unlocked state of a seat belt buckle |

| DE10046271B4 (en) | 1999-09-21 | 2010-11-25 | Takata Corp. | Closure, in particular buckle |

| CN201890755U (en) | 2010-11-29 | 2011-07-06 | 广西玉柴重工有限公司 | Chain failure-sensing mechanism |

| CN105271082A (en) | 2014-07-25 | 2016-01-27 | 徐秀萍 | Engineering machinery self-propelled aerial working movable arm connecting mechanism |

| EP3228392A1 (en) | 2016-04-05 | 2017-10-11 | BAUER Maschinen GmbH | Vibration ram |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3911646A1 (en) * | 1989-04-10 | 1990-10-11 | Anlagentech Baumasch Ind | Insertion of pile into jaws of pile driving head - involves chain which attaches pile to slider |

| US5332047A (en) | 1992-10-01 | 1994-07-26 | John Marino | Pile driving apparatus and method |

| DE9318190U1 (en) * | 1993-11-27 | 1994-01-27 | Bilfinger + Berger Bauaktiengesellschaft, 68165 Mannheim | Ramming device for ramming planks, in particular sheet piling |

| NL1005236C2 (en) * | 1997-02-10 | 1998-08-11 | Hollandsche Betongroep Nv | Installation for the removal of driven objects. |

| DE19931977A1 (en) * | 1999-07-09 | 2001-04-19 | Peter Loster | Device for detecting lock cracks on sheet piles, piles and the like |

| US6398188B1 (en) * | 2000-11-30 | 2002-06-04 | Mark T. Salman | Post puller |

| DE10322207B4 (en) * | 2003-05-16 | 2005-06-16 | Dr.Ing.H.C. F. Porsche Ag | Method for outputting a signal of a seatbelt warning device |

| WO2014169917A1 (en) * | 2013-04-19 | 2014-10-23 | Fractum 2012 Aps | A hammering device and a method for operating a hammering device |

| NL2011001C2 (en) * | 2013-06-18 | 2014-12-22 | Ihc Hydrohammer B V | Method of and driver for installing foundation elements in a ground formation. |

| ES2626780T3 (en) * | 2014-09-25 | 2017-07-26 | Bauer Maschinen Gmbh | Drilling apparatus and procedure to drive a pile element into the ground |

| CN107165167A (en) * | 2017-06-19 | 2017-09-15 | 上海衡拓船舶设备有限公司 | Marine guidance piling pile gripper |

| DK3502353T3 (en) * | 2017-12-22 | 2021-07-05 | Siemens Gamesa Renewable Energy As | Foundation construction system for an offshore wind turbine and method for installing an offshore wind turbine |

-

2019

- 2019-03-13 EP EP19162495.6A patent/EP3708714B1/en active Active

-

2020

- 2020-03-04 AU AU2020201592A patent/AU2020201592B2/en active Active

- 2020-03-11 US US16/815,143 patent/US11174613B2/en active Active

- 2020-03-13 CN CN202010176770.7A patent/CN111691422B/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3602609A1 (en) | 1986-01-29 | 1987-07-30 | Sebastian Hofmann | Device for holding and inserting a structural section in a clamping device |

| US5353482A (en) | 1993-03-31 | 1994-10-11 | Ziaylek Theodore Jun | Releasable latching apparatus with an electrical engagement monitoring means |

| EP0870653A1 (en) | 1997-04-11 | 1998-10-14 | TAKATA (EUROPE) VEHICLE SAFETY TECHNOLOGY GmbH | Belt buckle |

| DE69812493T2 (en) | 1997-07-25 | 2004-02-19 | Trw Inc., Lyndhurst | Method and device for displaying the locked or unlocked state of a seat belt buckle |

| DE10046271B4 (en) | 1999-09-21 | 2010-11-25 | Takata Corp. | Closure, in particular buckle |

| CN201890755U (en) | 2010-11-29 | 2011-07-06 | 广西玉柴重工有限公司 | Chain failure-sensing mechanism |

| CN105271082A (en) | 2014-07-25 | 2016-01-27 | 徐秀萍 | Engineering machinery self-propelled aerial working movable arm connecting mechanism |

| EP3228392A1 (en) | 2016-04-05 | 2017-10-11 | BAUER Maschinen GmbH | Vibration ram |

Also Published As

| Publication number | Publication date |

|---|---|

| US11174613B2 (en) | 2021-11-16 |

| EP3708714A1 (en) | 2020-09-16 |

| CN111691422B (en) | 2022-04-08 |

| US20200291595A1 (en) | 2020-09-17 |

| AU2020201592B2 (en) | 2021-04-15 |

| AU2020201592A1 (en) | 2020-10-01 |

| CN111691422A (en) | 2020-09-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3705629B1 (en) | Ramming apparatus and method for driving piles into ground | |

| EP2489823B1 (en) | Device for splitting solid materials | |

| EP2902582B1 (en) | Mast assembly and method for connecting a tool unit to the mast carriage of a mast assembly | |

| EP3708714B1 (en) | Securing device for securing a civil engineering element and civil engineering method | |

| EP3369864B1 (en) | Method of detecting obstructions during the operation of a vibration driver | |

| DE2257951B2 (en) | BUCKET EXCAVATOR WITH AN ELECTRIC DISPLAY DEVICE FOR ENGAGED METAL PARTS | |

| EP3670753B1 (en) | Driving apparatus and method for driving piles | |

| DE69203980T2 (en) | Improved device for lifting and hammering the foundation piles of offshore structures. | |

| DE69928848T2 (en) | Method and device for producing ground piles with extended pile heads | |

| EP3269882B1 (en) | Pile driver device | |

| DE102017128887A1 (en) | Method and device for securing a pit or trench | |

| DE2526889B2 (en) | DEVICE FOR REMOVING FEEDING ELEMENTS FROM THE RING CHAMBER OF A BUMPER CAP | |

| EP2530205A1 (en) | Method for laying a pipe at right angles and impact device for same | |

| DE4447973B4 (en) | Method for detecting lock jumps on sheet piles | |

| DE2550595B2 (en) | A ram and a pipe having device for the production of earth bores and in these arranged piles made of poured or compacted concrete | |

| EP3907371A1 (en) | Machine tool and method for processing a soil | |

| DE2355232A1 (en) | Road surface breaking machine for making trenches - has pivoted support for breaking hammers acting at different depths | |

| EP0237971B1 (en) | Apparatus for inserting and/or withdrawing a construction profile | |

| DE3304268C2 (en) | ||

| DE216258C (en) | ||

| DE102016014905B3 (en) | Tool adapter with a device for locking control of a quick-change device for construction equipment | |

| DE102012221457A1 (en) | Pipe positioning device for positioning pipe relative to another pipe, has coupling device for coupling to carrier device, particularly to excavator arm of excavator, and electrically or hydraulically actuated displacement device | |

| DE4303742C1 (en) | Dewatering ground with high water content | |

| DE19755228C2 (en) | Device for introducing an elongated profile into the ground | |

| DE20202414U1 (en) | Device for lifting an elongated profile |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20191001 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20201008 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502019000666 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| GRAT | Correction requested after decision to grant or after decision to maintain patent in amended form |

Free format text: ORIGINAL CODE: EPIDOSNCDEC |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1354653 Country of ref document: AT Kind code of ref document: T Effective date: 20210215 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: FGE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210413 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210513 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210414 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210413 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210513 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502019000666 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MDE Opponent name: LIEBHERR-WERK NENZING GMBH |

|

| 26 | Opposition filed |

Opponent name: LIEBHERR-WERK NENZING GMBH Effective date: 20211013 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20210331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210313 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210313 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20190313 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20240305 Year of fee payment: 6 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20240305 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20240305 Year of fee payment: 6 Ref country code: DE Payment date: 20240304 Year of fee payment: 6 Ref country code: GB Payment date: 20240304 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240304 Year of fee payment: 6 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |