EP3551939B1 - Household cooking appliance - Google Patents

Household cooking appliance Download PDFInfo

- Publication number

- EP3551939B1 EP3551939B1 EP17816503.1A EP17816503A EP3551939B1 EP 3551939 B1 EP3551939 B1 EP 3551939B1 EP 17816503 A EP17816503 A EP 17816503A EP 3551939 B1 EP3551939 B1 EP 3551939B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- door

- sealing device

- pane

- door profile

- cooking appliance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000010411 cooking Methods 0.000 title claims description 52

- 238000007789 sealing Methods 0.000 claims description 115

- 239000000725 suspension Substances 0.000 claims description 35

- 239000000463 material Substances 0.000 claims description 21

- 229910000831 Steel Inorganic materials 0.000 claims description 5

- 229920001296 polysiloxane Polymers 0.000 claims description 5

- 239000010959 steel Substances 0.000 claims description 5

- 239000011521 glass Substances 0.000 description 5

- 229910000639 Spring steel Inorganic materials 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 238000005265 energy consumption Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000007769 metal material Substances 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 238000007792 addition Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000007665 sagging Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/02—Doors specially adapted for stoves or ranges

- F24C15/04—Doors specially adapted for stoves or ranges with transparent panels

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/02—Doors specially adapted for stoves or ranges

- F24C15/021—Doors specially adapted for stoves or ranges sealings for doors or transparent panel

Definitions

- the present invention relates to a domestic cooking appliance.

- a domestic cooking appliance in particular an oven, can have a heatable cooking space.

- the cooking space can be locked with the help of a door.

- the door can have several panes which are arranged parallel to one another and spaced apart from one another and which are positioned relative to one another with the aid of door profiles. Sealing elements can be provided between the panes.

- the DE 103 14 214 A1 shows a furnace door for closing a furnace muffle with a multi-pane arrangement, consisting of at least an inner pane, an intermediate pane and an outer pane, with an air inlet opening in the lower door area and an air outlet opening in the upper door area, which are connected to the spaces between the panes of the oven door .

- a sealing element can be provided in the first intermediate space between the inner pane and the intermediate pane, which extends transversely to the panes in order to prevent an air flow from the air inlet opening to the air outlet opening via the first intermediate space.

- the DE 10 2011 088 082 A1 describes a door for a domestic cooking appliance with a first pane and a second pane, which is arranged at a distance from the first pane, and at least one sealing element arranged between the panes, the sealing element being an elongated component which is open in cross section and with a non-linear cross-sectional contour is formed, wherein the sealing element is formed reversibly deformable in at least one direction in the cross-sectional plane.

- the WO 2015/165499 A1 shows a door for an oven.

- the door includes a rear glass panel and a frame assembly having a first recess that releasably holds a lower end of the rear glass panel.

- the frame assembly includes a removable cover member with a snap-on portion for attaching / detaching the same and a flange for hiding and holding an upper end of the rear glass immovable.

- the EP 1 867 927 A2 describes a door for closing a loading opening of a cooking chamber of a cooking oven.

- the door comprises an outer pane, at least one inner pane, at least one holding element for holding the at least one inner pane, at least one cover element for covering the holding element, the at least one holding element and at least one cover element being produced separately and then connected to one another to form an assembly, with between the at least one cover element and the at least one holding element an air duct is formed, and wherein the assembly is the upper border of the door and / or is arranged in the upper region of the door.

- a domestic cooking appliance with a cooking space and a door for closing the cooking space comprises a first pane, a second pane arranged at a distance from the first pane, a first door profile, a second door profile arranged at a distance from the first door profile and a sealing device which is arranged in a gap provided between the first pane and the second pane , in order to seal the gap, the sealing device being attached to the first door profile and to the second door profile, the sealing device being hooked into the first door profile and the second door profile under prestress in such a way that the sealing device is elastically stretched when the same is installed Expansion is always maintained even after the assembly of the sealing device.

- the sealing device is fastened directly or directly to the door profiles, there is no need to fasten the sealing device directly to one of the panes. This enables simplified assembly and disassembly. This enables both a simplified production of the domestic cooking appliance and a simplified cleaning by a customer, since the sealing device can be easily dismantled. Furthermore, the fact that the sealing device is not directly on one of the Is attached prevents one or both of the discs from being damaged.

- the door preferably comprises more than two panes.

- the door can comprise four panes.

- the panes can for example be made of a glass material and be transparent at least in sections.

- the door can comprise the first pane, the second pane spaced apart from and parallel to the first pane, a third pane spaced apart from and parallel to the second pane, and a fourth pane arranged parallel to and spaced apart from the third pane.

- the fourth pane can be referred to as the outer pane or front pane.

- the first pane can be referred to as the inner pane.

- the second and third disks can each be referred to as an intermediate disk.

- a gap is provided between each of the disks.

- a first gap, in which the sealing device is arranged is provided between the first disk and the second disk.

- a second gap is provided between the second disk and the third disk and a third gap is provided between the third disk and the fourth disk.

- the door profiles are preferably attached to an inside of the fourth pane, for example glued to it.

- the door profiles can for example be made of a plastic material or a metal material.

- the panes can be positioned relative to one another.

- the panes are at least partially received in receiving sections of the door profiles.

- the panes can be positioned relative to one another at defined distances.

- the door profiles are arranged at least in sections between the first pane and the second pane. In the present case, “in sections” is to be understood as meaning that the door profiles are not arranged completely, but only partially between the first pane and the second pane.

- the door can have several of these sealing devices, which can also be arranged in the second gap and / or the third gap. Alternatively, no such sealing devices can be provided in the second gap and / or in the third gap, so that air can circulate in these gaps.

- the sealing device is provided in a lower area or on a lower edge of the door.

- the sealing device is positively connected to the first door profile and the second door profile.

- a positive connection is created by the interlocking or interlocking of at least two connection partners, in this case the sealing device and the door profiles. Due to the positive connection, the sealing device can easily be separated from the door profiles and reconnected to them. This enables particularly simple assembly and disassembly. There is no need for a form-fitting or material connection between the sealing device and one of the panes.

- the sealing device is hooked into the first door profile and the second door profile.

- the sealing device can be assembled and disassembled in a particularly simple manner.

- the seal can thereby be assembled and disassembled without tools.

- the sealing device is suspended under pretension in the first door profile and the second door profile.

- the sealing device is elastically stretched when the same is installed and this expansion is always maintained even after the sealing device has been installed. With the aid of the preload, sagging of the sealing device can be reliably prevented. This ensures optimal positioning of the sealing device.

- the sealing device has a first suspension hook for suspending the sealing device in the first door profile and a second suspension hook for suspending the sealing device in the second door profile.

- Each suspension hook preferably has a connecting section which is firmly connected to a sealing element of the sealing device. Furthermore, each hanging hook comprises a hooking section which is set up to engage with the respective door profile in a form-fitting manner. An intermediate section is preferably provided between the hooking section and the connecting section. Each suspension hook thus has a C-shaped geometry.

- the sealing device has an elastically deformable sealing element which is arranged between the first suspension hook and the second suspension hook and is firmly connected to them.

- the sealing element can be positively and / or cohesively connected to the suspension hook.

- the sealing element can be glued to the suspension hook.

- the sealing element can also be connected to the suspension hook in one piece, that is to say in one piece of material.

- the sealing element is preferably made of the same material as the suspension hook.

- the first suspension hook and the second suspension hook are made from a steel material and the sealing element is made from a silicone material.

- the hooks can be made of a plastic material, a sheet steel or a silicone material be made.

- the sealing element can also be made of a different material, for example spring steel.

- the sealing element has sealing lips which are designed to bear against the first pane and / or the second pane in a sealing manner.

- the sealing element preferably has a cavity in cross section.

- the sealing lips are particularly resiliently deformable.

- the sealing element can have two sealing lips, which are assigned to the first disk, and two sealing lips, which are assigned to the second disk.

- the first door profile and the second door profile each have a receiving section, in particular an opening, into which the sealing device is suspended.

- the receiving section can be designed, for example, as a rectangular opening or as a circular bore.

- the geometry of the receiving section depends on the geometry of the hooks.

- the geometry of the receiving section is basically arbitrary. In particular, the respective hooking portion of the suspension hook is passed through the receiving portion.

- first door profile and the second door profile each have a groove section into which the first suspension hook and the second suspension hook are inserted.

- the connecting section of the suspension hooks is preferably inserted into the groove section.

- the connecting section does not protrude beyond the door profile, as a result of which the respective pane can be placed flat on a surface of the door profile. This prevents damage or mechanical overloading of the disc.

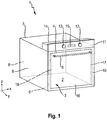

- the Fig. 1 shows a schematic perspective view of an embodiment of a domestic cooking appliance 1.

- the domestic cooking appliance 1 is preferably an oven, an oven with a steam cooking function, a microwave combination oven or the like.

- the household cooking appliance 1 has an oven muffle, muffle or a cooking space 2, which is with Can be locked using a door 3.

- the cooking space 2 can be arranged in the interior of a housing of the domestic cooking appliance 1.

- Door 3 is in the Fig. 1 shown in their closed position.

- the door 3 can be closed or opened by pivoting about a pivot axis provided at a lower end of the door 3.

- the door 3 can be hinged on the side of the cooking chamber 2.

- the door 3 can be arranged on a baking trolley that can be pulled out of the cooking space 2.

- a handle 5 can be provided on an upper section or an upper edge 4 of the door 3.

- the cooking chamber 2 has a floor 6, a ceiling 7 arranged opposite the floor 6, a rear wall 8 arranged opposite the closed door 3 and two side walls 9, 10 arranged opposite one another.

- the cooking space 2 is preferably cuboid or cube-shaped.

- the cooking chamber 2 can be made from a metal material, in particular from sheet steel.

- the domestic cooking appliance 1 further comprises control knobs 12, 13 provided on an operating panel 11.

- the control knobs 12, 13 can, for example, be rotatable.

- a control device 14 which is only shown schematically, can be provided for controlling the domestic cooking appliance 1.

- the control device 14 can be a regulating and / or control device.

- a display 15 can also be provided on the control panel 11. With the aid of the display 15, an operating state of the domestic cooking appliance 1 can be displayed. For example, with the aid of the display 15, a temperature set by means of the operating knobs 12, 13 can be displayed.

- the door 3 has several panes 16, of which in the Fig. 1 only one, namely a windshield, is shown. Furthermore, the door 3 comprises a first door profile 17 and a second door profile 18, which are spaced apart from one another and positioned parallel to one another.

- the door profiles 17, 18 can be attached to the rear of the pane 16, that is to say facing the cooking chamber 2, in particular glued to it.

- the door profiles 17, 18 run in a closed state of the door 3 along a z-direction z of the domestic cooking appliance 1. Furthermore, in FIG Fig. 1 an x-direction x and a y-direction y of the domestic cooking appliance 1 are also shown.

- the Fig. 2 shows a schematic partial sectional view of the door 3.

- the door 3 comprises several panes 16 and 19 to 21.

- the panes 16 and 19 to 21 can for example be made of a glass material and are at least partially transparent.

- the disk 19 can also be referred to as a first disk or inner disk

- the disk 20 can also be referred to as a second disk or first intermediate disk

- the disk 21 can also be referred to as a third disk or second inner disk

- the disk 16 can also be referred to as a fourth disk or front disk.

- the door profiles 17, 18 are preferably firmly connected, for example glued, to an inner surface 22 of the pane 16.

- Each door profile 17, 18 has a receiving section 23 for receiving the first pane 19.

- the receiving section 23 is designed, for example, in the shape of a hook and can encompass an edge 24, in particular an upper edge or a lower edge, of the first disk 19 at least in sections.

- Each door profile 17, 18 furthermore has a receiving section 25 which is set up to position the second pane 20 and the third pane 21 in the door 3.

- an edge 26, in particular an upper edge or a lower edge, of the second pane 20 and an edge 27, in particular an upper edge or a lower edge, of the third pane 21 can rest on the receiving section 25.

- the panes 16 and 19 to 21 can be arranged parallel to one another and at a distance from one another.

- Each disk 16 and 19 to 21 represents a plane.

- the second disk 20 is spaced apart from the first disk 19, the third disk 21 spaced apart from the second disk 20, and the fourth disk 16 spaced apart from the third disk 21.

- the distances between the disks 16 and 19 to 21 can be different or the same.

- Air can circulate between the disks 16 and 19 to 21.

- a first gap S1 is provided between the first disk 19 and the second disk 20

- a second gap S2 is provided between the second disk 20 and the third disk 21

- a third gap S3 is provided between the third disk 21 and the fourth disk 16.

- the door profiles 17, 18 are arranged between the first pane 19 and the fourth pane 16.

- the door profiles 17, 18 are, however, also arranged at least in sections between the first pane 19 and the second pane 20 and between the first pane 19 and the third pane 21.

- the door 3 further comprises a sealing device 28.

- the sealing device 28 is, as in FIG Fig. 2 shown, arranged between the first disc 19 and the second disc 20 in the first gap S1.

- the sealing device 28 can alternatively also be arranged between the second disk 20 and the third disk 21 or between the third disk 21 and the fourth disk 16.

- the sealing device 28 is fastened both to the first door profile 17 and to the second door profile 18.

- the sealing device 28 is positively connected to the first door profile 17 and the second door profile 18.

- a positive connection is created by the interlocking or interlocking of at least two connection partners, in this case the door profiles 17, 18 and the sealing device 28.

- the sealing device 28 is suspended in the first door profile 17 and the second door profile 18.

- the sealing device 28 is hooked into the door profiles 17, 18 under prestress.

- the one in the Fig. 3 Sealing device 28 shown in a schematic perspective view comprises an elastically deformable sealing element 29, which is made, for example, from a silicone material.

- the sealing element 29 extends perpendicular to the door profiles 17, 18 and is positioned between them.

- the sealing element 29 can have any geometry in cross section.

- the sealing element 29 can be designed to be hollow, at least in sections.

- the sealing element 29 comprises several sealing lips 30 to 33.

- the sealing lips 30, 31 are designed to seal the sealing element 29 against the first disk 19, and the sealing lips 32, 33 are designed to seal the sealing element 29 against the second disk 20.

- the sealing device 28 comprises a first hook 34 for hooking the sealing device 28 into the first door profile 17 and a second hook 35 for hooking the sealing device 28 into the second door profile 18.

- the hook 34, 35 are preferably made of a steel material.

- the suspension hooks 34, 35 can be connected to the sealing element 29 with a form fit or material fit. In the case of material connections, the connection partners are held together by atomic or molecular forces. Cohesive connections are non-detachable connections that can only be separated by destroying the connection means and / or the connection partner.

- the suspension hooks 34, 35 are glued to the sealing element 29.

- Each suspension hook 34, 35 comprises one Connecting section 36, which is firmly connected to the sealing element 29, a hooking section 37, which is arranged parallel to the connecting section 36, and an intermediate section 38, which connects the connecting section 36 to the hooking section 37.

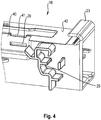

- the door profiles 17, 18 have, as in the Fig. 4 shown, each have a receiving section 39, in particular an opening or a bore.

- the sealing device 28 is suspended in the receiving sections 39, the hooking section 37 of the suspension hooks 34, 35 being passed through the receiving section 39.

- the receiving section 39 is designed, for example, as an opening breaking through a side wall 40 of the respective door profile 17, 18.

- the geometry of the receiving section 39 is arbitrary.

- the receiving section 39 can also be a circular bore.

- a groove section 41 arranged at a distance from it.

- the suspension hooks 34, 35 fixed to the respective door profile 17, 18. This defines the position of the sealing device 28 and it cannot slip.

- the sealing device 28 By hanging the sealing device 28 in the door profiles 17, 18, it is not necessary to fasten the sealing device 28 to one of the panes 19, 20, but can be used independently of the panes 19, 20 on the door profiles 17, which are connected to the fourth pane 16. 18 can be attached.

- the sealing device 28 can cover a greater width of the first gap S1 between the panes 19, 20 than if it is attached to only one of the panes 19, 20.

- the assembly of the sealing device 28 is clearly defined by the receiving sections 39 and the groove sections 41 on the door profiles 17, 18.

- the cross-sectional geometry and the material of the sealing element 29 are arbitrary.

- the sealing element 29 can also be made from a spring steel and formed in one piece with the suspension hooks 34, 35.

- the door profiles 17, 18 can be made of metal or plastic, for example.

- the Suspension hooks 34, 35 can also be made from a plastic material or from a silicone material.

- the sealing device 28 is preferably provided in a lower area or on a lower edge 43 of the door 3. The lower edge 43 is positioned facing away from the upper edge 4.

- the sealing device 28 can also be provided on the upper edge 4.

- each sealed gap can have a positive impact on energy consumption.

- Air circulation between certain panes 16 and 19 to 21, for example between panes 19, 20, is prevented and the door 3 can be ventilated between other panes 16 and 19 to 21, for example between panes 21, 16.

- the advantages of the domestic cooking appliance 1 are that the sealing device 28 is not mounted directly on one of the panes 16 and 19 to 21, but can be hooked directly into the door profiles 17, 18. In this way, the risk of one of the disks 16 and 19 to 21 being actuated by the suspension hooks 34, 35 can be prevented.

- the suspension hooks 34, 35 are securely installed in the receiving sections 39 of the door profiles 17, 18 and do not involve any risk of injury to a customer when the door 3 is dismantled and cleaned.

- the position of the sealing device 28 is guaranteed in a process-reliable manner. Incorrect assembly, for example too high or too low on one of the panes 16 and 19 to 21, both in production and by the customer when dismantling and cleaning the door 3, can be prevented and thus the function can also be ensured.

- the assembly of the sealing device 28 on the door profiles 17, 18 also makes the sealing device 28 independent of the geometry and size of the panes 16 and 19 to 21 and can therefore be used universally.

- the hanging hooks 34, 35 come to rest in the groove sections 41 of the door profiles 17, 18, it is not necessary to provide additional space for the hanging hooks 34, 35 between the first pane 19 and the second pane 20. As a result, the first gap S1 between the panes 19, 20 becomes larger, as a result of which improved air circulation is possible. In this way, improved energy efficiency can be achieved and a temperature of the fourth disk 16 can be reduced due to the insulating effect of the first gap S1.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Cookers (AREA)

- Electric Ovens (AREA)

Description

Die vorliegende Erfindung betrifft ein Haushaltsgargerät.The present invention relates to a domestic cooking appliance.

Ein Haushaltsgargerät, insbesondere ein Backofen, kann einen beheizbaren Garraum aufweisen. Der Garraum kann mit Hilfe einer Tür verschließbar sein. Die Tür kann mehrere parallel zueinander und beabstandet voneinander angeordnete Scheiben aufweisen, die mit Hilfe von Türprofilen relativ zueinander positioniert sind. Zwischen den Scheiben können Dichtelemente vorgesehen sein.A domestic cooking appliance, in particular an oven, can have a heatable cooking space. The cooking space can be locked with the help of a door. The door can have several panes which are arranged parallel to one another and spaced apart from one another and which are positioned relative to one another with the aid of door profiles. Sealing elements can be provided between the panes.

Die

Die

Die

Die

Vor diesem Hintergrund besteht eine Aufgabe der vorliegenden Erfindung darin, ein verbessertes Haushaltsgargerät zur Verfügung zu stellen.Against this background, it is an object of the present invention to provide an improved domestic cooking appliance.

Demgemäß wird ein Haushaltsgargerät mit einem Garraum und einer Tür zum Verschließend des Garraums vorgeschlagen. Die Tür umfasst dabei eine erste Scheibe, eine beabstandet von der ersten Scheibe angeordnete zweite Scheibe, ein erstes Türprofil, ein von dem ersten Türprofil beabstandet angeordnetes zweites Türprofil und eine Dichteinrichtung, die in einem zwischen der ersten Scheibe und der zweiten Scheibe vorgesehenen Spalt angeordnet ist, um den Spalt abzudichten, wobei die Dichteinrichtung an dem ersten Türprofil und an dem zweiten Türprofil befestigt ist, wobei die Dichteinrichtung unter Vorspannung derart in das erste Türprofil und das zweite Türprofil eingehängt ist, dass die Dichteinrichtung bei der Montage derselben elastisch gedehnt wird und diese Dehnung auch nach der Montage der Dichteinrichtung stets aufrechterhalten wird.Accordingly, a domestic cooking appliance with a cooking space and a door for closing the cooking space is proposed. The door comprises a first pane, a second pane arranged at a distance from the first pane, a first door profile, a second door profile arranged at a distance from the first door profile and a sealing device which is arranged in a gap provided between the first pane and the second pane , in order to seal the gap, the sealing device being attached to the first door profile and to the second door profile, the sealing device being hooked into the first door profile and the second door profile under prestress in such a way that the sealing device is elastically stretched when the same is installed Expansion is always maintained even after the assembly of the sealing device.

Dadurch, dass die Dichteinrichtung unmittelbar oder direkt an den Türprofilen befestigt ist, kann darauf verzichtet werden, die Dichteinrichtung unmittelbar an einer der Scheiben zu befestigen. Hierdurch ist eine vereinfachte Montage und Demontage möglich. Dies ermöglicht sowohl eine vereinfachte Herstellung des Haushaltsgargeräts als auch eine vereinfachte Reinigung durch einen Kunden, da die Dichteinrichtung einfach demontiert werden kann. Weiterhin wird dadurch, dass die Dichteinrichtung nicht direkt an einer der Scheiben befestigt ist, verhindert, dass eine der Scheiben oder beide Scheiben beschädigt werden.Because the sealing device is fastened directly or directly to the door profiles, there is no need to fasten the sealing device directly to one of the panes. This enables simplified assembly and disassembly. This enables both a simplified production of the domestic cooking appliance and a simplified cleaning by a customer, since the sealing device can be easily dismantled. Furthermore, the fact that the sealing device is not directly on one of the Is attached prevents one or both of the discs from being damaged.

Die Tür umfasst bevorzugt mehr als zwei Scheiben. Beispielsweise kann die Tür vier Scheiben umfassen. Die Scheiben können beispielsweise aus einem Glaswerkstoff gefertigt sein und zumindest abschnittsweise transparent sein. Insbesondere kann die Tür die erste Scheibe, die beabstandet und parallel von der ersten Scheibe angeordnete zweite Scheibe, eine beabstandet von der zweiten Scheibe und parallel zu dieser angeordnete dritte Scheibe sowie eine parallel zu der dritten Scheibe und beabstandet von dieser angeordnete vierte Scheibe umfassen. Die vierte Scheibe kann dabei als Außenscheibe oder Frontscheibe bezeichnet werden. Die erste Scheibe kann als Innenscheibe bezeichnet werden. Die zweite und dritte Scheibe können jeweils als Zwischenscheibe bezeichnet werden. Zwischen den Scheiben ist jeweils ein Spalt vorgesehen. Erfindungsgemäß ist zwischen der ersten Scheibe und der zweiten Scheibe ein erster Spalt vorgesehen, in dem die Dichteinrichtung angeordnet ist. Zwischen der zweiten Scheibe und der dritten Scheibe ist ein zweiter Spalt und zwischen der dritten Scheibe und der vierten Scheibe ist ein dritter Spalt vorgesehen.The door preferably comprises more than two panes. For example, the door can comprise four panes. The panes can for example be made of a glass material and be transparent at least in sections. In particular, the door can comprise the first pane, the second pane spaced apart from and parallel to the first pane, a third pane spaced apart from and parallel to the second pane, and a fourth pane arranged parallel to and spaced apart from the third pane. The fourth pane can be referred to as the outer pane or front pane. The first pane can be referred to as the inner pane. The second and third disks can each be referred to as an intermediate disk. A gap is provided between each of the disks. According to the invention, a first gap, in which the sealing device is arranged, is provided between the first disk and the second disk. A second gap is provided between the second disk and the third disk and a third gap is provided between the third disk and the fourth disk.

Die Türprofile sind vorzugsweise an einer Innenseite der vierten Scheibe befestigt, beispielsweise mit dieser verklebt. Die Türprofile können beispielsweise aus einem Kunststoffmaterial oder aus einem Metallwerkstoff gefertigt sein. Mit Hilfe der Türprofile sind die Scheiben relativ zueinander positionierbar. Hierzu sind die Scheiben zumindest teilweise in Aufnahmeabschnitten der Türprofile aufgenommen. Mit Hilfe der Türprofile können die Scheiben in definierten Abständen relativ zueinander positioniert werden. Beispielsweise sind die Türprofile zumindest abschnittsweise zwischen der ersten Scheibe und der zweiten Scheibe angeordnet. Unter "abschnittsweise" ist vorliegend zu verstehen, dass die Türprofile nicht vollständig, sondern nur zum Teil zwischen der ersten Scheibe und der zweiten Scheibe angeordnet sind. Die Tür kann mehrere dieser Dichteinrichtungen aufweisen, die auch in dem zweiten Spalt und/oder dem dritten Spalt angeordnet sein können. Alternativ können in dem zweiten Spalt und/oder in dem dritten Spalt auch keine derartigen Dichteinrichtungen vorgesehen sein, wodurch eine Luftzirkulation in diesen Spalten möglich ist. Die Dichteinrichtung ist in einem unteren Bereich beziehungsweise an einer Unterkante der Tür vorgesehen.The door profiles are preferably attached to an inside of the fourth pane, for example glued to it. The door profiles can for example be made of a plastic material or a metal material. With the help of the door profiles, the panes can be positioned relative to one another. For this purpose, the panes are at least partially received in receiving sections of the door profiles. With the help of the door profiles, the panes can be positioned relative to one another at defined distances. For example, the door profiles are arranged at least in sections between the first pane and the second pane. In the present case, “in sections” is to be understood as meaning that the door profiles are not arranged completely, but only partially between the first pane and the second pane. The door can have several of these sealing devices, which can also be arranged in the second gap and / or the third gap. Alternatively, no such sealing devices can be provided in the second gap and / or in the third gap, so that air can circulate in these gaps. The sealing device is provided in a lower area or on a lower edge of the door.

Gemäß einer Ausführungsform ist die Dichteinrichtung formschlüssig mit dem ersten Türprofil und dem zweiten Türprofil verbunden.According to one embodiment, the sealing device is positively connected to the first door profile and the second door profile.

Eine formschlüssige Verbindung entsteht durch das Ineinander- oder Hintergreifen von mindestens zwei Verbindungspartnern, in diesem Fall der Dichteinrichtung und den Türprofilen. Durch die formschlüssige Verbindung kann die Dichteinrichtung leicht von den Türprofilen getrennt und wieder mit diesen verbunden werden. Hierdurch ist eine besonders einfache Montage und Demontage möglich. Auf eine formschlüssige oder stoffschlüssige Verbindung der Dichteinrichtung mit einer der Scheiben kann verzichtet werden.A positive connection is created by the interlocking or interlocking of at least two connection partners, in this case the sealing device and the door profiles. Due to the positive connection, the sealing device can easily be separated from the door profiles and reconnected to them. This enables particularly simple assembly and disassembly. There is no need for a form-fitting or material connection between the sealing device and one of the panes.

Die Dichteinrichtung ist in das erste Türprofil und das zweiten Türprofil eingehängt.The sealing device is hooked into the first door profile and the second door profile.

Hierdurch kann die Dichteinrichtung besonders einfach montiert und demontiert werden. Insbesondere kann die Dichtung hierdurch werkzeugfrei montiert und demontiert werden.As a result, the sealing device can be assembled and disassembled in a particularly simple manner. In particular, the seal can thereby be assembled and disassembled without tools.

Die Dichteinrichtung ist unter Vorspannung in das erste Türprofil und das zweite Türprofil eingehängt.The sealing device is suspended under pretension in the first door profile and the second door profile.

Darunter ist zu verstehen, dass die Dichteinrichtung bei der Montage derselben elastisch gedehnt wird und diese Dehnung auch nach der Montage der Dichteinrichtung stets aufrechterhalten wird. Mit Hilfe der Vorspannung kann ein Durchhängen der Dichteinrichtung zuverlässig verhindert werden. Hierdurch ist eine optimale Positionierung der Dichteinrichtung gewährleistet.This means that the sealing device is elastically stretched when the same is installed and this expansion is always maintained even after the sealing device has been installed. With the aid of the preload, sagging of the sealing device can be reliably prevented. This ensures optimal positioning of the sealing device.

Gemäß einer weiteren Ausführungsform weist die Dichteinrichtung einen ersten Einhängehaken zum Einhängen der Dichteinrichtung in das erste Türprofil und einen zweiten Einhängehaken zum Einhängen der Dichteinrichtung in das zweite Türprofil auf.According to a further embodiment, the sealing device has a first suspension hook for suspending the sealing device in the first door profile and a second suspension hook for suspending the sealing device in the second door profile.

Jeder Einhängehaken weist vorzugsweise einen Verbindungsabschnitt auf, der mit einem Dichtelement der Dichteinrichtung fest verbunden ist. Weiterhin umfasst jeder Einhängehaken einen Einhakabschnitt, der dazu eingerichtet ist, in das jeweilige Türprofil formschlüssig einzugreifen. Zwischen dem Einhakabschnitt und dem Verbindungsabschnitt ist vorzugsweise ein Zwischenabschnitt vorgesehen. Jeder Einhängehaken weist somit eine C-förmige Geometrie auf.Each suspension hook preferably has a connecting section which is firmly connected to a sealing element of the sealing device. Furthermore, each hanging hook comprises a hooking section which is set up to engage with the respective door profile in a form-fitting manner. An intermediate section is preferably provided between the hooking section and the connecting section. Each suspension hook thus has a C-shaped geometry.

Gemäß einer weiteren Ausführungsform weist die Dichteinrichtung ein elastisch verformbares Dichtelement auf, das zwischen dem ersten Einhängehaken und dem zweiten Einhängehaken angeordnet und mit diesen fest verbunden ist.According to a further embodiment, the sealing device has an elastically deformable sealing element which is arranged between the first suspension hook and the second suspension hook and is firmly connected to them.

Beispielsweise kann das Dichtelement formschlüssig und/oder stoffschlüssig mit den Einhängehaken verbunden sein. Beispielsweise kann das Dichtelement mit den Einhängehaken verklebt sein. Alternativ kann das Dichtelement auch einteilig, das heißt, materialeinstückig, mit den Einhängehaken verbunden sein. In diesem Fall ist das Dichtelement bevorzugt aus dem gleichen Werkstoff gefertigt wie die Einhängehaken.For example, the sealing element can be positively and / or cohesively connected to the suspension hook. For example, the sealing element can be glued to the suspension hook. Alternatively, the sealing element can also be connected to the suspension hook in one piece, that is to say in one piece of material. In this case, the sealing element is preferably made of the same material as the suspension hook.

Gemäß einer weiteren Ausführungsform sind der erste Einhängehaken und der zweite Einhängehaken aus einem Stahlwerkstoff gefertigt und das Dichtelement ist aus einem Silikonwerkstoff gefertigt.According to a further embodiment, the first suspension hook and the second suspension hook are made from a steel material and the sealing element is made from a silicone material.

Alternativ können beliebige andere Werkstoffe eingesetzt werden. Beispielsweise können die Einhängehaken aus einem Kunststoffmaterial, einem Stahlblech oder aus einem Silikonwerkstoff gefertigt sein. Das Dichtelement kann ebenfalls aus einem anderen Werkstoff, beispielsweise aus Federstahl, gefertigt sein.Alternatively, any other materials can be used. For example, the hooks can be made of a plastic material, a sheet steel or a silicone material be made. The sealing element can also be made of a different material, for example spring steel.

Gemäß einer weiteren Ausführungsform weist das Dichtelement Dichtlippen auf, die dazu eingerichtet sind, dichtend an der ersten Scheibe und/oder an der zweiten Scheibe anzuliegen.According to a further embodiment, the sealing element has sealing lips which are designed to bear against the first pane and / or the second pane in a sealing manner.

Das Dichtelement weist im Querschnitt bevorzugt einen Hohlraum auf. Die Dichtlippen sind insbesondere federelastisch verformbar. Insbesondere kann das Dichtelement zwei Dichtlippen aufweisen, die der ersten Scheibe zugeordnet sind, sowie zwei Dichtlippen, die der zweiten Scheibe zugeordnet sind.The sealing element preferably has a cavity in cross section. The sealing lips are particularly resiliently deformable. In particular, the sealing element can have two sealing lips, which are assigned to the first disk, and two sealing lips, which are assigned to the second disk.

Gemäß einer weiteren Ausführungsform weisen das erste Türprofil und das zweite Türprofil jeweils einen Aufnahmeabschnitt, insbesondere einen Durchbruch, auf, in den die Dichteinrichtung eingehängt ist.According to a further embodiment, the first door profile and the second door profile each have a receiving section, in particular an opening, into which the sealing device is suspended.

Der Aufnahmeabschnitt kann beispielsweise als rechteckförmiger Durchbruch oder als kreisrunde Bohrung ausgebildet sein. Die Geometrie des Aufnahmeabschnitts ist abhängig von der Geometrie der Einhängehaken. Die Geometrie des Aufnahmeabschnitts ist grundsätzlich beliebig. Durch den Aufnahmeabschnitt ist insbesondere der jeweilige Einhakabschnitt der Einhängehaken hindurchgeführt.The receiving section can be designed, for example, as a rectangular opening or as a circular bore. The geometry of the receiving section depends on the geometry of the hooks. The geometry of the receiving section is basically arbitrary. In particular, the respective hooking portion of the suspension hook is passed through the receiving portion.

Gemäß einer weiteren Ausführungsform weisen das erste Türprofil und das zweite Türprofil jeweils einen Nutabschnitt auf, in den der erste Einhängehaken und der zweiten Einhängehaken eingelegt sind.According to a further embodiment, the first door profile and the second door profile each have a groove section into which the first suspension hook and the second suspension hook are inserted.

In den Nutabschnitt ist bevorzugt der Verbindungsabschnitt der Einhängehaken eingelegt. Hierdurch steht der Verbindungsabschnitt nicht über das Türprofil über, wodurch die jeweilige Scheibe flächig auf eine Oberfläche der Türprofile aufgelegt werden kann. Hierdurch wird eine Beschädigung oder eine mechanische Überlastung der Scheibe verhindert.The connecting section of the suspension hooks is preferably inserted into the groove section. As a result, the connecting section does not protrude beyond the door profile, as a result of which the respective pane can be placed flat on a surface of the door profile. This prevents damage or mechanical overloading of the disc.

Weitere mögliche Implementierungen des Haushaltsgargeräts umfassen auch nicht explizit genannte Kombinationen von zuvor oder im Folgenden bezüglich der Ausführungsbeispiele beschriebenen Merkmale oder Ausführungsformen. Dabei wird der Fachmann auch Einzelaspekte als Verbesserungen oder Ergänzungen zu der jeweiligen Grundform des Haushaltsgargeräts hinzufügen.Further possible implementations of the domestic cooking appliance also include combinations that are not explicitly mentioned above or below with regard to the exemplary embodiments features or embodiments described. The person skilled in the art will also add individual aspects as improvements or additions to the respective basic shape of the domestic cooking appliance.

Weitere vorteilhafte Ausgestaltungen des Haushaltsgargeräts sind Gegenstand der Unteransprüche sowie der im Folgenden beschriebenen Ausführungsbeispiele des Haushaltsgargeräts. Im Weiteren wird das Haushaltsgargerät anhand von bevorzugten Ausführungsformen unter Bezugnahme auf die beigelegten Figuren näher erläutert.

- Fig. 1

- zeigt eine schematische perspektivische Ansicht einer Ausführungsform eines Haushaltsgargeräts;

- Fig. 2

- zeigt eine schematische Teilschnittansicht einer Tür für das Haushaltsgargerät gemäß

Fig. 1 ; - Fig. 3

- zeigt eine schematische perspektivische Ansicht einer Ausführungsform einer Dichteinrichtung für die Tür gemäß

Fig. 2 ; - Fig. 4

- zeigt eine schematische perspektivische Teilansicht einer Ausführungsform eines Türprofils für die Tür gemäß

Fig. 2 ; - Fig. 5

- zeigt eine schematische perspektivische Teilansicht der Tür gemäß

Fig. 2 ; - Fig. 6

- zeigt eine weitere schematische Teilschnittansicht der Tür gemäß

Fig. 2 ; und - Fig. 7

- zeigt eine schematische perspektivische Ansicht der Tür gemäß

Fig. 2 .

- Fig. 1

- shows a schematic perspective view of an embodiment of a domestic cooking appliance;

- Fig. 2

- shows a schematic partial sectional view of a door for the domestic cooking appliance according to FIG

Fig. 1 ; - Fig. 3

- FIG. 13 shows a schematic perspective view of an embodiment of a sealing device for the door according to FIG

Fig. 2 ; - Fig. 4

- shows a schematic perspective partial view of an embodiment of a door profile for the door according to FIG

Fig. 2 ; - Fig. 5

- shows a schematic perspective partial view of the door according to FIG

Fig. 2 ; - Fig. 6

- shows a further schematic partial sectional view of the door according to FIG

Fig. 2 ; and - Fig. 7

- FIG. 13 shows a schematic perspective view of the door according to FIG

Fig. 2 .

In den Figuren sind gleiche oder funktionsgleiche Elemente mit denselben Bezugszeichen versehen worden, sofern nichts anderes angegeben ist.In the figures, elements that are the same or have the same function have been given the same reference symbols, unless otherwise stated.

Die

Der Garraum 2 weist einen Boden 6, eine dem Boden 6 gegenüberliegend angeordnete Decke 7, eine der geschlossenen Tür 3 gegenüberliegend angeordnete Rückwand 8 und zwei einander gegenüberliegend angeordnete Seitenwände 9, 10 auf. Der Garraum 2 ist vorzugsweise quader- oder würfelförmig. Der Garraum 2 kann aus einem Metallwerkstoff, insbesondere aus einem Stahlblech, gefertigt sein.The cooking chamber 2 has a

Das Haushaltsgargerät 1 umfasst weiterhin an einer Bedienblende 11 vorgesehene Bedienknäufe 12, 13. Die Bedienknäufe 12, 13 können beispielsweise drehbar sein. Rückseitig an der Bedienblende 11 kann eine nur schematisch gezeigte Steuereinrichtung 14 zum Steuern des Haushaltsgargeräts 1 vorgesehen sein. Die Steuereinrichtung 14 kann eine Regel- und/oder Steuereinrichtung sein. An der Bedienblende 11 kann weiterhin ein Anzeigedisplay 15 vorgesehen sein. Mit Hilfe des Anzeigedisplays 15 kann ein Betriebszustand des Haushaltsgargeräts 1 angezeigt werden. Beispielsweise kann mit Hilfe des Anzeigedisplays 15 eine mittels der Bedienknäufe 12, 13 eingestellte Temperatur angezeigt werde.The

Die Tür 3 weist mehrere Scheiben 16 auf, von denen in der

Die

Jedes Türprofil 17, 18 weist einen Aufnahmeabschnitt 23 zum Aufnehmen der ersten Scheibe 19 auf. Der Aufnahmeabschnitt 23 ist beispielsweise hakenförmig ausgebildet und kann eine Kante 24, insbesondere eine Oberkante oder eine Unterkante, der ersten Scheibe 19 zumindest abschnittsweise umgreifen. Jedes Türprofil 17, 18 weist weiterhin einen Aufnahmeabschnitt 25 auf, der dazu eingerichtet ist, die zweite Scheibe 20 sowie die dritte Scheibe 21 in der Tür 3 zu positionieren. Hierzu können eine Kante 26, insbesondere eine Oberkante oder eine Unterkante, der zweiten Scheibe 20 sowie eine Kante 27, insbesondere eine Oberkante oder eine Unterkante, der dritten Scheibe 21 an dem Aufnahmeabschnitt 25 anliegen.Each

Mit Hilfe der Türprofile 17, 18 können die Scheiben 16 und 19 bis 21 parallel zueinander und beabstandet voneinander angeordnet sein. Dabei stellt jede Scheibe 16 und 19 bis 21 eine Ebene dar. Insbesondere ist die zweite Scheibe 20 beabstandet von der ersten Scheibe 19, die dritte Scheibe 21 beabstandet von der zweiten Scheibe 20 und die vierte Scheibe 16 beabstandet von der dritten Scheibe 21 angeordnet. Die Abstände der Scheiben 16 und 19 bis 21 können dabei unterschiedlich oder gleich sein. Zwischen den Scheiben 16 und 19 bis 21 kann Luft zirkulieren. Zwischen der ersten Scheibe 19 und der zweiten Scheibe 20 ist ein erster Spalt S1, zwischen der zweiten Scheibe 20 und der dritten Scheibe 21 ist ein zweiter Spalt S2 und zwischen der dritten Scheibe 21 und der vierten Scheibe 16 ist ein dritter Spalt S3 vorgesehen. Die Türprofile 17, 18 sind zwischen der ersten Scheibe 19 und der vierten Scheibe 16 angeordnet. Die Türprofile 17, 18 sind jedoch auch zumindest abschnittsweise zwischen der ersten Scheibe 19 und der zweiten Scheibe 20 sowie zwischen der ersten Scheibe 19 und der dritten Scheibe 21 angeordnet.With the help of the door profiles 17, 18, the

Die Tür 3 umfasst weiterhin eine Dichteinrichtung 28. Die Dichteinrichtung 28 ist, wie in der

Die Dichteinrichtung 28 umfasst neben dem Dichtelement 29 einen ersten Einhängehaken 34 zum Einhängen der Dichteinrichtung 28 in das erste Türprofil 17 und einen zweiten Einhängehaken 35 zum Einhängen der Dichteinrichtung 28 in das zweite Türprofil 18. Die Einhängehaken 34, 35 sind vorzugsweise aus einem Stahlwerkstoff gefertigt. Die Einhängehaken 34, 35 können formschlüssig oder stoffschlüssig mit dem Dichtelement 29 verbunden sein. Bei stoffschlüssigen Verbindungen werden die Verbindungspartner durch atomare oder molekulare Kräfte zusammengehalten. Stoffschlüssige Verbindungen sind nicht lösbare Verbindungen, die sich nur durch Zerstörung der Verbindungsmittel und/oder der Verbindungspartner trennen lassen. Beispielsweise sind die Einhängehaken 34, 35 mit dem Dichtelement 29 verklebt. Jeder Einhängehaken 34, 35 umfasst einen Verbindungsabschnitt 36, der fest mit dem Dichtelement 29 verbunden ist, einen Einhakabschnitt 37, der parallel zu dem Verbindungsabschnitt 36 angeordnet ist, sowie einen Zwischenabschnitt 38, der den Verbindungsabschnitt 36 mit dem Einhakabschnitt 37 verbindet.In addition to the sealing

Die Türprofile 17, 18 weisen, wie in der

Mit Hilfe des Aufnahmeabschnitts 39 und des Nutabschnitts 41 sind, wie in den

Bei einer wie zuvor beschriebenen Tür 3 hat die Abdichtung der Spalte S1, S2 und/oder S3 zwischen den Scheiben 16 und 19 bis 21 einen positiven Einfluss auf den Energieverbrauch und somit auf die Garergebnisse. Insbesondere kann jeder abgedichtete Spalt einen positiven Einfluss auf den Energieverbrauch haben. Luftzirkulation zwischen bestimmten Scheiben 16 und 19 bis 21, beispielsweise zwischen den Scheiben 19, 20, wird verhindert und die Durchlüftung der Tür 3 kann zwischen anderen Scheiben 16 und 19 bis 21, beispielsweise zwischen den Scheiben 21, 16, erfolgen. Die Vorteile des Haushaltsgargeräts 1 liegen darin, dass die Dichteinrichtung 28 nicht direkt auf einer der Scheiben 16 und 19 bis 21 montiert wird, sondern unmittelbar in die Türprofile 17, 18 eingehängt werden kann. Hierdurch kann die Gefahr einer Betätigung einer der Scheiben 16 und 19 bis 21 durch die Einhängehaken 34, 35 verhindert werden.With a

Die Einhängehaken 34, 35 sind in den Aufnahmeabschnitten 39 der Türprofile 17, 18 sicher verbaut und bergen auch für einen Kunden beim Zerlegen und Reinigen der Tür 3 keine Verletzungsgefahr. Durch das Vorsehen der Aufnahmeabschnitte 39 und der Nutabschnitte 41 an den Türprofilen 17, 18 ist die Position der Dichteinrichtung 28 prozesssicher gewährleistet. Eine falsche Montage, beispielsweise zu hoch oder zu tief an einer der Scheiben 16 und 19 bis 21 sowohl in der Fertigung als auch durch den Kunden beim Zerlegen und Reinigen der Tür 3 kann verhindert werden und somit auch die Funktion sichergestellt werden. Die Montage der Dichteinrichtung 28 an den Türprofilen 17, 18 macht die Dichteinrichtung 28 zudem unabhängig von der Geometrie und der Größe der Scheiben 16 und 19 bis 21 und kann somit universell eingesetzt werden. Dadurch, dass die Einhängehaken 34, 35 in den Nutabschnitten 41 der Türprofile 17, 18 zum Liegen kommen, ist es nicht erforderlich, zwischen der ersten Scheibe 19 und der zweiten Scheibe 20 einen zusätzlichen Bauraum für die Einhängehaken 34, 35 vorzusehen. Hierdurch wird der erste Spalt S1 zwischen den Scheiben 19, 20 größer, wodurch eine verbesserte Luftzirkulation möglich ist. Hierdurch kann eine verbesserte Energieeffizienz erreicht werden kann und eine Temperatur der vierten Scheibe 16 kann aufgrund der Isolationswirkung des ersten Spalts S1 reduziert werden kann.The suspension hooks 34, 35 are securely installed in the receiving

- 11

- HaushaltsgargerätDomestic cooking appliance

- 22

- GarraumCooking space

- 33

- Türdoor

- 44th

- OberkanteTop edge

- 55

- GriffHandle

- 66th

- Bodenground

- 77th

- Deckeceiling

- 88th

- RückwandBack wall

- 99

- SeitenwandSide wall

- 1010

- SeitenwandSide wall

- 1111

- BedienblendeControl panel

- 1212th

- BedienknaufControl knob

- 1313th

- BedienknaufControl knob

- 1414th

- SteuereinrichtungControl device

- 1515th

- AnzeigedisplayDisplay screen

- 1616

- Scheibedisc

- 1717th

- TürprofilDoor profile

- 1818th

- TürprofilDoor profile

- 1919th

- Scheibedisc

- 2020th

- Scheibedisc

- 2121

- Scheibedisc

- 2222nd

- InnenflächeInner surface

- 2323

- AufnahmeabschnittReceiving section

- 2424

- KanteEdge

- 2525th

- AufnahmeabschnittReceiving section

- 2626th

- KanteEdge

- 2727

- KanteEdge

- 2828

- DichteinrichtungSealing device

- 2929

- DichtelementSealing element

- 3030th

- DichtlippeSealing lip

- 3131

- DichtlippeSealing lip

- 3232

- DichtlippeSealing lip

- 3333

- DichtlippeSealing lip

- 3434

- EinhängehakenSuspension hook

- 3535

- EinhängehakenSuspension hook

- 3636

- VerbindungsabschnittConnection section

- 3737

- EinhakabschnittHooking section

- 3838

- ZwischenabschnittIntermediate section

- 3939

- AufnahmeabschnittReceiving section

- 4040

- SeitenwandSide wall

- 4141

- NutabschnittGroove section

- 4242

- Oberflächesurface

- 4343

- UnterkanteLower edge

- S1S1

- Spaltgap

- S2S2

- Spaltgap

- S3S3

- Spaltgap

- xx

- x-Richtungx direction

- yy

- y-Richtungy direction

- zz

- z-Richtungz-direction

Claims (8)

- Household cooking appliance (1) having a cooking chamber (2) and a door (3) for closing the cooking chamber (2), wherein the door (3) includes a first pane (19), a second pane (20) arranged at a spacing from the first pane (19), a first door profile (17), a second door profile (18) arranged at a spacing from the first door profile (17), and a sealing device (28) that is arranged in a gap (S1) provided between the first pane (19) and the second pane (20), in order to seal the gap (S1), wherein the sealing device (28) is fastened to the first door profile (17) and the second door profile (18), characterised in that the sealing device (28) is suspended in the first door profile (17) and the second door profile (18) in a pretensioned manner, the sealing device (28) is resiliently expanded during the assembly thereof and this expansion is also constantly maintained after assembly of the sealing device (28).

- Household cooking appliance according to claim 1, characterised in that the sealing device (28) is connected form-fittingly to the first door profile (17) and the second door profile (18).

- Household cooking appliance according to claim 1 or 2, characterised in that the sealing device (28) has a first suspension hook (34) for suspending the sealing device (28) in the first door profile (17), and a second suspension hook (35) for suspending the sealing device (28) in the second door profile (18).

- Household cooking appliance according to claim 3, characterised in that the sealing device (28) has a resiliently deformable sealing element (29) that is arranged between the first suspension hook (34) and the second suspension hook (35) and is firmly connected thereto.

- Household cooking appliance according to claim 4, characterised in that the first suspension hook (34) and the second suspension hook (35) are made from a steel material, and the sealing element (29) is made from a silicone material.

- Household cooking appliance according to claim 4 or 5, characterised in that the sealing element (29) has sealing lips (30 - 33) that are intended to abut sealingly against the first pane (19) and/or the second pane (20).

- Household cooking appliance according to one of claims 3 - 6, characterised in that the first door profile (17) and the second door profile (18) each have a receiving portion (39), in particular an aperture, in which the sealing device (28) is suspended.

- Household cooking appliance according to one of claims 3 - 7, characterised in that the first door profile (17) and the second door profile (18) each have a groove portion (41) in which the first suspension hook (34) and the second suspension hook (35) are laid.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL17816503T PL3551939T3 (en) | 2016-12-12 | 2017-11-24 | Household cooking appliance |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016224757.3A DE102016224757A1 (en) | 2016-12-12 | 2016-12-12 | Haushaltsgargerät |

| PCT/EP2017/080357 WO2018108483A1 (en) | 2016-12-12 | 2017-11-24 | Household cooking appliance |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3551939A1 EP3551939A1 (en) | 2019-10-16 |

| EP3551939B1 true EP3551939B1 (en) | 2021-04-07 |

Family

ID=60702616

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17816503.1A Active EP3551939B1 (en) | 2016-12-12 | 2017-11-24 | Household cooking appliance |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10845061B2 (en) |

| EP (1) | EP3551939B1 (en) |

| CN (1) | CN110036242B (en) |

| DE (1) | DE102016224757A1 (en) |

| PL (1) | PL3551939T3 (en) |

| WO (1) | WO2018108483A1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TR201909193A2 (en) * | 2019-06-20 | 2021-01-21 | Bsh Ev Aletleri San Ve Tic As | ONE DOOR FOR HOME APPLIANCE |

| DE102020209242A1 (en) | 2020-07-22 | 2022-01-27 | BSH Hausgeräte GmbH | door and household cooking appliance |

| USD956466S1 (en) * | 2020-10-15 | 2022-07-05 | Samsung Electronics Co., Ltd. | Microwave |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3200812A (en) * | 1963-09-24 | 1965-08-17 | Mills Prod Inc | Oven door window unit |

| US3244165A (en) * | 1964-08-31 | 1966-04-05 | Borg Warner | Seal for glass oven door |

| DE4333033C1 (en) * | 1993-09-29 | 1995-05-24 | Schott Glas | Temperature-insulating viewing window or door for a device with an internal temperature that deviates from its ambient temperature |

| DE29503872U1 (en) * | 1995-03-07 | 1996-07-04 | AEG Hausgeräte GmbH, 90429 Nürnberg | Door to lock the oven muffle of a baking and roasting oven |

| DE10138889B4 (en) | 2001-08-08 | 2004-04-08 | BSH Bosch und Siemens Hausgeräte GmbH | Oven door sealing profile and oven door |

| FR2830897B1 (en) * | 2001-10-17 | 2006-11-17 | Saint Gobain | INSULATING GLAZING AND METHOD OF MANUFACTURING |

| FR2846029B1 (en) * | 2002-10-17 | 2005-07-01 | Saint Gobain | INSULATING GLAZING |

| DE10314214B4 (en) | 2003-03-28 | 2021-10-28 | BSH Hausgeräte GmbH | Oven door for closing an oven muffle of an oven |

| DE102006027610A1 (en) * | 2006-06-13 | 2007-12-20 | Electrolux Home Products Corporation N.V. | Door for closing the feed opening of a cooking chamber of a cooking oven, in particular a household oven |

| TR201005080A2 (en) * | 2010-06-23 | 2010-12-21 | Vestel Beyaz Eşya Sanayi̇ Ve Ti̇caret Anoni̇m Şi̇rketi̇@ | Cooking appliance door. |

| DE102011088073B4 (en) | 2011-12-09 | 2024-08-01 | BSH Hausgeräte GmbH | Door for a household appliance and cooking appliance with such a door |

| DE102011088082B4 (en) | 2011-12-09 | 2022-03-31 | BSH Hausgeräte GmbH | Door for a household appliance and household appliance with a door |

| CN105408693A (en) * | 2012-12-28 | 2016-03-16 | 阿塞里克股份有限公司 | A door comprising detachable panels and an oven wherein the door is used |

| WO2015165499A1 (en) | 2014-04-29 | 2015-11-05 | Arcelik Anonim Sirketi | Door with improved disassembly/reassembly for use in an oven |

| DE102015108618A1 (en) * | 2015-06-01 | 2016-12-01 | Miele & Cie. Kg | Garraummuffel |

| CN205227439U (en) * | 2015-11-27 | 2016-05-11 | 广东沃尔姆斯电器有限公司 | Multilayer door body of readily removable structure |

-

2016

- 2016-12-12 DE DE102016224757.3A patent/DE102016224757A1/en not_active Withdrawn

-

2017

- 2017-11-24 PL PL17816503T patent/PL3551939T3/en unknown

- 2017-11-24 WO PCT/EP2017/080357 patent/WO2018108483A1/en active Application Filing

- 2017-11-24 US US16/320,561 patent/US10845061B2/en active Active

- 2017-11-24 CN CN201780076562.6A patent/CN110036242B/en active Active

- 2017-11-24 EP EP17816503.1A patent/EP3551939B1/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| PL3551939T3 (en) | 2021-10-25 |

| CN110036242A (en) | 2019-07-19 |

| WO2018108483A1 (en) | 2018-06-21 |

| CN110036242B (en) | 2021-02-05 |

| US20190242588A1 (en) | 2019-08-08 |

| US10845061B2 (en) | 2020-11-24 |

| DE102016224757A1 (en) | 2018-06-14 |

| EP3551939A1 (en) | 2019-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3551938B1 (en) | Household appliance | |

| EP3551939B1 (en) | Household cooking appliance | |

| DE10051643B4 (en) | Hood for a fan filter | |

| EP3333489B1 (en) | Household cooking appliance | |

| DE102009028808A1 (en) | Inner frame for extractor hood and extractor hood | |

| EP1867927A2 (en) | Door of an oven, in particular of a household oven and method for producing such door | |

| WO2022017794A1 (en) | Door and domestic cooking device | |

| EP2553343B1 (en) | Oven door and method for fastening a door cover to such an oven door | |

| DE102008025907B4 (en) | muffle furnace | |

| WO2002044620A1 (en) | Oven | |

| DE102011088082B4 (en) | Door for a household appliance and household appliance with a door | |

| EP2634493B1 (en) | Door for a domestic appliance for preparing food with a support element | |

| DE102011084571A1 (en) | Device for the treatment of food with improved door connection | |

| EP2430368B1 (en) | Door comprising a support element | |

| DE102010063906A1 (en) | Oven door and oven with a oven door | |

| DE10328885B4 (en) | Heating device, in particular oven | |

| DE102010003901A1 (en) | Hanging protection for food and hoods | |

| WO2022017793A1 (en) | Door and domestic cooking device | |

| DE10106824B4 (en) | Cooking device frame and cooking device | |

| EP1548367B1 (en) | Device for closing the cavity opening of a household appliance | |

| EP2740871B1 (en) | Device for a domestic appliance with a hinge and a coupling device and domestic appliance with such a device | |

| DE102012208659B4 (en) | Holding device for a door pane of a cooking device door and cooking device door | |

| DE102015114739B4 (en) | Extractor hood | |

| DE102009050414A1 (en) | Device for use as holder for exhaust gas hose of mobile room air-conditioning device for e.g. sucking fresh air through door opening, has fastening units for attaching air hose at passage opening and device at frame, respectively | |

| EP4185817A1 (en) | Door and domestic cooking appliance |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20190712 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20201120 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1380169 Country of ref document: AT Kind code of ref document: T Effective date: 20210415 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017010034 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20210407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210707 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210807 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210708 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210707 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210809 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017010034 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20220110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210807 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211124 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211130 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20211130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211124 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230504 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20171124 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1380169 Country of ref document: AT Kind code of ref document: T Effective date: 20221124 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231123 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221124 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20231115 Year of fee payment: 7 Ref country code: FR Payment date: 20231122 Year of fee payment: 7 Ref country code: DE Payment date: 20231130 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20231115 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210407 |