EP3241618A1 - Grille de tamis - Google Patents

Grille de tamis Download PDFInfo

- Publication number

- EP3241618A1 EP3241618A1 EP17168443.4A EP17168443A EP3241618A1 EP 3241618 A1 EP3241618 A1 EP 3241618A1 EP 17168443 A EP17168443 A EP 17168443A EP 3241618 A1 EP3241618 A1 EP 3241618A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- grate

- grate bars

- bars

- normal

- screen surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/46—Constructional details of screens in general; Cleaning or heating of screens

- B07B1/4609—Constructional details of screens in general; Cleaning or heating of screens constructional details of screening surfaces or meshes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/12—Apparatus having only parallel elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/46—Constructional details of screens in general; Cleaning or heating of screens

- B07B1/4609—Constructional details of screens in general; Cleaning or heating of screens constructional details of screening surfaces or meshes

- B07B1/4618—Manufacturing of screening surfaces

Definitions

- the invention relates to a grate for size-dependent separation of bulk materials, comprising a plurality of juxtaposed, spaced apart grate bars, which form a screen surface and which have a smaller dimension in the width direction which is parallel to the screen surface and normal to the longitudinal direction of the grate bars than in the height direction wherein the height direction is normal to the screen surface and normal to the longitudinal direction of the grate bars and wherein the normal to the longitudinal axis cross-section of the grate bars tapers in a subsequent to the screen surface first portion of the grate bars with increasing distance from the screen surface, so that in this height range, the width a gap between two grate bars in the height direction extended.

- the US 4,268,384 A shows a sieve with conical grate bars, which is used to deposit solids from suspensions.

- the grate bars are to be arranged normal to the conveying direction.

- the DE 10 2014 011 679 A1 shows a screening device with profiled bars that can be designed as a sieve drum.

- the radii of the rounded flanks have a common center at the head of the screen bar, wherein the screen bars may be arranged normal to the conveying direction or inclined to the axis of the screening drum.

- cantilevered screening machines which essentially include the circular vibrating screens, linear vibrating screens and elliptical vibrating screens, are usually mounted on a base via spring elements, directly or indirectly.

- a drive unit is a screen box, containing one or more sieves, vibrated.

- the underlying object of the invention is achieved in that the normal to the longitudinal axis cross-section of the grate bars tapers in a subsequent to the screen surface first portion of the grate bars with increasing distance from the screen surface, so that in this height range, the width of a Gaps extended between two grate bars in the vertical direction, wherein the grate bars are arranged parallel to each other, in the conveying direction of the bulk material.

- the first portion is conical, that is, by planes inclined toward each other.

- the first portion is formed of two flat plates which are arranged at an acute angle to each other, wherein the cavity formed by the two plates is closed by a third flat plate which is parallel to the screen surface.

- a second section of the grate bars may be formed straight, for example as a flat plate, so that in this height range, the width of a gap between two grate bars in the height direction remains the same. Due to the conical design of the first section, the tendency to blockage is already reduced.

- the second section may be integral with one of the two panels of the first section be formed, which are arranged at an acute angle to each other.

- the first section can be the same height as the second section.

- a plurality of widthwise transverse panels may be provided which divide the gaps between two grate bars into a plurality of chambers.

- the grate bars will be arranged parallel to each other, in the conveying direction of the bulk material.

- the grate according to the invention is preferably used in free-running screening machines, which are usually mounted via spring elements - directly or indirectly - on a substrate, wherein by means of a drive unit a screen box containing one or more sieves, is set in vibration. Accordingly, it can be provided that the grate according to the invention is part of a free-moving screening machine. In other words, the present invention can be realized by providing a free-running screening machine with one or more screening gratings according to the invention.

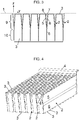

- Fig. 1 shows a schematic view of a grate according to the invention.

- the grate is arranged inclined in the operating state, the bulk material is placed left on top of the screen surface 1 and migrates on this down to the right, in the longitudinal direction x.

- a grate bar 2 can be seen, which runs parallel to the screen surface 1 or whose upper side forms the screen surface 1.

- the gaps between the grate bars 2 are closed by a plurality of transverse plates 3 extending in the width direction y (normal to the plane of the drawing), so that the grate is subdivided into several chambers in the longitudinal direction x.

- the transverse plates 3 are inclined against the conveying direction of the bulk material.

- the transverse plates 3 are bent at the top thereof and are there in the form of a continuous bar on top of the grate bars 2.

- the grate bars 2 are connected to each other by a common support portion 4 and fixed in their mutual position.

- Fig. 2 which made the top view of the grate Fig. 1 shows can be seen that the height of the grate bars, so their dimension in the height direction z in Fig. 1 , the height of the grate bars 2 is here about 10 to 15 times the width of the grate bars 2.

- the grate comprises in this example seven grate bars 2, are common, depending on the application, four to twelve grate bars 2.

- Fig. 3 shows a vertical section through the grate Fig. 1 respectively.

- Fig. 2 thus a section transverse to the longitudinal axis x of the screen bars 2, so that the width direction y and the height direction z lie in the plane of the drawing.

- Each of the screen bars is formed of three plates 5-7, with first and second plates 5, 6 being arranged at an acute angle to one another and the cavity 8 formed by the two plates 5, 6 is closed by a third flat plate 7 which is parallel to the screen surface 1.

- the first plate 5 is flat and slightly less than half as high as the second plate 6.

- the second plate 6 is angled approximately halfway up, wherein the flat upper part of the plate 6 together with the plate 5, the cavity 8 with the pointed Angle forms.

- the upper part of the plate 6 thus forms together with the plate 5 the - in the height direction z starting at the screen surface 1 - first section 9 of the grate bars 2 from.

- the upper part of the plate 6 and plate 5 in each case include the same angle with the height direction z.

- the width of the widened gap between 2 grate bars remains constant.

- Fig. 4 shows the grate according to the invention in axonometric view, here again the cross plates 3 are clearly visible.

- the plates 5-7 and the transverse plates 3 are usually made of metal and are welded together.

- Fig. 5 shows a sieve with a sieve box 11, which is driven by a drive unit 12.

- the transverse plates 3 and support sections 4 are aligned with each other.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Combined Means For Separation Of Solids (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17168443.4A EP3241618A1 (fr) | 2017-04-27 | 2017-04-27 | Grille de tamis |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17168443.4A EP3241618A1 (fr) | 2017-04-27 | 2017-04-27 | Grille de tamis |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP3241618A1 true EP3241618A1 (fr) | 2017-11-08 |

Family

ID=58638776

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17168443.4A Withdrawn EP3241618A1 (fr) | 2017-04-27 | 2017-04-27 | Grille de tamis |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP3241618A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109622366A (zh) * | 2019-01-11 | 2019-04-16 | 北京昊辰投资担保有限公司 | 物料分离机以及分离方法 |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB425877A (en) * | 1934-09-13 | 1935-03-22 | Louis Herrmann | Improvements in or relating to sifting and screening grates or sieves |

| US4268384A (en) | 1977-03-21 | 1981-05-19 | Rosaen Borje O | Spin-off filter head assembly |

| US4283278A (en) * | 1978-03-23 | 1981-08-11 | N. Greening Limited | Screens |

| WO1996026794A1 (fr) * | 1995-02-28 | 1996-09-06 | Neil Deryck Bray Graham | Dispositif de criblage et appareil comprenant ce dispositif |

| WO2003013742A1 (fr) * | 2001-08-07 | 2003-02-20 | Power-Glides Screens Limited | Systeme de degrillage de suspension |

| WO2003084802A1 (fr) * | 2002-04-09 | 2003-10-16 | Thyssenkrupp Stahl Ag | Structure de liaison en y d'un cadre porteur de vehicule a moteur |

| AT509855A4 (de) * | 2010-07-29 | 2011-12-15 | Ife Aufbereitungstechnik Gmbh | Sieb |

| DE102014011679A1 (de) | 2013-08-20 | 2015-02-26 | Andritz Fiedler Gmbh | Profilierter Siebstab und Siebvorrichtung aus profilierten Siebstäben |

-

2017

- 2017-04-27 EP EP17168443.4A patent/EP3241618A1/fr not_active Withdrawn

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB425877A (en) * | 1934-09-13 | 1935-03-22 | Louis Herrmann | Improvements in or relating to sifting and screening grates or sieves |

| US4268384A (en) | 1977-03-21 | 1981-05-19 | Rosaen Borje O | Spin-off filter head assembly |

| US4283278A (en) * | 1978-03-23 | 1981-08-11 | N. Greening Limited | Screens |

| WO1996026794A1 (fr) * | 1995-02-28 | 1996-09-06 | Neil Deryck Bray Graham | Dispositif de criblage et appareil comprenant ce dispositif |

| WO2003013742A1 (fr) * | 2001-08-07 | 2003-02-20 | Power-Glides Screens Limited | Systeme de degrillage de suspension |

| WO2003084802A1 (fr) * | 2002-04-09 | 2003-10-16 | Thyssenkrupp Stahl Ag | Structure de liaison en y d'un cadre porteur de vehicule a moteur |

| AT509855A4 (de) * | 2010-07-29 | 2011-12-15 | Ife Aufbereitungstechnik Gmbh | Sieb |

| DE102014011679A1 (de) | 2013-08-20 | 2015-02-26 | Andritz Fiedler Gmbh | Profilierter Siebstab und Siebvorrichtung aus profilierten Siebstäben |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109622366A (zh) * | 2019-01-11 | 2019-04-16 | 北京昊辰投资担保有限公司 | 物料分离机以及分离方法 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102014009702B3 (de) | Kunststoffsiebbelag für eine Siebmaschine zum Klassieren von insbesondere feinkörnigem Schüttgut | |

| DE3006364B1 (de) | Lochplatten-Siebboden mit Selbstreinigungswirkung | |

| DE3827259A1 (de) | Siebanordnung | |

| EP0521192A1 (fr) | Elément pour épurateur | |

| DE202016103754U1 (de) | Siebmaschine | |

| EP3241618A1 (fr) | Grille de tamis | |

| EP3275562B1 (fr) | Éperon | |

| AT15451U1 (de) | Siebrost | |

| EP1228814A2 (fr) | Dispositif de tamisage | |

| AT524317B1 (de) | Abstreifleiste und Bausatz zur Verwendung in einer Anlage zur Erzeugung einer Papierbahn | |

| AT505122B1 (de) | Siebelement | |

| EP2412451B1 (fr) | Crible | |

| DE3790016C2 (fr) | ||

| DE3114573C2 (de) | Siebfeld für Vibrationssiebe | |

| DE102014009704B3 (de) | Kunststoffsiebbelag für eine Siebmaschine zum Klassieren von insbesondere grobkörnigem Schüttgut | |

| DE602004011125T2 (de) | Strukturelle anordnung für schwingeinrichtungen | |

| DE10065930B4 (de) | Verfahren zur Herstellung von Sieben, die zur Nasssiebung von Papierfasersuspensionen verwendbar sind | |

| DE19506084A1 (de) | Siebeinheit zum Sortieren von Suspensionen | |

| DE2923662C2 (de) | Schwingsieb, insbesondere Kreisschwingsieb | |

| EP3917690B1 (fr) | Système de tamis vibrant constitué d'au moins deux machines de tamisage agencées en rangée | |

| DE10116367A1 (de) | Siebeinrichtung zur Nasssiebung von Papierfasersuspensionen | |

| EP3248695A1 (fr) | Dispositif de tamisage | |

| EP2409784B1 (fr) | Rouleau de criblage pour un dispositif de criblage de matériau pouvant être putréfié | |

| DE102019107261B3 (de) | Siebherstellverfahren | |

| DE19635156C2 (de) | Verfahren zur Herstellung von Sieben |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20180509 |