EP3113941B1 - Coulisseau porte-outil - Google Patents

Coulisseau porte-outil Download PDFInfo

- Publication number

- EP3113941B1 EP3113941B1 EP15709661.1A EP15709661A EP3113941B1 EP 3113941 B1 EP3113941 B1 EP 3113941B1 EP 15709661 A EP15709661 A EP 15709661A EP 3113941 B1 EP3113941 B1 EP 3113941B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- slide

- sliding

- wedge

- guide

- bed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000463 material Substances 0.000 claims description 8

- 238000006073 displacement reaction Methods 0.000 claims description 5

- 238000003825 pressing Methods 0.000 description 8

- 238000009434 installation Methods 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000004080 punching Methods 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 230000001771 impaired effect Effects 0.000 description 2

- 230000003993 interaction Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000005555 metalworking Methods 0.000 description 2

- 229910000906 Bronze Inorganic materials 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000010974 bronze Substances 0.000 description 1

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 1

- 230000006735 deficit Effects 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000009776 industrial production Methods 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/24—Perforating, i.e. punching holes

- B21D28/32—Perforating, i.e. punching holes in other articles of special shape

- B21D28/325—Perforating, i.e. punching holes in other articles of special shape using cam or wedge mechanisms, e.g. aerial cams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B1/00—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen

- B30B1/40—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen by wedge means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/02—Dies; Inserts therefor; Mounting thereof; Moulds

- B30B15/026—Mounting of dies, platens or press rams

Definitions

- the invention relates to a tool slide.

- Wedge drives are used in tools in metalworking, e.g. used in forming presses. Associated with these wedge drives are usually facilities or tools that allow punching or otherwise deforming.

- a conventional wedge drive has an upper guide part comprising a slider element and a slider guide element and a lower guide part comprising a driver element and vice versa. The wedge drives are moved by the slider guide element by a drive applying a generally vertical pressing force.

- On the part of the driver element wedge drives are mounted in the tool or the press on a base plate on which the workpiece to be machined is placed directly or via a corresponding support device.

- a wedge drive for redirecting a vertical pressing force in an angularly acting force for the forming process.

- This wedge drive consists of a drive wedge, on which acts a vertical force of a corresponding work press, and a slide wedge, which transmits the force in the horizontal.

- the driver wedge and the slide wedge run either over a rounded cooperating region or, in another embodiment, over a roller.

- a wedge press with a prism-shaped wedge guide wherein the contact surfaces are roof-shaped or channel-like and with the roof or gutter extending over the entire pressure-receiving width of the wedge.

- overhead wedge drives used in the body industry consist of a driver, a slider, and a slider receiver.

- a driver On the top of the slider recording acts a vertical force that pushes the slider recording down.

- the driver is firmly anchored in the tool, so that when pressing on the slide holder, the slide anchored in the slide holder is pushed in any direction outside the vertical working direction.

- the slider depends in his leadership movable in the slide holder.

- the driver sits rigidly in the lower part and specifies the working direction of the slider.

- the spring-loaded slider sets on the driver and is pushed by the continuing slide holder over the driver surface in the working direction.

- a wedge drive which is produced in a continuous industrial production process and should have long service lives.

- angle brackets are present, which are formed of bronze and have attached in the angle bar sliding elements made of graphite.

- this wedge drive for deflecting a vertical pressing force with a driver, a slider and a slider receiving equipped, the driver has a prismatic guide and the travel of the slider on the driver is shorter than the travel of the slider on the slider recording and the ratio of the paths to each other is at least 1 to 1.5 and the angle ⁇ between the traverse paths is 50 ° to 70 °.

- the driver element has a prismatic surface, wherein the flanks of the prismatic surface are formed sloping outwardly.

- this wedge drive has forced return brackets on two opposite sides in respective grooves of the slider element and the driver element. In this way, in the case of a breakage of the slider element in its starting position retrieving spring element ensures a return of the slider element at spring break and thereby to avoid tearing out of screwed punching elements.

- the slider element is attached to the slider guide member via the angle brackets and retaining screws and can be moved along the angle strips relative to the slider guide element.

- the movable slide member In the rear stroke, in which the press tool has exceeded its lower suction point and its two parts move apart again, usually the movable slide member is pushed back by means of a suitably designed resilient element to its original position, after which the process can be restarted.

- the retraction force required for retrieving the slider element is usually between 2% and 10% of the actual working force and the weight of the slider element.

- the size of the pressing force here are the dimensions of the pressure-transmitting surfaces referred to as sliding surfaces be determining the respective inclinations of linear guides in the slider element receiving and tilting of the driver element and the interaction of the surfaces and inclinations and the structure of the slider element itself.

- the pressures to be transmitted are usually between ⁇ 100 kN up to several 10,000 kN.

- the linear guide in the slide element holder is intended to guide the movable slide element without play and in the process must endure high press forces and realize long service life.

- a tolerance of the running accuracy of the movable slide element a tolerance of 0.02 mm is specified.

- such wedge drives or slides consist of a slide assembly, which in turn consists of a driver, a slide part and a slide bed.

- the slide part is fastened with retaining elements on the slide bed, wherein the slide part between the driver and slide bed is slidably suspended.

- Corresponding bevels on slide bed and driver are arranged inclined in opposite directions, so that the slide member "pushed out” when moving together slide valve and driver between the two parts. Since, as already stated, in this case act very large forces, a corresponding guide must be provided.

- the known guides here are the cover strip guide, the guide with guide clips, the guide with guide columns and the dovetail guide ( DE 10 2007 045 703 A1 ).

- the main slide guide on the sliding surfaces must be carried out thereby offset inwards, so that less power transmission is possible.

- a wedge drive is known, wherein the wedge drive is to have a sliding element holder, a movable slide carriage and a driver and is formed with sliding surfaces between the slide carriage and the driver element, wherein at least one sliding surface a clamping device should be present, the pressing force adjustable during assembly of the Working tool simulated to produce a backlash between the at least one slide carriage and the at least one slider receptacle.

- a high tolerance accuracy is to be achieved, namely when mounted in the tool slide upper part comprising the slide carriage and the slider element recording on the one hand and the driver on-03292PWOEP dererupt, this being achieved in that when the working tool is mounted on the slide, ie when the working tool, such as a punch, is attached to the slider, the slides are held together with the simulated pressing force.

- the object of the invention is to provide a slider guide, which has optimized space and power transmission properties with improved assembly capability.

- the slider guide between slider body and slide bed is designed as a prismatic guide or flat guide, wherein also a guide bar with prismatic or dovetailed cross-section is mounted in a groove with a corresponding cross-section and the web overlapping sliding elements of the respective other corresponding slide member.

- the guide play is adjustable according to the invention by the interaction of at least two oblique surfaces between a sliding element and the slide bed which supports this. For this purpose, a separate sliding element can also be provided.

- this guide is applied to a known slider assembly consisting of driver, slider member and slider bed, the slider member being slidably supported in the slider bed. Between the driver and the slide part sliding pairings are arranged.

- the setting of the guide clearance by means of a separate component is at least secured, possibly also made.

- This member is mechanically applied in a direction of adjustment to the sliding member and / or the sliding members having the inclined surface or the inclined surfaces.

- the component may represent a distance between a fixed part of the slider body and / or slider bed, on the one hand, and the adjustable sliding surface, specified for the adjustment made.

- the component itself may be wedge-shaped or wedge-shaped with a bevel, which cooperates with a corresponding inclined surface of the sliding surface to be adjusted, the sliding surface displaced.

- an actuating means is provided for the component, with which the component in a simple manner from the outside, the sliding surface actuated, can be adjusted.

- This is in particular an adjusting screw, with which the component, this moving, can be acted upon relative to the sliding surface.

- the slide bed has the dovetail-shaped recess for receiving the dovetail spring, wherein on the outside of the dovetail spring, a sliding surface and the slide bed at least one sliding element is formed.

- the sliding element is wedge-shaped with a bevel.

- This bevel is in this case formed on the groove-side short surface of an L-shaped sliding element, wherein the groove with a corresponding wedge-like surface, in particular a corresponding oblique surface is formed.

- both sliding elements or only one sliding element may have the slope.

- the L-shaped sliding element may in this case also be formed of individual sliding elements, which are L-shaped relative to one another, but this increases the assembly effort.

- an adjustment of the slide bed to the slider body can be achieved by oppositely moving the sliding strips or sliding elements.

- the invention relates to a tool slide, in particular wedge drive, at least comprising a slide bed and a slide part, wherein the slide part is slidably disposed on the slide bed with a prism guide and a groove and a protruding into the groove web are provided, wherein between the web and the groove at least one Sliding element is provided, wherein a detachable from the slide part driver is present and between the slide part and the driver in the attached state also a prismatic guide consists of inclined elements of the slider body and corresponding inclined surfaces of the driver, wherein between the slide bed and the slider body a prism guide or flat guide such is formed, that sliding elements of the slider bed and corresponding sliding elements of the slider body are arranged with respect to an x-axis inclined at a prism guide or perpendicular to a flat guide, wherein the Slide member towards the groove has a wedge-like, tapered surface, with which it rests on a corresponding surface of the groove wall and the corresponding groove wall has a corresponding wedge-like

- the invention further relates to a tool slide, wherein the sliding elements are L-shaped sliding strips or sliding plates, which have the groove center facing surfaces with which they define a space between them and the slider body towards sliding surfaces are formed, being symmetrical to the vertical axis of the Guide member or the guide web upwardly into the groove extends, wherein the guide web has elongated surfaces, with which it is formed adjacent to the surfaces of the L-shaped slide strips.

- the sliding elements are L-shaped sliding strips or sliding plates, which have the groove center facing surfaces with which they define a space between them and the slider body towards sliding surfaces are formed, being symmetrical to the vertical axis of the Guide member or the guide web upwardly into the groove extends, wherein the guide web has elongated surfaces, with which it is formed adjacent to the surfaces of the L-shaped slide strips.

- the invention relates to a tool slide, wherein the guide body is formed as an elongated rail or web-like component, wherein the web is prismatic or dovetail widening in the projecting into the groove portion, wherein a guide prism or a dovetail guide is formed, which in the groove superimposed, wherein the web is mounted with prismatic surfaces on corresponding surfaces of the sliding strips in the groove.

- the invention also relates to a tool slide, wherein a fitting piece is present, which is inserted between a wall of the slide bed and a wall of the sliding element and holds a defined position of the sliding element.

- the invention relates to a tool slide, wherein the fitting piece is arranged with a screw on the slide bed or the sliding member.

- the invention relates to a tool slide, wherein the fitting piece has at least one wedge-shaped inclined surface which corresponds with an inclined surface of the slide bed or an inclined surface of the sliding element as a wedge drive for displacing the sliding element.

- the invention also relates to a tool slide, in which the fitting has wedge-like inclined surfaces which correspond both to an inclined surface of the slide bed and with an inclined surface of the sliding element as a wedge drive for moving the sliding member.

- the invention relates to a tool slide, wherein arranged for adjusting the guide clearance, the fitting piece between an edge or surface of the axially located in front of or behind the slide strip slide bed. This edge or surface is spaced from an end face of the sliding strip.

- the invention further relates to a tool slide, wherein the fitting piece to hold it in place, with a fixing part the edge or surface of the slide bed over protrudes, especially in the region of a heel formed for this purpose and is fixed there by means of a screw, both passes through the fitting and now the material of the slide bed is screwed, whereby the axial distance between the edge and the edge is fixed.

- the fitting piece is arranged between the edges, wherein the fitting piece is movably arranged between the edges and the overhanging region and the step are spaced, so that by screwing the screw, the fitting piece is arranged in the area between the edges pressed into, wherein the Gleitancen worne edge or surface of the fitting is provided with a bevel such that the fitting is formed widening and / or the edge of the slide strip is provided with a corresponding slope such that when you push the fitting into the area between the edges of the slide bar is moved, whereby the guide play is reduced.

- the wedge has a bend, which is arranged on the wedge such that the free End of the bend is in the range of the material of the pusher bed or the slide bar and is penetrated by a screw which is rotatably mounted in the bend, the screw with its screw head and / or with a corresponding device on the wedge acts such that a Screw the screw into the slide bed or the slide bar moves the wedge into or out of the gap.

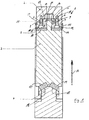

- An inventive tool slide 1 has a slide bed 2, a slider body 3 and a driver. 4

- the slide part 3 is arranged hanging on the slide bed 2 in the case shown, wherein the slide part 3 can be lifted by the driver 4.

- the driver 4 is usually arranged in a first (in the case shown the lower) mold half, while the slide part 3 via the slide bed 2 at a corresponding second (upper) mold half (not shown) is arranged.

- the slide bed 2 is approximately box-shaped and has an elongated rectangular groove 5, wherein in addition to the elongated rectangular groove 5 screw holes 6 for receiving corresponding screws (not shown) are provided.

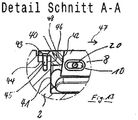

- the groove 5 and the adjacent, the groove defining surfaces 7 form a bearing surface for L-shaped slide strips 8, which rest on the surfaces 7 and hineinerarranged with an L-leg 9 in the groove 5.

- the L-shaped wear strips 8 have mounting holes 10 for screwing mounting screws for placement in the screw holes 6.

- the L-shaped wear strips 8 have the Nutmitte facing diverging surfaces 11, with which they define a prismatic space between them.

- the surfaces 22 extend relative to the thickness of the L-leg 9 between the Nutrichwandung 19 along the longitudinal extent of the L-shaped wear strips 8 obliquely so that the L-legs 9 are wedge-shaped or wedge-shaped.

- This bevel or wedge shape runs at an angle of 1 ° to 5 °.

- the Nutrichwandept 19 are formed in a corresponding manner with respect to the longitudinal extent bevel, so that a displacement of the slide strips 8 according to the longitudinal direction, the surfaces 11 moves more or less towards Nutmitte.

- the L-shaped slide strips Towards the slider body 3, the L-shaped slide strips have sliding surfaces 12, which are planar and perpendicular to an X-axis 13 shown.

- the slider body 3 has sliding surfaces or sliding strips 14 which correspond to the surfaces 12 and are designed as sliding partners to the L-shaped slide strips 8.

- a guide web 15 which is designed in particular as a guide prism or dovetail, up into the groove 5 in.

- the guide prism 15 has elongated prismatic surfaces 16, with which it rests against the surfaces 11 of the L-shaped slide strips 8.

- the slider body 3 has further slide strips 17, which are arranged obliquely with respect to the X-axis 13 and correspond with prismatic guide surfaces 18 of the driver 4.

- the strips 17 form, as they are connected to the slider body, lift-off sliding strips, which are brought along when moving together of the upper tool part and the lower tool part in operative connection with the surfaces 18.

- the obliquely corresponding sliding elements 17, 18 between the slider body and driver form a so-called prism guide.

- the tool slide 1 also consists of a slide bed 2 and a slider body 3 (the driver 4 is not shown).

- the slide part 3 is arranged hanging on the slide bed 2 in the case shown, wherein the slide part 3 can be lifted by the driver 4.

- the slide bed 2 is approximately box-shaped and has an elongated groove 5.

- the Nutgetwandungen 19 extending from the groove bottom, converge and thus form a dovetail groove.

- the groove 5 bounding surfaces 7 converge with each other.

- On the surfaces 7 are L-shaped sliding strips 8, which extend with a narrow, short L-leg 9 into the groove.

- the L-shaped sliding strips have to the surfaces 7 towards contact surfaces 11 and the slider body 3 toward sliding surfaces 12, which are planar and obliquely divergent with respect to a vertical axis. These surfaces 12 slide on corresponding sliding surfaces 14 of the slider body.

- the sliding surfaces 14 of the slider body 3 are accordingly formed roof-shaped inclined, with respect to the vertical axis centrally centrally symmetrically arranged the guide bar 15 or dovetailed part of the guide web 15 of the slider body is located on the short L-shaped legs 9 of the slide strips 8 prismatic Surfaces 16 are formed adjacent.

- the surfaces 16 and 14 close the approximately the same angle as the surfaces 9, 12 and are in the example shown approximately perpendicular to each other.

- the leadership of the slider body in the slide bed must be adjustable or the slide strips 8 and the prism 15 must be adjusted to each other.

- the mounting holes 10 in the wear strips 8 as elongated holes so that they are along the mounting screws 20 and thus along an adjustment direction 21 slidably.

- the displacement of the slide strips 8 along the direction 21 does not change any existing gaps or gaps between the surfaces of the slide strips 8 and the L-leg 9 and the guide prism 15. Relative to the longitudinal extension and the directions 21, therefore, run the contact surfaces 22nd the L-leg 9 of the L-shaped slide strips analogous to the first embodiment 8 wedge-like or wedge-shaped. This means that they change their thickness relative to the longitudinal extent.

- the slope has, for example, a slope of 1-5 degrees.

- the oblique contact surfaces 22 on the L-legs 9 of the L-shaped sliding strips 8 are directed to corresponding corresponding surfaces 19 of the groove 5.

- a displacement along the direction 21 thus causes, due to the inclined surfaces 22, 19, the distance between the surfaces 11 of the L-leg 9 and the surfaces 16 of the guide web 15 or guide prism 15 is reduced or eliminated.

- both both slide strips 8 and only one slide bar 8 can be moved.

- a fitting 40 is provided according to the invention.

- the fitting 40 is disposed between an edge or surface 41 of the axially located in front of or behind the slide strip 8 slide bed 2 and this edge or surface 41 spaced from an end face 42 of the slide bar 8.

- the fitting overhangs the edge or surface 41 to the slide bed 2 with a fixing part 43, in particular in the region of a heel 44 formed for this purpose, and is there fixed by means of a screw 45, both the fitting 40 passes through and is screwed into the material of the slide bed 2.

- the axial distance between the edge 41 and the edge 42 can thus be determined, so that the position of the screws 20 is fixed within the slots 10.

- the fittings between the edges 41, 42 may have different widths.

- the fitting piece is also disposed between the edges 41, 42, but is movably arranged between the edges 41, 42 in that the overhanging portion 43 and the Level 44 are spaced apart from each other so that by screwing in the screw 55, the fitting 40 seen from the outside can be pushed deeper into the area between the edges 41, 42.

- the sliding strip-side edge or surface 46 of the fitting 40 is provided with a bevel such that the fitting 40 widens outwardly.

- the edge 42 of the sliding strip 8 is provided with a corresponding slope such that when pushing in the fitting 40 in the area between the edges 41, 42, the slide bar 8 is moved in the direction of the arrow 47.

- the direction 47 is also the direction with which the guide play is reduced.

- the fitting 40 are screwed into the area between the edges 41, 42 and thus the slide bar 8 are moved accordingly in one direction to less guide play.

- the advantage here is that by screwing the fitting piece from the outside, which is relatively easy to accomplish, the adjustment or adjustment of the guide clearance is easily possible.

- the screws 45 are reset from the outside against damage behind the outer surface of the slide bed 2 and still achieve good, especially with an angle key or the like tools.

- a further advantageous embodiment follows the adjustment in another way.

- the surfaces 19 of the groove 5 and the slider bed 2 and / or the surface 22, which faces the wall 19, formed with a slope.Wenn both surfaces 19, 22 are formed obliquely, the formation of the slopes is such that it is in the same direction, ie the surfaces diverge from one another or converge and define a wedge-shaped gap between them.

- a corresponding wedge-shaped fitting is used in this embodiment, which either an inclined surface 64 to the wall 22 or an inclined surface 65 depending on the design Wall 19 out or two inclined surfaces 64, 65 to sloping walls 19, 22 out has. Accordingly, this wedge bears against these walls 19, 22 and extends between the sliding strip 8 and the groove 5.

- this wedge 60 is moved in or out in accordance with a direction of movement 61 in the gap between the surfaces 19, 22, the slide bar 8 is moved either entirely in the direction of a groove center 62 or in each case moves the directions 23 away from it.

- the wedge 60 In order to move the wedge-shaped fitting piece or the wedge 60 into and out of the gap, the wedge 60 has an offset 63, which is arranged on the wedge such that the free end of the cap 63 is in the region of the material of Slider and here in particular in the area of the slide bed 2 is located.

- the cranked portion 63 is penetrated by a screw 66 which is rotatably mounted in the bend 63.

- This screw 66 acts with its screw head or with a corresponding device the cranked region 63, so that screwing the screw 66 into the slide bed 2 (FIG. Fig. 8 ) moves the wedge into the gap between the surfaces 19, 22 and unscrewing the screw moves the wedge 60 out again.

- the screw 66 is not screwed into the slide, in particular in the slide bed 2, but directly in the sliding plates 8, which ultimately leads to the same result when screwing in and out.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Machine Tool Units (AREA)

- Bearings For Parts Moving Linearly (AREA)

- Framework For Endless Conveyors (AREA)

- Mounting, Exchange, And Manufacturing Of Dies (AREA)

Claims (11)

- Glissière d'outil, en particulier entraînement de coin, au moins comprenant un lit de glissement (2) et une partie de glissement (3), dans laquelle la partie de glissement (3) est monté de façon coulissante sur le lit de glissement (2) avec un guide prismatique et une rainure (5) et une âme s'étendant dans la rainure (15) sont prévues, dans laquelle au moins un élément coulissant (8) est prévu entre l'âme (15) et la rainure (5), dans laquelle un moteur (4) détachable de la partie de glissement (3) est présent et entre la partie de glissement (3) et le moteur dans un état appliqué existe également un guide prismatique d'éléments inclinés (17) du corps de glissement (3) et de surfaces inclinées (18) correspondantes du moteur (4), dans laquelle entre le lit de glissement (2) et le corps de glissement (3) un guidage prismatique ou un guide plat est formé de telle sorte que des éléments coulissants (8) du lit de glissement (2) et des éléments coulissants (14) correspondants du corps de glissement (3) sont incliné par rapport à un axe x (13) dans un guide prismatique, ou sont disposés verticalement dans un guide plat, caractérisé en ce que l'élément coulissant (8) comporte une surface (22) biseautée en forme de coin vers la rainure (5), avec laquelle il repose sur une surface correspondante (19) de la paroi de rainure (5) et la paroi de rainure (19) comporte un biseautage en forme de coin correspondant, de telle sorte qu'un déplacement axial de l'élément coulissant (8) correspondant à une direction de l'axe longitudinal (23) réduit ou élargit une fente (25) entre l'âme (15) et l'élément coulissant (8).

- Glissière d'outil selon la revendication 1, caractérisé en ce que les éléments coulissants sont des bandes de glissement (8) en forme de L ou des plaques de glissement (8), qui comprennent des surfaces (11) tournés vers le centre de la rainure, avec lesquelles elles définissent un espace intermédiaire entre elles et ont des surfaces de glissement (12) vers le corps de glissement (3), dans laquelle symétriquement par rapport à l'axe vertical, la partie de guidage (15) ou l'âme de guidage (15) s'étend vers le haut dans la rainure (5), dans laquelle l'âme de guidage (15) comprends des surfaces de forme allongée (16) avec lesquelles elle est formée de manière adjacente aux surfaces (11) des bandes de glissement (8) en forme de L.

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que le corps de guidage (15) est formé en tant qu'un élément allongé en forme de rail ou en forme d'âme, le corps de guidage (15) étant formée de manière à s'élargir de manière prismatique ou en forme de queue d'aronde dans la zone s'étendant dans la rainure (5), un guide prismatique ou un guide en queue d'aronde étant formé, qui est entreposé dans la rainure (5), l'âme (15) avec des surfaces prismatiques (16) étant entreposé sur des surfaces correspondantes (11) des bandes de glissement (8) dans la rainure (5).

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée qu'un adapteur (40, 60) est présent, qui est inséré entre une paroi (19, 41) de la chambre de glissement (2) et une paroi de l'élément coulissant (8) et qui tient une position définie de l'élément coulissant (8).

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que l'adapteur est disposé avec une vis (45, 66) sur le lit de glissement (2) ou le l'élément coulissant (8).

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que l'adapteur présente au moins une surface biseautée en forme de coin (64, 65), qui correspond avec une surface inclinée (19) du lit de glissement ou une surface inclinée (22) de l'élément coulissant (8) comme entrainement à clavette pour le déplacement de l'élément coulissant (8).

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que l'adapteur (2) comprend des surfaces inclinées en forme de coin (64, 65), qui correspond avec une surface inclinée (19) du lit de glissement ou une surface inclinée (22) de l'élément coulissant (8) comme entrainement à clavette pour le déplacement de l'élément coulissant (8).

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que pour le réglage du jeu l'adapteur (40) est disposé entre un bord ou une surface (41) du lit de glissement qui est disposé axialement de face ou derrière l'élément coulissant (8), ce bord ou cette surface étant éloigné d'une face avant (42) de l'élément coulissant (8).

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que l'adapteur (40), pour le maintenir en place, avec une partie de fixation (43) surplombe le bord ou la surface (41) en direction vers le lit de glissements, en particulier dans la zone d'un épaulement (44) formé à cet effet et y est fixé au moyen d'une vis (45), qui passe à travers l'adapteur (40) et maintenant est vissé au matériau du lit de glissement (2), de sorte que la distance axiale entre le bord (41) et le bord (42) est fixe.

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que l'adapteur (40) est disposé entre les bords (41, 42), l'adapteur (40) étant disposé mobile entre les bords (41, 42) et la partie en surplomb (43) et l'étage (44) étant éloigné de sorte que par vissage de la vis (55) l'adapteur (40) est disposé tel qu'il est susceptible d'être poussé dans la zone entre les bords (41, 42), le bord ou la surface (46) du coté de l'élément de coulissement de l'adapteur étant équipé d'un biseautage tel que l'adapteur 40 est formé s'élargissant et/ou le bord 42 de l'élément coulissant (8) est équipé d'un biseautage correspondant tel que durant le poussage vers l'intérieur de l'adapteur (40) dans la zone entre les bords (41, 42) l'élément de coulissement (8) est déplacé, par quoi le jeu de guidage est minimisé.

- Glissière d'outil selon l'une quelconque des revendications précédentes, caractérisée en ce que dans le but de déplacer l'adapteur en forme de coin (40) ou la cale (60) dans la fente en forme de coin entre les surfaces (19, 22) de la chambre de glissement (2) et la bande de glissement (8) et hors de celui-ci, la cale (60) présente une partie coudée (63) qui est disposé sur la cale (60) de telle sorte que l'extrémité libre de la partie coudée est située dans la région du matériau du lit glissement (2) ou de la bande de glissement (8) et est traversée par une vis (66), qui est entreposée dans la partie coudée (63) de manière rotative, dans laquelle la vis (66) avec sa tête de vis et / ou avec un moyen correspondant agit sur la cale (60) de telle sorte qu'un vissage de la vis (66) dans le lit de glissement (2) ou la bande de glissement (8) déplace la cale (60) dans ou en dehors de la fente.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102014102998 | 2014-03-06 | ||

| PCT/EP2015/054663 WO2015132356A1 (fr) | 2014-03-06 | 2015-03-05 | Coulisseau porte-outil |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3113941A1 EP3113941A1 (fr) | 2017-01-11 |

| EP3113941B1 true EP3113941B1 (fr) | 2018-05-09 |

Family

ID=52672250

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15709661.1A Active EP3113941B1 (fr) | 2014-03-06 | 2015-03-05 | Coulisseau porte-outil |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20170014890A1 (fr) |

| EP (1) | EP3113941B1 (fr) |

| JP (1) | JP2017507036A (fr) |

| KR (1) | KR20160129901A (fr) |

| CN (1) | CN106103069B (fr) |

| DE (1) | DE112015000008B4 (fr) |

| ES (1) | ES2683496T3 (fr) |

| WO (1) | WO2015132356A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202015106966U1 (de) | 2015-12-21 | 2016-01-28 | Harald Weigelt | Keiltrieb |

| KR102631351B1 (ko) | 2016-10-07 | 2024-01-31 | 삼성전자주식회사 | 피어-투 피어 통신을 수행할 수 있는 저장 장치와 이를 포함하는 데이터 저장 시스템 |

| DE202017100989U1 (de) | 2017-02-22 | 2017-04-21 | Fibro Gmbh | Keiltrieb mit optimierter Führung |

| WO2019127588A1 (fr) * | 2017-12-31 | 2019-07-04 | 常君斌 | Dispositif de fabrication |

| DE102018111366B4 (de) * | 2018-05-14 | 2024-03-07 | F I B R O Gmbh | Keiltrieb mit justierbarer Führungsvorrichtung |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2329324B2 (de) * | 1973-06-08 | 1975-11-27 | Langenstein & Schemann Ag, 8630 Coburg | Keilpresse mit einer Einrichtung zur Verhinderung unerwünschter Bewegungen des Keiles |

| DE2439217A1 (de) * | 1974-08-16 | 1976-03-04 | Langenstein & Schemann Ag | Keipresse mit einer keilfuehrung |

| DE2640318A1 (de) * | 1976-08-09 | 1978-03-16 | Weingarten Ag Maschf | Keiltrieb zur umleitung einer vertikalen presskraft in eine fuer den umformvorgang hierzu winklig wirkende kraft |

| ES2069654T3 (es) * | 1990-11-09 | 1995-05-16 | Umix Co Ltd | Matriz con leva deslizante. |

| DE19753549C2 (de) * | 1997-12-03 | 2000-02-17 | Harald Weigelt | Keiltrieb |

| JP3757635B2 (ja) * | 1998-08-26 | 2006-03-22 | オイレス工業株式会社 | カム装置 |

| DE50013358D1 (de) * | 2000-10-13 | 2006-10-05 | Harald Weigelt | Keiltrieb |

| US6990844B1 (en) * | 2004-07-27 | 2006-01-31 | Anchor Lamina America, Inc. | Narrow aerial and die-mount cams |

| US7191635B2 (en) * | 2004-11-18 | 2007-03-20 | Danly Iem, Llc | Press mounted cam |

| DE102005029140B4 (de) * | 2005-06-23 | 2008-04-03 | Elke Weigelt | Werkzeugbefestigungseinrichtung für einen Keiltrieb |

| DE102007045703A1 (de) * | 2007-09-24 | 2009-04-09 | Harald Weigelt | Keiltrieb mit Schieberaufnahme |

| US8430385B2 (en) * | 2007-09-24 | 2013-04-30 | Harald Weigelt | Wedge drive with slider receiving means |

| DE102008061420B9 (de) * | 2008-12-10 | 2011-02-10 | voestalpine Gießerei Linz GmbH | Keiltrieb |

| CN201524750U (zh) * | 2009-10-15 | 2010-07-14 | 嘉兴迈特尔宝欣机械工业有限公司 | 冲压模具上用的悬吊式斜楔机构 |

| JP2011140048A (ja) * | 2010-01-08 | 2011-07-21 | Sankyo Oilless Industry Inc | カム装置 |

| KR101139272B1 (ko) * | 2011-02-16 | 2012-04-26 | 주식회사 루보 | 캠슬라이드의 편심구동방지수단이 구비된 에어리얼 캠 유니트 |

| DE102012014546A1 (de) * | 2012-07-21 | 2014-01-23 | Strack Norma Gmbh & Co. Kg | Keiltrieb |

-

2015

- 2015-03-05 JP JP2016572908A patent/JP2017507036A/ja not_active Withdrawn

- 2015-03-05 DE DE112015000008.9T patent/DE112015000008B4/de not_active Expired - Fee Related

- 2015-03-05 ES ES15709661.1T patent/ES2683496T3/es active Active

- 2015-03-05 US US15/124,004 patent/US20170014890A1/en not_active Abandoned

- 2015-03-05 WO PCT/EP2015/054663 patent/WO2015132356A1/fr active Application Filing

- 2015-03-05 KR KR1020167027681A patent/KR20160129901A/ko unknown

- 2015-03-05 CN CN201580012354.0A patent/CN106103069B/zh not_active Expired - Fee Related

- 2015-03-05 EP EP15709661.1A patent/EP3113941B1/fr active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| US20170014890A1 (en) | 2017-01-19 |

| KR20160129901A (ko) | 2016-11-09 |

| EP3113941A1 (fr) | 2017-01-11 |

| JP2017507036A (ja) | 2017-03-16 |

| DE112015000008B4 (de) | 2016-03-10 |

| CN106103069B (zh) | 2018-08-03 |

| ES2683496T3 (es) | 2018-09-26 |

| DE112015000008A5 (de) | 2015-11-19 |

| WO2015132356A1 (fr) | 2015-09-11 |

| CN106103069A (zh) | 2016-11-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2197660B1 (fr) | élément de translation mobile et transmission par clavette avec un tel élément de translation mobile | |

| EP3113941B1 (fr) | Coulisseau porte-outil | |

| DE102008061420B9 (de) | Keiltrieb | |

| EP1197319B2 (fr) | Entraînement par coin | |

| EP2874804B1 (fr) | Mécanisme à came | |

| EP3393693B1 (fr) | Mécanisme à clavette | |

| EP3113891B1 (fr) | Coulisseau porte-outil | |

| DE102015103112B4 (de) | Werkzeugschieber | |

| DE102014102993B4 (de) | Werkzeugschieber | |

| EP2885108B1 (fr) | Dispositif de levage avec mécanisme à genouillère | |

| DE102011089682A1 (de) | Matrize für eine Stanzvorrichtung, Stanzwerkzeug für eine Stanzvor-richtung mit einer solchen Matrize sowie Verfahren zum Heraus-schneiden von Werkstückteilen aus Werkstücken mit einer entspre-chenden Matrize | |

| EP0557866B1 (fr) | Cisaille à ferrailles | |

| EP2674231B1 (fr) | Dispositif destiné au pliage de pièces métalliques | |

| EP2457672A1 (fr) | Amortisseur de matrice | |

| EP3512695B1 (fr) | Transmission par courroie trapézoïdale et procédé de production d'une transmission par courroie trapézoïdale à guidage optimisé | |

| DE8516029U1 (de) | Längsführung, insbesondere für eine Kreissäge | |

| CH711192B1 (de) | Vorrichtung zum Abbremsen eines Gleisfahrzeugs. | |

| DE102012013661A1 (de) | Justiervorrichtung | |

| EP2527070A1 (fr) | Scie circulaire de format avec dispositif de guidage | |

| DE29705002U1 (de) | Stanzvorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20160902 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20171108 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| GRAR | Information related to intention to grant a patent recorded |

Free format text: ORIGINAL CODE: EPIDOSNIGR71 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| INTC | Intention to grant announced (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20180327 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 997213 Country of ref document: AT Kind code of ref document: T Effective date: 20180515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502015004206 Country of ref document: DE |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: VOESTALPINE CAMTEC GMBH |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180509 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2683496 Country of ref document: ES Kind code of ref document: T3 Effective date: 20180926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180809 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180809 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180810 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502015004206 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502015004206 Country of ref document: DE Representative=s name: HGF EUROPE LLP, DE Ref country code: DE Ref legal event code: R081 Ref document number: 502015004206 Country of ref document: DE Owner name: VOESTALPINE CAMTEC GMBH, AT Free format text: FORMER OWNER: VOESTALPINE GIESSEREI LINZ GMBH, LINZ, AT Ref country code: DE Ref legal event code: R082 Ref document number: 502015004206 Country of ref document: DE Representative=s name: HGF EUROPE LP, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502015004206 Country of ref document: DE Representative=s name: HGF EUROPE LLP, DE Ref country code: DE Ref legal event code: R082 Ref document number: 502015004206 Country of ref document: DE Representative=s name: HGF EUROPE LP, DE |

|

| 26N | No opposition filed |

Effective date: 20190212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190305 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190305 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180910 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190306 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 997213 Country of ref document: AT Kind code of ref document: T Effective date: 20200305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180909 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20150305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180509 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240327 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502015004206 Country of ref document: DE Representative=s name: WSL PATENTANWAELTE PARTNERSCHAFT MBB, DE |