EP3113941B1 - Tool slide - Google Patents

Tool slide Download PDFInfo

- Publication number

- EP3113941B1 EP3113941B1 EP15709661.1A EP15709661A EP3113941B1 EP 3113941 B1 EP3113941 B1 EP 3113941B1 EP 15709661 A EP15709661 A EP 15709661A EP 3113941 B1 EP3113941 B1 EP 3113941B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- slide

- sliding

- wedge

- guide

- bed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000463 material Substances 0.000 claims description 8

- 238000006073 displacement reaction Methods 0.000 claims description 5

- 238000003825 pressing Methods 0.000 description 8

- 238000009434 installation Methods 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000004080 punching Methods 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 230000001771 impaired effect Effects 0.000 description 2

- 230000003993 interaction Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000005555 metalworking Methods 0.000 description 2

- 229910000906 Bronze Inorganic materials 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000010974 bronze Substances 0.000 description 1

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 1

- 230000006735 deficit Effects 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000009776 industrial production Methods 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/24—Perforating, i.e. punching holes

- B21D28/32—Perforating, i.e. punching holes in other articles of special shape

- B21D28/325—Perforating, i.e. punching holes in other articles of special shape using cam or wedge mechanisms, e.g. aerial cams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B1/00—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen

- B30B1/40—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen by wedge means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/02—Dies; Inserts therefor; Mounting thereof; Moulds

- B30B15/026—Mounting of dies, platens or press rams

Definitions

- the invention relates to a tool slide.

- Wedge drives are used in tools in metalworking, e.g. used in forming presses. Associated with these wedge drives are usually facilities or tools that allow punching or otherwise deforming.

- a conventional wedge drive has an upper guide part comprising a slider element and a slider guide element and a lower guide part comprising a driver element and vice versa. The wedge drives are moved by the slider guide element by a drive applying a generally vertical pressing force.

- On the part of the driver element wedge drives are mounted in the tool or the press on a base plate on which the workpiece to be machined is placed directly or via a corresponding support device.

- a wedge drive for redirecting a vertical pressing force in an angularly acting force for the forming process.

- This wedge drive consists of a drive wedge, on which acts a vertical force of a corresponding work press, and a slide wedge, which transmits the force in the horizontal.

- the driver wedge and the slide wedge run either over a rounded cooperating region or, in another embodiment, over a roller.

- a wedge press with a prism-shaped wedge guide wherein the contact surfaces are roof-shaped or channel-like and with the roof or gutter extending over the entire pressure-receiving width of the wedge.

- overhead wedge drives used in the body industry consist of a driver, a slider, and a slider receiver.

- a driver On the top of the slider recording acts a vertical force that pushes the slider recording down.

- the driver is firmly anchored in the tool, so that when pressing on the slide holder, the slide anchored in the slide holder is pushed in any direction outside the vertical working direction.

- the slider depends in his leadership movable in the slide holder.

- the driver sits rigidly in the lower part and specifies the working direction of the slider.

- the spring-loaded slider sets on the driver and is pushed by the continuing slide holder over the driver surface in the working direction.

- a wedge drive which is produced in a continuous industrial production process and should have long service lives.

- angle brackets are present, which are formed of bronze and have attached in the angle bar sliding elements made of graphite.

- this wedge drive for deflecting a vertical pressing force with a driver, a slider and a slider receiving equipped, the driver has a prismatic guide and the travel of the slider on the driver is shorter than the travel of the slider on the slider recording and the ratio of the paths to each other is at least 1 to 1.5 and the angle ⁇ between the traverse paths is 50 ° to 70 °.

- the driver element has a prismatic surface, wherein the flanks of the prismatic surface are formed sloping outwardly.

- this wedge drive has forced return brackets on two opposite sides in respective grooves of the slider element and the driver element. In this way, in the case of a breakage of the slider element in its starting position retrieving spring element ensures a return of the slider element at spring break and thereby to avoid tearing out of screwed punching elements.

- the slider element is attached to the slider guide member via the angle brackets and retaining screws and can be moved along the angle strips relative to the slider guide element.

- the movable slide member In the rear stroke, in which the press tool has exceeded its lower suction point and its two parts move apart again, usually the movable slide member is pushed back by means of a suitably designed resilient element to its original position, after which the process can be restarted.

- the retraction force required for retrieving the slider element is usually between 2% and 10% of the actual working force and the weight of the slider element.

- the size of the pressing force here are the dimensions of the pressure-transmitting surfaces referred to as sliding surfaces be determining the respective inclinations of linear guides in the slider element receiving and tilting of the driver element and the interaction of the surfaces and inclinations and the structure of the slider element itself.

- the pressures to be transmitted are usually between ⁇ 100 kN up to several 10,000 kN.

- the linear guide in the slide element holder is intended to guide the movable slide element without play and in the process must endure high press forces and realize long service life.

- a tolerance of the running accuracy of the movable slide element a tolerance of 0.02 mm is specified.

- such wedge drives or slides consist of a slide assembly, which in turn consists of a driver, a slide part and a slide bed.

- the slide part is fastened with retaining elements on the slide bed, wherein the slide part between the driver and slide bed is slidably suspended.

- Corresponding bevels on slide bed and driver are arranged inclined in opposite directions, so that the slide member "pushed out” when moving together slide valve and driver between the two parts. Since, as already stated, in this case act very large forces, a corresponding guide must be provided.

- the known guides here are the cover strip guide, the guide with guide clips, the guide with guide columns and the dovetail guide ( DE 10 2007 045 703 A1 ).

- the main slide guide on the sliding surfaces must be carried out thereby offset inwards, so that less power transmission is possible.

- a wedge drive is known, wherein the wedge drive is to have a sliding element holder, a movable slide carriage and a driver and is formed with sliding surfaces between the slide carriage and the driver element, wherein at least one sliding surface a clamping device should be present, the pressing force adjustable during assembly of the Working tool simulated to produce a backlash between the at least one slide carriage and the at least one slider receptacle.

- a high tolerance accuracy is to be achieved, namely when mounted in the tool slide upper part comprising the slide carriage and the slider element recording on the one hand and the driver on-03292PWOEP dererupt, this being achieved in that when the working tool is mounted on the slide, ie when the working tool, such as a punch, is attached to the slider, the slides are held together with the simulated pressing force.

- the object of the invention is to provide a slider guide, which has optimized space and power transmission properties with improved assembly capability.

- the slider guide between slider body and slide bed is designed as a prismatic guide or flat guide, wherein also a guide bar with prismatic or dovetailed cross-section is mounted in a groove with a corresponding cross-section and the web overlapping sliding elements of the respective other corresponding slide member.

- the guide play is adjustable according to the invention by the interaction of at least two oblique surfaces between a sliding element and the slide bed which supports this. For this purpose, a separate sliding element can also be provided.

- this guide is applied to a known slider assembly consisting of driver, slider member and slider bed, the slider member being slidably supported in the slider bed. Between the driver and the slide part sliding pairings are arranged.

- the setting of the guide clearance by means of a separate component is at least secured, possibly also made.

- This member is mechanically applied in a direction of adjustment to the sliding member and / or the sliding members having the inclined surface or the inclined surfaces.

- the component may represent a distance between a fixed part of the slider body and / or slider bed, on the one hand, and the adjustable sliding surface, specified for the adjustment made.

- the component itself may be wedge-shaped or wedge-shaped with a bevel, which cooperates with a corresponding inclined surface of the sliding surface to be adjusted, the sliding surface displaced.

- an actuating means is provided for the component, with which the component in a simple manner from the outside, the sliding surface actuated, can be adjusted.

- This is in particular an adjusting screw, with which the component, this moving, can be acted upon relative to the sliding surface.

- the slide bed has the dovetail-shaped recess for receiving the dovetail spring, wherein on the outside of the dovetail spring, a sliding surface and the slide bed at least one sliding element is formed.

- the sliding element is wedge-shaped with a bevel.

- This bevel is in this case formed on the groove-side short surface of an L-shaped sliding element, wherein the groove with a corresponding wedge-like surface, in particular a corresponding oblique surface is formed.

- both sliding elements or only one sliding element may have the slope.

- the L-shaped sliding element may in this case also be formed of individual sliding elements, which are L-shaped relative to one another, but this increases the assembly effort.

- an adjustment of the slide bed to the slider body can be achieved by oppositely moving the sliding strips or sliding elements.

- the invention relates to a tool slide, in particular wedge drive, at least comprising a slide bed and a slide part, wherein the slide part is slidably disposed on the slide bed with a prism guide and a groove and a protruding into the groove web are provided, wherein between the web and the groove at least one Sliding element is provided, wherein a detachable from the slide part driver is present and between the slide part and the driver in the attached state also a prismatic guide consists of inclined elements of the slider body and corresponding inclined surfaces of the driver, wherein between the slide bed and the slider body a prism guide or flat guide such is formed, that sliding elements of the slider bed and corresponding sliding elements of the slider body are arranged with respect to an x-axis inclined at a prism guide or perpendicular to a flat guide, wherein the Slide member towards the groove has a wedge-like, tapered surface, with which it rests on a corresponding surface of the groove wall and the corresponding groove wall has a corresponding wedge-like

- the invention further relates to a tool slide, wherein the sliding elements are L-shaped sliding strips or sliding plates, which have the groove center facing surfaces with which they define a space between them and the slider body towards sliding surfaces are formed, being symmetrical to the vertical axis of the Guide member or the guide web upwardly into the groove extends, wherein the guide web has elongated surfaces, with which it is formed adjacent to the surfaces of the L-shaped slide strips.

- the sliding elements are L-shaped sliding strips or sliding plates, which have the groove center facing surfaces with which they define a space between them and the slider body towards sliding surfaces are formed, being symmetrical to the vertical axis of the Guide member or the guide web upwardly into the groove extends, wherein the guide web has elongated surfaces, with which it is formed adjacent to the surfaces of the L-shaped slide strips.

- the invention relates to a tool slide, wherein the guide body is formed as an elongated rail or web-like component, wherein the web is prismatic or dovetail widening in the projecting into the groove portion, wherein a guide prism or a dovetail guide is formed, which in the groove superimposed, wherein the web is mounted with prismatic surfaces on corresponding surfaces of the sliding strips in the groove.

- the invention also relates to a tool slide, wherein a fitting piece is present, which is inserted between a wall of the slide bed and a wall of the sliding element and holds a defined position of the sliding element.

- the invention relates to a tool slide, wherein the fitting piece is arranged with a screw on the slide bed or the sliding member.

- the invention relates to a tool slide, wherein the fitting piece has at least one wedge-shaped inclined surface which corresponds with an inclined surface of the slide bed or an inclined surface of the sliding element as a wedge drive for displacing the sliding element.

- the invention also relates to a tool slide, in which the fitting has wedge-like inclined surfaces which correspond both to an inclined surface of the slide bed and with an inclined surface of the sliding element as a wedge drive for moving the sliding member.

- the invention relates to a tool slide, wherein arranged for adjusting the guide clearance, the fitting piece between an edge or surface of the axially located in front of or behind the slide strip slide bed. This edge or surface is spaced from an end face of the sliding strip.

- the invention further relates to a tool slide, wherein the fitting piece to hold it in place, with a fixing part the edge or surface of the slide bed over protrudes, especially in the region of a heel formed for this purpose and is fixed there by means of a screw, both passes through the fitting and now the material of the slide bed is screwed, whereby the axial distance between the edge and the edge is fixed.

- the fitting piece is arranged between the edges, wherein the fitting piece is movably arranged between the edges and the overhanging region and the step are spaced, so that by screwing the screw, the fitting piece is arranged in the area between the edges pressed into, wherein the Gleitancen worne edge or surface of the fitting is provided with a bevel such that the fitting is formed widening and / or the edge of the slide strip is provided with a corresponding slope such that when you push the fitting into the area between the edges of the slide bar is moved, whereby the guide play is reduced.

- the wedge has a bend, which is arranged on the wedge such that the free End of the bend is in the range of the material of the pusher bed or the slide bar and is penetrated by a screw which is rotatably mounted in the bend, the screw with its screw head and / or with a corresponding device on the wedge acts such that a Screw the screw into the slide bed or the slide bar moves the wedge into or out of the gap.

- An inventive tool slide 1 has a slide bed 2, a slider body 3 and a driver. 4

- the slide part 3 is arranged hanging on the slide bed 2 in the case shown, wherein the slide part 3 can be lifted by the driver 4.

- the driver 4 is usually arranged in a first (in the case shown the lower) mold half, while the slide part 3 via the slide bed 2 at a corresponding second (upper) mold half (not shown) is arranged.

- the slide bed 2 is approximately box-shaped and has an elongated rectangular groove 5, wherein in addition to the elongated rectangular groove 5 screw holes 6 for receiving corresponding screws (not shown) are provided.

- the groove 5 and the adjacent, the groove defining surfaces 7 form a bearing surface for L-shaped slide strips 8, which rest on the surfaces 7 and hineinerarranged with an L-leg 9 in the groove 5.

- the L-shaped wear strips 8 have mounting holes 10 for screwing mounting screws for placement in the screw holes 6.

- the L-shaped wear strips 8 have the Nutmitte facing diverging surfaces 11, with which they define a prismatic space between them.

- the surfaces 22 extend relative to the thickness of the L-leg 9 between the Nutrichwandung 19 along the longitudinal extent of the L-shaped wear strips 8 obliquely so that the L-legs 9 are wedge-shaped or wedge-shaped.

- This bevel or wedge shape runs at an angle of 1 ° to 5 °.

- the Nutrichwandept 19 are formed in a corresponding manner with respect to the longitudinal extent bevel, so that a displacement of the slide strips 8 according to the longitudinal direction, the surfaces 11 moves more or less towards Nutmitte.

- the L-shaped slide strips Towards the slider body 3, the L-shaped slide strips have sliding surfaces 12, which are planar and perpendicular to an X-axis 13 shown.

- the slider body 3 has sliding surfaces or sliding strips 14 which correspond to the surfaces 12 and are designed as sliding partners to the L-shaped slide strips 8.

- a guide web 15 which is designed in particular as a guide prism or dovetail, up into the groove 5 in.

- the guide prism 15 has elongated prismatic surfaces 16, with which it rests against the surfaces 11 of the L-shaped slide strips 8.

- the slider body 3 has further slide strips 17, which are arranged obliquely with respect to the X-axis 13 and correspond with prismatic guide surfaces 18 of the driver 4.

- the strips 17 form, as they are connected to the slider body, lift-off sliding strips, which are brought along when moving together of the upper tool part and the lower tool part in operative connection with the surfaces 18.

- the obliquely corresponding sliding elements 17, 18 between the slider body and driver form a so-called prism guide.

- the tool slide 1 also consists of a slide bed 2 and a slider body 3 (the driver 4 is not shown).

- the slide part 3 is arranged hanging on the slide bed 2 in the case shown, wherein the slide part 3 can be lifted by the driver 4.

- the slide bed 2 is approximately box-shaped and has an elongated groove 5.

- the Nutgetwandungen 19 extending from the groove bottom, converge and thus form a dovetail groove.

- the groove 5 bounding surfaces 7 converge with each other.

- On the surfaces 7 are L-shaped sliding strips 8, which extend with a narrow, short L-leg 9 into the groove.

- the L-shaped sliding strips have to the surfaces 7 towards contact surfaces 11 and the slider body 3 toward sliding surfaces 12, which are planar and obliquely divergent with respect to a vertical axis. These surfaces 12 slide on corresponding sliding surfaces 14 of the slider body.

- the sliding surfaces 14 of the slider body 3 are accordingly formed roof-shaped inclined, with respect to the vertical axis centrally centrally symmetrically arranged the guide bar 15 or dovetailed part of the guide web 15 of the slider body is located on the short L-shaped legs 9 of the slide strips 8 prismatic Surfaces 16 are formed adjacent.

- the surfaces 16 and 14 close the approximately the same angle as the surfaces 9, 12 and are in the example shown approximately perpendicular to each other.

- the leadership of the slider body in the slide bed must be adjustable or the slide strips 8 and the prism 15 must be adjusted to each other.

- the mounting holes 10 in the wear strips 8 as elongated holes so that they are along the mounting screws 20 and thus along an adjustment direction 21 slidably.

- the displacement of the slide strips 8 along the direction 21 does not change any existing gaps or gaps between the surfaces of the slide strips 8 and the L-leg 9 and the guide prism 15. Relative to the longitudinal extension and the directions 21, therefore, run the contact surfaces 22nd the L-leg 9 of the L-shaped slide strips analogous to the first embodiment 8 wedge-like or wedge-shaped. This means that they change their thickness relative to the longitudinal extent.

- the slope has, for example, a slope of 1-5 degrees.

- the oblique contact surfaces 22 on the L-legs 9 of the L-shaped sliding strips 8 are directed to corresponding corresponding surfaces 19 of the groove 5.

- a displacement along the direction 21 thus causes, due to the inclined surfaces 22, 19, the distance between the surfaces 11 of the L-leg 9 and the surfaces 16 of the guide web 15 or guide prism 15 is reduced or eliminated.

- both both slide strips 8 and only one slide bar 8 can be moved.

- a fitting 40 is provided according to the invention.

- the fitting 40 is disposed between an edge or surface 41 of the axially located in front of or behind the slide strip 8 slide bed 2 and this edge or surface 41 spaced from an end face 42 of the slide bar 8.

- the fitting overhangs the edge or surface 41 to the slide bed 2 with a fixing part 43, in particular in the region of a heel 44 formed for this purpose, and is there fixed by means of a screw 45, both the fitting 40 passes through and is screwed into the material of the slide bed 2.

- the axial distance between the edge 41 and the edge 42 can thus be determined, so that the position of the screws 20 is fixed within the slots 10.

- the fittings between the edges 41, 42 may have different widths.

- the fitting piece is also disposed between the edges 41, 42, but is movably arranged between the edges 41, 42 in that the overhanging portion 43 and the Level 44 are spaced apart from each other so that by screwing in the screw 55, the fitting 40 seen from the outside can be pushed deeper into the area between the edges 41, 42.

- the sliding strip-side edge or surface 46 of the fitting 40 is provided with a bevel such that the fitting 40 widens outwardly.

- the edge 42 of the sliding strip 8 is provided with a corresponding slope such that when pushing in the fitting 40 in the area between the edges 41, 42, the slide bar 8 is moved in the direction of the arrow 47.

- the direction 47 is also the direction with which the guide play is reduced.

- the fitting 40 are screwed into the area between the edges 41, 42 and thus the slide bar 8 are moved accordingly in one direction to less guide play.

- the advantage here is that by screwing the fitting piece from the outside, which is relatively easy to accomplish, the adjustment or adjustment of the guide clearance is easily possible.

- the screws 45 are reset from the outside against damage behind the outer surface of the slide bed 2 and still achieve good, especially with an angle key or the like tools.

- a further advantageous embodiment follows the adjustment in another way.

- the surfaces 19 of the groove 5 and the slider bed 2 and / or the surface 22, which faces the wall 19, formed with a slope.Wenn both surfaces 19, 22 are formed obliquely, the formation of the slopes is such that it is in the same direction, ie the surfaces diverge from one another or converge and define a wedge-shaped gap between them.

- a corresponding wedge-shaped fitting is used in this embodiment, which either an inclined surface 64 to the wall 22 or an inclined surface 65 depending on the design Wall 19 out or two inclined surfaces 64, 65 to sloping walls 19, 22 out has. Accordingly, this wedge bears against these walls 19, 22 and extends between the sliding strip 8 and the groove 5.

- this wedge 60 is moved in or out in accordance with a direction of movement 61 in the gap between the surfaces 19, 22, the slide bar 8 is moved either entirely in the direction of a groove center 62 or in each case moves the directions 23 away from it.

- the wedge 60 In order to move the wedge-shaped fitting piece or the wedge 60 into and out of the gap, the wedge 60 has an offset 63, which is arranged on the wedge such that the free end of the cap 63 is in the region of the material of Slider and here in particular in the area of the slide bed 2 is located.

- the cranked portion 63 is penetrated by a screw 66 which is rotatably mounted in the bend 63.

- This screw 66 acts with its screw head or with a corresponding device the cranked region 63, so that screwing the screw 66 into the slide bed 2 (FIG. Fig. 8 ) moves the wedge into the gap between the surfaces 19, 22 and unscrewing the screw moves the wedge 60 out again.

- the screw 66 is not screwed into the slide, in particular in the slide bed 2, but directly in the sliding plates 8, which ultimately leads to the same result when screwing in and out.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Machine Tool Units (AREA)

- Bearings For Parts Moving Linearly (AREA)

- Framework For Endless Conveyors (AREA)

- Mounting, Exchange, And Manufacturing Of Dies (AREA)

Description

Die Erfindung betrifft einen Werkzeugschieber.The invention relates to a tool slide.

Werkzeugschieber, welche auch Keiltriebe genannt werden, sind bekannt.Tool slides, which are also called wedge drives, are known.

Keiltriebe werden in Werkzeugen in der Metallbearbeitung, z.B. bei Umformpressen eingesetzt. Verbunden mit diesen Keiltrieben sind üblicherweise Einrichtungen bzw. Werkzeuge, die ein Stanzen oder anderweitiges Verformen ermöglichen. Ein üblicher Keiltrieb besitzt ein oberes Führungsteil umfassend ein Schieberelement und ein Schieberführungselement und einen unteren Führungsteil umfassend ein Treiberelement bzw. umgekehrt. Die Keiltriebe werden seitens des Schieberführungselements durch einen eine im Allgemeinen vertikale Presskraft aufbringenden Antrieb bewegt. Seitens des Treiberelements sind Keiltriebe in dem Werkzeug bzw. der Presse auf einer Grundplatte befestigt, auf der auch das zu bearbeitende Werkstück direkt oder über eine entsprechende Auflageeinrichtung aufgelegt ist.Wedge drives are used in tools in metalworking, e.g. used in forming presses. Associated with these wedge drives are usually facilities or tools that allow punching or otherwise deforming. A conventional wedge drive has an upper guide part comprising a slider element and a slider guide element and a lower guide part comprising a driver element and vice versa. The wedge drives are moved by the slider guide element by a drive applying a generally vertical pressing force. On the part of the driver element wedge drives are mounted in the tool or the press on a base plate on which the workpiece to be machined is placed directly or via a corresponding support device.

Aus der

Aus der

Aus der

Üblicherweise bestehen oben hängende Keiltriebe, die in der Karosserieindustrie verwendet werden, aus einem Treiber, einem Schieber und einer Schieberaufnahme. Auf die Oberseite der Schieberaufnahme wirkt eine senkrechte Kraft, die die Schieberaufnahme nach unten drückt. Der Treiber ist im Werkzeug fest verankert, so dass beim Druck auf die Schieberaufnahme der in der Schieberaufnahme verankerte Schieber in eine beliebige Richtung außerhalb der senkrechten Arbeitsrichtung gedrückt wird.Usually, overhead wedge drives used in the body industry consist of a driver, a slider, and a slider receiver. On the top of the slider recording acts a vertical force that pushes the slider recording down. The driver is firmly anchored in the tool, so that when pressing on the slide holder, the slide anchored in the slide holder is pushed in any direction outside the vertical working direction.

Häufig werden oben hängende Keiltriebe eingesetzt. Bei dieser Bauart hängt der Schieber in seiner Führung beweglich in der Schieberaufnahme. Der Treiber sitzt starr im Unterteil und gibt die Arbeitsrichtung des Schiebers vor. Beim Abwärtshub der Presse setzt der ausgefederte Schieber auf den Treiber auf und wird von der weiterlaufenden Schieberaufnahme über die Treiberfläche in Arbeitsrichtung geschoben.Frequently, overhead wedge drives are used. In this design, the slider depends in his leadership movable in the slide holder. The driver sits rigidly in the lower part and specifies the working direction of the slider. During the downward stroke of the press, the spring-loaded slider sets on the driver and is pushed by the continuing slide holder over the driver surface in the working direction.

Die aus diesem Stand der Technik bekannten Keiltriebe weisen Nachteile auf, so dass die eingesetzten Schieber häufig nur kurze Standzeiten besitzen und aufgrund ihres konstruktiven Aufbaus hohem Verschleiß ausgesetzt sind. Sie müssen daher häufig bereits nach kurzen Laufzeiten ausgetauscht werden, weil sie Verschleißerscheinungen zeigen, so dass eine exakte Umlenkung der vertikalen Presskräfte nicht mehr möglich ist, was bei der Metallbearbeitung zu nicht akzeptablen Toleranzen führt.The known from this prior art wedge drives have disadvantages, so that the slide used often have short lives and are exposed due to their structural design high wear. Therefore, they often need to be replaced after a short period of time because they show signs of wear, so that an exact Redirecting the vertical pressing forces is no longer possible, which leads to unacceptable tolerances in metalworking.

Aus der

Aus der

Aus der

Aus der

Ferner wird ausgeführt, dass die lineare Führung in der Schieberelementaufnahme das bewegbare Schieberelement spielfrei führen soll und dabei hohe Pressenkräfte ertragen und hohe Standzeiten realisieren muss. Als Toleranz der Laufgenauigkeit des bewegbaren Schieberelements wird eine Toleranz von 0,02 mm angegeben.Furthermore, it is stated that the linear guide in the slide element holder is intended to guide the movable slide element without play and in the process must endure high press forces and realize long service life. As a tolerance of the running accuracy of the movable slide element, a tolerance of 0.02 mm is specified.

Wie bereits im Stand der Technik auch ausgeführt, bestehen derartige Keiltriebe bzw. Schieber aus einer Schieberbaugruppe, welche wiederum aus einem Treiber, einem Schieberteil und einem Schieberbett besteht. Hierbei ist das Schieberteil mit Halteelementen am Schieberbett befestigt, wobei das Schieberteil zwischen Treiber und Schieberbett gleitend aufgehängt ist. Entsprechende Schrägen an Schieberbett und Treiber sind derart gegensinnig geneigt angeordnet, dass das Schieberteil beim Zusammenfahren von Schieberbett und Treiber zwischen beiden Teilen "herausgedrückt" wird. Da, wie bereits ausgeführt, hierbei sehr große Kräfte wirken, muss eine entsprechende Führung vorgesehen sein.As already stated in the prior art, such wedge drives or slides consist of a slide assembly, which in turn consists of a driver, a slide part and a slide bed. In this case, the slide part is fastened with retaining elements on the slide bed, wherein the slide part between the driver and slide bed is slidably suspended. Corresponding bevels on slide bed and driver are arranged inclined in opposite directions, so that the slide member "pushed out" when moving together slide valve and driver between the two parts. Since, as already stated, in this case act very large forces, a corresponding guide must be provided.

Die bekannten Führungen sind hierbei die Deckleistenführung, die Führung mit Führungsklammern, die Führung mit Führungssäulen und die Schwalbenschwanzführung (

Der überwiegende Teil dieser Führungen ist an der Außenfläche des Schiebers angebracht. Hierbei muss festgestellt werden, dass die Kraftübertragung und die Führung nicht optimal sind.The majority of these guides are attached to the outer surface of the slider. It must be noted that the power transmission and the leadership are not optimal.

Einerseits muss die Hauptschieberführung über die Gleitflächen hierdurch nach innen versetzt ausgeführt werden, so dass weniger Kraftübertragung möglich ist. Zudem ergibt sich häufig ein hoher Platzbedarf und es konnten Verformungen durch Einleiten von Betriebskräften (Arbeits- und Rückzugskräfte) festgestellt werden.On the one hand, the main slide guide on the sliding surfaces must be carried out thereby offset inwards, so that less power transmission is possible. In addition, often results in a high space requirement and it could be found deformations by initiating operating forces (work and withdrawal forces).

Bei der bekannten Schwalbenschwanzführung ist von Nachteil, dass hierbei relativ häufig das Spiel nachgearbeitet werden muss, was bedeutet, dass der Schieber komplett deinstalliert werden muss. Auch bei allen anderen Schiebern ist die Montage und Demontage sehr komplex und aufwändig. Diese kann einerseits nur nach hinten im gesamten Schieberkörper durchgeführt werden, wobei insbesondere bei großen Schiebern aufgrund des hohen Gewichts des Schieberkörpers und der stark beschränkten Bauräume große Massen in eng gestellter Führung unter Zuhilfenahme eines Krans bewegt werden müssen. Bei Klammerschiebern muss seitlicher Bauraum für die Montage und Demontage vorgesehen werden, so dass eine optimierte Stellung der Schieber für bestimmte Anwendungen nicht sicher gewährleistet ist.In the known dovetail guide has the disadvantage that this relatively often the game must be reworked, which means that the slide must be completely uninstalled. Even with all other sliders, the assembly and disassembly is very complex and expensive. On the one hand, this can only be carried out to the rear in the entire slider body, with large masses having to be moved in close alignment with the aid of a crane, especially in the case of large sliders, due to the high weight of the slider body and the greatly limited installation space. In the case of clip-type slides, lateral installation space must be provided for assembly and disassembly, so that an optimized position of the slides is not guaranteed for certain applications.

Aus der

Aus der

Die Aufgabe wird mit einem Werkzeugschieber mit den Merkmalen des Anspruchs 1 gelöst.The object is achieved with a tool slide with the features of

Vorteilhafte Weiterbildungen sind in den Unteransprüchen gekennzeichnet.Advantageous developments are characterized in the subclaims.

Erfindungsgemäß ist die Schieberführung zwischen Schieberkörper und Schieberbett als Prismenführung oder Flachführung ausgebildet, wobei zudem ein Führungssteg mit prismatischem oder schwalbenschwanzförmigem Querschnitt in einer Nut mit entsprechendem Querschnitt und dem Steg lagernden Gleitelementen des jeweiligen anderen korrespondierenden Schieberbauteils gelagert ist. Ergänzend zu der prismenförmigen bzw. schwalbenschwanzförmigen Ausführung ist erfindungsgemäß das Führungsspiel durch das Zusammenspiel von zumindest zwei schrägen Flächen zwischen einem Gleitelement und dem dieses lagernden Schieberbetts einstellbar. Hierfür kann zudem ein gesondertes Gleitelement vorgesehen sein.According to the slider guide between slider body and slide bed is designed as a prismatic guide or flat guide, wherein also a guide bar with prismatic or dovetailed cross-section is mounted in a groove with a corresponding cross-section and the web overlapping sliding elements of the respective other corresponding slide member. In addition to the prism-shaped or dovetail-shaped embodiment, the guide play is adjustable according to the invention by the interaction of at least two oblique surfaces between a sliding element and the slide bed which supports this. For this purpose, a separate sliding element can also be provided.

Im Einzelnen wird diese Führung bei einer bekannten Schieberbaugruppe, welche aus Treiber, Schieberteil und Schieberbett besteht, angewendet, wobei das Schieberteil im Schieberbett gleitend gelagert ist. Zwischen dem Treiber und dem Schieberteil sind Gleitpaarungen angeordnet.Specifically, this guide is applied to a known slider assembly consisting of driver, slider member and slider bed, the slider member being slidably supported in the slider bed. Between the driver and the slide part sliding pairings are arranged.

Bei einer vorteilhaften Weiterbildung wird die Einstellung des Führungsspiels mittels eines gesonderten Bauteils zumindest gesichert, gegebenenfalls auch vorgenommen. Dieses Bauteil wird in einer Einstellrichtung mechanisch auf das Gleitelement und/oder die Gleitelemente, welche die schräge Fläche oder die schrägen Flächen aufweisen, einwirken gelassen. Hierbei kann das Bauteil einerseits einen für die vorgenommene Einstellung spezifizierten Abstand zwischen einem feststehenden Teil des Schieberkörpers und/oder Schieberbetts einerseits und der verstellbaren Gleitfläche andererseits darstellen.In an advantageous development, the setting of the guide clearance by means of a separate component is at least secured, possibly also made. This member is mechanically applied in a direction of adjustment to the sliding member and / or the sliding members having the inclined surface or the inclined surfaces. In this case, on the one hand, the component may represent a distance between a fixed part of the slider body and / or slider bed, on the one hand, and the adjustable sliding surface, specified for the adjustment made.

Darüber hinaus kann erfindungsgemäß das Bauteil selbst keilartig oder keilförmig mit einer Schräge ausgebildet sein, welche mit einer korrespondierenden schrägen Fläche der zu verstellenden Gleitfläche, die Gleitfläche verschiebend zusammenwirkt. In diesem Fall ist für das Bauteil ein Betätigungsmittel vorgesehen, mit welchem das Bauteil in einfacher Weise von außen, die Gleitfläche betätigend, verstellt werden kann. Dies ist insbesondere eine Stellschraube, mit welcher auf das Bauteil, dieses bewegend, relativ zur Gleitfläche eingewirkt werden kann.In addition, according to the invention, the component itself may be wedge-shaped or wedge-shaped with a bevel, which cooperates with a corresponding inclined surface of the sliding surface to be adjusted, the sliding surface displaced. In this case, an actuating means is provided for the component, with which the component in a simple manner from the outside, the sliding surface actuated, can be adjusted. This is in particular an adjusting screw, with which the component, this moving, can be acted upon relative to the sliding surface.

Bei einer insbesondere prismenförmigen bzw. schwalbenschwanzförmigen Ausbildung besitzt beispielsweise das Schieberbett die schwalbenschwanzförmige Ausnehmung zur Aufnahme der schwalbenschwanzförmigen Feder, wobei außenseitig an der schwalbenschwanzförmigen Feder eine Gleitfläche und am Schieberbett zumindest ein Gleitelement ausgebildet ist.In a particular prismatic or dovetail-shaped configuration, for example, the slide bed has the dovetail-shaped recess for receiving the dovetail spring, wherein on the outside of the dovetail spring, a sliding surface and the slide bed at least one sliding element is formed.

Das Gleitelement ist keilartig mit einer Schräge ausgebildet. Diese Schräge ist hierbei an der nutseitigen kurzen Fläche eines L-förmigen Gleitelements ausgebildet, wobei die Nut mit einer korrespondierenden keilartigen Fläche, insbesondere einer korrespondierenden schrägen Fläche ausgebildet ist.The sliding element is wedge-shaped with a bevel. This bevel is in this case formed on the groove-side short surface of an L-shaped sliding element, wherein the groove with a corresponding wedge-like surface, in particular a corresponding oblique surface is formed.

Hierbei können beide Gleitelemente oder nur ein Gleitelement die Schräge aufweisen. Durch Verschieben des Gleitelements entlang der Richtung der Schräge (üblicherweise in Längsrichtung der langgestreckten Gleitleisten) wird das Führungsspiel zwischen dem Schieberbett und dem Schieberkörper verändert.Here, both sliding elements or only one sliding element may have the slope. By moving the sliding element along the direction of the slope (usually in the longitudinal direction of the elongated sliding strips), the guide clearance between the slide bed and the slider body is changed.

Das L-förmige Gleitelement kann hierbei auch aus Einzelgleitelementen, die L-förmig zueinander stehen, ausgebildet sein, was jedoch den Montageaufwand erhöht.The L-shaped sliding element may in this case also be formed of individual sliding elements, which are L-shaped relative to one another, but this increases the assembly effort.

Insbesondere in dem Fall, in dem beide Gleitelemente die Schräge aufweisen, kann durch gegensinniges Verschieben der Gleitleisten bzw. Gleitelemente auch eine Justierung des Schieberbetts zum Schieberkörper erzielt werden.In particular, in the case in which both sliding elements have the slope, an adjustment of the slide bed to the slider body can be achieved by oppositely moving the sliding strips or sliding elements.

Die Erfindung betrifft einen Werkzeugschieber, insbesondere Keiltrieb, zumindest umfassend ein Schieberbett und ein Schieberteil, wobei das Schieberteil am Schieberbett gleitend mit einer Prismenführung angeordnet ist und eine Nut und ein in die Nut ragender Steg vorgesehen sind, wobei zwischen dem Steg und der Nut zumindest ein Gleitelement vorgesehen ist, wobei ein vom Schieberteil abnehmbarer Treiber vorhanden ist und zwischen dem Schieberteil und dem Treiber in aufgesetztem Zustand ebenfalls eine Prismenführung aus schräggestellten Elementen des Schieberkörpers und korrespondierenden schrägen Flächen des Treibers besteht, wobei zwischen dem Schieberbett und dem Schieberkörper eine Prismenführung oder Flachführung derart ausgebildet ist, dass Gleitelemente des Schieberbetts und korrespondierende Gleitelemente des Schieberkörpers mit Bezug auf eine x-Achse geneigt bei einer Prismenführung oder senkrecht bei einer Flachführung angeordnet sind, wobei das Gleitelement zur Nut hin eine keilartige, angeschrägte Fläche besitzt, mit der es auf einer entsprechenden Fläche der Nutwandung aufliegt und die korrespondierende Nutwandung über eine korrespondierende keilartige Anschrägung verfügt, so dass ein axiales Verschieben des Gleitelements entsprechend einer Längsachsenrichtung einen Spalt zwischen Steg und Gleitelement verringert oder vergrößert.The invention relates to a tool slide, in particular wedge drive, at least comprising a slide bed and a slide part, wherein the slide part is slidably disposed on the slide bed with a prism guide and a groove and a protruding into the groove web are provided, wherein between the web and the groove at least one Sliding element is provided, wherein a detachable from the slide part driver is present and between the slide part and the driver in the attached state also a prismatic guide consists of inclined elements of the slider body and corresponding inclined surfaces of the driver, wherein between the slide bed and the slider body a prism guide or flat guide such is formed, that sliding elements of the slider bed and corresponding sliding elements of the slider body are arranged with respect to an x-axis inclined at a prism guide or perpendicular to a flat guide, wherein the Slide member towards the groove has a wedge-like, tapered surface, with which it rests on a corresponding surface of the groove wall and the corresponding groove wall has a corresponding wedge-like chamfer, so that an axial displacement of the sliding element according to a longitudinal axis direction reduces a gap between the web and sliding member or increased.

Die Erfindung betrifft ferner einen Werkzeugschieber, wobei die Gleitelemente L-förmige Gleitleisten oder Gleitplatten sind, welche zur Nutmitte hin weisende Flächen besitzen, mit denen sie einen Zwischenraum zwischen sich begrenzen und zum Schieberkörper hin Gleitflächen besitzen, ausgebildet sind, wobei sich symmetrisch zur Hochachse das Führungsteil oder der Führungssteg nach oben in die Nut hinein erstreckt, wobei der Führungssteg langgestreckte Flächen besitzt, mit denen er an den Flächen der L-förmigen Gleitleisten anliegend ausgebildet ist.The invention further relates to a tool slide, wherein the sliding elements are L-shaped sliding strips or sliding plates, which have the groove center facing surfaces with which they define a space between them and the slider body towards sliding surfaces are formed, being symmetrical to the vertical axis of the Guide member or the guide web upwardly into the groove extends, wherein the guide web has elongated surfaces, with which it is formed adjacent to the surfaces of the L-shaped slide strips.

Zudem betrifft die Erfindung einen Werkzeugschieber, wobei der Führungskörper als langgestrecktes schienen- oder stegartiges Bauteil ausgebildet ist, wobei sich der Steg prismatisch bzw. schwalbenschwanzförmig erweiternd in dem in die Nut hineinragenden Bereich ausgebildet ist, wobei ein Führungsprisma oder eine Schwalbenschwanzführung ausgebildet wird, welches in der Nut lagert, wobei der Steg mit prismatischen Flächen an korrespondierenden Flächen der Gleitleisten in der Nut gelagert ist.In addition, the invention relates to a tool slide, wherein the guide body is formed as an elongated rail or web-like component, wherein the web is prismatic or dovetail widening in the projecting into the groove portion, wherein a guide prism or a dovetail guide is formed, which in the groove superimposed, wherein the web is mounted with prismatic surfaces on corresponding surfaces of the sliding strips in the groove.

Die Erfindung betrifft auch einen Werkzeugschieber, wobei ein Passstück vorhanden ist, welches zwischen einer Wandung des Schieberbetts und einer Wandung des Gleitelements eingesetzt ist und eine definierte Position des Gleitelements hält.The invention also relates to a tool slide, wherein a fitting piece is present, which is inserted between a wall of the slide bed and a wall of the sliding element and holds a defined position of the sliding element.

Weiter betrifft die Erfindung einen Werkzeugschieber, bei dem das Passstück mit einer Schraube am Schieberbett oder dem Gleitelement angeordnet ist.Furthermore, the invention relates to a tool slide, wherein the fitting piece is arranged with a screw on the slide bed or the sliding member.

Zudem betrifft die Erfindung einen Werkzeugschieber, wobei das Passstück zumindest eine keilartige schräge Fläche besitzt, die mit einer schrägen Fläche des Schieberbetts oder einer schrägen Fläche des Gleitelements als Keilantrieb zum Verschieben des Gleitelements korrespondiert.In addition, the invention relates to a tool slide, wherein the fitting piece has at least one wedge-shaped inclined surface which corresponds with an inclined surface of the slide bed or an inclined surface of the sliding element as a wedge drive for displacing the sliding element.

Die Erfindung betrifft auch einen Werkzeugschieber, bei dem das Passstück keilartige schräge Flächen besitzt, die sowohl mit einer schrägen Fläche des Schieberbetts als auch mit einer schrägen Fläche des Gleitelements als Keilantrieb zum Verschieben des Gleitelements korrespondiert.The invention also relates to a tool slide, in which the fitting has wedge-like inclined surfaces which correspond both to an inclined surface of the slide bed and with an inclined surface of the sliding element as a wedge drive for moving the sliding member.

Weiter betrifft die Erfindung einen Werkzeugschieber, wobei zum Einstellen des Führungsspiels das Passstück zwischen einer Kante bzw. Fläche des axial vor oder hinter der Gleitleiste befindlichen Schieberbetts angeordnet. Diese Kante bzw. Fläche ist von einer Stirnfläche der Gleitleiste beabstandet.Furthermore, the invention relates to a tool slide, wherein arranged for adjusting the guide clearance, the fitting piece between an edge or surface of the axially located in front of or behind the slide strip slide bed. This edge or surface is spaced from an end face of the sliding strip.

Die Erfindung betrifft ferner einen Werkzeugschieber, bei dem das Passstück, um es an seinem Ort zu halten, mit einem Festlegungsteil die Kante bzw. Fläche zum Schieberbett hin überkragt, insbesondere im Bereich eines hierfür gebildeten Absatzes und dort mittels einer Schraube festgelegt ist, die sowohl das Passstück durchgreift und nun das Material des Schieberbetts eingeschraubt ist, wodurch der axiale Abstand zwischen der Kante und der Kante festgelegt ist.The invention further relates to a tool slide, wherein the fitting piece to hold it in place, with a fixing part the edge or surface of the slide bed over protrudes, especially in the region of a heel formed for this purpose and is fixed there by means of a screw, both passes through the fitting and now the material of the slide bed is screwed, whereby the axial distance between the edge and the edge is fixed.

Bei einer Ausführungsform der Erfindung ist das Passstück zwischen den Kanten angeordnet, wobei das Passstück zwischen den Kanten beweglich angeordnet ist und der überkragende Bereich und die Stufe beabstandet sind, so dass durch Einschrauben der Schraube das Passstück in den Bereich zwischen die Kanten hinein drückbar angeordnet ist, wobei die gleitleistenseitige Kante bzw. Fläche des Passstücks mit einer Anschrägung derart versehen ist, dass sich das Passstück sich erweiternd ausgebildet ist und/oder die Kante der Gleitleiste mit einer korrespondierenden Schräge derart versehen ist, dass beim Hereindrücken des Passstücks in den Bereich zwischen den Kanten die Gleitleiste verschoben wird, wodurch das Führungsspiel verringert wird.In one embodiment of the invention, the fitting piece is arranged between the edges, wherein the fitting piece is movably arranged between the edges and the overhanging region and the step are spaced, so that by screwing the screw, the fitting piece is arranged in the area between the edges pressed into, wherein the Gleitleistenseitige edge or surface of the fitting is provided with a bevel such that the fitting is formed widening and / or the edge of the slide strip is provided with a corresponding slope such that when you push the fitting into the area between the edges of the slide bar is moved, whereby the guide play is reduced.

Bei einer weiteren Ausführungsform der Erfindung besitzt zum Zwecke des Bewegens des keilförmigen Passstücks bzw. Keils in den keilförmigen Spalt zwischen den Flächen des Schieberbetts und der Gleitleiste hinein und aus diesem heraus, der Keil eine Abkröpfung, welche am Keil derart angeordnet ist, dass das freie Ende der Abkröpfung sich im Bereich des Materials des Schieberbetts oder der Gleitleiste befindet und von einer Schraube durchgriffen wird, welche in der Abkröpfung drehbar gelagert ist, wobei die Schraube mit ihrem Schraubenkopf und/oder mit einer entsprechenden Einrichtung auf den Keil derart einwirkt, dass ein Einschrauben der Schraube in das Schieberbett oder die Gleitleiste den Keil in den Spalt hineinbewegt bzw. herausbewegt.In a further embodiment of the invention has for the purpose of moving the wedge-shaped fitting or wedge in the wedge-shaped gap between the surfaces of the slide bed and the slide bar in and out of this, the wedge has a bend, which is arranged on the wedge such that the free End of the bend is in the range of the material of the pusher bed or the slide bar and is penetrated by a screw which is rotatably mounted in the bend, the screw with its screw head and / or with a corresponding device on the wedge acts such that a Screw the screw into the slide bed or the slide bar moves the wedge into or out of the gap.

Die Erfindung wird anhand einer Zeichnung beispielhaft erläutert. Es zeigen dabei:

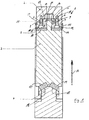

- Figur 1:

- einen erfindungsgemäßen Werkzeugschieber in einer geschnittenen Ansicht;

- Figur 2:

- den

Schieber nach Figur 1 in einer weiteren Ausführungsform in einer teilgeschnittenen Ansicht; - Figur 3:

- das Schieberbett des erfindungsgemäßen Schiebers mit den Einstellungen der Gleitleisten;

- Figur 4:

- den Stellzustand nach

Fig. 3 in einer Ansicht von der Rückseite; - Figur 5:

- das Schieberbett nach

Fig. 3 in einer weiteren Verstellansicht der Leisten; - Figur 6:

- den Stellzustand nach

Fig. 5 in einer Ansicht von der Rückseite; - Figur 7:

- eine weitere Ausführungsform des erfindungsgemäßen Werkzeugschiebers mit einer weiteren Ausführungsform der Einstellung der Gleitleisten;

- Figur 8:

- das Schieberbett in einer Ansicht nach

Fig. 7 von der Rückseite, den Verstellmechanismus in geschlossenem Zustand zeigend; - Figur 9:

- eine weitere teilgeschnittene Ansicht des Werkzeugschiebers nach

Fig. 7 ; - Figur 10:

- eine Ansicht nach

Fig. 9 auf die Rückseite des Werkzeugschiebers in einem offenen Zustand; - Figur 11:

- den erfindungsgemäßen Werkzeugschieber mit einem Passstück zum festlegen der Gleitleiste;

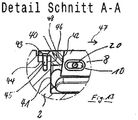

- Figur 12:

- den Werkzeugschieber nach

Fig. 11 in einer Detailansicht entsprechend der Schnittlinie A-A; - Figur 13:

- eine weitere Ausführungsform des Passstücks in einem Werkzeugschieber nach

Fig. 11 mit einer Stellschräge; - Figur 14:

- einen Werkzeugschieber in abgehobenem Zustand mit unten liegendem Treiber, wobei die Prismenführung in nicht festgelegtem Zustand mit Spaltmaßen vorliegt;

- Figur 15:

- der Werkzeugschieber nach

Fig. 11 in zusammengefahrenem Zustand, wobei der fertigungsbedingte Versatz über die Spaltmaße und die Zentrierung auf dem Treiber eingestellt ist; - Figur 16:

- der Werkzeugschieber nach

Fig. 11 in zusammengefahrenem Zustand mit festgelegten Spaltmaßen nach dem Einstellen des Führungsspiels über die einstellbaren Leisten; - Figur 17:

- einen Schieber mit Deckleistenführung nach dem Stand der Technik;

- Figur 18:

- einen Schieber mit Säulenführung nach dem Stand der Technik;

- Figur 19:

- einen Schieber mit Klammerführung nach dem Stand der Technik;

- Figur 20:

- einen Schieber mit Schwalbenschwanzführung nach dem Stand der Technik.

- FIG. 1:

- a tool slide according to the invention in a sectional view;

- FIG. 2:

- the slider behind

FIG. 1 in a further embodiment in a partially sectioned view; - FIG. 3:

- the slide bed of the slide according to the invention with the settings of the slide strips;

- FIG. 4:

- the setting state

Fig. 3 in a view from the back; - FIG. 5:

- the slide bed after

Fig. 3 in a further adjustment view of the strips; - FIG. 6:

- the setting state

Fig. 5 in a view from the back; - FIG. 7:

- a further embodiment of the tool slide according to the invention with a further embodiment of the adjustment of the slide strips;

- FIG. 8:

- the slide bed in a view after

Fig. 7 from the back, showing the adjusting mechanism in the closed state; - FIG. 9:

- another partially cut view of the tool slide after

Fig. 7 ; - FIG. 10:

- a view

Fig. 9 on the back of the tool slide in an open state; - FIG. 11:

- the tool slide according to the invention with a fitting for fixing the slide strip;

- FIG. 12:

- after the tool slide

Fig. 11 in a detailed view corresponding to the section line AA; - FIG. 13:

- a further embodiment of the fitting piece in a tool slide after

Fig. 11 with a setting slope; - FIG. 14:

- a tool slide in the off-hook condition with the driver below, with the prism guide in an unfixed condition with gaps;

- FIG. 15:

- the tool slide after

Fig. 11 in collapsed condition, with the manufacturing offset across gap and centering set on the driver; - FIG. 16:

- the tool slide after

Fig. 11 in collapsed condition with specified gaps after setting the guide clearance over the adjustable strips; - FIG. 17:

- a slider with cover strip guide according to the prior art;

- FIG. 18:

- a slider with column guide according to the prior art;

- FIG. 19:

- a slider with staple guide according to the prior art;

- FIG. 20:

- a slider with dovetail guide according to the prior art.

Ein erfindungsgemäßer Werkzeugschieber 1 besitzt ein Schieberbett 2, einen Schieberkörper 3 und einen Treiber 4.An

Das Schieberteil 3 ist am Schieberbett 2 im gezeigten Fall hängend angeordnet, wobei das Schieberteil 3 vom Treiber 4 abhebbar ist. Der Treiber 4 ist üblicherweise in einer ersten (im gezeigten Fall der unteren) Werkzeughälfte angeordnet, während das Schieberteil 3 über das Schieberbett 2 an einer korrespondierenden zweiten (oberen) Werkzeughälfte (nicht gezeigt) angeordnet ist.The

Das Schieberbett 2 ist in etwa kastenförmig ausgebildet und besitzt eine länglich rechteckige Nut 5, wobei neben der länglich rechteckigen Nut 5 Schraublöcher 6 für die Aufnahme von entsprechenden Schrauben (nicht gezeigt) vorgesehen sind. Die Nut 5 und die benachbarten, die Nut begrenzenden Flächen 7 bilden eine Auflagefläche für L-förmige Gleitleisten 8, welche auf den Flächen 7 aufliegen und sich mit einem L-Schenkel 9 in die Nut 5 hineinerstrecken.The

Die L-förmigen Gleitleisten 8 besitzen Montagelöcher 10 zum Einschrauben von Montageschrauben zur Anordnung in den Schraublöchern 6. Die L-förmigen Gleitleisten 8 besitzen zur Nutmitte hin weisende divergierende Flächen 11, mit denen sie einen prismatischen Zwischenraum zwischen sich begrenzen.The L-shaped wear strips 8 have mounting

Zu den die Nut 5 seitlich begrenzenden Wandungen 19 hin und an diesen anliegend besitzen die L-Schenkel 9 Gleitflächen 22. Die Flächen 22 verlaufen bezogen auf die Dicke der L-Schenkel 9 zwischen der Nutseitenwandung 19 entlang der Längserstreckung der L-förmigen Gleitleisten 8 schräg, sodass die L-Schenkel 9 keilartig oder keilförmig ausgebildet sind. Diese Schräge bzw. Keilform verläuft hierbei mit einem Winkel von 1° bis 5°. Die Nutseitenwandungen 19 sind in korrespondierender Weise mit einer bezogen auf die Längserstreckung Schräge ausgebildet, sodass ein Verschieben der Gleitleisten 8 entsprechend der Längsrichtung die Flächen 11 mehr oder weniger zur Nutmitte hin bewegt.To the

Zum Schieberkörper 3 hin besitzen die L-förmigen Gleitleisten Gleitflächen 12, welche eben und bezüglich einer gezeigten X-Achse 13 senkrecht ausgebildet sind.Towards the

Der Schieberkörper 3 besitzt zu den Flächen 12 hin korrespondierende Gleitflächen bzw. Gleitleisten 14, welche als Gleitpartner zu den L-förmigen Gleitleisten 8 ausgebildet sind.The

Symmetrisch zur Hochachse erstreckt sich zwischen den Gleitleisten 14 ein Führungssteg 15, der insbesondere als Führungsprisma oder Schwalbenschwanz ausgebildet ist, nach oben in die Nut 5 hinein. Das Führungsprisma 15 besitzt dabei langgestreckte prismatische Flächen 16, mit denen es an den Flächen 11 der L-förmigen Gleitleisten 8 anliegt.Symmetrically to the vertical axis extends between the sliding

Dem Treiber zugewandt besitzt der Schieberkörper 3 weitere Gleitleisten 17, welche bezogen auf die X-Achse 13 schräg angeordnet sind und mit prismatischen Führungsflächen 18 des Treibers 4 korrespondieren. Die Leisten 17 bilden, da sie mit dem Schieberkörper verbunden sind, abhebbare Gleitleisten, welche beim Zusammenfahren des Werkzeugoberteils und des Werkzeugunterteils in Wirkverbindung mit den Flächen 18 mitgebracht werden.Facing the driver, the

Da die Führungsflächen der L-förmigen Gleitleisten 8 und die korrespondierenden Flächen 12 der Leisten 14 in Bezug auf die X-Achse 13 senkrecht angeordnet sind und auch senkrecht zum Führungsprisma 15 angeordnet sind, spricht man bei dieser Ausführungsform von einer sogenannten Flachführung.Since the guide surfaces of the L-shaped slide strips 8 and the corresponding

Die schräg gestellten korrespondierenden Gleitelemente 17, 18 zwischen Schieberkörper und Treiber bilden eine sogenannte Prismenführung.The obliquely corresponding sliding

Bei einer weiteren vorteilhaften Ausführungsform (

Das Schieberteil 3 ist am Schieberbett 2 im gezeigten Fall hängend angeordnet, wobei das Schieberteil 3 vom Treiber 4 abhebbar ist. Das Schieberbett 2 ist in etwa kastenförmig ausgebildet und besitzt eine längliche Nut 5. Die Nutseitenwandungen 19, die sich vom Nutboden erstrecken, verlaufen konvergierend und bilden somit eine Schwalbenschwanznut. Die die Nut 5 begrenzenden Flächen 7 konvergieren miteinander. Auf den Flächen 7 liegen L-förmige Gleitleisten 8 auf, welche sich mit einem schmalen, kurzen L-Schenkel 9 in die Nut hinein erstrecken. Die L-förmigen Gleitleisten besitzen zu den Flächen 7 hin Anlageflächen 11 und zum Schieberkörper 3 hin Gleitflächen 12, welche eben und bezüglich einer Hochachse schräg divergierend ausgebildet sind. Diese Flächen 12 gleiten auf entsprechenden Gleitflächen 14 des Schieberkörpers 3.The

Die Gleitflächen 14 des Schieberkörpers 3 sind dementsprechend dachförmig geneigt ausgebildet, wobei sich bezogen auf die Hochachse zentral mittig symmetrisch angeordnet der Führungssteg 15 bzw. schwalbenschwanzförmige Teil des Führungsstegs 15 des Schieberkörpers befindet, wobei an den kurzen L-förmigen Schenkeln 9 der Gleitleisten 8 die prismatischen Flächen 16 anliegend ausgebildet sind. Die Flächen 16 und 14 schließen dabei den in etwa gleichen Winkel ein wie die Flächen 9, 12 und stehen im gezeigten Beispiel in etwa senkrecht aufeinander.The sliding surfaces 14 of the

Da eine exakte Passung und Führung der Werkzeugschieber insbesondere zwischen dem Schieberbett und dem Schieberkörper notwendig ist, muss die Führung des Schieberkörpers im Schieberbett einstellbar sein bzw. müssen die Gleitleisten 8 und das Prisma 15 aufeinander eingestellt werden.Since an exact fit and guidance of the tool slide, in particular between the slide bed and the slider body is necessary, the leadership of the slider body in the slide bed must be adjustable or the slide strips 8 and the

Hierzu sind (

Das Verschieben der Gleitleisten 8 entlang der Richtung 21 ändert noch nichts an gegebenenfalls vorhandenen Spalten oder Abständen zwischen den Oberflächen der Gleitleisten 8 bzw. der L-Schenkel 9 und des Führungsprismas 15. Bezogen auf die Längserstreckung bzw. die Richtungen 21 verlaufen daher die Anlageflächen 22 der L-Schenkel 9 der L-förmigen Gleitleisten analog zur ersten Ausführungsform 8 keilartig bzw. keilförmig. Das bedeutet, dass sie bezogen auf die Längserstreckung ihre Dicke ändern. Die Schräge besitzt beispielsweise eine Steigung von 1-5 Grad.The displacement of the slide strips 8 along the

Die schrägen Anlageflächen 22 an den L-Schenkeln 9 der L-förmigen Gleitleisten 8 sind zu entsprechenden korrespondierenden Flächen 19 der Nut 5 gerichtet.The oblique contact surfaces 22 on the L-legs 9 of the L-shaped sliding

Ein Verschieben entlang der Richtung 21 bewirkt somit, dass aufgrund der schrägen Flächen 22, 19 der Abstand zwischen den Flächen 11 der L-Schenkel 9 und den Flächen 16 des Führungsstegs 15 bzw. Führungsprisma 15 verringert bzw. beseitigt wird. Hierbei können sowohl beide Gleitleisten 8 als auch nur eine Gleitleiste 8 bewegt werden.A displacement along the

Da dies gleichzeitig auf eine Annäherung der Gleitleisten bzw. Entfernung der Gleitleisten in Querrichtung, d.h. der Richtung 23, bewirkt, müssten hierbei die Langlöcher 10 jedoch so ausgebildet sein, dass eine schwimmende Lagerung auch in Richtung 23 um die Schrauben 20 herum ermöglicht wird.Since this at the same time on an approximation of the wear strips or removal of the wear strips in the transverse direction, ie the

Um die Gleitleisten 8 an das Führungsprisma 15 anzupassen und damit auch die exakte Position des Schieberkörpers im Schieberbett anzupassen, kann beispielsweise von einer Anschlagposition der Schrauben 20 in den Langlöchern 10 (

Um eine entsprechende Einstellung des Führungsspiels von außen festzulegen (

Dies bedeutet, dass nach dem Verstellen und Festlegen der Gleitleiste 8 über die Schrauben 20, die in den Langlöchern 10 ruhen, zur Sicherung dieser Einstellung ein passendes Passstück 40 eingesetzt wird.This means that after adjusting and fixing the

Bei einer weiteren vorteilhaften Ausführungsform der Erfindung (

Selbstverständlich ist es auch möglich eine dem Schieberbett zugewandte Kante 48 des Passstücks 40 mit der entsprechenden Schräge auszubilden und dementsprechend die Kante 41 am Schieberbett mit einer korrespondierenden Schräge, die in gleicher Weise wirkt wie die erste Ausführungsform, auszubilden.Of course, it is also possible to form the slider

Insbesondere bei einem schrägen Einbau der Gleitleisten 8 sind die Schrauben 45 von außen gegen Beschädigung hinter die Außenfläche des Schieberbetts 2 zurückgesetzt und trotzdem insbesondere mit einem Winkelschlüssel oder dergleichen Werkzeugen gut zu erreichen.In particular, in an oblique installation of the sliding

Bei einer weiteren vorteilhaften Ausführungsform (

Um den Abstand zwischen der Gleitfläche 11 und einem zwischen den Gleitflächen 11 gelagerten Prismas 15 mit Gleitflächen 16 einzustellen, wird bei dieser Ausführungsform ein korrespondierendes keilförmiges Passstück eingesetzt, welches je nach Ausführung entweder eine schräge Fläche 64 zur Wandung 22 hin oder eine schräge Fläche 65 zur Wandung 19 hin oder zwei schräge Flächen 64, 65 zu schrägen Wandungen 19, 22 hin besitzt. Dieser Keil liegt dementsprechend an diesen Wandungen 19, 22 an und erstreckt sich zwischen die Gleitleiste 8 und die Nut 5.In order to adjust the distance between the sliding

Wird dieser Keil 60 entsprechend einer Bewegungsrichtung 61 in den Spalt zwischen den Flächen 19, 22 hinein- oder herausbewegt, wird dementsprechend die Gleitleiste 8 zur Gänze entweder in Richtung einer Nutmitte 62 bewegt oder entsprechend jeweils den Richtungen 23 von dieser weg bewegt.If this

Um das keilförmige Passstück bzw. den Keil 60 in den Spalt hinein- und aus diesem heraus bewegen zu können, besitzt der Keil 60 eine Abkröpfung 63, welche am Keil derart angeordnet ist, dass das freie Ende der Abköpfung 63 sich im Bereich des Materials des Schiebers und hier insbesondere im Bereich des Schieberbetts 2 befindet. Der abgekröpfte Bereich 63 wird von einer Schraube 66 durchgriffen, welche in der Abkröpfung 63 drehbar gelagert ist. Diese Schraube 66 wirkt mit ihrem Schraubenkopf oder mit einer entsprechenden Einrichtung auf den abgekröpften Bereich 63, sodass ein Einschrauben der Schraube 66 in das Schieberbett 2 (

Bei einer weiteren Ausführungsform ist die Schraube 66 nicht im Schieber, insbesondere im Schieberbett 2, sondern direkt in den Gleitplatten 8 eingeschraubt, was letztlich beim Ein- und Ausschrauben zum gleichen Ergebnis führt.In a further embodiment, the screw 66 is not screwed into the slide, in particular in the

Bei der Erfindung ist von Vorteil, dass durch die von außen einstellbaren und verschiebbaren Gleitleisten eine einfache, jedoch sehr zuverlässige und robuste Verstellmöglichkeit mit guter Erreichbarkeit selbst in sehr engen Einbausituationen erreicht wird, wobei zum Einstellen nicht der gesamte Schieber demontiert werden muss, sondern das Einstellen der Passstücke mit den entsprechenden Schrauben hierfür ausreicht.

Bei der Erfindung ist zudem von Vorteil, dass durch die einstellbaren Gleitleisten und deren L-förmige Form einerseits und das prismatische Führungsprisma 15 auf der anderen Seite eine sehr kompakte, aber auch sehr stabile Führung des Schieberkörpers 3 im Schieberbett 2 erzielt wird und zudem in einfacher Weise geringste Toleranzen einstellbar sind.In the invention it is advantageous that a simple, but very reliable and robust adjustment with good accessibility is achieved even in very tight installation situations by the externally adjustable and sliding wear strips, not adjusting the entire slide must be dismantled, but adjusting the fitting pieces with the appropriate screws sufficient for this.

In the invention it is also advantageous that a very compact, but also very stable guidance of the

- 11

- Werkzeugschiebertool pusher

- 22

- Schieberbettslider bed

- 33

- Schieberkörperslider body

- 44

- Treiberdriver

- 55

- länglich rechteckige Nutoblong rectangular groove

- 66

- Schraublöcherscrew

- 77

- Begrenzungsflächeboundary surface

- 88th

- L-förmige GleitleistenL-shaped sliding strips

- 99

- L-SchenkelL-leg

- 1010

- Montagelöchermounting holes

- 1111

- Anlageflächencontact surfaces

- 1212

- Gleitflächensliding surfaces

- 1313

- X-AchseX axis

- 1414

- GleitleistenWear Strips

- 1515

- Führungsprismaguide prism

- 1616

- langgestreckte prismatische Flächenelongated prismatic surfaces

- 1717

- GleitleistenWear Strips

- 1818

- Gleitflächen am TreiberSliding surfaces on the driver

- 1919

- NutseitenwandungenNutseitenwandungen

- 2020

- Schraubenscrew

- 2121

- Verstellrichtungadjustment

- 2222

- Anlageflächencontact surfaces

- 2323

- Richtungdirection

- 2424

- Mittelliniecenter line

- 2525

- Spaltgap

- 4040

- Passstückspud

- 4141

- Kante/FlächeEdge / surface

- 4242

- Stirnfläche/KanteFace / edge

- 4343

- Festlegungsteilsetting part

- 4444

- Absatzparagraph

- 4545

- Schraubescrew

- 4646

- Kante/FlächeEdge / surface

- 4747

- Pfeilrichtungarrow

- 4848

- Kanteedge

- 5555

- Schraubescrew

- 6060

- Keilwedge

- 6161

- Bewegungsrichtungmovement direction

- 6262

- Nutmittegroove center

- 6363

- Abkröpfungbend

- 6464

- schräge Keilflächeoblique wedge surface

- 6565

- schräge Keilflächeoblique wedge surface

- 6666

- Schraubescrew

Claims (11)

- Tool slide, in particular wedge drive, at least comprising a slide bed (2) and a slide part (3), wherein the slide part (3) is slidably disposed on the slide bed (2) with a prismatic guide and a groove (5) and a web (15) projecting into the groove are provided, wherein at least one sliding element (8) is provided between the web (15) and the groove (5), wherein a driver (4) which can be detached from the slide part (3) is present and between the slide part (3) and the driver in the attached state also a prismatic guide of inclined elements (17) of the slider body (3) and corresponding oblique surfaces (18) of the driver (4) exists, wherein between the slide bed (2) and the slider body (3) a prismatic guide or a flat guide is formed such that sliding elements (8) of the slide bed (2) and corresponding sliding elements (14) of the slider body (3) with respect to an x-axis (13) are disposed inclined in case of a prism guide or perpendicular in case of a flat guide, characterized in that the sliding element (8) has a wedge-like tapered surface (22) towards the groove (5), with which it rests on a corresponding surface (19) of the groove wall (5) and the corresponding groove wall (19) has a corresponding wedge-like bevel so that an axial displacement of the sliding element (8) corresponding to a longitudinal axis direction (23) reduces or enlarges a gap (25) between web (15) and sliding element (8).

- Tool slide according to claim 1, characterized in that the sliding elements are L-shaped sliding strips (8) or sliding plates (8) which have surfaces (11) pointing towards the centre of the groove, with which they define a space between them and have sliding surfaces (12) towards the slider body (3), wherein the guide part (15) or the guide web (15) extends upward into the groove (5), wherein the guide web (15) has elongated surfaces (16), with which it is formed fitting on the surfaces (11) of the L-shaped slide strips (8).

- Tool slide according to claim 1, characterized in that the guide body (15) is formed as an elongated rail or web-like component, wherein the web (15) is formed widening prismatically or in a dovetail-shaped manner in the portion projecting into the groove (5), wherein a prismatic guide or a dovetail guide is formed, which bears in the groove (5), wherein the bar (15) is embedded with prismatic surfaces (16) on corresponding surfaces (11) of the slide bars (8) in the groove (5).

- Tool slide according to one of the preceding claims, characterized in that a fitting piece (40, 60) is present, which is inserted between a wall (19, 41) of the slide bed (2) and a wall of the slide element (8) and holds a defined position of the sliding element (8).

- Tool slide according to one of the preceding claims, characterized in that the fitting piece is arranged on the slide bed (2) or the sliding element (8) with a screw (45, 66).

- Tool slide according to one of the preceding claims, characterized in that the fitting piece has at least one wedge-like inclined surface (64, 65), which corresponds with an inclined surface (19) of the slide bed or an inclined surface (22) of the sliding element (8) as a wedge drive for displacing the sliding member (8).

- Tool slide according to one of the preceding claims, characterized in that the fitting piece (2) has wedge-like oblique surfaces (64, 65) which engage both with an inclined surface (19) of the slide bed (2) and an inclined surface (22) of the sliding element (8) as a wedge drive for displacing the sliding member (8).

- Tool slide according to one of the preceding claims, characterized in that for adjusting the guiding game the fitting piece (40) is disposed between an edge or surface (41) of the slide bed which is disposed axially before or behind the slide bar (8),

wherein the edge or surface is spaced from an end surface (42) of the sliding bar (8). - Tool slide according to one of the preceding claims, characterized in that the fitting piece (40), in order to hold it in place, overhangs the edge or surface (41) towards the slide bed (2) with a fixing part (43), in particular in the region of a ledge (44) formed for this purpose and is fixed there by means of a screw (45), which passes through as well the fitting piece (40) and now is screwed in the material of the slide bed (2), whereby the axial distance between the edge (41) and the edge (42) is fixed.

- Tool slide according to one of the preceding claims, characterized in that the fitting piece (40) is arranged between the edges (41, 42), wherein the fitting piece (40) is arranged to be movable between the edges (41, 42) and the overhanging region (43) and the ledge (44) are spaced apart, so that by screwing the screw (55), the fitting piece (40) is arranged so as to be susceptible to be pushed into the region between the edges (41, 42), wherein the sliding edge side edge or surface (46) of the fitting piece (40) is provided with a bevel such that the fitting piece 40 is formed so that it widens and / or the border 42 of the sliding band (8) is provided with a corresponding bevel such that during pushing of the fitting piece (40) into the region between the edges (41, 42) the sliding piece (8) is displaced, whereby the guiding play is reduced.

- Tool slide according to one of the preceding claims, characterized in that for the purpose of moving the wedge-shaped fitting piece (40) or wedge (60) into or out of the wedge-shaped gap between the surfaces (19, 22) of the slide bed (2) and the slide bar (8), the wedge (60) has a bend (63) which is so arranged on the wedge (60) that the free end of the bend is in the region of the material of the slide bed (2) or the slide band (8) and is penetrated by a screw (66) which rotatably mounted in the bend (63), wherein the screw (66) acts on the wedge (60) with its screw head and / or with a corresponding device such that screwing the screw (66) into the slide bed (2) or the slide band (8) moves the wedge (60) into or out of the gap.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|