EP3020877A1 - Dispositif de rinçage de canalisations de liquides, en particulier des canalisations d'eau potable et/ou sanitaire dans des batiments - Google Patents

Dispositif de rinçage de canalisations de liquides, en particulier des canalisations d'eau potable et/ou sanitaire dans des batiments Download PDFInfo

- Publication number

- EP3020877A1 EP3020877A1 EP15194051.7A EP15194051A EP3020877A1 EP 3020877 A1 EP3020877 A1 EP 3020877A1 EP 15194051 A EP15194051 A EP 15194051A EP 3020877 A1 EP3020877 A1 EP 3020877A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- control module

- module

- flushing

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B9/00—Cleaning hollow articles by methods or apparatus specially adapted thereto

- B08B9/02—Cleaning pipes or tubes or systems of pipes or tubes

- B08B9/027—Cleaning the internal surfaces; Removal of blockages

- B08B9/032—Cleaning the internal surfaces; Removal of blockages by the mechanical action of a moving fluid, e.g. by flushing

- B08B9/0321—Cleaning the internal surfaces; Removal of blockages by the mechanical action of a moving fluid, e.g. by flushing using pressurised, pulsating or purging fluid

- B08B9/0325—Control mechanisms therefor

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03B—INSTALLATIONS OR METHODS FOR OBTAINING, COLLECTING, OR DISTRIBUTING WATER

- E03B7/00—Water main or service pipe systems

- E03B7/07—Arrangement of devices, e.g. filters, flow controls, measuring devices, siphons, valves, in the pipe systems

- E03B7/08—Arrangement of draining devices, e.g. manual shut-off valves

Definitions

- the invention relates to a device for flushing liquid lines, especially drinking and / or service water pipes in buildings.

- the DE 10 2011 013 955 A1 one Method and a device for the automatic rinsing of liquid lines, especially drinking water pipes known.

- the device shown there includes means for measuring the temperature, means for detecting, storing and evaluating the measured temperature and means for performing a rinsing operation, which are arranged together on a base frame, and is relatively complex due to their construction and also requires a relatively large amount of space their assembly.

- the invention has for its object to provide a device of the type specified, on the one hand is very compact and also allows a common as well as separate assembly of rinsing and control components, whereby an individual adaptation to existing space conditions is ensured, and a relatively easy connection to the respective liquid line guaranteed.

- the device according to the invention is formed from a flushing module having a housing and can be connected to the respective fluid line and also a control module having a housing for connection and detection, evaluation or control of shut-off and detection components of at least one flushing module.

- the housings of the flushing module and of the control module are designed to be connectable to one another. Due to the special compact design of the device relatively little space is required for individual installation of the same, which is also ensured by the two individual modules separate mounting the same at different locations.

- the flushing module has a fitting housing with two connection stubs arranged coaxially with one another and a plurality of receiving stubs extending transversely thereto between the connection stubs and receiving bores for the shut-off and detection components extending therein.

- the connection piece at one end of the fitting housing with the respective liquid line for hot or cold liquids is connectable and the connection piece at the other end of the fitting housing opens into a connectable to the public sewer network sewage outlet or in a connectable to a gray water tank greywater outlet.

- the fitting housing may preferably be formed in one piece.

- the shut-off and detection components in the intake ports may be a manual shut-off valve, a temperature sensor, an electromagnetic purge valve, and a volume sensor. Due to the manually operated shut-off valve, the flushing module can be shut off against unintentional flushing under certain conditions.

- the temperature sensor in conjunction with the control module allows a fully automatic flushing of the respective line as a function of the temperature by opening the normally closed electromagnetic flush valve.

- the volume sensor detects the complete flushing volume, wherein after reaching the predetermined by the control module flushing volume, the flush valve is closed.

- connection piece at the other end of the fitting housing and the sewage or greywater outlet a free outlet with two coaxially arranged connection piece can be provided.

- the one connecting piece of the free outlet can be connected to the connecting piece at the other end of the fitting housing and the other connection piece of the free outlet can flow into the sewage or gray water outlet.

- a bell trap can be provided, are avoided by the unpleasant odors from the sewage or gray water outlet.

- the free outlet may preferably have an overflow monitoring device, which may be, for example, a float switch.

- the control module may comprise contact elements and / or connection sockets for at least one temperature sensor, a volume sensor, a flushing valve and an overflow monitoring device.

- the control module can also have contact elements and / or connection sockets for at least one further external temperature sensor and / or a further external volume sensor. This makes it possible to connect a further temperature sensor and / or a further volume sensor, which can or may be provided at any point of the liquid line, to the control module and those obtained from the further temperature sensor and / or a further volume sensor Values to be considered.

- control module can have a USB connection socket, via which the control module can be read out or via which data can be transmitted to the control module. Furthermore, the control module can be connected to a building control device of a building management system via the USB connection socket.

- the housing of the flushing module and the housing of the control module can preferably be formed from a PU foam. This ensures especially in the flushing module for a good sound and heat insulation.

- the housing of the flushing module and the housing of the control module can be connected by means of a plurality of snaps, whereby a fast and accurate connection is ensured.

- At least one longitudinal groove in the region of at least one of the lateral edges may be formed on the front side of the housing of the control module, in which the housing of the flushing module engages in a form-fitting manner with a spring integrally formed on at least one of the lateral edges on the rear side of the housing of the flushing module can.

- the interlocking engagement improves the stability of the two-piece device after assembly of the two housings and increases the strength of the connection.

- a longitudinal groove may be provided on each of the lateral edges of the housing of the control module, wherein on the back of the housing of the flushing module in each case a longitudinal spring may be formed on each of the lateral edges of the housing of the flushing module.

- this allows the flushing module to be connected either to the left or to the right with the control module.

- top and the bottom of the housing of the flushing module and in the top and bottom of the housing of the control module can be formed over a portion of the depth of the housing extending T-groove-like slots, with which an attachment of the device to a wall or on a other place is possible.

- device 1 is provided for flushing liquid lines, especially drinking and / or service water pipes in buildings and provides if necessary, ie in bacteria or germ formation in the water or the like. due, for example, to low water temperatures, for automatic flushing of the respective fluid line.

- the device 1 consists on the one hand of a housing 2 exhibiting and with the respective liquid line (not shown) connectable Spülmodul 3 and on the other hand from a likewise a housing 4 exhibiting control module 5 for connection and detection, for evaluation or control of shut-off and Detection components of at least one flushing module 3.

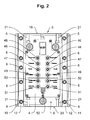

- the in Fig. 1 and 2 and 5 to 7 illustrated control module 5 shows an embodiment thereof for connection and for the detection, evaluation or control of shut-off and detection components for two rinsing modules 3, wherein each flush module 3 takes over the flushing of separate fluid lines (eg a hot water pipe and a cold water pipe).

- the housings 2, 4 of the flushing module 3 and the control module 5, which preferably consist of a PU foam for insulation purposes (sound and temperature), are designed to be connectable to one another.

- the connection of the two housings 2, 4 via a plurality of snaps, the items 6, 7 are held in the PU foam (see in particular Fig. 5 and 6 ).

- An additional backup can be done by means of screws (not shown), which extend through holes 8 in the housing 2 of the flushing module 3 into the housing 4 of the control module 5.

- the particular compact design of the device 1, which requires relatively little space, allows an individual assembly of the same.

- the positive interlocking improves the stability of the two-part device 1 after assembly of the housings 2, 4 and increases the strength of the connection.

- rinsing module 3 In Fig. 1 only one rinsing module 3 is mounted on the right side of the control module 5. The grooves 12 and the springs 16 also allow attachment of the flushing module 3 on the left side of the control module 5.

- the control module 5 shown is, as already mentioned above, however, also provided for receiving two rinsing modules 3, wherein also a stringing or Chaining of several rinsing modules 3 and several control modules 5 with connection options for a rinsing module 3 or two rinsing modules 3 is possible.

- T-slot nuts 23 are inserted into the T-slot slots 21, which clamp over the heads of screws 24 each have a leg 25 of the bracket 22 and the housing 2, 4.

- the flushing module 3 has a preferably integrally formed fitting housing 26 with two coaxially arranged connecting pieces 27, 28 and a plurality of connecting pieces 27, 28 extending transversely thereto receiving socket 29, 30, 31, 32 with therein receiving holes 33, 34, 35, 36 for the shut-off and detection components on.

- the connecting piece 27 at one end of the fitting housing 26 is connectable to the respective liquid line and the connecting piece 28 opens at the other end of the fitting housing 26 in a connectable to the public sewer network sewage outlet or in a connectable to a gray water tank greywater outlet (not shown).

- a free outlet 37 is provided with two coaxially arranged connection piece 38, 39, wherein the one connecting piece 38 of the free outlet 37 with the connecting piece 28 at the other end of the fitting housing 26 is connected and the other connection piece 39 of the free outlet 37 opens into the sewage or gray water outlet.

- a bell trap 40 is provided in the free outlet 37.

- the free outlet 37 has an overflow monitoring device 41, which may be, for example, a float switch.

- a manual shut-off valve 42 in the receiving port 30, a temperature sensor 43, in the receiving port 31, an electromagnetic flush valve 44 and the receiving port 32, a flow sensor 45 is inserted, wherein the arrangement in the valve body 26 of the order corresponding to the previous list of the connecting piece 27 for the respective liquid line to the connecting piece 28 for the free outlet 37 corresponds.

- the control module 5 To connect the shut-off and detection components of the flushing module 3, i. the temperature sensor 43, the electromagnetic flush valve 44 and the volume sensor 45 and the overflow monitoring device 41, with the control module 5, the control module 5 contact elements (not shown) and / or connection sockets 46, 47, 48, 49.

- a further external temperature sensor and / or a further external volume sensor is required, which can or may be provided at any point of the fluid line.

- the control module 5 contact elements (also not shown) and / or connection sockets 50, 51 on.

- control module 5 has a USB connection socket 52 and / or a Bluetooth interface and / or an NFC interface, via which the acquired data can be read out by the control module 5 or can be transmitted to the control module via the presettings.

- the USB port 52 and / or the Bluetooth interface and / or the NFC interface may or may also be used to connect the control module 5 with a building control device of a building control system.

- a flushing process of the respective liquid line can be initiated by the control module 5, taking into account the line usage with respect to the time, the temperature and possibly the volume consumed in the respective liquid line (only with a further external volume sensor). This ensures hygienic operation and optimizes flushing quantities, since all parameters, such as temperature, flushing times and quantities, are recorded in the control module 5.

Landscapes

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Mechanical Engineering (AREA)

- Devices For Dispensing Beverages (AREA)

- Domestic Plumbing Installations (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE202014008946.9U DE202014008946U1 (de) | 2014-11-12 | 2014-11-12 | Vorrichtung zum Spülen von Flüssigkeitsleitungen, insbesondere Trink- und/oder Brauchwasserleitungen in Gebäuden |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3020877A1 true EP3020877A1 (fr) | 2016-05-18 |

| EP3020877B1 EP3020877B1 (fr) | 2020-10-28 |

Family

ID=52106714

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15194051.7A Active EP3020877B1 (fr) | 2014-11-12 | 2015-11-11 | Dispositif de rinçage de canalisations de liquides, en particulier des canalisations d'eau potable et/ou sanitaire dans des batiments |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3020877B1 (fr) |

| DE (1) | DE202014008946U1 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202018003798U1 (de) * | 2018-08-16 | 2019-11-24 | Gebr. Kemper Gmbh + Co. Kg Metallwerke | Spülvorrichtung mit Generator |

| DE102018118334A1 (de) * | 2018-07-30 | 2020-01-30 | Aba Beul Gmbh | Einhebelmischarmatur |

| EP3604698A1 (fr) | 2018-08-01 | 2020-02-05 | ABA Beul GmbH | Procédé et système de rinçage permettant de rincer des réseaux d'alimentation en eau |

| DE102018118910A1 (de) * | 2018-08-03 | 2020-02-06 | Aba Beul Gmbh | Spülmodul und Verfahren zum Spülen von Flüssigkeitsleitungen |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015113886A1 (de) * | 2015-08-21 | 2017-02-23 | Viega Gmbh & Co. Kg | Vorrichtung, System und Verfahren zum selbsttätigen Spülen mit Mehrfachventil |

| DE202016000480U1 (de) | 2016-01-27 | 2016-02-22 | Aba Beul Gmbh | Vorrichtung zum Spülen von Flüssigkeitsleitungen, insbesondere Trink- und/oder Brauchwasserleitungen in Gebäuden |

| DE202016100854U1 (de) * | 2016-02-18 | 2017-05-23 | Uponor Innovation Ab | Sicherungseinrichtung |

| DE202017100660U1 (de) | 2017-02-08 | 2018-05-11 | Viega Technology Gmbh & Co. Kg | Spülvorrichtung für eine Sanitäreinrichtung sowie Toiletten- oder Urinalspülung |

| DK3363956T3 (da) * | 2017-02-17 | 2020-07-20 | Geberit Int Ag | Indretning til automatisk skylning |

| DE102017111074A1 (de) * | 2017-05-22 | 2018-11-22 | Schell Gmbh & Co. Kg | Vorrichtung zur Ableitung von bei der Spülung und/oder thermischen Desinfektion von Rohrleitungen in Sanitärinstallationen anfallenden Spülwassers |

| DE102020000841A1 (de) * | 2019-12-09 | 2021-06-10 | Rico Andres | Spülvorrichtung, System und Verfahren zur Durchführung von Hygienespülungen |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5921270A (en) * | 1997-03-13 | 1999-07-13 | Mccarty; Wilfred L. | Automatic flush system for water lines |

| EP1964983A1 (fr) * | 2007-03-01 | 2008-09-03 | Geberit Technik Ag | Dispositif destiné au lavage automatique de conduites d'eau |

| GB2478124A (en) * | 2010-02-24 | 2011-08-31 | City Water & Environmental Consultants Ltd | Water Sanitary Management System |

| DE102011013955A1 (de) | 2011-03-14 | 2012-09-20 | Viega Gmbh & Co. Kg | Verfahren und Vorrichtung zum selbsttätigen Spülen |

| DE202013102154U1 (de) * | 2013-05-16 | 2014-08-18 | Hans Sasserath Gmbh & Co. Kg | Anordnung zur Durchführung einer Hygienespülung in einer Wasserinstallation |

-

2014

- 2014-11-12 DE DE202014008946.9U patent/DE202014008946U1/de active Active

-

2015

- 2015-11-11 EP EP15194051.7A patent/EP3020877B1/fr active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5921270A (en) * | 1997-03-13 | 1999-07-13 | Mccarty; Wilfred L. | Automatic flush system for water lines |

| EP1964983A1 (fr) * | 2007-03-01 | 2008-09-03 | Geberit Technik Ag | Dispositif destiné au lavage automatique de conduites d'eau |

| GB2478124A (en) * | 2010-02-24 | 2011-08-31 | City Water & Environmental Consultants Ltd | Water Sanitary Management System |

| DE102011013955A1 (de) | 2011-03-14 | 2012-09-20 | Viega Gmbh & Co. Kg | Verfahren und Vorrichtung zum selbsttätigen Spülen |

| DE202013102154U1 (de) * | 2013-05-16 | 2014-08-18 | Hans Sasserath Gmbh & Co. Kg | Anordnung zur Durchführung einer Hygienespülung in einer Wasserinstallation |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018118334A1 (de) * | 2018-07-30 | 2020-01-30 | Aba Beul Gmbh | Einhebelmischarmatur |

| EP3604698A1 (fr) | 2018-08-01 | 2020-02-05 | ABA Beul GmbH | Procédé et système de rinçage permettant de rincer des réseaux d'alimentation en eau |

| DE102018118651A1 (de) * | 2018-08-01 | 2020-02-06 | Aba Beul Gmbh | Verfahren und Spülsystem zum Spülen von Wasserleitungsnetzen |

| DE102018118651A8 (de) * | 2018-08-01 | 2020-04-09 | Aba Beul Gmbh | Verfahren und Spülsystem zum Spülen von Wasserleitungsnetzen |

| DE102018118910A1 (de) * | 2018-08-03 | 2020-02-06 | Aba Beul Gmbh | Spülmodul und Verfahren zum Spülen von Flüssigkeitsleitungen |

| DE202018003798U1 (de) * | 2018-08-16 | 2019-11-24 | Gebr. Kemper Gmbh + Co. Kg Metallwerke | Spülvorrichtung mit Generator |

Also Published As

| Publication number | Publication date |

|---|---|

| DE202014008946U1 (de) | 2014-11-27 |

| EP3020877B1 (fr) | 2020-10-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3020877A1 (fr) | Dispositif de rinçage de canalisations de liquides, en particulier des canalisations d'eau potable et/ou sanitaire dans des batiments | |

| EP2500475B1 (fr) | Procédé et dispositif pur un rinçage automatique des tuyeaux | |

| EP1964983B1 (fr) | Dispositif destiné au lavage automatique de conduites d'eau | |

| EP3337931B1 (fr) | Dispositif et procede destine au lavage automatique de conduites d'eau avec vanne multiple | |

| EP2778560B1 (fr) | Robinetterie de chauffage | |

| DE102013001584A1 (de) | Sanitäranordnung | |

| WO2014029699A1 (fr) | Dispositif de protection contre les fuites | |

| DE102014208261B4 (de) | Trink- und Brauchwassersystem eines Gebäudes und Verfahren zur Steuerung des Trink- und Brauchwassersystems | |

| DE202013102154U1 (de) | Anordnung zur Durchführung einer Hygienespülung in einer Wasserinstallation | |

| EP3208388A1 (fr) | Station de lavage pour un système de circulation en anneau ou en ligne, système de circulation en anneau ou en ligne | |

| AT500673B1 (de) | Mehrwegventil | |

| DE102011008804A1 (de) | Sanitärarmatur | |

| DE202016100854U1 (de) | Sicherungseinrichtung | |

| DE10259664A1 (de) | Geräteanordnung für eine Hausinstallation | |

| DE102007015424A1 (de) | Berührungslos steuerbare Waschtischarmatur | |

| DE102007010963A1 (de) | Wasserübergabesystem | |

| DE102018104571A1 (de) | Mischarmatur | |

| DE102009031044A1 (de) | Anschluss einer sekundären Leitung einer Reinwasser-Hauptversorgungsleitung an ein Dialysegerät oder dergleichen | |

| EP2755014B1 (fr) | Système d'acheminement et de soutirage d'eau sanitaire pour un lavabo et vanne de prélèvement d'échantillons pour un tel système | |

| DE202016000480U1 (de) | Vorrichtung zum Spülen von Flüssigkeitsleitungen, insbesondere Trink- und/oder Brauchwasserleitungen in Gebäuden | |

| DE202009014967U1 (de) | Montageblock für den Anschluss von Geräten | |

| DE102017111073B4 (de) | Vorrichtung zur Spülung und/oder thermischen Desinfektion von Rohrleitungen | |

| AT13751U1 (de) | Vorrichtung zum Ausfiltern von metallischen Kleinteilen aus Flüssigkeiten | |

| EP3406570A1 (fr) | Robinetterie à eau destinée au coupage de l'eau potable traitée | |

| EP2982805A1 (fr) | Piece intercalaire de raccordement multifonctionnelle et ses utilisations |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20161111 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20181213 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20200528 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1328365 Country of ref document: AT Kind code of ref document: T Effective date: 20201115 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502015013700 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20201028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210301 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210128 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210228 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502015013700 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201111 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210128 |

|

| 26N | No opposition filed |

Effective date: 20210729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201228 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201111 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210128 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1328365 Country of ref document: AT Kind code of ref document: T Effective date: 20201111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210228 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201028 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230123 Year of fee payment: 8 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230524 |