EP2945876B1 - Contenant muni d'un dispositif de fermeture - Google Patents

Contenant muni d'un dispositif de fermeture Download PDFInfo

- Publication number

- EP2945876B1 EP2945876B1 EP14700066.5A EP14700066A EP2945876B1 EP 2945876 B1 EP2945876 B1 EP 2945876B1 EP 14700066 A EP14700066 A EP 14700066A EP 2945876 B1 EP2945876 B1 EP 2945876B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- lid

- closing means

- locking means

- closure device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000012459 cleaning agent Substances 0.000 claims description 2

- 238000005406 washing Methods 0.000 claims description 2

- 239000004033 plastic Substances 0.000 description 14

- 229920003023 plastic Polymers 0.000 description 14

- 210000003811 finger Anatomy 0.000 description 11

- -1 polypropylenes Polymers 0.000 description 10

- 239000004743 Polypropylene Substances 0.000 description 7

- 229920001155 polypropylene Polymers 0.000 description 7

- 210000003813 thumb Anatomy 0.000 description 6

- 239000003599 detergent Substances 0.000 description 4

- 210000004247 hand Anatomy 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 3

- 239000013543 active substance Substances 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 239000002655 kraft paper Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 239000004566 building material Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000004851 dishwashing Methods 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 210000005224 forefinger Anatomy 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 229920005604 random copolymer Polymers 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 210000002023 somite Anatomy 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D17/00—Detergent materials or soaps characterised by their shape or physical properties

- C11D17/04—Detergent materials or soaps characterised by their shape or physical properties combined with or containing other objects

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D43/00—Lids or covers for rigid or semi-rigid containers

- B65D43/14—Non-removable lids or covers

- B65D43/16—Non-removable lids or covers hinged for upward or downward movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D43/00—Lids or covers for rigid or semi-rigid containers

- B65D43/14—Non-removable lids or covers

- B65D43/22—Devices for holding in closed position, e.g. clips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D50/00—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures

- B65D50/02—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions

- B65D50/04—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions requiring the combination of simultaneous actions, e.g. depressing and turning, lifting and turning, maintaining a part and turning another one

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2251/00—Details relating to container closures

- B65D2251/10—Details of hinged closures

- B65D2251/1016—Means for locking the closure in closed position

- B65D2251/1033—Protuberances and cavities provided on a horizontal flange respectively of the container or base and the closure, and penetrating one into the other, e.g. of the press-button type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00018—Overall construction of the lid

- B65D2543/00064—Shape of the outer periphery

- B65D2543/00074—Shape of the outer periphery curved

- B65D2543/00101—Shape of the outer periphery curved square-like or rectangular-like

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00018—Overall construction of the lid

- B65D2543/00259—Materials used

- B65D2543/00296—Plastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00435—Lids secured to an intermediate ring or like annular member fixed to the container mouth

Definitions

- the invention relates to a container comprising pre-portioned washing and / or cleaning agents, with a closure device.

- the closure device has a frame and a lid with at least two closing means.

- active substances for example from the group of laundry detergents, dishwashing detergents, pharmaceuticals, personal care products, agricultural auxiliaries, building materials, dyes, adhesives or foodstuffs, in a free-flowing or pourable form or else as predosed quantities, which are e.g. be stored as pre-dosed units in a container.

- plastic containers which may be transparent, inter alia, known.

- closure devices in association with the associated container, often have a frame which defines an opening for withdrawing active substance from the container, which opening can be closed by a lid.

- the lid is typically held in a closed position by one or more closing means.

- the one or more closing means hold the lid in the closed position on the frame, even if other forces act on the frame or on the lid. These forces can elastically deform the closure device and in the worst case undesirably open the closure device. Such forces can z. B. occur during transport, or in the context of mishandling, for example, if a child tries to open the lid in an unintended manner.

- the closing means u. a. easy to use to open the lid in a planned way.

- EP 1 088 769 A1 (Owens-Illinois Clousure) a container which has a closing means on opposite sides of its frame. To the To open containers in a designated manner, the user must use two hands, each hand holding a closure means in the open position while the lid is being tilted up.

- the first and the second closing means can by

- WO 2011/094685 A2 is a packaging for detergent units known.

- the closure means To open the lid of the package, the closure means must be opened by applying force to a tab located in a lid portion and opening it. The opening of the closing means and the lid must not be done simultaneously.

- the closing means holds the lid only in a closed position when the tab is brought by pressing on a frame section back into the closed position.

- US 2009/255 842 A describes a container comprising blister packs with the features of the preamble of claim 1.

- the object of the invention is therefore to provide a generic closure device which is able to hold a lid with a frame securely in a closed position, but still easy to open user-friendly.

- the container comprises pre-portioned detergents and / or cleaners having at least one lateral dimension equal to or greater than 31.7 mm. Preferably these do not fit into a cylinder according to ISO standard 8124-1 (second edition, dated 2009-03-15), 5.2, and thus pass the "small parts test”.

- the closure device includes an opening defining frame and an associated lid, the lid being pivotally coupled to a side of the frame via a pivot axis for pivoting between a closed position and an open position.

- the lid thus closes when changing to the closed position, the corresponding opening in the frame.

- At least a first and a second closing means are provided on the closure device, each comprising a lid portion and a frame portion.

- the closing means hold the lid in the closed position.

- the closure device can only be properly opened when all closing means are in the open position, wherein the first closing means can be opened by direct application of force to the associated frame section and the second closing means can be opened by direct application of force to the associated lid section.

- the first and second closing means are further spaced from one another on the closure device. Furthermore, the first and the second closing means are arranged on a side opposite to the pivot axis of the lid assembly side.

- the closing means are designed and arranged such that a simultaneous actuation of two closing means is usually possible only with both hands of the user.

- the closure device may also comprise, in addition to the first and second closing means, further closing means, which are preferably designed either as the first or the second closing means.

- the direct forces acting on the first, second, or the further closing means are each independent of each other. It follows that the closure device can not be opened in an unintentional manner, for example by children easily. It should be clearly distinguished between opening the entire closure device and opening a single closure means. The scheduled opening of the entire closure device, so that the opening is released, can only be achieved if all the individual closure means are transferred to an open or in an unlocked position.

- the closing means are the first and the second closing means.

- the provision of two closure means provides a simple solution yet provides sufficient closure security for most applications.

- the closing means are the first, the second, and another closing means. With the provision of a third closure means, a higher closure security level of the entire closure device is achieved. Further independent closing means can additionally increase the security against seizing.

- a closing means In the closed position of the lid relative to the frame, a closing means can be brought into an unlocked position of the closing means by the action of force on a lid or frame section associated with the closing means.

- the closing means can be opened only under specific force on specific areas. Unintentional opening of individual closure means or even the entire closure device is thus effectively avoided.

- the user presses, preferably with the thumb of the left hand, on the one of the first Closing means associated frame portion, and at the same time with the thumb of the right hand on the second closure means associated lid portion.

- the pivotal movement of the lid to open this from the closed position is then carried out simultaneously with the right hand.

- the other fingers of both hands can hold the closure device in place.

- the fingers are positioned the other way around and the pivotal movement of the lid is then carried out with the left hand.

- the second closing means is arranged between the first and third closing means.

- the third closing means is preferably designed as the first closing means.

- the shutter device is preferably opened by pushing the user with each one left / right hand finger on the associated frame portions of the outermost (first and third) closing means.

- the user must press simultaneously with the thumb of the right / left hand on the second closure means associated lid portion, the right / left hand also to open the pivotal movement of the lid to this performs.

- Other right / left hand fingers simultaneously hold the device.

- the right / left hand is preferably over the left / right hand to allow the opening of the device by the lid pivoting movement.

- the hand movements can also swap pages, i. be done with the other hand.

- the second closing means is located between the first and third, and the third closing means is analogous to the first (i.e., openable by the action of force on the frame portion).

- the closure device is preferably opened by the user presses with one finger of one hand on the associated frame portion of the first closing means and presses simultaneously with the other hand with thumb and forefinger on the lid and the second closure means associated lid portions and the lid pivoting movement performs. The other hand also holds the closure device.

- the lid is pressed onto the frame with sufficient force to lock the individual closing means.

- the first closing means can be opened by direct application of force to the associated frame section. It is preferred that the associated frame section comprises a corresponding printing surface.

- the second closing means is openable by direct Force on the associated lid section. It is preferred that the associated lid portion comprises a corresponding pressure surface. As a pressure surface (s) in this sense is (are) a (multiple) surface (s) to understand the force.

- the pressure surfaces are configured so that they can be operated with one finger at a time. It is preferable to configure the second closing means such that the lid is transferred from the closing position to the opened position while the user's fingers are in constant contact with the printing surface (s) without interruption.

- the closing means are configured in such a way that the direct application of force to bring a closure means into the open position takes place within a force value range between 0.1 and 15 N, preferably between 1 and 5 N.

- This range of values includes relatively weak forces that the user can comfortably apply to use the closure device.

- the lid portion belonging to the first closing means and the corresponding frame portion each form a snap-in closure. Additionally or alternatively, it makes sense that the lid portion belonging to the second closing means and the corresponding frame portion each form a snap-in lock.

- At least one cover section assigned to a closing means comprises a pressure surface that is set back from an outer wall area of the frame in the direction of the opening. It is preferred that the pressure surface of the second closing means is set back relative to the outer wall area of the lid. In one embodiment of the invention, the pressure surfaces of the closing means, which can be opened by direct application of force on the associated lid portion, are set back relative to the outer wall area of the frame. With recessed pressure surface (s) an increased degree of safety of the closure device is achieved because the closure means can not be actuated without more precise positioning of the force.

- the pressure surface of the first closure means to the outer wall portion of the frame is planar.

- Flat in this case means that the pressure surface and the outer wall portion of the frame are arranged geometrically in a same plane.

- the pressure surfaces and the lid are integrally formed.

- the one-piece design of printing surface and lid reduces the number of components and the number of manufacturing process steps.

- An alternative but less preferred variant is to form the pressure surface as a separate part, which is fastened to the lid during the manufacture of the closure device.

- At least one frame section assigned to a closing means comprises a pressure surface which is planar over an outer wall area of the frame.

- Flat in this case means that the pressure surface and the outer wall portion of the frame are arranged geometrically in the same plane.

- the pressure surfaces and the frame are integrally formed.

- the one-piece design of printing surface and frame reduces the number of components and the number of manufacturing process steps.

- An alternative but less preferred variant is to form the pressure surface as a separate part, which is attached to the lid during the manufacture of the closure device.

- the closure device comprises at least one pressure surface or a surface which is suitable from a hand, preferably a finger, to be acted upon with a force.

- a hand preferably a finger

- all printing surfaces are designed in this way.

- the pressure surface is arranged perpendicular to the lid surface.

- the pressure surface is a lever handle which protrudes from the lid, preferably from the upper edge of the lid.

- At least one pressure surface comprises means for opening.

- the aids can be, for example, elevations and / or depressions. By means of a suitable haptic surface design, the aids allow better adhesive properties to the user's finger or hand. According to a preferred shape, the aids are designed as ribs.

- markings are provided on the closure device, which indicate to a user which closing means can be used to tip up the lid and thus open it.

- suitable labels are e.g. Symbols such as a triangle or an arrow indicating a direction of movement.

- At least one of the closing means comprises a tamper-evident closure. It is further preferred that this closure means comprise a recessed pressure surface such that the tamper-evident closure is planar with the outer wall portion of the frame or lid, preferably the lid, i. is in the same plane.

- the tamper-evident closure is configured in such a way that it must preferably be completely separated from the closure device before the lid is first opened, at least partially broken off.

- first and second closing means mentioned in the description also refer to an optional third or further closing means, if any.

- a third and a further closing means can have the same configuration of the first closing means.

- the third closing means has the structural design of the second closing means.

- the lid is pivotally connected to the frame via a pivot axis disposed on one side of the frame.

- the lid and the frame can advantageously be designed as a one-piece component, preferably made of plastic.

- the lid with the frame typical known variants of pivotal designs may be used, e.g. are also known in conventional household products from the trade.

- the lid and the frame may alternatively be designed as independent parts, preferably as two plastic parts.

- the connection between the lid and the frame may alternatively be designed as independent parts, preferably as two plastic parts.

- the lid and frame are permanently connected to the pivot axis, under normal conditions of use.

- the lid and the frame can also be designed as a one-piece component, preferably made of plastic.

- the frame can be detachably or permanently connected to an associated container.

- the frame is coupled to a container attachable.

- the frame is part of a container and formed integrally therewith, frame and container preferably made of plastic.

- plastic any suitable plastic material can be used, preferably plastics are selected from the group of polyolefins. Particularly preferred are the following plastics from the class of polypropylenes; Polyethylene; Polypropylene-containing blends; Polyethylene-containing blends; Polypropylene-containing co-polymers and / or random co-polymers; Polyethylene-containing co-polymers.

- the container is preferably transparent and may include other parts such as e.g. a label.

- the container is preferably made of polyethylene terephthalate (PET), polypropylene (PP), or their derivative-based plastics.

- the frame preferably contains plastic from the polypropylene class.

- the lid preferably contains plastic from the polypropylene class.

- the lid is colored. If the lid and the frame are integral, it is further preferred that the lid and frame are made of the same colored plastic.

- the proximal distance between two closing means measured at the circumference of the frame is less than 20 cm, more preferably less than 15 cm.

- the maximum distance between the outermost two closing means is less than 15 cm.

- the greatest proximal distance between the outermost two closing means is less than 15 cm, preferably less than 10 cm.

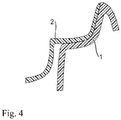

- This embodiment is particularly preferred with a lid which is flush with respect to the frame, so that the lid edge can not be touched for opening. See also Fig. 4 , It is preferred that the closure device is configured such that the lid edge, in the closed position of the closure device, is disposed below the uppermost edge of the frame.

- the pivot axis defines a first side of the closure device.

- the closing means are arranged according to the invention on an arrangement side opposite the pivot axis.

- an arrangement of the individual closing means "over the corner" of the frame is also possible, but not according to the invention.

- a closure means is arranged centrally on an arrangement side opposite the pivot axis.

- both the first and the second closing means are arranged on one half of the arrangement side of the frame opposite the pivot axis.

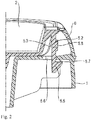

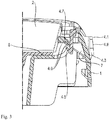

- Fig. 1 shows a container according to the invention (without content) with an embodiment of a closure device 10.

- a lid 2 is pivotally mounted on a frame 1 of the closure device 10, so that a pivot axis 3 is defined.

- the closure device 10 comprises a first 4 and a second closing means 4, 5.

- the closing means 4,5 basically keep the lid in the closed position, not shown.

- Fig.1 shows the open position of the closure device 10.

- the first closing means 4 comprises an associated frame section 4.1 and an associated lid section 4.2.

- the second closing means 5 comprises an associated frame section 5.1 and an associated lid section 5.2.

- the first closing means 4 can be opened by direct application of force to the associated frame section 4.1, which preferably comprises a pressure surface 4.8.

- the second closing means 5 is in turn, by direct force on the associated lid portion 5.2, which preferably comprises a pressure surface 5.8, openable.

- all closing means 4, 5 must be open, ie both the first and the second closing means.

- the user presses, preferably with the thumb of the left hand, on the frame section 4.1 associated with the first closing means 4 and simultaneously with the thumb of the right hand on the lid section 5.2 associated with the second closing means 5.

- the other fingers of both hands can hold the closure device 10 in position.

- the pivoting movement of the lid to open it is then carried out with the right hand.

- the fingers are positioned the other way around and the lid pivot movement is then carried out with the left hand.

- the latching edge 4.7, 5.7 is preferably part of a latching slot 4.6, 5.6.

- the second closing means 5 comprises at least two, more preferably three locking parts.

- the locking parts cooperate with the locking edge 5.7.

- Fig. 4 shows a sketch of a cross section through the lid and frame.

- a lid edge terminates flush with the frame, and preferably below an uppermost edge of the frame (may be more pronounced than shown in the figure). Thus, a force is applied to the lid to open it difficult because an area for the application is not present.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Wood Science & Technology (AREA)

- Organic Chemistry (AREA)

- Closures For Containers (AREA)

Claims (12)

- Récipient avec des produits de lavage et/ou de nettoyage pré-dosés, ayant une dimension latérale supérieure ou égale à 31,7 mm, et avec un dispositif de fermeture (10), qui :- présente un châssis (1) définissant une ouverture (9) et un couvercle (2) recouvrant l'ouverture (9) couplé au châssis de façon inclinable via un axe de pivotement (3) disposé sur un côté du châssis (1), pour passer d'une position fermée, dans laquelle le couvercle (2) scelle l'ouverture (9), à une position ouverte, dans laquelle le couvercle (2) est écarté du châssis (1) et libère ainsi l'ouverture (9), le châssis (1) étant couplé en pouvant être fixé au récipient,- présente au moins un premier et un deuxième systèmes de verrouillage (4, 5), constitués respectivement d'une partie du couvercle (4.2, 5.2) et d'une partie correspondante du châssis (4.1, 5.1), pour maintenir le couvercle (2) en position fermée contre le châssis (1), caractérisé en ce que le premier système de verrouillage (4) peut s'ouvrir par action directe d'une force sur la partie, correspondante du châssis (4.1), le deuxième système de verrouillage (5) peut s'ouvrir par action directe d'une force sur la partie correspondante du couvercle (5.2), et le premier et le deuxième systèmes de verrouillage (4, 5) s'écartent l'un de l'autre,

le premier et le deuxième systèmes de verrouillage (4, 5) étant disposés sur le côté (11) opposé à l'axe de pivotement (3). - Récipient selon la revendication 1, caractérisé en ce qu'un troisième système de verrouillage est prévu dans le dispositif de fermeture (10), qui s'ouvre par action directe d'une force sur une partie assignée du couvercle.

- Récipient selon la revendication 1, caractérisé en ce qu'un troisième système de verrouillage est prévu dans le dispositif de fermeture (10), qui s'ouvre par action directe d'une force sur une partie assignée du châssis.

- Récipient selon une des revendications 1 ou 2, caractérisé en ce que la partie du couvercle (5.2) assignée au deuxième et/ou - dans le cas de la revendication 2 - au troisième système de verrouillage (5) possède une surface dé pression (5.8) destinée à l'action de force, qui est en retrait par rapport à une partie de la paroi externe du châssis (1) dans la direction de l'ouverture (9).

- Récipient selon une des revendications 1 ou 3, caractérisé en ce que la partie du châssis (4.1) assignée au premier et/ou - dans le cas de la revendication 3 - au troisième système de verrouillage (4) possède une surface de pression (4.8) destinée à l'action de force, qui est au même niveau qu'une partie de la paroi externe du châssis (1).

- Récipient selon la revendication 2, caractérisé en ce qu'en outre, le troisième système de verrouillage est disposé du même côté (11) où sont aussi disposés les premiers et deuxièmes systèmes de verrouillage (4, 5).

- Récipient selon l'une des revendications précédentes, caractérisé en ce que respectivement deux systèmes de verrouillage (4, 5) sont disposés sur une partie respective du châssis et une partie respective du couvercle du dispositif de fermeture (10) avec un intervalle inférieur à 20 cm.

- Récipient selon l'une des revendications précédentes, caractérisé en ce que l'intervalle entre le premier et le deuxième système de verrouillage (4, 5) du dispositif de fermeture (10) est inférieur à 15 cm.

- Récipient selon l'une des revendications précédentes, caractérisé en ce que l'intervalle entre le premier et un troisième système de verrouillage du dispositif de fermeture (10) est inférieur à 15 cm.

- Récipient selon l'une des revendications précédentes, caractérisé en ce qu'au moins un des systèmes de verrouillage (4, 5) du dispositif de fermeture (10) comprend une fermeture inviolable.

- Récipient selon l'une des revendications précédentes, caractérisé en ce que le couvercle (2) et le châssis (1) du dispositif de fermeture (10) sont réalisés en une seule pièce.

- Récipient selon l'une des revendications précédentes, caractérisé en ce que le couvercle (2) et le châssis (1) du dispositif de fermeture (10) sont réalisés sous forme de pièces indépendantes.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL14700066T PL2945876T3 (pl) | 2013-01-16 | 2014-01-06 | Pojemnik z urządzeniem zamykającym |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013200532 | 2013-01-16 | ||

| PCT/EP2014/050070 WO2014111284A1 (fr) | 2013-01-16 | 2014-01-06 | Contenant muni d'un dispositif de fermeture |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2945876A1 EP2945876A1 (fr) | 2015-11-25 |

| EP2945876B1 true EP2945876B1 (fr) | 2017-11-01 |

Family

ID=48917546

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14700066.5A Active EP2945876B1 (fr) | 2013-01-16 | 2014-01-06 | Contenant muni d'un dispositif de fermeture |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20150315532A1 (fr) |

| EP (1) | EP2945876B1 (fr) |

| ES (1) | ES2655849T3 (fr) |

| PL (1) | PL2945876T3 (fr) |

| WO (1) | WO2014111284A1 (fr) |

Families Citing this family (43)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013226962A1 (de) * | 2013-12-20 | 2015-06-25 | Henkel Ag & Co. Kgaa | Verschlussvorrichtung |

| DE102014223029A1 (de) | 2014-11-12 | 2016-05-12 | Henkel Ag & Co. Kgaa | Verschlussvorrichtung und Behälter |

| JP6471555B2 (ja) * | 2015-03-18 | 2019-02-20 | 凸版印刷株式会社 | 蓋開閉機構 |

| DE102016215846A1 (de) | 2016-08-23 | 2018-03-01 | Henkel Ag & Co. Kgaa | Verschlussvorrichtung und Behälter mit einer solchen Verschlussvorrichtung |

| US10850897B2 (en) * | 2016-09-28 | 2020-12-01 | Planet Canit, Llc | Container with child-resistant lid release and microdosing |

| US10759576B2 (en) * | 2016-09-28 | 2020-09-01 | The Procter And Gamble Company | Closure interlocking mechanism that prevents accidental initial opening of a container |

| USD818932S1 (en) * | 2016-10-12 | 2018-05-29 | Marcellus Lee Reid | Reinforced covers for storage compartments |

| DE102016222205A1 (de) | 2016-11-11 | 2018-05-17 | Henkel Ag & Co. Kgaa | Verschlussvorrichtung und Behälter mit einer solchen Verschlussvorrichtung |

| CA3061179A1 (fr) | 2017-05-05 | 2018-11-08 | Csp Technologies, Inc. | Recipient comportant des elements adaptes aux seniors et comprenant une securite enfant et son procede d'utilisation et de fabrication |

| USD872478S1 (en) | 2017-06-12 | 2020-01-14 | Yeti Coolers, Llc | Container |

| USD838984S1 (en) | 2017-06-12 | 2019-01-29 | Yeti Coolers, Llc | Container |

| USD872485S1 (en) | 2017-06-12 | 2020-01-14 | Yeti Coolers, Llc | Container |

| USD828029S1 (en) | 2017-06-12 | 2018-09-11 | Yeti Coolers, Llc | Container |

| USD873020S1 (en) | 2017-06-12 | 2020-01-21 | Yeti Coolers, Llc | Container |

| US11685573B2 (en) | 2017-06-12 | 2023-06-27 | Yeti Coolers, Llc | Carry strap for container |

| USD828028S1 (en) | 2017-06-12 | 2018-09-11 | Yeti Coolers, Llc | Container |

| USD840150S1 (en) | 2017-06-12 | 2019-02-12 | Yeti Coolers, Llc | Container |

| CA178734S (en) | 2017-06-12 | 2019-05-31 | Yeti Coolers Llc | Container |

| US12108853B2 (en) | 2019-01-06 | 2024-10-08 | Yeti Coolers, Llc | Luggage system |

| USD838983S1 (en) | 2017-06-12 | 2019-01-29 | Yeti Coolers, Llc | Container |

| US11976498B2 (en) | 2017-06-12 | 2024-05-07 | Yeti Coolers, Llc | Container and latching system |

| AU2018284207B2 (en) | 2017-06-12 | 2023-11-30 | Yeti Coolers, Llc | Container and latching system |

| USD869160S1 (en) | 2017-06-12 | 2019-12-10 | Yeti Coolers, Llc | Container |

| DE102017212589A1 (de) | 2017-07-21 | 2019-01-24 | Henkel Ag & Co. Kgaa | Behälter |

| EP3483087B1 (fr) * | 2017-11-08 | 2020-12-30 | The Procter & Gamble Company | Produit de consommation |

| US10934064B2 (en) | 2017-11-08 | 2021-03-02 | The Procter & Gamble Company | Consumer product that includes a container and unit dose articles |

| EP3489165B1 (fr) | 2017-11-23 | 2022-08-17 | The Procter & Gamble Company | Fermeture pour un récipient présentant une protubérance asymétrique |

| EP3489164B1 (fr) | 2017-11-23 | 2023-01-25 | The Procter & Gamble Company | Fermeture pour un récipient comprenant trois positions |

| JP7046205B2 (ja) * | 2018-03-09 | 2022-04-01 | エム アンド エム インダストリーズ、インコーポレイテッド | チャイルドレジスタンス・ペール |

| USD949086S1 (en) | 2018-05-24 | 2022-04-19 | Stephen Christopher Swift | Reinforced cover for storage compartments |

| USD907445S1 (en) | 2018-12-11 | 2021-01-12 | Yeti Coolers, Llc | Container accessories |

| USD904829S1 (en) | 2018-12-11 | 2020-12-15 | Yeti Coolers, Llc | Container accessories |

| DK3905917T3 (da) | 2019-01-06 | 2023-09-11 | Yeti Coolers Llc | Bagagesystem |

| US12119505B2 (en) | 2019-07-29 | 2024-10-15 | Brightz, ltd. | Multi-purpose battery pack |

| DE102019132879A1 (de) * | 2019-12-03 | 2021-06-10 | Henkel Ag & Co. Kgaa | Papierverpackung mit kindersicherem Verschluss |

| US11040810B1 (en) | 2019-12-10 | 2021-06-22 | Planet Canit, Llc | Self-opening packaging with child-resistant closure |

| USD954436S1 (en) | 2020-06-30 | 2022-06-14 | Yeti Coolers, Llc | Luggage |

| USD963344S1 (en) | 2020-06-30 | 2022-09-13 | Yeti Coolers, Llc | Luggage |

| USD961926S1 (en) | 2020-06-30 | 2022-08-30 | Yeti Coolers, Llc | Luggage |

| USD951643S1 (en) | 2020-06-30 | 2022-05-17 | Yeti Coolers, Llc | Luggage |

| USD994438S1 (en) | 2020-12-16 | 2023-08-08 | Yeti Coolers, Llc | Container |

| USD985937S1 (en) | 2020-12-16 | 2023-05-16 | Yeti Coolers, Llc | Container |

| USD960648S1 (en) | 2020-12-16 | 2022-08-16 | Yeti Coolers, Llc | Container accessory |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3840152A (en) * | 1973-06-18 | 1974-10-08 | None Such Enterprises Inc | Sealable and resealable container |

| FR2429718A1 (en) * | 1978-06-27 | 1980-01-25 | Sono Werkzeug | Box for jewels, medicaments or cosmetic articles - has two pairs of locks each released by thumb and forefinger |

| DE3643599A1 (de) * | 1986-12-19 | 1988-06-30 | Henkel Kgaa | Kindergesicherter deckel einer grosspackung |

| GB8700600D0 (en) * | 1987-01-12 | 1987-02-18 | Reed Packaging Ltd | Lidded container |

| US4746008A (en) * | 1987-07-01 | 1988-05-24 | Heverly Karen H | Child-resistant box for storage of hazardous materials |

| EP0478687B1 (fr) * | 1989-06-23 | 1992-12-23 | WEIDENHAMMER PACKUNGEN KG GMBH & CO | Recipient, notamment pour produits coulants |

| JP2597037Y2 (ja) * | 1993-10-12 | 1999-06-28 | 住友電装株式会社 | 電気接続箱の嵌合構造 |

| EP1505004B1 (fr) * | 2001-08-30 | 2012-07-11 | Yoshino Kogyosho Co., Ltd. | Capuchon de securite et recipient a capuchon de securite |

| JP2005510431A (ja) * | 2001-11-30 | 2005-04-21 | ウエスト・ファーマスーティカル・サービシーズ・インコーポレイテッド | 対小児安全容器 |

| US7549541B2 (en) * | 2005-07-26 | 2009-06-23 | Rexam Closure Systems Inc. | Child-resistant compact for blister card products |

| WO2007065240A1 (fr) * | 2005-12-07 | 2007-06-14 | Intini Thomas D | Emballage |

| US20090255842A1 (en) * | 2008-04-09 | 2009-10-15 | Rexam Closure Systems Inc. | Child-resistant compact for blister card products |

| US20090283437A1 (en) * | 2008-05-14 | 2009-11-19 | Astrazeneca Ab | Item dispenser with multi-section wells |

| GB0901806D0 (en) * | 2009-02-04 | 2009-03-11 | Archimedes Dev Ltd | A child resistant container |

| SE535456C2 (sv) * | 2010-10-18 | 2012-08-14 | Swedish Match North Europe Ab | Barnsäker behållare |

-

2014

- 2014-01-06 ES ES14700066.5T patent/ES2655849T3/es active Active

- 2014-01-06 WO PCT/EP2014/050070 patent/WO2014111284A1/fr active Application Filing

- 2014-01-06 EP EP14700066.5A patent/EP2945876B1/fr active Active

- 2014-01-06 PL PL14700066T patent/PL2945876T3/pl unknown

-

2015

- 2015-07-14 US US14/798,643 patent/US20150315532A1/en not_active Abandoned

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2945876A1 (fr) | 2015-11-25 |

| US20150315532A1 (en) | 2015-11-05 |

| ES2655849T3 (es) | 2018-02-21 |

| WO2014111284A1 (fr) | 2014-07-24 |

| PL2945876T3 (pl) | 2018-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2945876B1 (fr) | Contenant muni d'un dispositif de fermeture | |

| EP2242697B1 (fr) | Couvercle d'un récipient | |

| EP2408683B1 (fr) | Couvercle d'un contenant | |

| DE69319442T2 (de) | Kindergesicherter verschluss mit versenkt eingebauter verriegelung | |

| EP3083427B1 (fr) | Dispositif de fermeture de récipient à couvercle pivotant | |

| DE60217758T2 (de) | Ausgabekapsel mit gesicherter Öffnung | |

| EP0056469A1 (fr) | Charnière pliante en matière plastique à effet déclic | |

| DE20119188U1 (de) | Vorrichtung zur Ausgabe von filmartig dünnen Oblaten aus Nahrungs- oder Erfrischungsmitteln | |

| DE2000413C3 (de) | BehälterverschluB | |

| WO2016075027A1 (fr) | Dispositif de fermeture et récipient | |

| DE19622144C1 (de) | Ausgießelement | |

| WO2018086914A1 (fr) | Dispositif de fermeture et récipient muni d'un tel dispositif de fermeture | |

| DE102006018527B4 (de) | Verschluss für ein Behältnis | |

| DE10361167A1 (de) | Verpackungsbox für Laborgegenstände | |

| EP3504131B1 (fr) | Dispositif de fermeture et récipient muni dudit dispositif de fermeture | |

| EP0868360A1 (fr) | Capuchon de fermeture | |

| EP0597246A2 (fr) | Dispositif d'ouverture sur le couvercle d'un emballage de produits liquides | |

| DE102007035475A1 (de) | Kompakte Kosmetikbox | |

| DE10139852A1 (de) | Box mit einem auf Druck öffnenden Innendeckel | |

| WO2019015984A1 (fr) | Contenant | |

| EP2512949B1 (fr) | Fermeture de récipient à l'épreuve des enfants | |

| EP1240083B1 (fr) | Bouteille en matière plastique | |

| DE202019101663U1 (de) | Schnappverschluss mit Sicherheitsverriegelung | |

| AT525699A1 (en) | Plate with opening aid for cans | |

| WO2008122298A1 (fr) | Bouchon comportant un dispositif indicateur d'ouverture |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20150602 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20161118 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170620 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 941780 Country of ref document: AT Kind code of ref document: T Effective date: 20171115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502014006038 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2655849 Country of ref document: ES Kind code of ref document: T3 Effective date: 20180221 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20171101 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180301 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180202 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502014006038 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 |

|

| 26N | No opposition filed |

Effective date: 20180802 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180106 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180106 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20181218 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20190111 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 941780 Country of ref document: AT Kind code of ref document: T Effective date: 20190106 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190106 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171101 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140106 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171101 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20210602 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200106 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20230124 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20230120 Year of fee payment: 10 Ref country code: DE Payment date: 20230123 Year of fee payment: 10 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230530 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502014006038 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240131 |