EP2867390B1 - Verfahren zur produktion von weissblech, und damit hergestellter gegenstand - Google Patents

Verfahren zur produktion von weissblech, und damit hergestellter gegenstand Download PDFInfo

- Publication number

- EP2867390B1 EP2867390B1 EP13733301.9A EP13733301A EP2867390B1 EP 2867390 B1 EP2867390 B1 EP 2867390B1 EP 13733301 A EP13733301 A EP 13733301A EP 2867390 B1 EP2867390 B1 EP 2867390B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- electrolyte

- tin

- anodic treatment

- treatment

- anodic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Revoked

Links

- 239000005028 tinplate Substances 0.000 title description 36

- 238000004519 manufacturing process Methods 0.000 title description 2

- 238000011282 treatment Methods 0.000 claims description 94

- 229910001887 tin oxide Inorganic materials 0.000 claims description 56

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 claims description 53

- 238000002161 passivation Methods 0.000 claims description 49

- 238000000034 method Methods 0.000 claims description 48

- 239000003792 electrolyte Substances 0.000 claims description 41

- UCKMPCXJQFINFW-UHFFFAOYSA-N Sulphide Chemical compound [S-2] UCKMPCXJQFINFW-UHFFFAOYSA-N 0.000 claims description 31

- 239000000243 solution Substances 0.000 claims description 30

- 238000010186 staining Methods 0.000 claims description 26

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims description 22

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 claims description 20

- 150000001768 cations Chemical class 0.000 claims description 10

- 235000013305 food Nutrition 0.000 claims description 9

- 229910000029 sodium carbonate Inorganic materials 0.000 claims description 9

- 229910019142 PO4 Inorganic materials 0.000 claims description 8

- 229910000831 Steel Inorganic materials 0.000 claims description 8

- 150000001450 anions Chemical class 0.000 claims description 8

- 239000010959 steel Substances 0.000 claims description 8

- 239000010452 phosphate Substances 0.000 claims description 7

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 claims description 6

- 238000003487 electrochemical reaction Methods 0.000 claims description 5

- -1 halogen anions Chemical class 0.000 claims description 5

- 239000000203 mixture Substances 0.000 claims description 5

- 238000004806 packaging method and process Methods 0.000 claims description 5

- 238000012545 processing Methods 0.000 claims description 5

- 229910052723 transition metal Inorganic materials 0.000 claims description 4

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical group [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 claims description 3

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 claims description 3

- JOPOVCBBYLSVDA-UHFFFAOYSA-N chromium(6+) Chemical class [Cr+6] JOPOVCBBYLSVDA-UHFFFAOYSA-N 0.000 claims description 3

- 238000001035 drying Methods 0.000 claims description 3

- 230000000737 periodic effect Effects 0.000 claims description 3

- BTBUEUYNUDRHOZ-UHFFFAOYSA-N Borate Chemical compound [O-]B([O-])[O-] BTBUEUYNUDRHOZ-UHFFFAOYSA-N 0.000 claims description 2

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 claims description 2

- 229910001413 alkali metal ion Inorganic materials 0.000 claims description 2

- 229940077464 ammonium ion Drugs 0.000 claims description 2

- 239000007864 aqueous solution Substances 0.000 claims description 2

- 150000001649 bromium compounds Chemical class 0.000 claims description 2

- 238000006388 chemical passivation reaction Methods 0.000 claims description 2

- 238000005520 cutting process Methods 0.000 claims description 2

- 150000002222 fluorine compounds Chemical class 0.000 claims description 2

- 229910052736 halogen Inorganic materials 0.000 claims description 2

- 229910001848 post-transition metal Inorganic materials 0.000 claims description 2

- 229910021653 sulphate ion Inorganic materials 0.000 claims description 2

- 150000003624 transition metals Chemical class 0.000 claims description 2

- 238000004804 winding Methods 0.000 claims description 2

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 claims 1

- 150000001805 chlorine compounds Chemical class 0.000 claims 1

- 239000010410 layer Substances 0.000 description 61

- 239000011651 chromium Substances 0.000 description 20

- 230000008569 process Effects 0.000 description 18

- 239000004922 lacquer Substances 0.000 description 15

- 238000012360 testing method Methods 0.000 description 9

- 238000000576 coating method Methods 0.000 description 8

- 239000008367 deionised water Substances 0.000 description 8

- 238000007254 oxidation reaction Methods 0.000 description 8

- 229940001593 sodium carbonate Drugs 0.000 description 8

- 239000000126 substance Substances 0.000 description 8

- 238000002474 experimental method Methods 0.000 description 7

- 230000003647 oxidation Effects 0.000 description 7

- 235000021317 phosphate Nutrition 0.000 description 7

- 230000009467 reduction Effects 0.000 description 7

- 230000015572 biosynthetic process Effects 0.000 description 6

- 238000004659 sterilization and disinfection Methods 0.000 description 5

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 4

- 239000002585 base Substances 0.000 description 4

- 238000004090 dissolution Methods 0.000 description 4

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 3

- 239000005864 Sulphur Substances 0.000 description 3

- 238000006243 chemical reaction Methods 0.000 description 3

- ZCDOYSPFYFSLEW-UHFFFAOYSA-N chromate(2-) Chemical class [O-][Cr]([O-])(=O)=O ZCDOYSPFYFSLEW-UHFFFAOYSA-N 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 238000005260 corrosion Methods 0.000 description 3

- 230000007797 corrosion Effects 0.000 description 3

- 238000003869 coulometry Methods 0.000 description 3

- SOCTUWSJJQCPFX-UHFFFAOYSA-N dichromate(2-) Chemical compound [O-][Cr](=O)(=O)O[Cr]([O-])(=O)=O SOCTUWSJJQCPFX-UHFFFAOYSA-N 0.000 description 3

- 239000010408 film Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 238000002203 pretreatment Methods 0.000 description 3

- 150000003839 salts Chemical class 0.000 description 3

- 241000894007 species Species 0.000 description 3

- 239000007921 spray Substances 0.000 description 3

- 238000003860 storage Methods 0.000 description 3

- QHGNHLZPVBIIPX-UHFFFAOYSA-N tin(ii) oxide Chemical class [Sn]=O QHGNHLZPVBIIPX-UHFFFAOYSA-N 0.000 description 3

- AFNRRBXCCXDRPS-UHFFFAOYSA-N tin(ii) sulfide Chemical compound [Sn]=S AFNRRBXCCXDRPS-UHFFFAOYSA-N 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- MBMLMWLHJBBADN-UHFFFAOYSA-N Ferrous sulfide Chemical compound [Fe]=S MBMLMWLHJBBADN-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- JVTAAEKCZFNVCJ-REOHCLBHSA-N L-lactic acid Chemical compound C[C@H](O)C(O)=O JVTAAEKCZFNVCJ-REOHCLBHSA-N 0.000 description 2

- XYQRXRFVKUPBQN-UHFFFAOYSA-L Sodium carbonate decahydrate Chemical compound O.O.O.O.O.O.O.O.O.O.[Na+].[Na+].[O-]C([O-])=O XYQRXRFVKUPBQN-UHFFFAOYSA-L 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 229910052784 alkaline earth metal Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 239000011247 coating layer Substances 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 230000001627 detrimental effect Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 238000007598 dipping method Methods 0.000 description 2

- 230000012010 growth Effects 0.000 description 2

- 238000007602 hot air drying Methods 0.000 description 2

- JVTAAEKCZFNVCJ-UHFFFAOYSA-N lactic acid Chemical compound CC(O)C(O)=O JVTAAEKCZFNVCJ-UHFFFAOYSA-N 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 150000007524 organic acids Chemical class 0.000 description 2

- 235000005985 organic acids Nutrition 0.000 description 2

- 229920000620 organic polymer Polymers 0.000 description 2

- 239000007800 oxidant agent Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 102000004169 proteins and genes Human genes 0.000 description 2

- 108090000623 proteins and genes Proteins 0.000 description 2

- 238000011160 research Methods 0.000 description 2

- 239000011734 sodium Substances 0.000 description 2

- 229940018038 sodium carbonate decahydrate Drugs 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 150000004763 sulfides Chemical class 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 230000004222 uncontrolled growth Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- WRIDQFICGBMAFQ-UHFFFAOYSA-N (E)-8-Octadecenoic acid Natural products CCCCCCCCCC=CCCCCCCC(O)=O WRIDQFICGBMAFQ-UHFFFAOYSA-N 0.000 description 1

- LQJBNNIYVWPHFW-UHFFFAOYSA-N 20:1omega9c fatty acid Natural products CCCCCCCCCCC=CCCCCCCCC(O)=O LQJBNNIYVWPHFW-UHFFFAOYSA-N 0.000 description 1

- BTXXTMOWISPQSJ-UHFFFAOYSA-N 4,4,4-trifluorobutan-2-one Chemical compound CC(=O)CC(F)(F)F BTXXTMOWISPQSJ-UHFFFAOYSA-N 0.000 description 1

- QSBYPNXLFMSGKH-UHFFFAOYSA-N 9-Heptadecensaeure Natural products CCCCCCCC=CCCCCCCCC(O)=O QSBYPNXLFMSGKH-UHFFFAOYSA-N 0.000 description 1

- BQACOLQNOUYJCE-FYZZASKESA-N Abietic acid Natural products CC(C)C1=CC2=CC[C@]3(C)[C@](C)(CCC[C@@]3(C)C(=O)O)[C@H]2CC1 BQACOLQNOUYJCE-FYZZASKESA-N 0.000 description 1

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 1

- 241000251468 Actinopterygii Species 0.000 description 1

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 description 1

- 229910005391 FeSn2 Inorganic materials 0.000 description 1

- 241000282414 Homo sapiens Species 0.000 description 1

- 239000007836 KH2PO4 Substances 0.000 description 1

- 239000005642 Oleic acid Substances 0.000 description 1

- ZQPPMHVWECSIRJ-UHFFFAOYSA-N Oleic acid Natural products CCCCCCCCC=CCCCCCCCC(O)=O ZQPPMHVWECSIRJ-UHFFFAOYSA-N 0.000 description 1

- 244000046052 Phaseolus vulgaris Species 0.000 description 1

- 235000010627 Phaseolus vulgaris Nutrition 0.000 description 1

- 240000004713 Pisum sativum Species 0.000 description 1

- 235000010582 Pisum sativum Nutrition 0.000 description 1

- 229910021607 Silver chloride Inorganic materials 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 description 1

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 1

- 150000001242 acetic acid derivatives Chemical class 0.000 description 1

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- 238000007743 anodising Methods 0.000 description 1

- 239000002518 antifoaming agent Substances 0.000 description 1

- 150000001518 atomic anions Chemical class 0.000 description 1

- 150000001642 boronic acid derivatives Chemical class 0.000 description 1

- 239000008366 buffered solution Substances 0.000 description 1

- 150000004649 carbonic acid derivatives Chemical class 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000001311 chemical methods and process Methods 0.000 description 1

- 150000003841 chloride salts Chemical class 0.000 description 1

- 150000001860 citric acid derivatives Chemical class 0.000 description 1

- 238000005097 cold rolling Methods 0.000 description 1

- 239000013065 commercial product Substances 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 235000005822 corn Nutrition 0.000 description 1

- 230000002596 correlated effect Effects 0.000 description 1

- 230000000875 corresponding effect Effects 0.000 description 1

- 239000007822 coupling agent Substances 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- KPUWHANPEXNPJT-UHFFFAOYSA-N disiloxane Chemical class [SiH3]O[SiH3] KPUWHANPEXNPJT-UHFFFAOYSA-N 0.000 description 1

- MQRJBSHKWOFOGF-UHFFFAOYSA-L disodium;carbonate;hydrate Chemical compound O.[Na+].[Na+].[O-]C([O-])=O MQRJBSHKWOFOGF-UHFFFAOYSA-L 0.000 description 1

- VDQVEACBQKUUSU-UHFFFAOYSA-M disodium;sulfanide Chemical compound [Na+].[Na+].[SH-] VDQVEACBQKUUSU-UHFFFAOYSA-M 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000001978 electrochemical passivation Methods 0.000 description 1

- 238000005868 electrolysis reaction Methods 0.000 description 1

- 239000008151 electrolyte solution Substances 0.000 description 1

- 238000006056 electrooxidation reaction Methods 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 238000009499 grossing Methods 0.000 description 1

- 239000000383 hazardous chemical Substances 0.000 description 1

- ZYCMDWDFIQDPLP-UHFFFAOYSA-N hbr bromine Chemical compound Br.Br ZYCMDWDFIQDPLP-UHFFFAOYSA-N 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- XLYOFNOQVPJJNP-ZSJDYOACSA-N heavy water Substances [2H]O[2H] XLYOFNOQVPJJNP-ZSJDYOACSA-N 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- QXJSBBXBKPUZAA-UHFFFAOYSA-N isooleic acid Natural products CCCCCCCC=CCCCCCCCCC(O)=O QXJSBBXBKPUZAA-UHFFFAOYSA-N 0.000 description 1

- 239000004310 lactic acid Substances 0.000 description 1

- 235000014655 lactic acid Nutrition 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 235000013372 meat Nutrition 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 229910000402 monopotassium phosphate Inorganic materials 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000012299 nitrogen atmosphere Substances 0.000 description 1

- ZQPPMHVWECSIRJ-KTKRTIGZSA-N oleic acid Chemical compound CCCCCCCC\C=C/CCCCCCCC(O)=O ZQPPMHVWECSIRJ-KTKRTIGZSA-N 0.000 description 1

- 239000005008 organosol coating Substances 0.000 description 1

- 238000011056 performance test Methods 0.000 description 1

- 150000002978 peroxides Chemical class 0.000 description 1

- ACVYVLVWPXVTIT-UHFFFAOYSA-M phosphinate Chemical compound [O-][PH2]=O ACVYVLVWPXVTIT-UHFFFAOYSA-M 0.000 description 1

- 150000003013 phosphoric acid derivatives Chemical class 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229920003009 polyurethane dispersion Polymers 0.000 description 1

- GNSKLFRGEWLPPA-UHFFFAOYSA-M potassium dihydrogen phosphate Chemical compound [K+].OP(O)([O-])=O GNSKLFRGEWLPPA-UHFFFAOYSA-M 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 235000021067 refined food Nutrition 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000005201 scrubbing Methods 0.000 description 1

- HKZLPVFGJNLROG-UHFFFAOYSA-M silver monochloride Chemical compound [Cl-].[Ag+] HKZLPVFGJNLROG-UHFFFAOYSA-M 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 229910052979 sodium sulfide Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 238000007655 standard test method Methods 0.000 description 1

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 235000013311 vegetables Nutrition 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 239000000080 wetting agent Substances 0.000 description 1

- 238000004876 x-ray fluorescence Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/48—After-treatment of electroplated surfaces

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C22/00—Chemical surface treatment of metallic material by reaction of the surface with a reactive liquid, leaving reaction products of surface material in the coating, e.g. conversion coatings, passivation of metals

- C23C22/73—Chemical surface treatment of metallic material by reaction of the surface with a reactive liquid, leaving reaction products of surface material in the coating, e.g. conversion coatings, passivation of metals characterised by the process

- C23C22/76—Applying the liquid by spraying

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D11/00—Electrolytic coating by surface reaction, i.e. forming conversion layers

- C25D11/02—Anodisation

- C25D11/34—Anodisation of metals or alloys not provided for in groups C25D11/04 - C25D11/32

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D3/00—Electroplating: Baths therefor

- C25D3/02—Electroplating: Baths therefor from solutions

- C25D3/30—Electroplating: Baths therefor from solutions of tin

Definitions

- the invention relates to a method for forming a passivation layer on an article having at least one tinplated surface having excellent sulphur staining resistance and to an article produced by said method.

- Tin is used to protect the steel base from corrosion both externally (aerobic conditions) and internally when in contact with foods (anaerobic). Under the anaerobic conditions expected inside an internally plain processed food can, tin will normally behave as the sacrificial anode, dissolving very slowly whilst protecting the steel base from corrosion and creating a reducing environment in the can. It is this mechanism that has enabled the plain tinplate can to maintain its long history and proven track record of providing wholesome food on a year round basis and safe storage for long periods of time.

- Some foods especially protein rich meat and fish and, to a lesser extent, vegetables (e.g. peas, beans, corn etc.) contain naturally occurring sulphur compounds. These can react with a plain tinplate surface to give a purple-black stain of tin sulphide. Although the stain is harmless, it may serve to change the passivation of the tinplate surface, which, in turn, could alter the rate of tin uptake. Whilst an overall increase in passivation is more likely to slow tin uptake, localised areas of staining can have a detrimental effect, especially if a corrosion accelerator such as oxygen is also present. Degree of sulphide staining is also influenced by pH, process time and temperature and the presence of certain cations.

- Passivation refers to the chemical treatment applied after tin deposition which stabilises the surface characteristics of tinplate by controlling tin oxide formation and growth.

- Passivation treatments can be electro-chemical or chemical. Electrochemical treatments involve the use of an external electric current. At present, cathodic dichromate (CDC) treatments are usually applied.

- CDC cathodic dichromate

- a CDC treatment is an electrochemical passivation treatment. Chromates are based on hexavalent chromium and these are nowadays considered to be hazardous substances being potentially harmful to the environment and a risk in terms of worker safety. Consequently, intensive research efforts are being made towards developing passivation treatments free from hexavalent chromium, also denoted as Cr(VI)-free passivation treatments.

- the most common method to improve the sulphide staining resistance of Cr(VI)-free passivated tinplate is to increase the thickness of the passivation layer itself (e.g. by using process conditions leading to thicker applied wet films, or by using more concentrated treatment solutions, or by employing longer treatment time, etc.) This leads to enhanced barrier properties, thus suppressing the formation of sulphide stains.

- passivation layers are mechanically weak and the risk of cohesive failure within the passivation layer increases with thickness. Cohesive failure of the passivation layer (in particular during heavy deformation that is encountered in e.g. canmaking) leads to loss of adhesion and delamination of organic coatings that are applied over the passivation layer.

- WO2012097926 discloses a method for electrolytically passivating tinplate by anodic polarisation in an alkalic aqueous electrolyte comprising a watersoluble silicate of composition M 2 O.nSiO 2 , wherein M is an alkalimetal-ion or a quaternary Ammonium-ion and n is a natural number between 0.8 and 7.

- US3616307 discloses a method of anodizing a tin-coated ferrous article by subjecting the article as anode to alectrolysis in an aqueous electrolyte comprising a solution of phospate in which the phosphate radical is present in an amount between 2 and 90 g/l and a hypophosphite in which the hypophosphite radical is present in an amount between 0.5 and 50 g/l at a current density of 8 to 100 asf (86 to 1076 A/m 2 ).

- the layer of tin oxide has to be further coated with a thin film of releasing agent and baked at 450 °F (232 °C) for 2 hours to cure the releasing agent and to stabilise the oxide film.

- US 2010/181201 discloses an electrolyte for passifying tin plated steel consisting of a mixture of organic hydroxyl acids and phenol organic acids

- the object of the invention is to provide a method to improve the sulphide staining resistance of tinplate that has been passivated using Cr(VI)-free passivation systems.

- Another object of the invention is to provide a method to improve the sulphide staining resistance of tinplate that has been passivated using Cr(VI)-free passivation systems that can be integrated into existing electrolitic tinning lines.

- Still another object of the invention is to provide a tinplated article having excellent sulphide staining resistance that is at least similar to that of a cathodic dichromate passivation treatment.

- the invention solves the problem of poor sulphide staining resistance of tinplate by subjecting the tinplate to an anodic treatment in a suitable aqueous electrolyte which is carried out within certain boundaries of treatment time, current density and total charge passed, in order to be effective in achieving the required sulphur staining resistance.

- a very thin layer of tin oxide on the tinplate surface is formed by the electrochemical anodic treatment. This tin oxide layer provides the improvement in sulphide staining resistance and together with the subsequent chemical Cr(VI)-free passivation treatment provides a tinplate which delivers the same, or a better performance than the known CDC-treated tinplate.

- An essential element of the invention is the thickness of the tin oxide layer (D), which is expressed in Coulomb/m 2 and represents the total charge needed to reduce the layer to metallic tin.

- the efficiency thus represents the ratio of the thickness D of the produced oxide layer to the applied charge density (A x t), and can be estimated by plotting D as a function of (A x t).

- the tin oxide layer thickness is determined using a coulometric method.

- the tin oxide layer is reduced by a controlled small cathodic current in a 0.1% solution of hydrobromic acid (HBr) that is freed from oxygen by scrubbing with nitrogen.

- the progress of the reduction of the oxide is monitored by measuring the reduction potential, and the charge passed (A*t) for the complete reduction serves as a measure of the tin oxide layer thickness.

- a cylindrical electrolysis cell is used having a circular aperture of ca. 4 cm diameter on one end. The other end of the cell contains a platinum counter electrode and an Ag/AgCl reference electrode.

- the test specimen covers the aperture, which is sealed using an O-ring to make a water-tight connection of well defined area (13.69 cm 2 in this case), and is tightened into place using an air-pressure cylinder.

- the cell is connected to the electrolyte solution by a flexible tube so that it can be filled and emptied under nitrogen atmosphere.

- a cathodic current density of -0.40 A/m 2 is applied to the sample using a potentiostat-galvanostat, and the potential is measured until the reduction is complete.

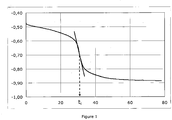

- a typical potential-time curve is shown in Fig. 1 , from which the tin oxide layer thickness is determined based on the inflection point of the potential drop at time t i .

- the sole purpose of the electrolyte is to enable the anodic treatment, not to deposit foreign species contained in the electrolyte onto the substrate surface.

- the pH is not lower than 8.5.

- a suitable maximum pH value is 11 or even 10.5.

- the electrolyte comprises monoatomic cations from Group 1 or 2 from the periodic table or polyatomic cations, and poly-atomic anions.

- Group 1 and Group 2 elements, according to the new IUPAC numbering comprise the alkali metals and the alkali earth metals. It is important that the electrolyte does not contain mono-atomic halogen anions (Group 17) such as Cl - , F - because these anions prevent the tin-oxide layer from forming.

- the article is optionally rinsed and dried before it is passed on to the subsequent step, i.e. the Cr(VI)-free passivation treatment.

- the need to rinse the anodically treated tinplate depends on the exact nature of the Cr(VI)-free passivation system, certain systems will be more susceptible than others to contamination of electrolyte being present on the tinplate surface.

- the Cr(VI)-free passivation system is applied to the anodically treated tinplate surface by application techniques that are common for such passivation systems. Suitable application techniques include: dipping, dipping with squeegee rolls, rotor-spray application, rotor-spray application supported by the use of a smoothing roll, spray application, spray-squeegee application, application by means of a roll coater systems, application by slot coating, slot curtain coating, etc.

- the strip is dried and passed on for final processing steps such as oiling, winding, cutting, etc.

- the total D as specified above can be achieved by any combination of A and t, but a combination of a high current density (A > 0.1 A/dm 2 , preferably A > 1.0 A/ dm 2 ) in combination with a short treatment time (t ⁇ 1 s) is preferred in view of its processability on a high-speed tinning line.

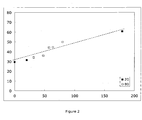

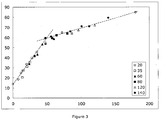

- a and t in the anodic treatment which is further demonstrated in Example 1 and Figures 2 and 3 , implies that the process can be operated at short treatment times, by adjusting the applied current density accordingly.

- the method according to the invention can be employed in industrial tinning lines running at line speeds in excess of 300 m/min to speeds of up to 1000 m/min.

- the anodic treatment is performed in-line with or immediately after electrolytic tinning, and wherein the anodic treatment time (t) is at most 5 seconds, preferably at most 2 seconds, more preferably between 0.05 seconds and 1.5 seconds. This range and the more preferable ranges are consistent with high speeds processing lines.

- the anodic treatment is performed in-line with an industrial electrolytic tinning line, and wherein the current density during the anodic treatment (A) is at least 10 A/m 2 , preferably at least 50 A/m 2 and more preferably at least 100 A/m 2 , and/or at most 4000 A/m 2 , preferably at most 2000 A/m 2 or more preferably at most 1000 A/m 2 . This range and the more preferable ranges are consistent with high speeds processing lines.

- the electrolyte to be employed can be an aqueous solution of an acid, a base or a salt.

- the main function of the electrolyte is to support the electrochemical reaction intended by the anodic treatment while the ionic species present in the electrolyte do not take part in the electrochemical modification of the tinplate surface.

- the preferred electrolyte contains cations from Group 1 (e.g. Na + , K + ) or Group 2 (e.g. Mg 2+ , Ca 2+ ) from the Periodic Table or polyatomic cations (e.g. NH 4 + ), and polyatomic anions (phosphates, borates, sulphates, carbonates and the like).

- the anion may be the conjugate base of an organic acid (e.g. acetates, citrates). Since it is of importance that the pH be maintained within certain boundaries, a buffered solution could be used.

- the electrolyte may contain other chemical additives, such as surfactants, wetting agents, anti-foaming agents etc. to support the electrochemical treatment, provided these additives do not adversely affect the formation of the tin oxide.

- the anodic treatment of the tin-plated surface converts the extreme outer layer of the tin surface from metallic tin into tin oxide by electrochemical oxidation.

- the tin oxide layer produced as such provides a barrier against sulphide staining.

- the tin oxide layer is, however, not sufficiently stable and/or passive in itself and will, during prolonged storage under ambient and/or humid conditions, or during heat treatments such as baking and stoving, continue to grow into a thicker tin oxide layer with undesirable properties (poor wettability, yellowish appearance, poor lacquer adhesion).

- the Cr(VI)-free passivation system If we consider the Cr(VI)-free passivation system on its own, it usually will provide a stable passivation layer protecting the tinplate against uncontrolled growth of tin oxides and furthermore providing good adhesion of organic coatings. However, the Cr(VI)-free passivation layer in almost all investigated cases has a poor resistance against sulphide staining.

- a tin oxide layer of the correct thickness is applied by employing the anodic treatment under proper process conditions, and then the tin oxide layer is passivated and/or stabilised against further uncontrolled growth, by applying a Cr(VI)-free passivation system on top of it, by using a non-electrolytic application method.

- the anodic treatment of the present invention must take place after tinning and/or flow melting and before the application of a Cr(VI)-free passivation system.

- the Cr(VI)-free passivation system before which the anodic treatment is applied must be a chemical passivation treatment, preferably a so-called no-rinse process, for the application of a no-rinse, dry-in-place passivation system.

- the anodic pre-treatment is not expected to work in combination with a Cr(VI)-free passivation system that itself is applied electrolytically.

- the anodic pre-treatment is not expected to work in combination with a Cr(VI)-free passivation system that is applied by a cathodic electrochemical process, since such a process will remove the anodic treatment layer through electrochemical reduction.

- Suitable no-rinse Cr(VI)-free passivation systems that can be used in combination with the anodic treatment of this invention are e.g.:

- the anodic treatment of the present invention is capable of applying the suitable tin oxide layer on a very short time scale (down to 0.1 s), using environmentally friendly chemical solutions, and with a very low energy consumption.

- the method according to the invention also works with a thickness of the tin oxide layer of e.g. 150 or 200 C/m 2 it is preferable for the thickness of the tin oxide layer D to be at most 100 C/m 2 .

- a value above 100 is not possible to achieve economically in the high speed tinplating process and it also leads to a reduced adhesion of subsequently applied organic coatings.

- the preferred range for the tin oxide layer thickness D is therefore 30 to 100 C/m 2 .

- a suitable minimum value of D is 40 C/m 2 .

- a suitable maximum value for D from a process efficiency point of view is 80 C/m 2 or even 60 C/m 2 .

- the polyatomic anion in the electrolyte is a phosphate, a borate, a sulphate, or a carbonate anion.

- the cation in the electrolyte is Na + , K + (Group 1) and/or Ca 2+ (Group 2) and/or polyatomic e.g. NH4 + .

- the article is a strip of packaging steel provided with a tin layer on at least one side (for typical chemical compositions see e.g. EN10202-2001 or ASTM 623M).

- This strip is produced in a known way, e.g. by cold rolling and annealing and optionally temper rolling a steel strip of suitable composition, followed by electrolytic tinplating.

- the article is further provided with an organic coating layer such as epoxy-phenolic gold lacquers, epoxy-anhydride white lacquers, PVC or vinyl organosol coatings, polyester lacquers, epoxy-amino or epoxy-acrylic-amino waterborne coatings.

- an organic coating layer such as epoxy-phenolic gold lacquers, epoxy-anhydride white lacquers, PVC or vinyl organosol coatings, polyester lacquers, epoxy-amino or epoxy-acrylic-amino waterborne coatings.

- This Example describes various lab-scale trials that are aimed to demonstrate the anodic treatment using various electrolytes and process conditions regarding current density A and treatment time t.

- non-passivated tinplate was used.

- the material was produced on an industrial electrolytic tinning line (ETL).

- ETL electrolytic tinning line

- the applied tin coating weight is about 2.8 g/m 2 .

- the amount of free tin is about 1.9 g/m 2 and the amount of FeSn 2 alloy is about 1.1 g/m 2 , corresponding to about 0.9 g/m 2 of tin in the alloy layer.

- the tinplate strip was passed on the coiler while by-passing the chromate passivation section. In this way, non-passivated tinplate without contamination with chromium-residues is obtained.

- the tinplate sample was placed in the electrolyte at 50°C, and connected as the anode to a galvanostat.

- Various current densities in the range 0.2 - 1.4 A/dm 2

- treatment times in the range 0.4 - 9.0 s

- the sample was removed from the electrolyte, rinsed with deionised water and dried at ambient temperature. The tin oxide layer thickness was then determined as described above.

- Figure 1 gives a typical curve of reduction potential (V) as a function of time (t) in a tin oxide reduction experiment.

- Figure 2 gives the tin oxide layer thickness (in C/m 2 ) as a function of the charge passed (A*t) in the anodic treatment using the phosphate solution for different current densities (see legend) and time combinations.

- the dashed line serves as a guide to the eye.

- Figure 3 gives the tin oxide layer thickness (in C/m 2 ) as a function of the charge passed (A*t) in the anodic treatment using the sodium carbonate solution for different current densities and time combinations. For instance, a current density of 120 A/m 2 for 0.4 seconds resulted in the same layer thickness as a current density of 60 A/m 2 for 0.8 seconds.

- the dashed lines serve as guide to the eye. From the different current densities (see legend) and the associated differences in treatment time it is clearly visible that the different combinations of time (t) and current density (A) result in the same tin layer thickness.

- the amount of tin oxide produced in the anodic treatment is a unique function of the charge passed. For a given charge, it does not matter whether this was achieved by e.g. a low current density and a long treatment time or by a high current density and a correspondingly short treatment time. Thus, the process of tin oxidation can be very easily controlled over the total charge passed and, in an industrial process can be made independent of e.g. line speed.

- a Cr(VI)-free passivation treatment was applied to the tinplate using a spray-and-squeegee application unit.

- the passivation solution was a commercial product, denoted GranodineTM 1456, from Henkel AG & Co. KGaA (Düsseldorf, Germany) containing, among other things, fluoro-titanates, fluoro-zirconates and organic polymers.

- a passivation solution containing 150 g/l of GranodineTM 1456 in deionised water was used in the experiments.

- the passivation solution was sprayed onto one side of the strip using an Ahlbrandt IQ-140 Rotorspray system.

- the strip was then passed through a (non-driven) pair of rollers consisting of a stainless steel coater roll and a polyurethane-coated backing roll, in which the applied wet film is homogenised and the excess liquid is squeezed off from the strip.

- a (non-driven) pair of rollers consisting of a stainless steel coater roll and a polyurethane-coated backing roll, in which the applied wet film is homogenised and the excess liquid is squeezed off from the strip.

- the strip is heated to 70°C using an inductive heater and subsequently passed through an air dryer operated at 90°C air temperature.

- the as-received, non-passivated tinplate coils were first passed through the line and were given a cathodic treatment in sodium carbonate using the electrochemical treatment tank. This is done to remove the 'natural' tin oxide layer that has developed on the non-passivated tinplate material during storage. A total cathodic current density of 1.11 A/dm 2 was employed during 0.72 s, giving a total charge density of 80 C/m 2 . Then, the treated coil was placed back on the uncoiler and subjected to the following treatments:

- the amount of tin oxide present on the treated surface was measured directly after preparing the samples, using the coulometric method described above. Then, the samples were stored at ambient temperature in dry air during 14 weeks, after which the tin oxide layer thickness was determined again. If the increase in tin oxide layer thickness during this period is 10 C/m 2 or less, the stability of the tin oxide layer is considered to be adequate.

- Our test method to determine sulphide staining resistance is based on measuring the dissolution rate of tin oxide during exposure to a sulphide solution. It is found that the rate of dissolution of tin oxides correlated strongly with the development of sulphide staining in real-life testing.

- the advantage of our method is that the results can be easily quantified, and offers a better and faster way to investigate sulphide staining as compared to the more commonly used visual observation.

- a particularly convenient method employs a solution containing 5 g/l NaOH and 5 g/l Na 2 S*3H 2 O maintained at 30°C.

- the samples were lacquered with a white-coloured, epoxy-anhydride internal food can lacquer.

- This lacquer is critical regarding adhesion and very discriminating in sterilisation tests and is commonly used in stringent product evaluation.

- the lacquer was applied at 10 - 12 g/m 2 dry coating weight.

- the lacquered panels were sterilised at 121°C during 60 minutes, in the following media:

- Comp.Ex. 1 shows that no treatment at all of the tinplate surface leads to poor tin oxide stability, poor sulphide staining resistance and poor lacquer adhesion.

- Comp.Ex. 2 shows that a Cr(VI)-free passivation treatment stabilises the tin oxide surface, provides excellent lacquer adhesion, but has a poor resistance to sulphide staining.

- Comp.Ex. 3 shows that the anodic treatment of the present invention provides much improved sulphide staining resistance, but since it is applied without further passivation treatment, the tin oxide layer is not stable and lacquer adhesion is poor.

- Inventive Examples 1 - 3 show that the combination of anodic treatment in combination with a Cr(VI)-free passivation treatment leads to the desired combination of improved sulphide staining resistance, a stable tin oxide layer and good lacquer adhesion.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Claims (9)

- Verfahren zum Ausbilden einer Passivierungsschicht auf einem Streifen Verpackungsstahl, versehen mit wenigstens einer verzinnten Oberfläche zum Ausbilden einer Zinnoxidschicht auf der verzinnten Oberfläche, um eine exzellente Beständigkeit gegen Sulfidflecken des Streifens Verpackungsstahl bereitzustellen, für die Herstellung eines Verpackungsbehälters oder einer Dose zum Verpacken von Lebensmitteln, wobei das Verfahren die folgenden Schritte umfasst:- Unterziehen der verzinnten Oberfläche einer anodischen Behandlung bei einem pH-Wert von zwischen 8 und 11,5 in einem geeigneten wässrigen Elektrolyt, wobei der geeignete Elektrolyt eine Phosphatlösung, Boratlösung, Sulfatlösung oder eine Carbonatlösung ist, und wobei der Elektrolyt für die anodische Behandlung keine einatomigen Halogenanionen (Gruppe 17) wie etwa Cl-, F- enthält, wobei die Dicke der Zinnoxidschicht (D), die in Coulomb/m2 ausgedrückt ist und die Gesamtladung repräsentiert, welche zum Reduzieren der Schicht zu metallischem Zinn notwendig ist, bezogen ist auf die Zeit der anodischen Behandlung (t), Stromdichte (A) durch D = E x A x t, wobei E für die Effizienz der elektrochemischen Reaktion steht und wobei D wenigstens 30 C/m2 und höchstens 100 C/m2 beträgt;- wobei der Elektrolyt einatomige Kationen der Gruppe 1 oder 2 des Periodensystems oder mehratomige Kationen, und mehratomige Anionen umfasst;- der Elektrolyt kein wasserlösliches Silikat der Zusammensetzung M2O·nSiO2 umfasst, wobei M ein Alkalimetallion oder ein quartäres Ammoniumion ist und n eine natürliche Zahl zwischen 0,8 und 7 ist;- wobei die anodische Behandlung auf einem industriellen Verzinnungsband durchgeführt wird, das mit einer Bandgeschwindigkeit von über 300 m/min betrieben wird;- wobei die anodische Behandlung in einem Durchgang mit oder sofort nach der Elektrolytverzinnung durchgeführt wird, und wobei die Zeit der anodischen Behandlung (t) höchstens 5 Sekunden beträgt;- optionales Spülen und Trocknen der anodisch behandelten verzinnten Oberfläche- Unterziehen der anodisch behandelten verzinnten Oberfläche einer chemischen Passivierungsbehandlung, die ohne die Verwendung hexavalenter Chromverbindungen erfolgt- Trocknen der passivierten anodisch behandelten verzinnten Oberfläche- abschließende Bearbeitung, wie etwa Ölen, Wickeln, Schneiden usw.

- Verfahren nach Anspruch 1, wobei D höchstens 80 C/m2 beträgt.

- Verfahren nach einem der vorhergehenden Ansprüche, wobei der pH-Wert des Elektrolyts für die anodische Behandlung nicht über 8,5 liegt.

- Verfahren nach einem der vorhergehenden Ansprüche, wobei der pH-Wert des Elektrolyts für die anodische Behandlung nicht über 11,0, vorzugsweise nicht über 10,5 liegt.

- Verfahren nach einem der vorhergehenden Ansprüche, wobei der Elektrolyt für die anodische Behandlung eines oder mehrere von Na+, K+, Mg2+, Ca2+, NH4 + enthält.

- Verfahren nach einem der vorhergehenden Ansprüche, wobei der Elektrolyt für die anodische Behandlung keine- einatomigen Anionen wie etwa Fluoride, Chloride, Bromide und/oder keine- Kationen von oder enthaltend Innen-Übergangsmetalle(n), Übergangsmetalle(n) und Post-Übergangsmetalle(n) enthält.

- Verfahren nach einem der vorhergehenden Ansprüche, wobei der Elektrolyt für die anodische Behandlung hauptsächlich aus einer Lösung aus Natriumcarbonat besteht, vorzugsweise mit einem pH-Wert von zwischen 10 und 11,5.

- Verfahren nach einem der vorhergehenden Ansprüche, wobei die Zeit der anodischen Behandlung (t) höchstens 2 Sekunden, vorzugsweise zwischen 0,05 Sekunden und 1,5 Sekunden beträgt.

- Verfahren nach einem der vorhergehenden Ansprüche, wobei die anodische Behandlung in einem Durchgang mit einem industriellen elektrolytischen Verzinnungsband durchgeführt wird, und wobei die Stromdichte während der anodischen Behandlung (A) wenigstens 10 A/m2, vorzugsweise wenigstens 50 A/m2 und stärker bevorzugt wenigstens 100 A/m2 und/oder höchstens 4000 A/m2, vorzugsweise höchstens 2000 A/m2 oder stärker bevorzugt höchstens 1000 A/m2 beträgt.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RS20171072A RS56562B1 (sr) | 2012-07-02 | 2013-07-02 | Postupak za proizvodnju belog lima i proizvod proizveden njime |

| EP13733301.9A EP2867390B1 (de) | 2012-07-02 | 2013-07-02 | Verfahren zur produktion von weissblech, und damit hergestellter gegenstand |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12174561 | 2012-07-02 | ||

| PCT/EP2013/063912 WO2014006031A1 (en) | 2012-07-02 | 2013-07-02 | Method for producing tinplate and product produced therewith |

| EP13733301.9A EP2867390B1 (de) | 2012-07-02 | 2013-07-02 | Verfahren zur produktion von weissblech, und damit hergestellter gegenstand |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2867390A1 EP2867390A1 (de) | 2015-05-06 |

| EP2867390B1 true EP2867390B1 (de) | 2017-09-06 |

Family

ID=48745951

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13733301.9A Revoked EP2867390B1 (de) | 2012-07-02 | 2013-07-02 | Verfahren zur produktion von weissblech, und damit hergestellter gegenstand |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2867390B1 (de) |

| ES (1) | ES2644868T3 (de) |

| RS (1) | RS56562B1 (de) |

| WO (1) | WO2014006031A1 (de) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013107505A1 (de) * | 2013-07-16 | 2015-01-22 | Thyssenkrupp Rasselstein Gmbh | Verfahren zum Auftragen einer wässrigen Behandlungslösung auf die Oberfläche eines bewegten Stahlbands |

| DE102013109801B4 (de) * | 2013-09-09 | 2020-07-09 | Thyssenkrupp Rasselstein Gmbh | Mit einer Polymerbeschichtung beschichtetes Weißblech und Verfahren zu dessen Herstellung |

| CN103840106B (zh) * | 2014-02-26 | 2016-01-13 | 江苏安博瑞新材料有限公司 | 铝箔的浸润方法及其浸润池、电池包装膜的制造方法 |

| CN104562120A (zh) * | 2015-01-23 | 2015-04-29 | 张家港市新港星科技有限公司 | 一种带钢镀锡的方法 |

| EP3318337A1 (de) * | 2016-11-03 | 2018-05-09 | PPG Industries Ohio, Inc. | Beschichtungszusammensetzung und beschichtungssystem |

| CN108796584B (zh) * | 2017-04-28 | 2020-08-25 | 宝山钢铁股份有限公司 | 一种镀锡产品表面钝化膜结构柔性控制方法 |

| CA3162200C (en) * | 2019-12-20 | 2024-04-16 | Jan Paul Penning | Method for manufacturing laminated tinplate, a laminated tinplate produced thereby and use thereof |

| KR20220153008A (ko) * | 2020-03-13 | 2022-11-17 | 타타 스틸 이즈무이덴 베.뷔. | 양철 스트립 부동태화 방법 및 부동태화된 양철 스트립의 제조 장치 |

| DE102021125696A1 (de) * | 2021-10-04 | 2023-04-06 | Thyssenkrupp Rasselstein Gmbh | Verfahren zur Passivierung der Oberfläche eines Weißblechs und Elektrolysesystem zur Durchführung des Verfahrens |

| EP4276219A1 (de) * | 2022-05-09 | 2023-11-15 | Atotech Deutschland GmbH & Co. KG | Verfahren zur nasschemischen herstellung einer stabilen zinnoxidschicht für leiterplatten (pcbs) |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2858004A1 (en) | 2012-01-12 | 2013-07-18 | Thyssenkrupp Rasselstein Gmbh | Method for passivating tinplate |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB416608A (en) * | 1933-07-25 | 1934-09-18 | John Campbell | Improvements in or relating to the colouring of tin and tin alloys and articles madetherefrom applicable also to protecting same against corrosion |

| US3616307A (en) * | 1969-05-16 | 1971-10-26 | Bethlehem Steel Corp | Process and composition for anodizing a tincoated article |

| CA1162504A (en) * | 1980-11-25 | 1984-02-21 | Mobuyuki Oda | Treating tin plated steel sheet with composition containing titanium or zirconium compounds |

| ITTO20030027A1 (it) * | 2003-01-21 | 2004-07-22 | Europa Metalli Spa | Metodo per formare uno strato di passivazione su un articolo presentante almeno una superficie stagnata. |

| DE102005045034A1 (de) * | 2005-09-21 | 2007-03-29 | Rasselstein Gmbh | Verfahren zur Passivierung der Oberfläche von beschichteten Metallbändern und Vorrichtung für das Aufbringen der Passivschicht auf ein metallisch beschichtetes Stahlband |

| US20100181201A1 (en) * | 2009-01-20 | 2010-07-22 | Bibber John W | Electrolytic passivated tin plated steel |

| DE102011002836A1 (de) * | 2011-01-18 | 2012-07-19 | Henkel Ag & Co. Kgaa | Vorbehandlung von Weißblech vor einer Lackierung |

-

2013

- 2013-07-02 EP EP13733301.9A patent/EP2867390B1/de not_active Revoked

- 2013-07-02 ES ES13733301.9T patent/ES2644868T3/es active Active

- 2013-07-02 WO PCT/EP2013/063912 patent/WO2014006031A1/en active Application Filing

- 2013-07-02 RS RS20171072A patent/RS56562B1/sr unknown

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2858004A1 (en) | 2012-01-12 | 2013-07-18 | Thyssenkrupp Rasselstein Gmbh | Method for passivating tinplate |

| WO2013104530A2 (de) * | 2012-01-12 | 2013-07-18 | Thyssenkrupp Rasselstein Gmbh | VERFAHREN ZUR PASSIVIERUNG VON WEIßBLECH |

Also Published As

| Publication number | Publication date |

|---|---|

| RS56562B1 (sr) | 2018-02-28 |

| WO2014006031A1 (en) | 2014-01-09 |

| ES2644868T3 (es) | 2017-11-30 |

| EP2867390A1 (de) | 2015-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2867390B1 (de) | Verfahren zur produktion von weissblech, und damit hergestellter gegenstand | |

| CN103108988B (zh) | 容器用钢板及其制造方法 | |

| EP2551377B1 (de) | Verfahren zur herstellung eines stahlblechs für einen container | |

| TWI418653B (zh) | A method for producing a steel sheet for a container material having a low environmental burden, a method for producing the same, and a method for producing the same, | |

| TWI439573B (zh) | A method for producing a steel sheet for a container material having a low environmental burden, a steel sheet for a container material having a small environmental burden, a precoated steel sheet for a laminated steel sheet and a container material for use in the container material | |

| CN103097581A (zh) | 容器用钢板的制造方法 | |

| JP5842988B2 (ja) | 容器用鋼板 | |

| EP3284850B1 (de) | Stahlblech für behälter und verfahren zur herstellung eines stahlblechs für behälter | |

| KR20020087461A (ko) | 합금화 용융아연도금강판 및 그 제조방법 | |

| CN107683351B (zh) | 容器用钢板及容器用钢板的制造方法 | |

| EP3260580B1 (de) | Stahlblech für einen behälter und verfahren zur herstellung eines stahlblechs für einen behälter | |

| JP6098763B2 (ja) | Snめっき鋼板及び化成処理鋼板並びにこれらの製造方法 | |

| CN105814240A (zh) | 容器用钢板及其制造方法 | |

| KR20220153008A (ko) | 양철 스트립 부동태화 방법 및 부동태화된 양철 스트립의 제조 장치 | |

| CN110938852B (zh) | 镀锡钢板的钝化工艺 | |

| JP2002356785A (ja) | 耐酸化性の優れた錫めっき鋼板およびその製造方法 | |

| JP7554805B2 (ja) | ブリキの表面を不動態化する方法およびこの方法を実施するための電解システム | |

| WO2016121277A1 (ja) | 表面処理鋼板の製造方法 | |

| EP4168610A1 (de) | Passivierungsverfahren für eine stahlzinnplatte, passivierte zinnplatte und beschichtete passivierte zinnplatte | |

| JP5678817B2 (ja) | 錫めっき鋼板の製造方法 | |

| WO2023195252A1 (ja) | 表面処理鋼板およびその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20150202 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20160914 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20170222 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 926037 Country of ref document: AT Kind code of ref document: T Effective date: 20170915 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602013026153 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2644868 Country of ref document: ES Kind code of ref document: T3 Effective date: 20171130 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171206 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 926037 Country of ref document: AT Kind code of ref document: T Effective date: 20170906 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171207 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602013026153 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180106 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: ARCELORMITTAL FRANCE RESEARCH & DEVELOPMENT INTELL Effective date: 20180530 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180702 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180702 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: ARCELORMITTAL FRANCE RESEARCH & DEVELOPMENT INTELL Effective date: 20180530 |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180702 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130702 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170906 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170906 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SK Payment date: 20210618 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20210622 Year of fee payment: 9 Ref country code: NL Payment date: 20210726 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RS Payment date: 20210621 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20210721 Year of fee payment: 9 Ref country code: FR Payment date: 20210727 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20210802 Year of fee payment: 9 Ref country code: GB Payment date: 20210727 Year of fee payment: 9 Ref country code: BE Payment date: 20210727 Year of fee payment: 9 Ref country code: DE Payment date: 20210728 Year of fee payment: 9 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R103 Ref document number: 602013026153 Country of ref document: DE Ref country code: DE Ref legal event code: R064 Ref document number: 602013026153 Country of ref document: DE |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MGE |

|

| 27W | Patent revoked |

Effective date: 20220215 |

|

| GBPR | Gb: patent revoked under art. 102 of the ep convention designating the uk as contracting state |

Effective date: 20220215 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MC4A Ref document number: E 25650 Country of ref document: SK Effective date: 20220215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY; INVALID AB INITIO Effective date: 20130702 |