EP2851321B1 - Paper sheet gathering device - Google Patents

Paper sheet gathering device Download PDFInfo

- Publication number

- EP2851321B1 EP2851321B1 EP13790159.1A EP13790159A EP2851321B1 EP 2851321 B1 EP2851321 B1 EP 2851321B1 EP 13790159 A EP13790159 A EP 13790159A EP 2851321 B1 EP2851321 B1 EP 2851321B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- component

- paper sheet

- stacking

- vanes

- gathering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 230000037431 insertion Effects 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H39/00—Associating, collating, or gathering articles or webs

- B65H39/02—Associating,collating or gathering articles from several sources

- B65H39/06—Associating,collating or gathering articles from several sources from delivery streams

- B65H39/065—Associating,collating or gathering articles from several sources from delivery streams by collecting in rotary carriers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/20—Delivering or advancing articles from machines; Advancing articles to or into piles by contact with rotating friction members, e.g. rollers, brushes, or cylinders

- B65H29/22—Delivering or advancing articles from machines; Advancing articles to or into piles by contact with rotating friction members, e.g. rollers, brushes, or cylinders and introducing into a pile

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/38—Delivering or advancing articles from machines; Advancing articles to or into piles by movable piling or advancing arms, frames, plates, or like members with which the articles are maintained in face contact

- B65H29/40—Members rotated about an axis perpendicular to direction of article movement, e.g. star-wheels formed by S-shaped members

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/70—Article bending or stiffening arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H31/00—Pile receivers

- B65H31/02—Pile receivers with stationary end support against which pile accumulates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2220/00—Function indicators

- B65H2220/09—Function indicators indicating that several of an entity are present

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/42—Piling, depiling, handling piles

- B65H2301/421—Forming a pile

- B65H2301/4214—Forming a pile of articles on edge

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/50—Auxiliary process performed during handling process

- B65H2301/51—Modifying a characteristic of handled material

- B65H2301/512—Changing form of handled material

- B65H2301/5121—Bending, buckling, curling, bringing a curvature

- B65H2301/51214—Bending, buckling, curling, bringing a curvature parallel to direction of displacement of handled material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2404/00—Parts for transporting or guiding the handled material

- B65H2404/60—Other elements in face contact with handled material

- B65H2404/65—Other elements in face contact with handled material rotating around an axis parallel to face of material and perpendicular to transport direction, e.g. star wheel

- B65H2404/655—Means for holding material on element

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2408/00—Specific machines

- B65H2408/10—Specific machines for handling sheet(s)

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/10—Handled articles or webs

- B65H2701/19—Specific article or web

- B65H2701/1912—Banknotes, bills and cheques or the like

Definitions

- the present application relates to a paper sheet gathering device, and particularly to a paper sheet gathering device that conveys paper money, checks, paper representing value and the like with vanes of stacking wheels.

- the paper sheet gathering device refers to a device that conveys paper sheets (such as paper money, checks and paper representing value) at a predetermined number (for example, 100) and gathers the same at a gathering component.

- paper sheets such as paper money, checks and paper representing value

- a predetermined number for example, 100

- the paper sheet gathering device paper sheets conveyed continuously are received between two adjacent vanes of the stacking wheel and thus are rotationally conveyed, such that the paper sheets are dropped and stacked on the gathering component.

- the paper sheets are supplied with power by conveying wheels, and are receives between any two vanes of the stacking wheel longitudinally or transversely, such that the paper sheets are rotationally conveyed with the rotation of the stacking wheel until they are conveyed to the gathering component for stacking.

- head portions of the paper sheet are interposed between root portions of the two adjacent vanes of the stacking wheel, while tail portions of the paper sheets are protruded out of the conveying wheel and are rotated, together with the head portions of the paper sheets, along with the stacking wheel.

- EP 0 104 383 A1 discloses a paper sheet gathering device according to the preamble of claim 1.

- An object of the present application is to provide a paper sheet gathering device which achieves the reliable reception of the paper sheets between wheel vanes, and can avoid the straggle of the paper sheets received between the wheel vanes, such that the paper sheets are uniformly aligned and are stacked on a gathering component.

- the present application provides a paper sheet gathering device including a conveying component, a clamping component, a guiding component and a gathering component which are connected with each other in sequence.

- the conveying component is configured for conveying the paper sheet to the clamping component.

- the clamping component includes a driving shaft and a plurality of stacking wheels fixedly connected to the driving shaft, and each stacking wheel has a plurality of vanes which have equal radians, thereby the paper sheet can be clamped between any two adjacent vanes and be rotationally conveyed to the guiding component.

- the guiding component is configured for receiving the paper sheet conveyed by the clamping component, and guiding and conveying the paper sheet to the gathering component.

- the gathering component is configured for gathering paper sheets conveyed by the guiding component.

- vanes of the plurality of stacking wheels have different radians.

- At least the vane of one of the plurality of stacking wheels has a different radian from those of the rest of the plurality of stacking wheels.

- the plurality of stacking wheels have the same vane opening direction.

- the paper sheet can be reliably received between adjacent vanes.

- the surface of the received paper sheet can be formed with convex-concave folds, thereby the friction force between the vane and the paper sheet is increased, which can effectively prevent the paper sheet from moving away from the vanes of the stacking wheel.

- the paper sheet can be uniformly aligned and stacked on the gathering component. Meanwhile the straggle of the paper sheets is avoided.

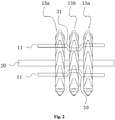

- the paper sheet gathering device 16 is a device for receiving paper sheet 11 such as paper money, checks and paper representing value longitudinally or transversely, the paper sheet gathering device 16 includes a conveying component, a clamping component, a guiding component 12 and a gathering component 15 which are connected with each other in sequence.

- the conveying component includes a pair of conveying rollers (10, 10') for conveying the paper sheet 11 to the clamping component.

- the clamping component includes a driving shaft and three stacking wheels 13 fixed to the driving shaft.

- Each stacking wheel 13 has a plurality of vanes 14 which have equal radians.

- the paper sheet 11 can be clamped by any two adjacent vanes, and is conveyed, with the rotation of the stacking wheel, to the guiding component.

- the guiding component 12 is configured for receiving the paper sheet 11 conveyed by the clamping component, and guiding and conveying the paper sheet to the gathering component 15.

- the gathering component 15 is configured for gathering the paper sheet 11 conveyed by the guiding component 12.

- the operating principle of the present application is as follows: paper sheets 11 are continuously supplied to the stacking wheel 13 one by one at a certain speed and in a predetermined direction by the pair of conveying rollers (10, 10'). Then the paper sheets 11 are conveyed one by one with the rotation of the stacking wheel 13, and are then conveyed by the guiding component while right and left sides of the paper sheets 11 are abutted on the guiding component 12. In this way, the paper sheets 11 are moved along the guiding component 12 which is inclined downward in the midcourse of the conveying. Finally, the paper sheets 11 are moved away from the stacking wheel 13 and are gathered on the gathering component 15 under their own weights.

- the three stacking wheels 13 includes: a pair of stacking wheels, that is, a first stacking wheel 13a and a second stacking wheel 13a, having the same radian and fixed to the driving shaft 20 at an interval narrower than the width of the paper sheet 11; and a third stacking wheel 13b fixed to the driving shaft 20.

- the phase of the third stacking wheel 13b is the same with that of the first and the second stacking wheels 13a, but the radian of vanes 14b of the third stacking wheel 13b is different from that of vanes 14a of the first and the second stacking wheels 13a, while the opening radians are the same, so as to ensure the smooth insertion of the paper sheet 11.

- the present application is characterized in that the third stacking wheel 13b is configured in a manner that it has the same phase as that of the first and the second stacking wheels 13a and has a radian different from that of the first and the second stacking wheels 13a.

- the paper sheet 11 moved into intervals between adjacent vanes 14a of the first and the second stacking wheels 13a is formed with an upwardly protruded convex fold 30 or a downwardly protruded concave fold 31 at the middle portion of the paper sheet 11 under the action of the vane 14b of the third stacking wheel 13b.

- the paper sheet 11 received between the vanes 14a is rotationally conveyed in a state that a certain friction force is applied thereon by the convex fold 30 and the concave fold 31, which can prevent the paper sheet 11 from being moved away from the vanes 14 of the first, second and third stacking wheels 13 easily while being rotationally conveyed, and thus preventing the straggle of the paper sheets 11 being rotationally conveyed.

- the distance between tops of adjacent vanes 14a of the first and second stacking wheels 13a along the outer circumference is designed as p; the vanes of the third stacking wheel 13b are designed to have the same phase as that of the vanes of the first and second stacking wheels 13a; and the vanes 14b of the third stacking wheel 13b are designed to have a radian different from that of the vanes 14a of the first and second stacking wheels 13a, with the minimum thereof being a half pitch, i.e., 1/2p, while the radians of the openings are the same or slightly different, so as to ensure the smooth insertion of the paper sheets 11.

- the minimum distance of the radian is not limited to the half pitch 1/2p, the same effect can be obtained in cases that the minimum distance of the radian is designed to be smaller or larger than the half pitch 1/2p.

- the shape of the radian is not limited to the present application, and may have any shape.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Pile Receivers (AREA)

- Discharge By Other Means (AREA)

- Delivering By Means Of Belts And Rollers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210153172.3A CN102658991B (zh) | 2012-05-17 | 2012-05-17 | 一种纸张类聚积装置 |

| PCT/CN2013/073169 WO2013170661A1 (zh) | 2012-05-17 | 2013-03-26 | 一种纸张类聚积装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2851321A1 EP2851321A1 (en) | 2015-03-25 |

| EP2851321A4 EP2851321A4 (en) | 2016-05-25 |

| EP2851321B1 true EP2851321B1 (en) | 2017-06-21 |

Family

ID=46768618

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13790159.1A Not-in-force EP2851321B1 (en) | 2012-05-17 | 2013-03-26 | Paper sheet gathering device |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20140327206A1 (enExample) |

| EP (1) | EP2851321B1 (enExample) |

| CN (1) | CN102658991B (enExample) |

| AU (1) | AU2013262326B2 (enExample) |

| CL (1) | CL2014001271A1 (enExample) |

| IN (1) | IN2014MN00909A (enExample) |

| WO (1) | WO2013170661A1 (enExample) |

| ZA (1) | ZA201403546B (enExample) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102658991B (zh) * | 2012-05-17 | 2014-12-31 | 广州广电运通金融电子股份有限公司 | 一种纸张类聚积装置 |

| EP2778105B1 (de) * | 2013-03-11 | 2016-10-26 | Wincor Nixdorf International GmbH | Vorrichtung und Verfahren zum Befüllen eines Transportbehälters mit Wertscheinen |

| ES2576112T3 (es) * | 2013-10-09 | 2016-07-05 | Wincor Nixdorf International Gmbh | Dispositivo y procedimiento para llenar un recipiente de transporte flexible con documentos de valor |

| CN106927284B (zh) * | 2015-12-31 | 2019-05-21 | 上海东冠纸业有限公司 | 一种餐巾纸机点纸装置 |

| CN106327714A (zh) * | 2016-08-25 | 2017-01-11 | 广州御银科技股份有限公司 | 一种钞票暂存结构 |

| CN107856997B (zh) * | 2017-12-13 | 2023-03-10 | 广州明森科技股份有限公司 | 一种转盘式卡片存储装置 |

| CN107914973B (zh) * | 2017-12-13 | 2023-11-10 | 广州明森科技股份有限公司 | 一种转盘以及包含该转盘的卡片存储机构 |

| CN107867496B (zh) * | 2017-12-13 | 2023-03-10 | 广州明森科技股份有限公司 | 一种转盘式卡片储存设备 |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3232348A1 (de) * | 1982-08-31 | 1984-03-01 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Vorrichtung zum stapeln von blattfoermigen gegenstaenden |

| US5040663A (en) * | 1988-06-02 | 1991-08-20 | Paper Converting Machine Company | Apparatus and method for stacking |

| JP2753386B2 (ja) * | 1990-11-19 | 1998-05-20 | 株式会社日立製作所 | 紙葉類堆積装置 |

| ITBO20000475A1 (it) * | 2000-07-31 | 2002-01-31 | Cat System S R L | Dispositivo per la separazione di gruppi di foglietti in una apparecchiatura per la formazione e la fascettatura di gruppi di fogli , quali |

| JP4791631B2 (ja) * | 2000-12-26 | 2011-10-12 | 株式会社東芝 | 紙葉類処理装置 |

| JP2002308508A (ja) * | 2001-04-13 | 2002-10-23 | Fuji Electric Co Ltd | 紙葉類収納装置 |

| US6832886B2 (en) * | 2001-07-27 | 2004-12-21 | C. G. Bretting Manufacturing Co., Inc. | Apparatus and method for stacking sheets discharged from a starwheel assembly |

| JP3880503B2 (ja) * | 2002-10-16 | 2007-02-14 | 日立オムロンターミナルソリューションズ株式会社 | 紙葉類集積繰出装置 |

| JP2005335949A (ja) * | 2004-04-30 | 2005-12-08 | Komori Corp | 排紙装置 |

| JP4265544B2 (ja) * | 2005-01-28 | 2009-05-20 | 沖電気工業株式会社 | 羽根車 |

| JP4495645B2 (ja) * | 2005-07-19 | 2010-07-07 | グローリー株式会社 | 紙幣搬送装置 |

| US7591468B2 (en) * | 2007-07-02 | 2009-09-22 | Xerox Corporation | Low noise compile paddles |

| JP5119133B2 (ja) * | 2008-11-20 | 2013-01-16 | 日立オムロンターミナルソリューションズ株式会社 | 紙葉類集積繰出装置 |

| JP5141577B2 (ja) * | 2009-01-27 | 2013-02-13 | 沖電気工業株式会社 | 紙葉類分離集積機構 |

| JP5385179B2 (ja) * | 2010-02-26 | 2014-01-08 | 富士通フロンテック株式会社 | 紙葉類集積装置 |

| CN201838068U (zh) * | 2010-11-01 | 2011-05-18 | 魏伟 | 一种点验钞机 |

| CN202025373U (zh) * | 2010-12-31 | 2011-11-02 | 南京理工速必得科技股份有限公司 | 基于纸币票面特征图像获取的点验钞机 |

| DE102011010923A1 (de) * | 2011-02-10 | 2012-08-16 | Giesecke & Devrient Gmbh | Vorrichtung zum Stapeln von Blattgut |

| CN202067306U (zh) * | 2011-06-02 | 2011-12-07 | 浙江维融电子有限公司 | 点钞机 |

| CN102431823B (zh) * | 2011-08-31 | 2014-08-27 | 新达通科技股份有限公司 | 一种薄片介质传送机构 |

| CN102658991B (zh) * | 2012-05-17 | 2014-12-31 | 广州广电运通金融电子股份有限公司 | 一种纸张类聚积装置 |

-

2012

- 2012-05-17 CN CN201210153172.3A patent/CN102658991B/zh active Active

-

2013

- 2013-03-26 WO PCT/CN2013/073169 patent/WO2013170661A1/zh not_active Ceased

- 2013-03-26 US US14/353,540 patent/US20140327206A1/en not_active Abandoned

- 2013-03-26 AU AU2013262326A patent/AU2013262326B2/en not_active Ceased

- 2013-03-26 IN IN909MUN2014 patent/IN2014MN00909A/en unknown

- 2013-03-26 EP EP13790159.1A patent/EP2851321B1/en not_active Not-in-force

-

2014

- 2014-05-14 CL CL2014001271A patent/CL2014001271A1/es unknown

- 2014-05-15 ZA ZA2014/03546A patent/ZA201403546B/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| EP2851321A1 (en) | 2015-03-25 |

| CL2014001271A1 (es) | 2014-09-05 |

| AU2013262326A1 (en) | 2014-05-29 |

| AU2013262326B2 (en) | 2015-08-20 |

| ZA201403546B (en) | 2015-07-29 |

| WO2013170661A1 (zh) | 2013-11-21 |

| CN102658991A (zh) | 2012-09-12 |

| IN2014MN00909A (enExample) | 2015-04-17 |

| CN102658991B (zh) | 2014-12-31 |

| US20140327206A1 (en) | 2014-11-06 |

| EP2851321A4 (en) | 2016-05-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2851321B1 (en) | Paper sheet gathering device | |

| JP5385179B2 (ja) | 紙葉類集積装置 | |

| WO2014070279A3 (en) | Endwall contouring | |

| US7329219B2 (en) | Folding apparatus in a web-fed rotary printing press | |

| US7914433B2 (en) | Folding roller and corresponding folding device | |

| DK201170173A (en) | Device and system for harvesting the energy of a fluid stream comprising | |

| US8496249B2 (en) | Method and apparatus for diverting printed products into three streams | |

| EP3148908B1 (en) | Air vortex assisted sheet flipping device | |

| CN102627201A (zh) | 自动分片机 | |

| CA2005731A1 (en) | Apparatus for assembling and depositing signatures | |

| JP6611644B2 (ja) | 紙葉類集積機構及び紙葉類処理装置 | |

| WO2014074190A3 (en) | Endwall contouring | |

| WO2012079065A3 (en) | Orbiting cam drive mechanism, pitch changing device and method | |

| CN105156630B (zh) | 变矩器 | |

| EP3120016B1 (en) | Crossflow axes rotary mechanical devices with dynamic increased swept area | |

| CN209514691U (zh) | 出票机 | |

| EP3621794B1 (de) | Vorrichtung zum fertigen eines dreidimensionalen verpackungserzeugnisses, wie eines polsterproduktes, aus einer ein- oder mehrlagigen papierbahn | |

| JP2019523199A (ja) | 案内ローラー及びいくつかのローラーを備えた輸送装置 | |

| US20150061221A1 (en) | Stacker Wheel for Stacking Sheets | |

| EP3597580B1 (en) | Device for transporting flexible sheets | |

| US9193193B2 (en) | Transmission device for plotters | |

| JPS6397571A (ja) | 紙葉類集積装置 | |

| US8413977B2 (en) | Device and method for delivering printed products from a saddle-shaped support | |

| CN209514692U (zh) | 出票机 | |

| CN209514690U (zh) | 出票机 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140410 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602013022623 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: B65H0029220000 Ipc: B65H0029700000 |

|

| RA4 | Supplementary search report drawn up and despatched (corrected) |

Effective date: 20160421 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B65H 31/02 20060101ALI20160415BHEP Ipc: B65H 29/70 20060101AFI20160415BHEP Ipc: B65H 29/40 20060101ALI20160415BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20170105 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 902741 Country of ref document: AT Kind code of ref document: T Effective date: 20170715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602013022623 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170922 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170921 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170921 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171021 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602013022623 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| 26N | No opposition filed |

Effective date: 20180322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180331 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20190328 Year of fee payment: 7 Ref country code: DE Payment date: 20190328 Year of fee payment: 7 Ref country code: FR Payment date: 20190328 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20190325 Year of fee payment: 7 Ref country code: AT Payment date: 20190328 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20190424 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180326 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 902741 Country of ref document: AT Kind code of ref document: T Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130326 Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602013022623 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 902741 Country of ref document: AT Kind code of ref document: T Effective date: 20200326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201001 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200326 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200326 |