EP2834026B1 - Ensemble poinçon et système pour la construction d'ensembles poinçon - Google Patents

Ensemble poinçon et système pour la construction d'ensembles poinçon Download PDFInfo

- Publication number

- EP2834026B1 EP2834026B1 EP12772877.2A EP12772877A EP2834026B1 EP 2834026 B1 EP2834026 B1 EP 2834026B1 EP 12772877 A EP12772877 A EP 12772877A EP 2834026 B1 EP2834026 B1 EP 2834026B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- punch

- stamping

- holding

- plate

- unit according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000004080 punching Methods 0.000 description 31

- 238000013459 approach Methods 0.000 description 6

- 230000008901 benefit Effects 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 230000008859 change Effects 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000007639 printing Methods 0.000 description 3

- 229910000760 Hardened steel Inorganic materials 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 229910000906 Bronze Inorganic materials 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000002730 additional effect Effects 0.000 description 1

- 238000004873 anchoring Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000010974 bronze Substances 0.000 description 1

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 230000003313 weakening effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41N—PRINTING PLATES OR FOILS; MATERIALS FOR SURFACES USED IN PRINTING MACHINES FOR PRINTING, INKING, DAMPING, OR THE LIKE; PREPARING SUCH SURFACES FOR USE AND CONSERVING THEM

- B41N6/00—Mounting boards; Sleeves Make-ready devices, e.g. underlays, overlays; Attaching by chemical means, e.g. vulcanising

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/24—Perforating, i.e. punching holes

- B21D28/34—Perforating tools; Die holders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41K—STAMPS; STAMPING OR NUMBERING APPARATUS OR DEVICES

- B41K1/00—Portable hand-operated devices without means for supporting or locating the articles to be stamped, i.e. hand stamps; Inking devices or other accessories therefor

- B41K1/36—Details

Definitions

- the present invention relates to a stamp unit for attachment to a top of a punch with a pressure plate, a punch and a punch plate and with a system for the construction of such stamp units.

- stamp units are so far built exclusively in such a way that a Wegprofiled forming die is made over its entire length with its punched cross-section by cutting it out of a full hardened block over its entire length by means of wire EDM.

- a common method of attaching the stamp in the stamp holder plate is to make a stamping die in the form of the stamp with the desired circumferential chamfering.

- the upper end of the forming punch is then heated and the chamfer on the punch is upset by means of a press in the stamping mold.

- the bevel of the upset head also serves to retract the punch, which occurs by the heating described the additional effect that as a result of the Anlass bines the hardness of the punch in the head area is reduced.

- a unit made in this way is fastened to an upper part of a punching tool, for example by means of two screws, which is usually a column-guided standard frame. It can be installed in a tool several individual punch units when several desired breakthroughs are to be made.

- the DE 103 11 911 A1 is a quick-change device for punching, cutting, punch or contour stamp described.

- the device comprises a punch holding plate with receiving bores for the punches.

- a displaceable clamping plate with free holes is arranged, whose arrangement corresponds to that of the mounting holes.

- a stamp of the quick-change device is designed as a punch, which has a widened head part at its end acted on pressure, which is arranged in the region of the clamping plate facing away from the end of the punch holder plate. Between the head part and the clamping plate of the punch passes through a spacer sleeve.

- Another stamp of the quick-change device is designed as a contour punch. This has a approach to which the clamping plate rests.

- the contour punch has a transverse bore into which a dowel pin is inserted.

- This dowel pin is flush mounted in a milling of the punch plate.

- the actual punching force is passed through the punch head.

- moving the clamping plate is the spacer sleeve and concerning the punch covered the contour of the dowel pin of the clamping plate so that the punch can not fall out and also forces when retracting the punch can be transferred.

- a stamp unit is described with a punch and a punch holder.

- Punch and punch holder are firmly connected together by means of an accessible from the side of the punch holder screw.

- the punch holder is formed by a punch holder upper part and a punch holder lower part, which are fixedly connected to each other by a screw, also formed in the stamp holder upper part screwed impact plate.

- the punch holder upper part passes through an annular spring carrier in an area of reduced cross-section, which is displaceably guided in this region of the punch holder upper part.

- a plurality of springs are effective between the punch holder top and the spring carrier and press the spring carrier against an approach of the punch holder lower part when not impact plate.

- the clamping punch encloses a punch guide.

- the punch guide lays on the workpiece to be punched and presses the spring carrier against the stamp holder upper part when the springs are compressed.

- the springs press the spring carrier and thus also the punch guide away from the punch holder upper part, so that material can be removed from the punch by means of the punch guide.

- a pin pull-out tool for removing a stop pin from an anchoring structure is known.

- the tool includes a slide hammer.

- the object of the present invention is to provide a punch unit and a system for the construction of stamp units whose production cost is reduced.

- the object is achieved according to the stamp unit according to the invention that in the stamp unit for attachment to an upper part of a punch, with a pressure plate, a punch and a punch holder plate, wherein the pressure plate between the punch and the punch holder plate is arranged, the punching forces of the punch plate over the pressure plate are transferred to the punch and the pressure plate acts on a punch thrust on a shoulder of the punch, wherein on the shoulder of the punch a holding shoe is provided which projects through a slot in the pressure plate and is secured in the punch plate.

- the solution according to the invention has the advantage that the length of the continuously profiled forming punch can be shortened by approximately 30%, whereby a considerable reduction in working time also occurs.

- the individual parts can also be releasably screwed together in the solution according to the invention, so that the upsetting and the production of an exact Anstauchmatrize for the production of the punch as well as the sanding of the upset punch after insertion into the punch plate.

- Another advantage is that punches with different shape cross sections can be used with standardized pressure plates and punch holding plates, since they no longer cut out according to the profiling of the punch Need to become. It is even possible that the cross section of the punch is larger than the stamp receiving plate in some areas, so that multiple receiving plates can be avoided. For example, if the dimensions of a through-profiled forming die have to be changed, it is not necessary to change the punch receiving plate as well.

- a holding shoe which projects through a slot in the pressure plate and is secured in the punch holding plate.

- the holding shoe is preferably made with certain dimensions, so that, as already indicated above, punch punches with different shape cross sections can be used together with standardized punch holding plates and pressure plates without problems whose openings are no longer adapted to the individual shape of the punch but the standardized holding shoe.

- the holding shoe is arranged at a right angle to the shoulder.

- the punch retaining plate releasable fastening means which cooperate with corresponding fastening means on the holding shoe. This makes it possible to change the punch in the tool, without the punch unit must be solved by the entire punching tool.

- at least one bore can be provided in the holding shoe, into which a bolt engages. After loosening the bolt is in this embodiment, easily pulling the punch down from the receptacle for the

- Holding shoe in the punch plate and the pressure plate possible.

- the standardized holding shoe also makes it possible to stock stamp blanks with a corresponding holding shoe and then, if necessary, to produce the desired shape of the punch in a very short time by simple wire erosion without any change to the mounting system of the punch in the stamp unit. It is only necessary to ensure that the shape of the cross-section reasonably evenly includes the holding shoe, wherein the projection of the holding shoe preferably always meets the stamp cross-section and does not project laterally.

- the bolts for attaching the holding shoe for example, have a threaded portion which is screwed into a threaded bore in the punch holder plate.

- the bolt has a conical head which cooperates with a conical bore in the retaining shoe.

- this can then pull the punch with his shoulder against the pressure plate, so that a play-free contact between the pressure plate and the shoulder of the punch is ensured.

- the stamp unit has a hold-down, which is guided by means of guide pins resiliently on the pressure plate.

- a hold-down is in the inventive arrangement the elements of a stamp unit particularly easy to implement, since the hardened pressure plate can easily record polished guide holes for the guide pin wear.

- the guide pins may be bronze or coated hardened steel, to name but two examples.

- a transverse web is provided in the slot of the punch holder plate for receiving the holding shoe of the punch.

- This crosspiece which is in the range of a Passungsrachens the punch, increases the stability of the punch plate in the region of the slot, so that it can not come to dimensional changes due to the high forces acting by tightening the mounting bolts.

- the slot in the punch-holding plate and the slot in the pressure plate are arranged offset eccentrically in alignment. Due to the asymmetrical arrangement of the pick-up tester for the punch shoe, very narrow punches can be positioned very close to one another, which can be an advantage for certain applications. Accordingly, the stamp units are then mounted with the sides of the lesser distance to the slots against each other in the tool.

- the punch has an approach for a pull-out device for pulling in the punching direction.

- the punches of the present system are installed after mounting the punch retainer plate to the end, after which the punch retainer plate is bolted and pinned, as the shoulder of the punch, depending on the design, obscures the bolt and pin holes after assembly.

- the proposed approach provides a way to set a pull-out tool to selectively exert impact pulses on the punch, so that it dissolves from the punch unit.

- the projection may have at least one blind or through bore lying transversely to the punching direction.

- a punching punch with larger punching surfaces it is also possible in another preferred embodiment to provide a threaded bore in the punching surface which is aligned parallel to the punching direction.

- the holes described above are axially in alignment with a fixation of the holding shoe, which is arranged centrally in the rule.

- this adapter element can easily consist of an external thread possibly directly on the guide rod of the slide hammer, while a transversal bore a U-shaped adapter can be provided by means of a transverse bolt, the positive connection to the punch for introducing the Produces impact pulses.

- the solution according to the invention allows standardized stamp holding plates and printing plates to be combined with stamping dies of different cross-sectional shape.

- punch holding plates and printing plates can be kept in pairs in a few standard sizes, which can then be freely combined with the punches due to the standardized holding shoes.

- Another advantage of the solution according to the invention is generally that it is possible to use punch holding plates and pressure plates whose cross section does not have to be substantially larger than the cross section of the punch. This allows a significantly higher packing density of Reach punch units during assembly in the punching tool. In individual cases, this can mean considerable cost advantages in punching operations.

- a punch unit can be advantageous in which a single punch plate and / or a single pressure plate are provided for receiving a plurality of punch punches. Accordingly, such a punch holding plate and / or pressure plate has a plurality of slots for receiving the respective holding shoe of a punch.

- the slots can be arranged parallel or at an arbitrary angle to each other, so that it is possible to arrange a plurality of punches very space-saving in the tool.

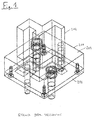

- a prior art stamp unit 200 is shown.

- This stamp unit 200 consists essentially of a forming punch 202, a punch receiving plate 204 and a pressure plate 206, wherein the punch holding plate 204 is disposed between the pressure plate 206 and the punch 202.

- the punching forces are applied by the pressure plate 206 to an upset head 208 (see FIG Fig. 2 ) of the forming die 202, wherein the pressure plate 206 is screwed by means of countersunk screws 210 with the punch holding plate 204.

- the forming punch 202 is also secured by means of its upset head 208 against falling out of the punch holding plate 204, which has a chamfer 212 for this purpose.

- the punch holding plate 204 After the upsetting of the head 208 of the forming punch 202, it is inserted into the punch holding plate 204, the punch holding plate 204 having a recessed cross section 213 corresponding to the forming cross section of the punch 202. After insertion of the forming die 202, the backside in the head region of the punch 202 is smoothed smooth, so that then the pressure plate 206 can be mounted without play. Mounting screws 214 serve to secure the unit 200 to the top of a punch tool (not shown).

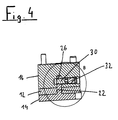

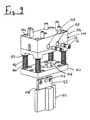

- a punch unit 10 in which a pressure plate 12 is arranged between a forming punch 14 and a punch holding plate 16.

- the punching forces are transmitted from the punch plate 16 via the pressure plate 12 on the punch 14, wherein the contact between the pressure plate 12 and the punch 14 takes place in the region of a shoulder 18, which does not mark the rear end of the punch 14.

- the shoulder 18 forms the head side of a shaped cross-section 20, wherein in the area the shoulder 18 as the rear end of the punch 14, a holding shoe 22 connects, which has a certain height relative to the shoulder 18 and a certain cross-section.

- the projection of the holding shoe 22 should completely hit the shoulder 18, since the mold cross section 20 is otherwise very difficult to produce and possibly also strength problems in the transition region between the holding shoe 22 and the shoulder 18 may occur.

- the shoulder 18 and the shoe are at right angles to each other.

- the holding shoe 22 engages in a slot 24 (see Fig. 7 ) on the underside of the punch plate 16 a.

- holes 26 in the holding shoe 22 are aligned with holes 28 in the punch receiving plate 24, which are provided with an internal thread.

- the intermediate pressure plate 12 is screwed to the punch holder plate 16.

- the bolts 30 also allow the transmission of tensile forces, such as occur during a return movement after a punching stroke. These forces can be in the order of 10 to 15% of the actual punching forces, so that sufficient strength in the area of the screw connection must be taken into account.

- the screw connection itself is in Fig. 4 and 5 illustrated in more detail.

- the holding shoe 22 is shown in cross-section and it can be seen that the holes 26 run in the holding shoe 22 from the edge regions in each case conically towards the center. Accordingly, this hole cooperates with a threaded bolt 30, whose head is frustoconical. As a result, the holding shoe and thus the punch 14 is precisely positioned when screwing the bolt by playing with his shoulder is pulled against the pressure plate.

- a second threaded bolt 32 serves to secure the first threaded bolt 30 with the truncated cone head.

- the solution shown makes it possible to use a plurality of punches 14 with very different shape cross sections with one and the same punch plate 16 and pressure plate 12 in combination.

- the punch holder plate must, according to the preceding description, only have a slot 24 for receiving the holding shoe and fastening means which cooperate with the attachment means of the punch 14 executed in the example as simple bores 26.

- the pressure plate itself need only be provided with a simple slot which is adapted to the cross-sectional shape of the holding shoe 22.

- the guidance or positioning of the punch 14 is taken over by the punch holder plate 16, so that the slot 34 (see Fig. 8 ) in the pressure plate 12 need not be made too great in terms of accuracy, which makes it possible to harden the pressure plate 12 even after the production of the slot 34, which reduces the cost.

- the stamp unit shown makes it possible, for example, to keep blanks of punches 14 ready, which already have the finished holding shoe 22 on their upper side, but in the shank region they have a round or square shape or rectangular cross-section, which allows the omission of a variety of shapes. This can then be produced in a simple manner by wire EDM, which is readily possible due to lack of undercut.

- Another great advantage of the solution shown is that the punch 14 can be removed without removing the punch unit 10 from the punching tool by the two fastening bolts 30, 32 are released.

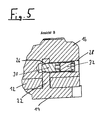

- a preferred embodiment of a stamp unit 110 is shown, which in turn has a punch plate 116, a pressure plate 112 and a punch 114. Also shown are the fastening bolts 30, 32, which are screwed into threaded bores 128 in the punch-holding plate 116 in order to cooperate with bores 126 on a holding shoe 122 of the punch 114 and fix it to the punch unit 110.

- the in Fig. 9 Stamp unit 110 shown a hold-down 140 which is guided on guide plate 144 and intermediate helical compression springs 142 movable on the pressure plate 112. This is made possible by the "bottom" pressure plate 112 which has respective guide holes for the guide pins 144 in the region of its four corners.

- the guide pins 144 themselves move during compression in free holes 146 in the punch holder plate 116.

- the hold-down 140 serves to hold down the sheet during punching and after the actual punching process as a scraper of the punch in the retraction movement. Since the molding cross-section of the punch 114 marks the largest cross-sectional area and the hold-down 140 has a recess 148 corresponding to the punch cross-section, the punch 114 can be easily removed downwards from the punch unit 110 despite the mounted hold-down 140.

- This construction is made possible only by the pressure plate 112 arranged below, because the hardened material of the pressure plate 112 allows the immediate formation of four ground guide holes 150 which would not be accommodated in the punch holder itself.

- the path of the blank holder 140 is limited by the height of the punch holder plate 116 minus the head height of the guide pin 144th

- Fig. 10 shows the stamp unit 114 from Fig. 9 from the punch side.

- the fastening bolts are replaced by corresponding fastening bolts 132 with laterally over the edge of the punch plate 116 protruding hexagonal heads 133, so that the bolts are accessible according to an open-end wrench even in narrow gaps between adjacent punch units.

- a punching surface 160 of the punch 114 axial threaded hole 162 into which an external thread 164 on a shaft 166 of a slide hammer 168 is screwed.

- the threaded hole 162 is axially aligned with the position of a fixing pin (not shown) of the punch receiving plate, ie axially aligned a suitably trained Passungsrachen 170 in the holding shoe 122 of the punch 114 (see also Fig. 11 ).

- the threaded hole 162 allows the form-fitting fixing of the slide hammer 168 designed as extracting device, wherein by means of the movable hammer 172, which is movable against a stop 174, impact pulses are introduced into the punch 114, so that it can be solved, which may be necessary to disassemble the punch unit from the tool or nachzuschleifen to the punch in the event of stumping.

- the positive connection between the turn as a slide hammer 168 and the transverse bore 362 takes place here by means of a U-shaped adapter 280, wherein a screw 282 by aligned holes in the leg ends and the Transversal bore 362 produces the positive connection between the adapter 280 and the punch 314.

- the adapter 280 is provided with a threaded bushing 284, in which the external thread 164 of the slide hammer can be screwed, so that the impulses exerted by the movable hammer 172 on the stop 174 pulses can be introduced into the punch for releasing it.

- the design of the in Fig. 14 punch punch 314 shown is formed with a band 315, because due to the very slim die shape without tape no sufficient shoulder surface would be available. In such a case, the punch can then be hard-milled or countersunk for production, similar to a Abstreifplatte integrated in the punch unit Fig. 9 is not possible with this form.

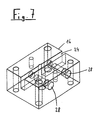

- a punch unit 410 is shown with a punch holding plate 416, a pressure plate 412 and a punch 414.

- This stamping unit broadly corresponds to the previously proposed punch units, so that a more detailed description of most details is omitted here.

- the slot 424 in the punch retainer plate 416 is formed with a crosspiece 425 which increases the rigidity of the punch retainer plate in this area.

- the crossbar 425 engages in the assembled state in the already provided Passungsrachen 470 of the punch. It has been shown that dimensional changes in the course of operation can be reduced by the crosspiece, which can be caused, for example, by tightening the fastening screws 432 and the forces thus introduced into the punch holding plate.

- a further embodiment of a punch unit 510 is shown, in which a likewise provided with a cross bar 525 slot 524 in the punch holding plate 516 as well as an aligned slot 534 in the pressure plate 512 is arranged eccentrically offset from one edge.

- a further punch unit 510 is shown, which is arranged back to back with the second punch unit 510.

- the punches 514 of the units can be pressed closer together as a result and can be accommodated in the tool in a correspondingly space-saving manner.

- the remaining details of the stamp units 510 need not be discussed in greater detail here, they will become apparent from the description of the preceding embodiments for those skilled in the drawing.

- a stamp unit 610 which has a special feature of a punch holding plate 616, the receptacles for three punches 614a, 614b and 614c has.

- three slots 624a, 624b and 624c are provided, which in turn are each divided by a transverse web 625.

- Escaping slots in the pressure plate 612, which is also integrally formed, are not recognizable, since the punch holding plate 616 and the pressure plate 612 are mounted together.

- Such an embodiment makes it possible to accommodate three punches in a desired cross-sectional shape and in the desired orientation to each other very space-saving closely together in the tool.

- Other combinations, for example, with two or four or more punch punches are of course readily possible.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mounting, Exchange, And Manufacturing Of Dies (AREA)

- Perforating, Stamping-Out Or Severing By Means Other Than Cutting (AREA)

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

- Punching Or Piercing (AREA)

- Forging (AREA)

Claims (14)

- Unité de poinçon pour la fixation à une partie supérieure d'un outil d'estampage comprenant une plaque de pression (12 ; 112), un poinçon d'estampage (14 ; 114) et une plaque de retenue de poinçon (16 ; 116), la plaque de pression (12 ; 112) étant disposée entre le poinçon d'estampage (14 ; 114) et la plaque de retenue de poinçon (16 ; 116), les forces d'estampage de la plaque de retenue de poinçon (16 ; 116) étant transmises par le biais de la plaque de pression (12 ; 112) au poinçon d'estampage (14 ; 114) et la plaque de pression (12 ; 112), lors d'une course d'estampage, agissant sur un épaulement (18 ; 118) du poinçon d'estampage (14 ; 114), caractérisée en ce qu'un sabot de retenue (22 ; 122) est prévu au niveau de l'épaulement (18 ; 118) du poinçon d'estampage (14 ; 114), lequel pénètre à travers une fente (34) dans la plaque de pression (12 ; 112) et est fixé dans la plaque de retenue de poinçon (16 ; 116).

- Unité de poinçon selon la revendication 1, caractérisée en ce qu'entre le sabot de retenue (22 ; 122) et l'épaulement (18 ; 118) est prévu un angle droit.

- Unité de poinçon selon la revendication 1 ou 2, caractérisée en ce que la plaque de retenue de poinçon (16 ; 116) présente des moyens de fixation amovibles qui coopèrent avec des moyens de fixation correspondants sur le sabot de retenue (22 ; 122).

- Unité de poinçon selon la revendication 3, caractérisée en ce qu'au moins un alésage (26 ; 126) est prévu dans le sabot de retenue (22 ; 122), dans lequel alésage s'engage un boulon (30).

- Unité de poinçon selon la revendication 4, caractérisée en ce que le boulon (30) présente une région filetée qui s'engage dans un alésage fileté (28) dans la plaque de retenue de poinçon (16).

- Unité de poinçon selon la revendication 4 ou 5, caractérisée en ce que la tête du boulon (30) et l'alésage fileté (28) sont réalisés sous forme conique, de telle sorte que le boulon (30), lors du vissage, tire le poinçon d'estampage (14 ; 114) avec un épaulement (18 ; 118) contre la plaque de pression (12 ; 112).

- Unité de poinçon selon l'une quelconque des revendications précédentes, caractérisée en ce que le sabot de retenue (22 ; 122), en projection, rejoint entièrement la section transversale du poinçon.

- Unité de poinçon selon l'une quelconque des revendications précédentes, caractérisée en ce que des éléments de fixation sont prévus sur la plaque de retenue de poinçon (16 ; 116) pour la connexion à une partie supérieure d'un outil d'estampage.

- Unité de poinçon selon l'une quelconque des revendications précédentes, caractérisée en ce qu'un serre-flan (140) est prévu, lequel est guidé au moyen de boulons de guidage (144) de manière élastique contre la plaque de pression (112).

- Unité de poinçon selon l'une quelconque des revendications précédentes, caractérisée en ce que le poinçon d'estampage présente une partie saillante pour un dispositif d'extraction pour l'extraction dans la direction d'estampage, la partie saillante présentant au moins un alésage borgne ou traversant (362) situé transversalement à la direction d'estampage.

- Unité de poinçon selon l'une quelconque des revendications 1 à 9, caractérisée en ce que le poinçon d'estampage présente une partie saillante pour un dispositif d'extraction pour l'extraction dans la direction d'estampage, la partie saillante présentant un alésage fileté (162) prévu dans la surface d'estampage, qui est orienté parallèlement à la direction d'estampage.

- Unité de poinçon selon l'une quelconque des revendications précédentes, caractérisée en ce qu'une entretoise (425 ; 525 ; 625) est prévue dans une Fente (424 ; 524 ; 624) dans la plaque de retenue de poinçon (416 ; 516 ; 616).

- Unité de poinçon selon l'une quelconque des revendications précédentes, caractérisée en ce qu'une plaque de retenue de poinçon unique (616) et/ou une plaque de pression unique (612) est pourvue d'évidements pour une pluralité de poinçons d'estampage (614a, 614b, 614c).

- Système pour la construction d'unités de poinçon selon l'une quelconque des revendications précédentes, constitué d'un nombre déterminé de plaques de retenue de poinçon (12) et de plaques de pression adaptées (14) dans des dimensions déterminées, ayant dans chaque cas une fente déterminée (24) dans la plaque de retenue de poinçon (16) et une fente (34) dans la plaque de pression pour recevoir de manière sélective des sabots de retenue (22) d'une pluralité de poinçons d'estampage (14) ayant des sections transversales de formes différentes.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102012006665 | 2012-04-03 | ||

| DE102012014698.1A DE102012014698B4 (de) | 2012-04-03 | 2012-07-25 | Stempeleinheit und System zum Aufbau von Stempeleinheiten |

| PCT/EP2012/003723 WO2013149630A1 (fr) | 2012-04-03 | 2012-09-05 | Ensemble poinçon et système pour la construction d'ensembles poinçon |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2834026A1 EP2834026A1 (fr) | 2015-02-11 |

| EP2834026B1 true EP2834026B1 (fr) | 2016-10-26 |

Family

ID=49209790

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12772877.2A Not-in-force EP2834026B1 (fr) | 2012-04-03 | 2012-09-05 | Ensemble poinçon et système pour la construction d'ensembles poinçon |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9579920B2 (fr) |

| EP (1) | EP2834026B1 (fr) |

| JP (1) | JP6063554B2 (fr) |

| DE (1) | DE102012014698B4 (fr) |

| WO (1) | WO2013149630A1 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102012014698B4 (de) * | 2012-04-03 | 2014-07-03 | Julia Vanderpool | Stempeleinheit und System zum Aufbau von Stempeleinheiten |

| DE102012025300A1 (de) | 2012-12-28 | 2014-07-03 | Julia Vanderpool | Verstellbare Stempelaufnahme |

| CN104552451B (zh) * | 2015-01-04 | 2017-04-26 | 京东方科技集团股份有限公司 | 一种裁切装置 |

| US9878461B2 (en) * | 2015-05-14 | 2018-01-30 | Omnitool, Inc. | Rigid punch tool |

| CN108942306B (zh) * | 2018-08-23 | 2021-01-08 | 四川福蓉科技股份公司 | 一种蘑菇头夹具 |

| CN110216192B (zh) * | 2019-05-28 | 2024-06-07 | 东莞智富五金制品有限公司 | 一种快速换模的冲压装置 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4092888A (en) * | 1977-07-01 | 1978-06-06 | Wilson Tool Company | Self-stripping punch and guide assembly |

| EP0000762A1 (fr) * | 1977-08-10 | 1979-02-21 | Houdaille Industries, Inc. | Outil poinçonneur avec dispositif de dégagement du poinçon et procédé de fabrication |

| GB2038690A (en) * | 1978-11-20 | 1980-07-30 | Mercer Nairne & Co Ltd | Improved punch assembly |

| EP0628364A1 (fr) * | 1993-06-07 | 1994-12-14 | Amada Metrecs Company, Limited | Outil de poinçonnage |

| DE10311911A1 (de) * | 2003-03-17 | 2004-10-07 | Gs-Konstruktion Gmbh | Schnellwechselvorrichtung für Stanz-, Schneid-, Loch- oder Konturstempel |

| DE102008062471A1 (de) * | 2008-12-16 | 2010-06-17 | Pass Stanztechnik Ag | Bearbeitungswerkzeug für ein Werkstück |

| DE102010025105A1 (de) * | 2010-06-25 | 2011-12-29 | Gerhard Ruoff | Stiftausziehwerkzeug für einen Einschlagstift mit Kopf |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US17455A (en) * | 1857-06-02 | Heel-cuttek for cutting out heels of boots and shoes | ||

| US1910296A (en) * | 1929-02-11 | 1933-05-23 | Guardian Trust Company | Punch retainer mechanism |

| US2420146A (en) * | 1945-09-21 | 1947-05-06 | Mueller Otto | Locking and ejecting device |

| US2997907A (en) * | 1957-11-22 | 1961-08-29 | Constantino Alfred | Self aligning punching apparatus |

| US3103845A (en) * | 1959-04-07 | 1963-09-17 | Porter Prec Products | Demountable retainer for punch and die sets |

| US3563124A (en) * | 1968-12-16 | 1971-02-16 | Dayton Progress Corp | Punch and die retainers |

| US3677118A (en) * | 1970-08-20 | 1972-07-18 | Bendix Corp | Diaphragm trimmer |

| US3935771A (en) * | 1975-02-10 | 1976-02-03 | Houdaille Industries, Inc. | Punch and stripping guide assembly |

| JPS5239881A (en) * | 1975-09-25 | 1977-03-28 | Hitachi Ltd | Puncher for a continous line |

| US4031787A (en) * | 1976-07-28 | 1977-06-28 | Houdaille Industries, Inc. | Punch and stripper assembly |

| US4064917A (en) * | 1976-10-18 | 1977-12-27 | Honeywell Information Systems Inc. | Apparatus for cutting and forming flexible beam leads of an integrated circuit chip |

| IT1156914B (it) * | 1978-03-13 | 1987-02-04 | Lavazza Gian Maria | Procedimento e dispositivo per tranciare da un nastro di lamiera una pluralita' di pezzi continui a forma di pettine |

| US4375774A (en) * | 1979-12-26 | 1983-03-08 | Wilson Tool Company | Adjustable punch head |

| US4377100A (en) * | 1981-02-19 | 1983-03-22 | Wallis Bernard J | Punch retainer |

| DE3241046A1 (de) * | 1982-11-06 | 1984-05-10 | Trumpf GmbH & Co, 7257 Ditzingen | Stanzmaschine, deren stanzstempel als mehrfachstempel ausgebildet ist |

| US4604931A (en) * | 1985-08-16 | 1986-08-12 | Harris Graphics Corporation | Quick change rotary punch |

| US4726270A (en) * | 1987-01-05 | 1988-02-23 | Lucas Rose E | Stamping system |

| US5038599A (en) * | 1990-04-10 | 1991-08-13 | Aip Inc. | Ball lock punch retainer |

| US5181438A (en) * | 1990-04-10 | 1993-01-26 | Aip Inc. | Ball lock punch retainer |

| JP2636127B2 (ja) * | 1993-02-03 | 1997-07-30 | 株式会社アマダメトレックス | パンチング金型 |

| US5839183A (en) * | 1996-09-23 | 1998-11-24 | Porter Precision Products Co. | Punch retainer |

| US5934165A (en) * | 1997-03-19 | 1999-08-10 | Strippit, Inc. | Adjustable punch assembly |

| JP3452491B2 (ja) * | 1998-08-04 | 2003-09-29 | 株式会社アマダ | パンチホルダ装置 |

| JP3551097B2 (ja) * | 1999-09-01 | 2004-08-04 | 松下電器産業株式会社 | プレス加工用パンチ |

| US6679147B1 (en) * | 1999-09-17 | 2004-01-20 | Michael J. Chaulklin | Insertable punch lock |

| US6276247B1 (en) * | 2000-03-03 | 2001-08-21 | Strippit, Inc. | Adjustable punch assembly with releasable locking |

| US6755110B2 (en) * | 2001-06-19 | 2004-06-29 | Wilson Tool International, Inc. | Adjustable length punch assembly |

| DE10261748B4 (de) * | 2002-12-30 | 2011-07-28 | Mate Precision Tooling GmbH, 61440 | Stanzwerkzeug |

| US7707919B1 (en) * | 2005-03-21 | 2010-05-04 | Moeller Manufacturing Company, Inc. | One-piece stripper retainer for a punch |

| JP2008073709A (ja) * | 2006-09-20 | 2008-04-03 | Umix Co Ltd | パンチャー |

| JP4909835B2 (ja) * | 2007-08-02 | 2012-04-04 | 株式会社小松製作所 | プレス機械の金型クランプ機構 |

| JP4462353B2 (ja) * | 2008-01-11 | 2010-05-12 | セイコーエプソン株式会社 | フレキシブル基板の製造方法及びフレキシブル基板打抜装置 |

| EP2522443B1 (fr) * | 2008-10-18 | 2014-07-30 | TRUMPF Werkzeugmaschinen GmbH + Co. KG | Programme de fonctionnement à commande d'un ensemble d'outil de poinçonnage destiné au traitement par poinçonnage de pièces usinées |

| US8820200B1 (en) * | 2009-05-27 | 2014-09-02 | Robert Richard Quinn | Modular die system |

| DE102012014698B4 (de) * | 2012-04-03 | 2014-07-03 | Julia Vanderpool | Stempeleinheit und System zum Aufbau von Stempeleinheiten |

-

2012

- 2012-07-25 DE DE102012014698.1A patent/DE102012014698B4/de not_active Expired - Fee Related

- 2012-09-05 EP EP12772877.2A patent/EP2834026B1/fr not_active Not-in-force

- 2012-09-05 WO PCT/EP2012/003723 patent/WO2013149630A1/fr not_active Ceased

- 2012-09-05 JP JP2015503759A patent/JP6063554B2/ja not_active Expired - Fee Related

- 2012-09-05 US US14/390,295 patent/US9579920B2/en not_active Expired - Fee Related

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4092888A (en) * | 1977-07-01 | 1978-06-06 | Wilson Tool Company | Self-stripping punch and guide assembly |

| EP0000762A1 (fr) * | 1977-08-10 | 1979-02-21 | Houdaille Industries, Inc. | Outil poinçonneur avec dispositif de dégagement du poinçon et procédé de fabrication |

| GB2038690A (en) * | 1978-11-20 | 1980-07-30 | Mercer Nairne & Co Ltd | Improved punch assembly |

| EP0628364A1 (fr) * | 1993-06-07 | 1994-12-14 | Amada Metrecs Company, Limited | Outil de poinçonnage |

| DE10311911A1 (de) * | 2003-03-17 | 2004-10-07 | Gs-Konstruktion Gmbh | Schnellwechselvorrichtung für Stanz-, Schneid-, Loch- oder Konturstempel |

| DE102008062471A1 (de) * | 2008-12-16 | 2010-06-17 | Pass Stanztechnik Ag | Bearbeitungswerkzeug für ein Werkstück |

| DE102010025105A1 (de) * | 2010-06-25 | 2011-12-29 | Gerhard Ruoff | Stiftausziehwerkzeug für einen Einschlagstift mit Kopf |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2013149630A1 (fr) | 2013-10-10 |

| DE102012014698A1 (de) | 2013-10-10 |

| US9579920B2 (en) | 2017-02-28 |

| DE102012014698B4 (de) | 2014-07-03 |

| WO2013149630A8 (fr) | 2014-10-02 |

| JP2015512344A (ja) | 2015-04-27 |

| JP6063554B2 (ja) | 2017-01-18 |

| EP2834026A1 (fr) | 2015-02-11 |

| US20150047521A1 (en) | 2015-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2834026B1 (fr) | Ensemble poinçon et système pour la construction d'ensembles poinçon | |

| EP2874804B1 (fr) | Mécanisme à came | |

| EP1893365B1 (fr) | Dispositif de fixation d'outil pour dispositif d'entraînement par came | |

| EP2794142B1 (fr) | Matrice d'un dispositif de poinçonnage et procédé de poinçonnage | |

| DE69701218T2 (de) | Vorrichtung zum entfernen von ausbruchteilen | |

| DE10315724A1 (de) | Durchsetzfügeverfahren und Werkzeug dafür | |

| DE602004000126T2 (de) | Verfahren zur Herstellung von selbststanzenden Muttern | |

| EP3039302A1 (fr) | Barre profilée et assemblage de profilés | |

| DE3120093A1 (de) | Nietmaschine, insbesondere zum aufnieten der bremsbelaege auf den belagtraeger von bremsbacken | |

| DE3721446C2 (de) | Stanzwerkzeug | |

| WO2015055288A1 (fr) | Ensemble de réception d'une dent broyeuse sur un cylindre broyeur d'un broyeur | |

| DE69004486T2 (de) | Schneidwerkzeughalter mit Abstreifvorrichtung. | |

| DE3719010A1 (de) | Aufspannvorrichtung fuer werkstuecke | |

| DE102009010363A1 (de) | Fördervorrichtung mit stufenloser Höhenverstellung | |

| DE102006053223B3 (de) | Loch- und Durchzugsstempel | |

| EP1604751B1 (fr) | Dispositif de poinçonnage et poinçon | |

| DE202008015601U1 (de) | System zum Aufbauen einer Vorrichtung zum Aufspannen von Werkstücken | |

| EP1559488A2 (fr) | Procédé de fabrication d'eléments creux ainsi outil à suivre pour la mise en oeuvre de ce procédé. | |

| DE10317015A1 (de) | Vorrichtung zum Stanzen von Werkstücken | |

| DE3406454C2 (fr) | ||

| EP2722116B1 (fr) | Procédé et paire de mâchoires de pincement destinés à la fabrication d'une vis de forage, et vis ou rivet de forage ou foreur | |

| DE102021134528B3 (de) | Stanzwerkzeug für den mobilen Einsatz | |

| EP1624983B1 (fr) | Dispositif d'elimination de bosses | |

| DE102005012297B4 (de) | Schmiedemaschine | |

| DE102018111809A1 (de) | Vorrichtung zum entfernen von abfällen aus bogenförmigem material, maschine und zugehöriges verfahren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140910 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B21D 28/34 20060101AFI20160330BHEP |

|

| PUAG | Search results despatched under rule 164(2) epc together with communication from examining division |

Free format text: ORIGINAL CODE: 0009017 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| B565 | Issuance of search results under rule 164(2) epc |

Effective date: 20160520 |

|

| INTG | Intention to grant announced |

Effective date: 20160520 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 839641 Country of ref document: AT Kind code of ref document: T Effective date: 20161115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502012008639 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20161026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170127 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170227 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170226 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502012008639 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170126 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170727 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170905 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170905 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170905 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170905 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171002 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 839641 Country of ref document: AT Kind code of ref document: T Effective date: 20170905 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170905 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120905 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20201124 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502012008639 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220401 |