EP2805633B9 - Trays made of conductive plastic material and device and method for automatically discharching trays filled with rod-shaped articles - Google Patents

Trays made of conductive plastic material and device and method for automatically discharching trays filled with rod-shaped articles Download PDFInfo

- Publication number

- EP2805633B9 EP2805633B9 EP14164574.7A EP14164574A EP2805633B9 EP 2805633 B9 EP2805633 B9 EP 2805633B9 EP 14164574 A EP14164574 A EP 14164574A EP 2805633 B9 EP2805633 B9 EP 2805633B9

- Authority

- EP

- European Patent Office

- Prior art keywords

- tray

- trays

- emptying

- rod

- shaped articles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004033 plastic Substances 0.000 title claims description 24

- 229920003023 plastic Polymers 0.000 title claims description 24

- 238000000034 method Methods 0.000 title claims description 21

- 239000000463 material Substances 0.000 title claims description 8

- 238000012546 transfer Methods 0.000 claims description 28

- 238000004519 manufacturing process Methods 0.000 claims description 11

- 238000012545 processing Methods 0.000 claims description 9

- 229920001940 conductive polymer Polymers 0.000 claims description 7

- 230000007246 mechanism Effects 0.000 claims description 6

- 238000004806 packaging method and process Methods 0.000 claims description 3

- 238000001746 injection moulding Methods 0.000 claims description 2

- 238000007599 discharging Methods 0.000 claims 9

- 230000007423 decrease Effects 0.000 claims 1

- 230000032258 transport Effects 0.000 description 17

- 230000008569 process Effects 0.000 description 10

- 241000208125 Nicotiana Species 0.000 description 6

- 235000002637 Nicotiana tabacum Nutrition 0.000 description 6

- 239000000835 fiber Substances 0.000 description 6

- 239000004020 conductor Substances 0.000 description 4

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 3

- 238000007600 charging Methods 0.000 description 3

- 235000019504 cigarettes Nutrition 0.000 description 3

- 229910052802 copper Inorganic materials 0.000 description 3

- 239000010949 copper Substances 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 230000018109 developmental process Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 230000005686 electrostatic field Effects 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 229920000265 Polyparaphenylene Polymers 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 239000003570 air Substances 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 238000007786 electrostatic charging Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 238000005192 partition Methods 0.000 description 2

- -1 poly(paraphenylene) Polymers 0.000 description 2

- 229920000553 poly(phenylenevinylene) Polymers 0.000 description 2

- 229920001197 polyacetylene Polymers 0.000 description 2

- 229920000767 polyaniline Polymers 0.000 description 2

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 239000004676 acrylonitrile butadiene styrene Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 239000012080 ambient air Substances 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000002242 deionisation method Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000003989 dielectric material Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 238000004091 panning Methods 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 229920000128 polypyrrole Polymers 0.000 description 1

- 229920000123 polythiophene Polymers 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/35—Adaptations of conveying apparatus for transporting cigarettes from making machine to packaging machine

- A24C5/352—Adaptations of conveying apparatus for transporting cigarettes from making machine to packaging machine using containers, i.e. boats

- A24C5/356—Emptying the boats into the hopper of the packaging machine

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/35—Adaptations of conveying apparatus for transporting cigarettes from making machine to packaging machine

- A24C5/352—Adaptations of conveying apparatus for transporting cigarettes from making machine to packaging machine using containers, i.e. boats

- A24C5/358—Boat constructions

Definitions

- the present invention relates to trays for receiving rod-shaped products of the tobacco processing industry, comprising a tray body formed by a rear wall, two at least substantially parallel and spaced apart side walls and a bottom wall, forming a receiving space for the products that is open at the front and at the top, wherein the tray can be designed as a shaft tray.

- the invention also relates to a tray emptying device for automatically emptying trays filled with rod-shaped products into a production or packaging machine in the tobacco processing industry, comprising a feed device for feeding trays filled with rod-shaped products, an emptying station with an emptying position for overhead emptying of the trays, a A transport device for transporting away the emptied trays and a transfer device for transporting the trays within the tray emptying device during an emptying cycle, and a method for automatically emptying trays filled with rod-shaped products, comprising the steps of feeding trays filled with products by means of a feed device, transporting the trays from the feed device into an emptying position of an emptying station by means of a transfer device, so that the trays are upside down in the emptying position , overhead emptying of the trays, transporting the empty trays by means of the transfer device from the emptying position to a transport device, and transporting away the empty trays by means of the transport device.

- the trays described are used in particular in the tobacco processing industry when processing rod-shaped products.

- Tobacco rods, cigarettes, filter rods and in particular filter rod segments or the like are kept in containers, the so-called trays, in particular for transport and storage.

- the containers can be designed as standard trays with a single receiving space for all products or as shaft trays in which the products are located in several shafts that are separate from one another.

- For further processing of the stored products these are delivered to downstream devices, such as packing machines or the like, or introduced into an existing mass flow.

- Such trays are now usually made of plastic such as polystyrene (PS) or acrylonitrile butadiene styrene (ABS), since this material is stable and at the same time light and inexpensive.

- PS polystyrene

- ABS acrylonitrile butadiene styrene

- Such trays are, for example, in DE-Gbm. 1,882,950.

- a downstream device in which trays are used is a tray emptying device, with the help of which rod-shaped articles that are stored in trays for various reasons are reintroduced into the production process.

- the tray emptying devices are combined with production machines to form a production arrangement for carrying out corresponding production processes, which include cigarette production, filter production and also the packaging of the same.

- Known tray emptying devices have transfer devices for manipulating or handling the trays, which are designed as a pivoting mechanism. With the known pivoting mechanism, all the trays, ie the full trays and the empty trays, are handled during the emptying cycle.

- An emptying cycle includes removing the full trays from the feed device, emptying the full trays overhead in the emptying station and delivering the empty trays to the removal device.

- tray emptying devices are, for example, in DE 10 2008 027 636 described.

- the WO2011/090395 two measures on the one hand blowing ionized compressed air into the bottom of the trays to neutralize the charge, on the other hand using an insert or an insert made of a conductive material inside the tray to essentially prevent the occurrence of electrostatic charges.

- a tray having the features of claim 1 .

- electrically conductive plastic as the tray material, any charging that occurs can be dissipated immediately. It is not necessary to apply an additional layer, insert or the like.

- the tray can be made structurally very simple.

- An electrically conductive plastic within the meaning of the invention is a plastic which--unlike plastics which are usually considered excellent insulators--has an electrical conductivity of at least 10 -10 S cm -1 .

- electrically conductive plastics are understood to mean the so-called intrinsically conductive polymers, which have conductivity per se.

- the tray is designed in one piece and is produced by injection molding. In this way, a very stable tray is obtained, which at the same time is inexpensive to produce.

- Existing molds for producing trays can also continue to be used, since only the material changes, while the tray mold remains identical.

- the tray according to the invention can also be a shaft tray, ie a tray in which the products lie in several shafts separated from one another by intermediate walls.

- the partitions are also made of electrically conductive plastic.

- the electrically conductive plastic is an intrinsically conductive polymer, in particular a doped intrinsically conductive polymer.

- the intrinsically conductive polymers are in particular cis-polyacetylene (cis-PA), trans-polyacetylene (trans-PA), poly(paraphenylene) (PPP), polythiophene, polypyrrole, poly(para-phenylene-vinylene) (PPV) and polyaniline (PANI).

- cis-PA cis-polyacetylene

- trans-PA trans-polyacetylene

- PPP poly(paraphenylene)

- PPP polythiophene

- polypyrrole poly(para-phenylene-vinylene)

- PANI polyaniline

- the conductive plastic tray according to the invention exhibits greatly reduced adhesion of the articles to its inner walls. This has an advantageous effect on the filling and the emptying operations, but this could possibly have an adverse effect on safe transport of the upright trays filled with rod-shaped articles, especially during acceleration and/or deceleration operations.

- the rear wall of the tray is inclined on its inside by at least 1 degree from the vertical relative to the vertical outside, with the wall thickness of the rear wall increasing from top to bottom toward the bottom wall.

- the bottom wall of the tray is inclined on its inside by at least 1 degree from the horizontal compared to the horizontal outside, with the wall thickness of the bottom wall decreasing from front to back towards the rear wall.

- the inner sides of the back wall and the bottom wall are inclined by approximately the same angular amount, such that the included angle is approximately 90 degrees.

- the trays are tilted for filling or emptying by means of a pivoting device in such a way that the inside of the rear wall of the tray is in the same, preferably vertical, plane as the upstream or downstream rear wall of the intermediate or buffer store of the tray filling device or the tray emptying device.

- a tray emptying device of the type mentioned at the outset in which at least one charge-dissipating element is provided on at least one device selected from the feed device, emptying station, removal device and transfer device, which is designed and set up to prevent contact between the tray and the grounded machine base frame.

- the trays are made of electrically conductive plastic, since this allows the charge produced by friction to be dissipated.

- the charge is discharged from the tray.

- Customary machines and devices in the tobacco processing industry have a machine base frame to which the individual components and parts are attached. This machine base frame is always grounded. It is therefore ideally suited to dissipate the resulting charge. To do this, it is necessary to establish a conductive connection between the charged trays and the machine base frame.

- this is provided by at least one charge-dissipating element, which is attached either to the feed device, to the emptying station, to the removal device or to the transfer device.

- the charge-dissipating element or the charge-dissipating elements can be designed in particular as contact surfaces made of metal. Silver, copper and iron, which are good electrical conductors, are particularly suitable as metals.

- its transfer device has a pivoting mechanism that performs a pivoting movement limited to 180°, with a pivoting cassette that can pivot about a stationary pivoting axis S, which is designed and set up for fixing, pivoting, and releasing the trays, with the pivoting axis containing the charge-dissipating element is.

- a particularly good discharge is guaranteed if the swivel mechanism is additionally provided with a copper mesh. Since the panning movement of the cassette is limited to 180°, problems caused by the braid twisting are eliminated.

- the feed device and/or removal device is/are designed as a conveyor belt, with the conveyor belt consisting of an electrically conductive plastic. In this way, the charging that occurs as a result of the friction between the trays and the conveyor belt is largely avoided.

- the object is also achieved by a method of the type mentioned at the outset, in which the trays of the present invention are used as trays and in which charge dissipation takes place in at least one of the method steps.

- the static charge in the trays is reduced to such an extent that stick-shaped products getting caught in the trays after the emptying process should essentially be ruled out.

- the method is particularly effective and at the same time simple, since no complex additional devices, for example for deionization, have to be provided.

- the in the Figures 1 to 3 Trays shown by way of example are used in the tobacco processing industry in particular for transporting and storing rod-shaped products such as cigarettes, filter rods or the like. for use.

- the in the Figures 4 to 6 The emptying device shown by way of example is used for sequentially emptying containers filled with rod-shaped products into an emptying magazine or the like.

- the features and feature combinations described below can also be implemented in combinations other than those shown.

- the Figures 1 to 3 show a shaft tray 1, which has two side walls 3 and 4, a bottom wall 5 and a rear wall 6 to form a tray body 2.

- the side walls 3 , 4 are arranged spaced apart essentially in parallel (may have draft angles, which cannot be seen from the figures) and laterally delimit a receiving space 7 defined by the tray body 2 .

- the bottom wall 5 delimits the receiving space 7 at the bottom.

- the shaft trays 1 are usually designed to be open at the front and at the top. Of course, front walls and cover elements can also be provided.

- the tray body 2 can be made in one piece or in several pieces.

- the receiving space 7 itself can be subdivided.

- a plurality of shaft walls 8 are preferably connected to the tray body 2 in a detachable or fixed manner in order to divide the receiving space 7 into a plurality of shafts 9 .

- the shaft walls 8 can also be formed integrally with the tray body 2 .

- the shaft walls 8 run parallel and spaced apart from one another or from the side walls 3, 4.

- the tray 1 can also be designed as a standard tray without shaft walls 8 .

- the tray is made of electrically conductive plastic , which is what is known as an intrinsically conductive polymer se has a conductivity.

- the in the figures 2 and 3 Trays shown is an example not according to the invention and is made of a plastic with the addition of additives.

- Fibers of an inorganic substance are included as an additive.

- Such fibers can in particular be stainless steel fibers or carbon fibers.

- the conductivity in the fiber direction is significantly higher than perpendicular to it.

- the fibers are formed substantially parallel to the longitudinal extent of the tray side and partition walls 3, 8.

- the fibers run essentially parallel to the longitudinal extent of the tray base 5.

- the emptying device 10 shown comprises a feed device 11, a transport device 12, an emptying station 32 and a transfer device 13.

- the feed device 11 is used for feeding and storing products-filled (full) trays 14 made of electrically conductive material.

- the feed device 11 is arranged above the transport device 12 and, like the transport device 12, runs essentially horizontally.

- Substantially horizontally also expressly includes a slight inclination at an angle greater than 0° and less than 5° with respect to a horizontally spanned plane, such that the feed device 11 falls slightly in the direction of the transfer device 13, so that the containers 14 with respect to a vertical orientation inclined by the corresponding angle ⁇ on the feeder 11 are.

- an inclination of 3° from the vertical is selected.

- the transport device 12 serves to transport the emptied trays 16 away.

- the full trays 14 can be transported by means of the transfer device 13 from a pick-up position 17 into the area of an emptying magazine 18 and back into a delivery position 19 .

- the emptying magazine 18 can be part of the emptying station 32 or arranged as a separate part under the emptying position.

- In the area of the pick-up position 17 there is a stopper 15 which holds the tray in the pick-up position 17 until it is picked up by the transfer device.

- the feed device 11 continues to run below the tray 14, as a result of which electrostatic charges build up in the tray in conventional devices.

- the feed device 11 is designed as a conveyor belt, the conveyor belt consisting of a conductive plastic.

- the transfer device 13 comprises a cassette 21 which can be moved up and down vertically and is designed to be pivotable. The vertical and pivoting movements can be carried out directly or indirectly by the cassette 21. Furthermore, the cassette 21 is designed and set up to hold a tray 14, 16 during the entire emptying process. This means that the cassette has devices for holding and/or gripping the trays 14, 16, by means of which the trays 14, 16 are fixed within the cassette 21 in a defined position, which can also be inclined to the vertical. Pneumatic gripping elements are preferably provided. The trays 14, 16 themselves can be held, for example, by metallic spring elements or the like. Of course, all other conventional holding and/or gripping mechanisms made of conductive material can also be used.

- a pick-up element 22 is optionally assigned to the cassette 21 for receiving or picking up the full trays 14 from the feed device 11 .

- the pick-up element 22 is furthermore set up and designed to position the full tray 14 within the cassette 21 so that it can be fixed in the "middle product" position.

- the "middle product” position also known as “constant edge”, is advantageous for handling different product lengths in the course of a format change.

- the pick-up element 22 can furthermore also have a push-off element (not shown), by means of which the ejection of the emptied tray 16 from the cassette 21 is supported.

- the push-off element can also be provided as a separate device.

- the emptying device 10 preferably has a lift device 23 as part of the transfer device 13 in order to carry out the vertical movements from the pick-up position 17 to the transfer position 20 in the region of the pivoting device 27 and back to the delivery position 19 .

- the lift device 23 includes vertically running guide rails 24 or the like, on or in which a lift fork 25 or the like is guided, as well as a drive unit 26.

- the transfer device 13 also includes a pivoting device 27. The pivoting device 27 is between the transfer position 20 and the emptying position arranged and set up and designed to carry out an overhead pivoting movement of the full tray 14 holding the cassette 21 via the emptying magazine 18 and the then emptied tray 16 holding the cassette 21 back.

- the pivoting device 27 is arranged at the upper end of the guide rails 24 and forms a swivel head.

- the pivoting device 27 has a latching device 28 and a rotatable and stationary shaft 29 , with the latching device 28 being mounted on the shaft 29 .

- the shaft 29 itself is stationarily but rotatably mounted on a frame or the like.

- the shaft 29, together with the cassette 21, forms the charge-dissipating element, with the aid of which the charge present in the tray can be discharged via the base frame 33 of the emptying device 10.

- a copper mesh (not shown) can be provided in the area of the shaft 29, which supports the charge dissipation.

- the latching device 28 comprises a plurality of latching bolts (not shown), which can be actuated, for example, by means of pneumatic cylinders (also not shown) or the like.

- This means that the movably mounted locking bolts can be moved from a retracted waiting position, in which the cassette 21 can be coupled in or out during transfer from the lifting device 23 to the pivoting device 27 and back, to a locking position in which the cassette 21 is fixed to the pivoting device 27 is connected, and are movable back.

- the cassette 21 can be detached from the lifting device 23 and connected to the pivoting device 27 and vice versa.

- the locking of the cassette 21 on the pivoting device 27 and the corresponding unlocking can also take place in other conventional ways, provided that the conductive connection between the pivoting device 27, cassette 21 and tray 14 is established.

- the distance between the axis of rotation D of the shaft 29 and the cassette 21, which is rotatably or pivotably mounted on the shaft 29 by means of the locking device 28, is small.

- the latching device 28 is very short in terms of structural shape, so that the cassette 21 describes a very narrow envelope curve with a small radius during the pivoting movement.

- the cassette 21 is arranged in the immediate vicinity of the shaft 29 or directly on it.

- a drive 30 for executing the pivoting movement is assigned to the transfer device 13 and is arranged as an extension of the shaft 29 .

- the pick-up position 17 for the full trays 14 and the delivery position 19 for the emptied containers 16 can be at different positions.

- the pick-up position 17 preferably corresponds to the delivery position 19.

- both the pick-up position 17 and the delivery position 19 is also at the same level, namely at the height of the feed device 11.

- a lift device 31 is arranged in the area of the lower removal device 12.

- the lift device 31 for transporting the emptied containers 16 from the delivery position 19 to the removal device is designed separately from the lift device 23 for transporting the full trays 14 from the collection position 17 to the emptying position and back to the delivery position 19.

- At least one full tray 14, but preferably several full trays 14, are arranged or stored on the feed device 11.

- the trays 14 stand with one narrow side on the feeding device 11, which slopes slightly in the direction of the transfer device 13, so that the trays 14 are transported at an angle ⁇ to the vertical in the direction of the transfer device 13 into the pick-up position 17.

- the trays 14 can also be transported without being inclined.

- One full tray 14 is transported from the pick-up position 17 to the emptying position in the area of the emptying magazine 18 .

- the transport preferably takes place in that the full tray 14 is pulled into the cassette 21 by the pick-up element 22 and positioned there.

- either the tray 14 itself or the cassette 21 is pivoted through an angle to the vertical which is greater than the angle ⁇ . With this overall inclination by the angle ⁇ to the vertical, the cassette 21 with the tray 14 is moved vertically upwards into the area of the emptying magazine 18 by means of the lifting device 23 .

- the cassette 21 is detached from the lifting device 23 and connected to the pivoting device 27 .

- locking bolts of the locking device 28 are moved from a waiting position into the locking position, so that the cassette 21 is firmly connected to the shaft 29 of the pivoting device 27 .

- the shaft 29 is connected to the machine base frame 33 at the same time, so that a charge dissipation any electrostatic charge present in the tray 14 occurs.

- the pivoting device 27 performs a pivoting movement, so that the tray 14 is upside down above the emptying magazine 18.

- the closing element of the tray 14 is opened so that the products fall down out of the container 14 into the emptying magazine 18 .

- the cassette 21 with the emptied tray 16 pivots back.

- the cassette 21 with the emptied tray 16 is detached from the pivoting device 27 and reconnected to the lifting device 23 .

- the lift device 23 transports the emptied tray 16 down to the delivery position 19. During the entire emptying process from the collection position 17 to the area of the emptying magazine 18 and back to the delivery position 19, the tray 14, 16 in the cassette can be moved up and down and pivoted 21 held.

- tray 14, 16 is held permanently in the cassette 21 during the entire emptying process, ie during transport and emptying.

- electrostatic charge generated in the process on trays 14, 16 must be dissipated.

Landscapes

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

- Filling Or Emptying Of Bunkers, Hoppers, And Tanks (AREA)

- Elimination Of Static Electricity (AREA)

Description

Die vorliegende Erfindung betrifft Schragen zur Aufnahme stabförmiger Produkte der Tabak verarbeitenden Industrie, umfassend einen durch eine Rückwand, zwei zumindest im Wesentlichen parallele und beabstandet zueinander angeordnete Seitenwände sowie eine Bodenwand gebildeten Schragenkörper unter Bildung eines nach vorn und nach oben offen ausgebildeten Aufnahmeraumes für die Produkte, wobei der Schragen als Schachtschragen ausgebildet sein kann.The present invention relates to trays for receiving rod-shaped products of the tobacco processing industry, comprising a tray body formed by a rear wall, two at least substantially parallel and spaced apart side walls and a bottom wall, forming a receiving space for the products that is open at the front and at the top, wherein the tray can be designed as a shaft tray.

Die Erfindung betrifft ferner eine Schragenentleereinrichtung zum automatischen Entleeren von mit stabförmigen Produkten gefüllten Schragen in eine Produktions- oder Verpackungsmaschine der Tabak verarbeitenden Industrie, umfassend eine Zuführeinrichtung zum Zuführen mit stabförmigen Produkten gefüllter Schragen, eine Entleerstation mit einer Entleerposition zum über Kopf Entleeren der Schragen, eine Abtransporteinrichtung zum Abtransportieren der entleerten Schragen sowie eine Übergabeeinrichtung zum Transportieren der Schragen innerhalb der Schragenentleereinrichtung während eines Entleerzyklus, sowie ein Verfahren zum automatischen Entleeren von mit stabförmigen Produkten gefüllten Schragen, umfassend die Schritte Zuführen von mit Produkten gefüllten Schragen mittels einer Zuführeinrichtung, Transportieren der Schragen von der Zuführeinrichtung in eine Entleerposition einer Entleerstation mittels einer Übergabeeinrichtung, so dass die Schragen über Kopf in der Entleerposition stehen, über Kopf Entleeren der Schragen, Transportieren der Leerschragen mittels der Übergabeeinrichtung von der Entleerposition auf eine Abtransporteinrichtung, und Abtransportieren der Leerschragen mittels der Abtransporteinrichtung.The invention also relates to a tray emptying device for automatically emptying trays filled with rod-shaped products into a production or packaging machine in the tobacco processing industry, comprising a feed device for feeding trays filled with rod-shaped products, an emptying station with an emptying position for overhead emptying of the trays, a A transport device for transporting away the emptied trays and a transfer device for transporting the trays within the tray emptying device during an emptying cycle, and a method for automatically emptying trays filled with rod-shaped products, comprising the steps of feeding trays filled with products by means of a feed device, transporting the trays from the feed device into an emptying position of an emptying station by means of a transfer device, so that the trays are upside down in the emptying position , overhead emptying of the trays, transporting the empty trays by means of the transfer device from the emptying position to a transport device, and transporting away the empty trays by means of the transport device.

Die beschriebenen Schragen kommen insbesondere in der Tabak verarbeitenden Industrie bei der Verarbeitung stabförmiger Produkte zum Einsatz. Tabakstöcke, Zigaretten, Filterstäbe und insbesondere Filterstabsegmente oder dergleichen werden in Behältern, den so genannten Schragen, insbesondere zum Transport und zur Speicherung aufbewahrt. Dabei können die Behälter als Standardschragen mit einem einzigen Aufnahmeraum für alle Produkte oder als Schachtschragen ausgebildet sein, in denen die Produkte in mehreren voneinander getrennten Schächten liegen. Zur Weiterverarbeitung der gespeicherten Produkte werden diese an nachgeordnete Vorrichtungen, wie z.B. Packmaschinen oder dergleichen abgegeben oder in einen vorhandenen Massenstrom eingeschleust.The trays described are used in particular in the tobacco processing industry when processing rod-shaped products. Tobacco rods, cigarettes, filter rods and in particular filter rod segments or the like are kept in containers, the so-called trays, in particular for transport and storage. The containers can be designed as standard trays with a single receiving space for all products or as shaft trays in which the products are located in several shafts that are separate from one another. For further processing of the stored products, these are delivered to downstream devices, such as packing machines or the like, or introduced into an existing mass flow.

Solche Schragen sind heutzutage üblicherweise aus Kunststoff wie beispielsweise Polystyrol (PS) oder Acrylnitril-Butadien-Styrol (ABS) hergestellt, da dieses Material stabil und gleichzeitig leicht sowie kostengünstig ist. Derartige Schragen sind zum Beispiel im DE-Gbm. 1 882 950 beschrieben.Such trays are now usually made of plastic such as polystyrene (PS) or acrylonitrile butadiene styrene (ABS), since this material is stable and at the same time light and inexpensive. Such trays are, for example, in DE-Gbm. 1,882,950.

Eine nachgeordnete Vorrichtung, in der Schragen zum Einsatz kommen, ist eine Schragenentleereinrichtung, mit Hilfe derer stabförmige Artikel, die aus unterschiedlichen Gründen in Schragen, gelagert werden, wieder in den Produktionsprozess einführt werden. Dazu sind die Schragenentleereinrichtungen mit Produktionsmaschinen zu einer Produktionsanordnung zum Ausführen entsprechender Herstellungsverfahren, zu denen die Zigarettenherstellung, die Filterherstellung und auch das Verpacken derselben gehören, kombiniert.A downstream device in which trays are used is a tray emptying device, with the help of which rod-shaped articles that are stored in trays for various reasons are reintroduced into the production process. For this purpose, the tray emptying devices are combined with production machines to form a production arrangement for carrying out corresponding production processes, which include cigarette production, filter production and also the packaging of the same.

Bekannte Schragenentleereinrichtungen weisen Übergabeeinrichtungen zum Handhaben bzw. zum Handling der Schragen auf, die als Schwenkmechanismus ausgebildet sind. Mit dem bekannten Schwenkmechanismus werden sämtliche Schragen, also die Vollschragen und die Leerschragen, während des Entleerzyklus gehandhabt. Ein Entleerzyklus umfasst das Abnehmen der Vollschragen von der Zuführeinrichtung, das über Kopf Entleeren der Vollschragen in der Entleerstation und das Abgeben der Leerschragen an die Abtransporteinrichtung.Known tray emptying devices have transfer devices for manipulating or handling the trays, which are designed as a pivoting mechanism. With the known pivoting mechanism, all the trays, ie the full trays and the empty trays, are handled during the emptying cycle. An emptying cycle includes removing the full trays from the feed device, emptying the full trays overhead in the emptying station and delivering the empty trays to the removal device.

Solche Schragenentleereinrichtungen sind zum Beispiel in der

Bei den bekannten Schragenentleereinrichtungen tritt das Problem auf, dass bei bzw. nach dem Entleeren stabförmige Produkte in dem Schragen verbleiben, obwohl der Schragen in der Schragenentleereinrichtung vollständig hätte entladen werden sollen. An Boden und/oder Wand des Schragens bleiben stabförmige Produkte hängen, da sich ein elektrostatisches Feld im Schragen gebildet hat, das die stabförmigen Produkte am Herausfallen hindert. Ein solches elektrostatisches Feld bildet sich aufgrund des Umstandes, dass die Schragen aus Kunststoff, einem dielektrischen Material hergestellt sind, durch Reibung. Reibung tritt auf der einen Seite auf, wenn die stabförmigen Produkte in den Schragen gefüllt werden, wobei sie gegen die Wände und den Boden des Schragens reiben. Dabei laden sich Schragenwände bzw. -boden und stabförmige Produkte mit unterschiedlichen Ladungen auf, was zur Bildung eines elektrostatischen Feldes führt, das verhindert, dass sich die Schragen in der Entleereinrichtung vollständig entleeren lassen, wie eigentlich gewünscht. Eine weitere Aufladung erfolgt dadurch, dass die Schragen auf ihrem Transport mit anderen Gegenständen aus Kunststoff in Berührung kommen. So sind zum Beispiel die Transportbänder zum einen der Zuführeinrichtung, zum anderen der Abtransporteinrichtung üblicherweise aus Kunststoff hergestellt. Durch die Reibung zwischen Schragen und Transportband entsteht wiederum elektrische Ladung. Besonders relevant tritt eine solche Ladung bei der Übergabe des Schragens von Zuführeinrichtung zu Entleerstation auf, wenn der Schragen mittels eines Stoppers zwecks Übergabe an die Entleereinrichtung angehalten wird, während das Transportband der Zuführeinrichtung unter dem Schragen weiterläuft. Je trockener die Umgebungsluft ist, umso größer ist dabei die entstehende elektrostatische Aufladung.With the known tray emptying devices, the problem arises that stick-shaped products remain in the tray during or after emptying, although the tray should have been completely discharged in the tray emptying device. Stick-shaped products get caught on the bottom and/or wall of the tray because an electrostatic field has formed in the tray, which prevents the stick-shaped products from falling out. Such an electrostatic field is created by friction due to the fact that the trays are made of plastic, a dielectric material. Friction occurs on one side when the rod-shaped Products are filled in the trays rubbing against the walls and bottom of the tray. The tray walls or floor and rod-shaped products are charged with different charges, which leads to the formation of an electrostatic field that prevents the trays in the emptying device from being completely emptied, as actually desired. Further charging occurs when the trays come into contact with other plastic objects during transport. For example, the conveyor belts on the one hand for the infeed device and on the other hand for the removal device are usually made of plastic. The friction between the tray and the conveyor belt in turn creates an electrical charge. Such a charge occurs in a particularly relevant manner during the transfer of the tray from the feed device to the emptying station if the tray is stopped by means of a stopper for the purpose of transfer to the emptying device, while the conveyor belt of the feed device continues to run under the tray. The drier the ambient air, the greater the resulting electrostatic charge.

Bislang wird diesem Problem Rechnung getragen, in dem die Leerschragen von einer Person kontrolliert und ggf. verbliebene stabförmige Produkte manuell entfernt werden. Mit einem zunehmenden Grad an Automatisierung in der Produktion, der insbesondere zur einer Kostensenkung führen soll, fehlt es im gesamten Prozess jedoch zunehmend an Personen, die eine solche Kontrollfunktion ausüben könnten.So far, this problem has been taken into account by having one person check the empty trays and manually removing any remaining stick-shaped products. However, with an increasing degree of automation in production, which is intended to lead in particular to reducing costs, there is an increasing lack of people throughout the process who could exercise such a control function.

Es ist daher wünschenswert, sicherzustellen, dass nach Möglichkeit keine stabförmigen Produkte nach dem Entleervorgang im Schragen verbleiben.It is therefore desirable to ensure that, if possible, no stick-shaped products remain in the tray after the emptying process.

Hierzu schlägt die

Das Vorsehen einer Einrichtung zum Einblasen ionisierter Druckluft ist konstruktiv aufwendig und mit erhöhten Kosten verbunden. Auch das Vorsehen von Einlagen oder Einsätzen ist aufwendig, da bei der Herstellung der Schragen ein zusätzlicher Arbeitsschritt des Einsetzens der Einlage erforderlich ist, was wiederum die Kosten erhöht. Auch besteht die Gefahr, dass sich Einlage oder Einsatz vom Schragen lösen, in die Maschinen geraten und zu Beschädigungen führen.The provision of a device for blowing in ionized compressed air is structurally complex and associated with increased costs. The provision of deposits or inserts is also expensive, since an additional work step of inserting the insert is required in the production of the trays, which in turn increases the costs elevated. There is also a risk that the insert or insert will come loose from the tray, get caught in the machine and cause damage.

Aufgabe der vorliegenden Erfindung ist es daher, einen Schragen zur Verfügung zu stellen, dessen vollständige Entleerung sichergestellt werden kann und der gleichzeitig einfach und kostengünstig herzustellen ist.It is therefore the object of the present invention to provide a tray which can be guaranteed to be completely emptied and which is at the same time simple and inexpensive to produce.

Diese Aufgabe wird erfindungsgemäß durch einen Schragen mit den Merkmalen des Anspruchs 1 gelöst. Durch die Verwendung von elektrisch leitfähigem Kunststoff als Schragenmaterial kann entstehende Aufladung unmittelbar abgeleitet werden. Es ist kein Aufbringen einer zusätzlichen Schicht, einer Einlage oder dergleichen erforderlich. Der Schragen kann konstruktiv sehr einfach hergestellt werden. Ein elektrisch leitfähiger Kunststoff im Sinne der Erfindung ist dabei ein Kunststoff, der - anders als Kunststoffe üblicherweise, die als hervorragende Isolatoren gelten - eine elektrische Leitfähigkeit von mindestens 10-10 S cm-1 aufweist. Im Sinne der Erfindung werden unter elektrisch leitfähigen Kunststoffen dabei die sogenannten intrinsisch leitfähigen Polymere verstanden, die per se eine Leitfähigkeit aufweisen.According to the invention, this object is achieved by a tray having the features of claim 1 . By using electrically conductive plastic as the tray material, any charging that occurs can be dissipated immediately. It is not necessary to apply an additional layer, insert or the like. The tray can be made structurally very simple. An electrically conductive plastic within the meaning of the invention is a plastic which--unlike plastics which are usually considered excellent insulators--has an electrical conductivity of at least 10 -10 S cm -1 . For the purposes of the invention, electrically conductive plastics are understood to mean the so-called intrinsically conductive polymers, which have conductivity per se.

Dies gelingt besonders gut, wenn der gesamte Schragen aus elektrisch leitfähigem Kunststoff gebildet ist. Vorteilhafterweise ist der Schragen dabei einstückig ausgebildet und im Spritzgussverfahren hergestellt. Auf diese Weise wird ein sehr stabiler Schragen erhalten, der gleichzeitig kostengünstig in der Herstellung ist. Auch können bereits vorhandene Formen zur Schragenherstellung weiter verwendet werden, da sich lediglich das Material ändert, während die Schragenform identisch bleibt.This works particularly well if the entire tray is made of electrically conductive plastic. Advantageously, the tray is designed in one piece and is produced by injection molding. In this way, a very stable tray is obtained, which at the same time is inexpensive to produce. Existing molds for producing trays can also continue to be used, since only the material changes, while the tray mold remains identical.

Der erfindungsgemäße Schragen kann auch ein Schachtschragen sein, d.h. ein Schragen, in dem die Produkte in mehreren voneinander durch Zwischenwände getrennten Schächten liegen. Vorteilhafterweise bestehen dabei auch die Zwischenwände aus elektrisch leitfähigem Kunststoff.The tray according to the invention can also be a shaft tray, ie a tray in which the products lie in several shafts separated from one another by intermediate walls. Advantageously, the partitions are also made of electrically conductive plastic.

Der elektrisch leitfähige Kunststoff ist ein intrinsisch leitfähiges Polymer, insbesondere ein dotiertes intrinsisch leitfähiges Polymer. Unter den intrinsisch leitfähigen Polymeren sind insbesondere das cis-Polyactetylen (cis-PA), das trans-Polyacetylen (trans-PA), Poly(paraphenylen) (PPP), Polythiophen, Polypyrrol, Poly(para-phenylen-vinylen) (PPV) und Polyanilin (PANI) zu nennen. Besonders bevorzugt, weil eine um mehrere Zehnerpotenzen höhere Leitfähigkeit aufweisend, sind solche Polymere, die dotiert sind, d.h. in die eine geringe Menge Fremdatome eingebaut sind.The electrically conductive plastic is an intrinsically conductive polymer, in particular a doped intrinsically conductive polymer. Among the intrinsically conductive polymers are in particular cis-polyacetylene (cis-PA), trans-polyacetylene (trans-PA), poly(paraphenylene) (PPP), polythiophene, polypyrrole, poly(para-phenylene-vinylene) (PPV) and polyaniline (PANI). Particularly preferred because one by several powers of ten Those polymers that are doped, ie in which a small amount of foreign atoms are incorporated, have higher conductivity.

Der erfindungsgemäße leitfähige Kunststoffschragen weist eine stark reduzierte Haftung der Artikel an dessen Innenwänden auf. Dies wirkt sich vorteilhaft auf die Füll- und die Entleervorgänge aus, jedoch könnte sich dies möglicherweise nachteilig hinsichtlich eines sicheren Transports der mit stabförmigen Artikeln gefüllten aufrecht stehenden Schragen, insbesondere bei Beschleunigungs- und/oder Verzögerungsvorgängen auswirken.The conductive plastic tray according to the invention exhibits greatly reduced adhesion of the articles to its inner walls. This has an advantageous effect on the filling and the emptying operations, but this could possibly have an adverse effect on safe transport of the upright trays filled with rod-shaped articles, especially during acceleration and/or deceleration operations.

In einer Weiterbildung des erfindungsgemäßen Schragen ist deshalb vorgesehen, dass die Rückwand des Schragens auf ihrer Inneseite um wenigstens 1 Grad aus der Senkrechten gegenüber der senkrechten Außenseite geneigt ist, wobei die Wandstärke der Rückwand von oben nach unten zur Bodenwand zunimmt.In a development of the tray according to the invention, it is therefore provided that the rear wall of the tray is inclined on its inside by at least 1 degree from the vertical relative to the vertical outside, with the wall thickness of the rear wall increasing from top to bottom toward the bottom wall.

Aufgrund der sich zur offenen Oberseite hin verjüngenden Rückwand ergeben sich zudem Vorteile bei der Herstellung des Kunststoffschragens, es ist hiermit nämlich eine sogenannte Entformungsschräge geschaffen.Due to the rear wall tapering towards the open upper side, there are also advantages in the production of the plastic bevel, namely a so-called demoulding bevel is created in this way.

In einer Weiterbildung des erfindungsgemäßen Schragens ist weiterhin vorgesehen, dass die Bodenwand des Schragens auf ihrer Innenseite um wenigstens 1 Grad aus der Waagerechten gegenüber der waagerechten Außenseite geneigt ist, wobei die Wandstärke der Bodenwand von vorn nach hinten zur Rückwand abnimmt.In a development of the tray according to the invention, it is also provided that the bottom wall of the tray is inclined on its inside by at least 1 degree from the horizontal compared to the horizontal outside, with the wall thickness of the bottom wall decreasing from front to back towards the rear wall.

Vorzugsweise sind die Innenseiten der Rückwand und der Bodenwand um etwa denselben Winkelbetrag geneigt, so dass der eingeschlossene Winkel etwa 90 Grad beträgt.Preferably, the inner sides of the back wall and the bottom wall are inclined by approximately the same angular amount, such that the included angle is approximately 90 degrees.

Durch die vorbeschriebenen Weiterbildungen ist nunmehr ein sicherer Transport der Artikel in aufrecht stehenden Schragen möglich, ohne dass die Fördermittel, insbesondere für den Transport von Vollschragen wie üblich in Schragenfülleinrichtungen und Schragenentleereinrichtungen geneigt ausgeführt sind. Um ein sicheres Füllen oder Entleeren der Schragen in den Schragenfülleinrichtungen bzw. in den Schragenentleereinrichtungen zu gewährleisten werden die Schragen zum Füllen bzw. zum Entleeren mittels einer Schwenkvorrichtung derart geneigt, dass die Innenseite der Rückwand des Schragens in derselben, vorzugsweise vertikalen Ebene liegt, wie die vorgeordnete oder nachgeordnete Rückwand des Zwischen- oder Pufferspeichers der Schragenfülleinrichtung bzw. der Schragenentleereinrichtung.The above-described developments now allow the articles to be transported safely in upright trays without the conveying means, in particular for the transport of full trays, being designed to be inclined as is customary in tray filling devices and tray emptying devices. In order to ensure safe filling or emptying of the trays in the tray filling devices or in the tray emptying devices, the trays are tilted for filling or emptying by means of a pivoting device in such a way that the inside of the rear wall of the tray is in the same, preferably vertical, plane as the upstream or downstream rear wall of the intermediate or buffer store of the tray filling device or the tray emptying device.

Die Aufgabe wird auch durch eine Schragenentleereinrichtung der eingangs genannten Art gelöst, bei der an zumindest einer Einrichtung, ausgewählt aus Zuführeinrichtung, Entleerstation, Abtransporteinrichtung und Übergabeeinrichtung, zumindest ein ladungsabführendes Element vorgesehen ist, das ausgebildet und eingerichtet ist, um einen Kontakt zwischen dem Schragen und dem geerdeten Maschinengrundgestell herzustellen.The object is also achieved by a tray emptying device of the type mentioned at the outset, in which at least one charge-dissipating element is provided on at least one device selected from the feed device, emptying station, removal device and transfer device, which is designed and set up to prevent contact between the tray and the grounded machine base frame.

Wie vorstehend ausgeführt ist es sehr vorteilhaft, wenn die Schragen aus elektrisch leitfähigem Kunststoff bestehen, da somit eine Ableitung der durch Reibung entstehenden Ladung möglich ist. Um den gewünschten Effekt zu erzielen ist es erforderlich, dass die Ladung aus dem Schragen abgeleitet wird. Übliche Maschinen und Einrichtungen in der tabakverarbeitenden Industrie weisen ein Maschinengrundgestell auf, an dem die einzelnen Komponenten und Teile angebracht sind. Dieses Maschinengrundgestell ist stets geerdet. Es ist daher bestens geeignet, die entstandene Ladung abzuleiten. Dazu ist es erforderlich, eine leitende Verbindung zwischen den mit Ladung behafteten Schragen und dem Maschinengrundgestell herzustellen. Erfindungsgemäß wird diese durch mindestens ein ladungsabführendes Element vorgesehen, das entweder an der Zuführeinrichtung, an der Entleerstation, an der Abtransporteinrichtung oder an der Übergabeeinrichtung angebracht ist. Das ladungsabführende Element bzw. die ladungsabführenden Elemente können insbesondere als Kontaktflächen aus Metall ausgebildet sein. Dabei als Metalle Silber, Kupfer und Eisen, die gute elektrische Leiter sind, besonders geeignet.As stated above, it is very advantageous if the trays are made of electrically conductive plastic, since this allows the charge produced by friction to be dissipated. In order to achieve the desired effect, it is necessary that the charge is discharged from the tray. Customary machines and devices in the tobacco processing industry have a machine base frame to which the individual components and parts are attached. This machine base frame is always grounded. It is therefore ideally suited to dissipate the resulting charge. To do this, it is necessary to establish a conductive connection between the charged trays and the machine base frame. According to the invention, this is provided by at least one charge-dissipating element, which is attached either to the feed device, to the emptying station, to the removal device or to the transfer device. The charge-dissipating element or the charge-dissipating elements can be designed in particular as contact surfaces made of metal. Silver, copper and iron, which are good electrical conductors, are particularly suitable as metals.

In einer bevorzugten Ausführungsform der Schragenentleereinrichtung weist deren Übergabeeinrichtung einen eine auf 180° begrenzte Schwenkbewegung ausführenden Schwenkmechanismus mit einer um eine ortsfeste Schwenkachse S schwenkbaren Schwenkkassette, die zum Fixieren, Schwenken und Freigeben der Schragen ausgebildet und eingerichtet ist, auf, wobei die Schwenkachse das ladungsabführende Element ist. Eine besonders gute Ableitung ist gewährleistet, wenn der Schwenkmechanismus zusätzlich mit einem Kupfergeflecht versehen ist. Da die Schwenkbewegung der Kassette auf 180° beschränkt ist, sind Probleme durch ein etwaiges Verdrehen des Geflechtes ausgeschlossen.In a preferred embodiment of the tray emptying device, its transfer device has a pivoting mechanism that performs a pivoting movement limited to 180°, with a pivoting cassette that can pivot about a stationary pivoting axis S, which is designed and set up for fixing, pivoting, and releasing the trays, with the pivoting axis containing the charge-dissipating element is. A particularly good discharge is guaranteed if the swivel mechanism is additionally provided with a copper mesh. Since the panning movement of the cassette is limited to 180°, problems caused by the braid twisting are eliminated.

Besonders vorteilhaft ist es, wenn im gesamten Prozess möglichst wenig elektrostatische Aufladung generiert wird. Gemäß einer vorteilhaften Ausführungsform ist es daher vorgesehen, dass Zuführeinrichtung und/oder Abtransporteinrichtung als Förderband ausgebildet ist bzw. sind, wobei das Förderband aus einem elektrisch leitfähigen Kunststoff besteht. Auf diese Weise wird bereits die Aufladung, die durch die Reibung zwischen Schragen und Förderband entsteht, weitestgehend vermieden.It is particularly advantageous if as little electrostatic charging as possible is generated throughout the entire process. According to an advantageous embodiment, it is therefore provided that the feed device and/or removal device is/are designed as a conveyor belt, with the conveyor belt consisting of an electrically conductive plastic. In this way, the charging that occurs as a result of the friction between the trays and the conveyor belt is largely avoided.

Schließlich wird die Aufgabe auch durch ein Verfahren der eingangs genannten Art gelöst, bei dem als Schragen die Schragen der vorliegenden Erfindung zum Einsatz kommen und bei dem in mindestens einem der Verfahrensschritte eine Ladungsabführung erfolgt. Mit einem solchen Verfahren wird die statische Aufladung in den Schragen so weit reduziert, dass ein Hängenbleiben von stabförmigen Produkten in den Schragen nach dem Entleervorgang im Wesentlichen ausgeschlossen sein sollte. Das Verfahren ist besonders effektiv und gleichzeitig einfach, da keine aufwendigen zusätzlichen Vorrichtungen zum Beispiel zur Deionisierung vorgesehen werden müssen.Finally, the object is also achieved by a method of the type mentioned at the outset, in which the trays of the present invention are used as trays and in which charge dissipation takes place in at least one of the method steps. With such a method, the static charge in the trays is reduced to such an extent that stick-shaped products getting caught in the trays after the emptying process should essentially be ruled out. The method is particularly effective and at the same time simple, since no complex additional devices, for example for deionization, have to be provided.

Weitere zweckmäßige und/oder vorteilhafte Merkmale und Ausgestaltungen ergeben sich aus den Unteransprüchen und der Beschreibung. Eine besonders bevorzugte Ausführungsform sowie das Verfahrensprinzip werden anhand der beigefügten Zeichnung näher erläutert. In der Zeichnung zeigt:

- Fig. 1

- eine perspektivische Darstellung eines erfindungsgemäßen als Schachtschragen ausgebildeten Schragens,

- Fig. 2

- eine Ausführungsform eines nicht erfindungsgemäßen Schragens,

- Fig. 3

- eine weitere Ausführungsform eines nicht erfindungsgemäßen Schragens,

- Fig. 4

- eine Seitenansicht der erfindungsgemäßen Entleereinrichtung mit einem auf der Zuführeinrichtung befindlichen Schragen in der Abholposition,

- Fig. 5

- die

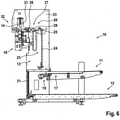

Entleereinrichtung gemäß Figur 4 mit dem in eine Kassette aufgenommenen Schragen während der vertikalen Aufwärtsbewegung und - Fig. 6

- die

Entleereinrichtung gemäß Figur 4 mit einer in die Entleerposition geschwenkten Kassette.

- 1

- a perspective view of a tray designed as a shaft tray according to the invention,

- 2

- an embodiment of a tray not according to the invention,

- 3

- a further embodiment of a tray not according to the invention,

- 4

- a side view of the emptying device according to the invention with a tray located on the feed device in the pick-up position,

- figure 5

- the emptying device according to

figure 4 with the tray received in a cassette during the vertical upward movement and - 6

- the emptying device according to

figure 4 with a cassette swiveled into the emptying position.

Der in den

Die

Der Schragen 1 kann auch ohne Schachtwände 8 als Standardschragen ausgebildet sein.The tray 1 can also be designed as a standard tray without

Der Schragen ist aus elektrisch leitfähigem Kunststoff hergestellt, wobei es sich um ein sogenanntes intrinsisch leitfähiges Polymere handelt, das per se eine Leitfähigkeit aufweist.The tray is made of electrically conductive plastic , which is what is known as an intrinsically conductive polymer se has a conductivity.

Der in den

Die in den

Die Übergabeeinrichtung 13 umfasst eine Kassette 21, die vertikal auf und ab bewegbar und schwenkbar ausgebildet ist. Die Vertikal- und Schwenkbewegungen sind direkt oder indirekt durch die Kassette 21 ausführbar. Des Weiteren ist die Kassette 21 zum Halten eines Schragens 14, 16 während des gesamten Entleervorgangs ausgebildet und eingerichtet. Das bedeutet, dass die Kassette Einrichtungen zum Halten und/oder Greifen der Schragen 14, 16 aufweist, mittels der die Schragen 14, 16 in einer definierten Position, die auch geneigt zur Vertikalen sein kann, innerhalb der Kassette 21 fixiert sind. Bevorzugt sind pneumatische Greifelemente vorgesehen. Das Halten der Schragen 14, 16 selbst kann z.B. durch metallische Federelemente oder dergleichen realisiert sein. Selbstverständlich sind auch alle anderen üblichen Halte- und/oder Greifmechanismen einsetzbar, welche aus leitfähigem Material bestehen. Zum Aufnehmen bzw. Abholen der vollen Schragen 14 von der Zuführeinrichtung 11 ist der Kassette 21 optional ein Abholelement 22 zugeordnet. Das Abholelement 22 ist des Weiteren dafür eingerichtet und ausgebildet, den vollen Schragen 14 innerhalb der Kassette 21 zu positionieren, so dass dieser in der "Mitte-Produkt"-Position fixierbar ist. Die auch unter dem Begriff "Konstante Kante" bekannte "Mitte-Produkt"-Position ist für eine Handhabung verschiedener Produktlängen im Zuge einer Formatumstellung vorteilhaft. Das Abholelement 22 kann weiterhin auch ein (nicht dargestelltes) Abschiebelement aufweisen, mittels der das Ausstoßen des entleerten Schragens 16 aus der Kassette 21 unterstützt wird. Das Abschiebelement kann auch als separate Einrichtung vorgesehen sein.The

Zur Ausübung der vertikalen Bewegungen von der Abholposition 17 in die Übergabeposition 20 im Bereich der Schwenkeinrichtung 27 und zurück in die Abgabeposition 19 weist die Entleereinrichtung 10 bevorzugt eine Lifteinrichtung 23 als Bestandteil der Übergabeeinrichtung 13 auf. Die Lifteinrichtung 23 umfasst vertikal verlaufende Führungsschienen 24 oder dergleichen, auf denen bzw. in denen eine Liftgabel 25 oder dergleichen geführt ist sowie eine Antriebseinheit 26. Des Weiteren umfasst die Übergabeeinrichtung 13 eine Schwenkeinrichtung 27. Die Schwenkeinrichtung 27 ist zwischen der Übergabeposition 20 und der Entleerposition angeordnet und zur Ausführung einer über-Kopf-Schwenkbewegung der den vollen Schragen 14 haltenden Kassette 21 über das Entleermagazin 18 sowie der den dann entleerten Schragen 16 haltenden Kassette 21 zurück eingerichtet und ausgebildet. Die Schwenkeinrichtung 27 ist am oberen Ende der Führungsschienen 24 angeordnet und bildet einen Schwenkkopf. Die Schwenkeinrichtung 27 weist eine Rastvorrichtung 28 und eine drehbare und ortsfeste Welle 29 auf, wobei die Rastvorrichtung 28 an der Welle 29 gelagert ist. Die Welle 29 selbst ist an einem Rahmen oder dergleichen ortsfest aber drehbar gelagert. Die Welle 29 bildet zusammen mit der Kassette 21 das ladungsabführende Element, mit Hilfe dessen die im Schragen vorhandene Ladung über das Grundgestell 33 der Entleereinrichtung 10 abgeleitet werden kann. Zusätzlich kann im Bereich der Welle 29 noch ein Kupfergeflecht (nicht gezeigt) vorgesehen sein, das die Ladungsableitung unterstützt.The emptying

Die Rastvorrichtung 28 umfasst mehrere (nicht dargestellte) Rastbolzen auf, die z.B. mittels (ebenfalls nicht dargestellten) Pneumatikzylindern oder dergleichen betätigbar sind. Das bedeutet, dass die beweglich gelagerten Rastbolzen aus einer zurückgezogenen Warteposition, in der die Kassette 21 bei der Übergabe von der Lifteinrichtung 23 an die Schwenkeinrichtung 27 und zurück ein- oder auskoppelbar ist, in eine Rastposition, in der die Kassette 21 fest mit der Schwenkeinrichtung 27 verbunden ist, und zurück bewegbar sind. Mit anderen Worten ist die Kassette 21 von der Lifteinrichtung 23 lösbar und mit der Schwenkeinrichtung 27 verbindbar und umgekehrt. Selbstverständlich kann die Verriegelung der Kassette 21 an der Schwenkeinrichtung 27 und die entsprechende Entriegelung auch auf andere übliche Weise erfolgen, sofern die leitfähige Verbindung zwischen Schwenkeinrichtung 27, Kassette 21 und Schragen 14 hergestellt ist. Der Abstand zwischen der Drehachse D der Welle 29 und der mittels der Rastvorrichtung 28 an der Welle 29 drehbar bzw. schwenkbar gelagerten Kassette 21 ist gering ausgebildet. Das bedeutet, dass die Rastvorrichtung 28 in Bezug auf die Bauform sehr kurz ausgebildet ist, so dass die Kassette 21 bei der Schwenkbewegung eine sehr enge Hüllkurve mit einem kleinen Radius beschreibt. Idealerweise ist die Kassette 21 in unmittelbarer Nähe zur Welle 29 bzw. direkt an dieser angeordnet. Ein Antrieb 30 zur Ausführung der Schwenkbewegung ist der Übergabeeinrichtung 13 zugeordnet und in Verlängerung der Welle 29 angeordnet.The latching

Die Abholposition 17 für die vollen Schragen 14 und die Abgabeposition 19 für die entleerten Behälter 16 können an unterschiedlichen Positionen liegen. Vorzugsweise entspricht die Abholposition 17 aber der Abgabeposition 19. Dadurch kann das Abholen eines vollen Schragens 14 von der Zuführeinrichtung 11 in die Kassette 21 und das Abgeben eines entleerten Behälters 16 aus der Kassette 21 gleichzeitig stattfinden. Dabei liegen in der bevorzugten Ausführungsform sowohl die Abholposition 17 als auch die Abgabeposition 19 auf demselben Niveau, nämlich auf der Höhe der Zuführeinrichtung 11. Um die aus der Kassette 21 abgeschobenen bzw. ausgestoßenen entleerten Schragen 16 in den Bereich der Abtransporteinrichtung 12 zu transportieren, ist im Bereich der unteren Abtransporteinrichtung 12 eine Lifteinrichtung 31 angeordnet. Die Lifteinrichtung 31 zum Transport der entleerten Behälter 16 von der Abgabeposition 19 auf die Abtransporteinrichtung ist separat zur Lifteinrichtung 23 zum Transport der vollen Schragen 14 von der Abholposition 17 in die Entleerposition und zurück in die Abgabeposition 19 ausgebildet. Es ist jedoch auch möglich, für den gesamten Transport der Schragen 14, 16 eine einzige Lifteinrichtung vorzusehen.The pick-up

Im Folgenden wird das Verfahrensprinzip anhand der

Mindestens ein voller Schragen 14, vorzugsweise jedoch mehrere volle Schragen 14 sind auf der Zuführeinrichtung 11 angeordnet bzw. bevorratet. Die Schragen 14 stehen mit einer Schmalseite auf der leicht in Richtung der Übergabeeinrichtung 13 abfallenden Zuführeinrichtung 11, so dass die Schragen 14 um den Winkel α zur Vertikalen geneigt in Richtung der Übergabeeinrichtung 13 in die Abholposition 17 transportiert werden. Die Schragen 14 können selbstverständlich auch ohne Neigung transportiert werden. Jeweils ein voller Schragen 14 wird aus der Abholposition 17 in die Entleerposition im Bereich des Entleermagazins 18 transportiert. Der Transport erfolgt vorzugsweise dadurch, dass der volle Schragen 14 durch das Abholelement 22 in die Kassette 21 gezogen und dort positioniert wird. Nachdem der Schragen 14 in der Kassette 21 fixiert worden ist, wird entweder der Schragen 14 selbst oder die Kassette 21 um einen Winkel zur Vertikalen geschwenkt, der größer ist als der Winkel α. Mit dieser Gesamtneigung um den Winkel β zur Vertikalen wird die Kassette 21 mit dem Schragen 14 mittels der Lifteinrichtung 23 vertikal nach oben in den Bereich des Entleermagazins 18 bewegt.At least one

Im Bereich der Übergabeposition 20 wird die Kassette 21 von der Lifteinrichtung 23 gelöst und mit der Schwenkeinrichtung 27 verbunden. Dazu werden Rastbolzen der Rastvorrichtung 28 aus einer Warteposition in die Rastposition bewegt, so dass die Kassette 21 fest mit der Welle 29 der Schwenkeinrichtung 27 verbunden ist. Die Welle 29 ist gleichzeitig mit dem Maschinengrundgestell 33 verbunden, so dass eine Ladungsableitung eventuell in dem Schragen 14 vorhandener elektrostatischer Aufladung erfolgt. Durch eine Drehung der Welle 29 führt die Schwenkeinrichtung 27 eine Schwenkbewegung aus, so dass der Schragen 14 über-Kopf über dem Entleermagazin 18 steht. Das Schließelement des Schragens 14 wird geöffnet, so dass die Produkte nach unten aus dem Behälter 14 in das Entleermagazin 18 fallen. Da die elektrostatische Ladung kurz zuvor über die Welle 29 und das Maschinengrundgestell 33 abgeleitet wird, besteht keine Anziehung mehr zwischen Produkten und Schragen 14, so dass der Schragen 14 vollständig entleert wird und keine Produkte am Boden 5 oder an den Wänden 3, 4, 6 des Schragen zurückbleiben. Nach dem vollständigen Entleeren des Schragens 14 schwenkt die Kassette 21 mit dem entleerten Schragen 16 zurück. Die Kassette 21 mit dem entleerten Schragen 16 wird von der Schwenkeinrichtung 27 gelöst und wieder mit der Lifteinrichtung 23 verbunden. Die Lifteinrichtung 23 transportiert den entleerten Schragen 16 nach unten in die Abgabeposition 19. Während des gesamten Entleervorgangs von der Abholposition 17 in den Bereich des Entleermagazins 18 und zurück in die Abgabeposition 19 wird der Schragen 14, 16 in der auf und ab bewegbaren und schwenkbaren Kassette 21 gehalten.In the area of the

Sobald sich die Kassette 21 nach dem Entleeren eines Schragens 14, 16 wieder in der Abgabeposition 19 befindet, die der Abholposition 17 entspricht, wird ein neuer voller Schragen 14 von der Zuführeinrichtung 11 abgeholt und in der Kassette 21 positioniert, während gleichzeitig der in der Kassette 21 befindliche entleerte Schragen 16 aus der Kassette 21 geschoben oder gestoßen wird. Das Ausschieben bzw. Ausstoßen kann durch den vollen Schragen 14 und/oder durch ein Abschiebelement erfolgen. Der entleerte Schragen 16 wird aus der Kassette 21 auf die Lifteinrichtung 31 geschoben, mittels der der entleerte Schragen 16 vom Niveau der Zuführeinrichtung 11 nach unten in den Bereich der Abtransporteinrichtung 12 transportiert und an diese abgegeben wird.As soon as the

Wie bereits erwähnt, sind nicht alle für das bevorzugte Ausführen des Verfahrens genannten Schritte notwendig. Entscheidend für ein einfaches und zuverlässiges Verfahren ist es, dass der Schragen 14, 16 während des gesamten Entleervorgangs, also während des Transports und des Entleerens, permanent in der Kassette 21 gehalten wird. Außerdem ist es für ein vollständiges Entleeren erforderlich, dass eine Ableitung der im Prozess am Schragen 14, 16 entstandenen elektrostatischen Ladung erfolgt.As already mentioned, not all of the steps mentioned for the preferred execution of the method are necessary. It is crucial for a simple and reliable method that the

Claims (8)

- Tray (1) for receiving rod-shaped articles of the tobacco-processing industry, comprising a tray body (2) formed by a rear wall (6), two side walls (3, 4) arranged at least substantially parallel and spaced-apart from each other and a bottom wall (5) providing a receiving space (7) for the products which is designed to be open to the front and above, wherein the tray (1) may be designed as a shaft tray, characterised in that the tray (1) is at least partially constructed of electrically conductive plastic material, wherein the electrically conductive plastic material is an intrinsically conductive polymer, in particular a doped intrinsically conductive polymer.

- Tray (1) according to claim 1, characterised in that the entire tray (1) is constructed of electrically conductive plastic material.

- Tray (1) according to claim 1 or 2, characterised in that it is constructed in one piece and is manufactured by injection moulding.

- Tray (1) according to any one of claims 1 to 3, characterised in that the rear wall (6) of the tray (1) is inclined on its inside by at least 1 degree from the perpendicular with respect to the vertical outer side, wherein the wall thickness of the rear wall (6) increases from top to bottom towards the bottom wall (5) and/or that the bottom wall (5) of the tray (1) is inclined on its inside by at least 1 degree from the horizontal with respect to the horizontal outer side, wherein the wall thickness of the bottom wall (5) decreases from front to rear towards the back wall (6).

- Tray discharging device (10) for automatically discharging trays (1, 14) filled with rod-shaped articles according to any one of claims 1 to 3, into a production or packaging machine of the tobacco-processing industry, comprising a feed device (11) for feeding in trays (14) filled with rod-shaped articles,a discharge station (32) with a discharge position for overhead emptying of the trays (14),a removal device (12) for transporting away the emptied trays (16) anda transfer unit (13) for transporting the trays (14, 16) within the tray discharging device (10) during a discharge cycle,characterised in that on at least one device, selected from feed device (11), discharge station (32), removal device (12) and transfer unit (13), at least one charge discharging element is provided, which is configured and adapted to establish a contact between the tray (1) and the earthed machine base frame (33).

- Tray discharging device (10) according to claim 5, characterised in that the transfer device (13) has a pivoting mechanism executing a pivoting movement limited to 180° with a pivot cassette (21) pivotable about a fixed pivot axis S which is configured and adapted for fixing, pivoting and releasing the trays (14, 16), wherein the pivot axis S is the charge discharging element.

- Tray discharging device (10) according to claim 5 or 6, characterised in that at least one of a feed device (11) and removal device (12) is configured as a conveyor belt, wherein the conveyor belt consists of an electrically conductive plastic material.

- Method for automatically discharging trays (14) filled with rod-shaped articles, comprising the steps- feeding in trays (14) filled with rod-shaped articles by means of a feed device (11),- transporting the trays (14) from the feed device (11) into a discharge position of a discharge station (32) by means of a transfer unit (13), so that the trays are overhead in the discharge position, overhead emptying of the trays,- transporting the empty trays (16) by means of the transfer unit (13) from the discharge station (32) onto a removal device (12), and- transporting away the empty trays (16) by means of the removal device (12),characterised in that the trays (14, 16) are trays according to any one of claims 1 to 3 and that charge discharging takes place in at least one of the method steps.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL14164574T PL2805633T5 (en) | 2013-04-15 | 2014-04-14 | Trays made of conductive plastic and device and method for automatically unloading trays filled with rod-shaped articles |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013103767.4A DE102013103767A1 (en) | 2013-04-15 | 2013-04-15 | Slides of conductive plastic and device and method for automatically emptying filled with rod-shaped products Schragen |

Publications (5)

| Publication Number | Publication Date |

|---|---|

| EP2805633A1 EP2805633A1 (en) | 2014-11-26 |

| EP2805633B1 EP2805633B1 (en) | 2016-05-25 |

| EP2805633B8 EP2805633B8 (en) | 2016-07-13 |

| EP2805633B2 EP2805633B2 (en) | 2021-12-29 |

| EP2805633B9 true EP2805633B9 (en) | 2022-03-23 |

Family

ID=50478753

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14164574.7A Active EP2805633B9 (en) | 2013-04-15 | 2014-04-14 | Trays made of conductive plastic material and device and method for automatically discharching trays filled with rod-shaped articles |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2805633B9 (en) |

| CN (1) | CN104097852B (en) |

| DE (1) | DE102013103767A1 (en) |

| PL (1) | PL2805633T5 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013114071A1 (en) * | 2013-12-16 | 2015-06-18 | Hauni Maschinenbau Ag | Tray and tray emptying device and method for automatically emptying trays filled with rod-shaped articles of the tobacco processing industry |

| DE102014116578A1 (en) * | 2014-10-24 | 2016-04-28 | Hauni Maschinenbau Ag | Arrangement and method for conveying a product mass flow formed from rod-shaped articles of the tobacco processing industry and containers for receiving and dispensing portions of the product mass flow |

| DE102014016161A1 (en) * | 2014-11-04 | 2016-05-04 | Hauni Maschinenbau Ag | Tray for receiving rod-shaped articles of the tobacco-processing industry and transport and / or storage arrangement comprising at least two trays for receiving rod-shaped articles of the tobacco-processing industry |

| DE202015105643U1 (en) | 2015-10-23 | 2015-11-23 | Hauni Maschinenbau Ag | Slides of conductive plastic |

| EP3465225B1 (en) * | 2016-06-03 | 2021-03-10 | Roche Diagnostics GmbH | Laboratory sample distribution system and laboratory automation system |

| CN111480880B (en) * | 2020-04-30 | 2024-10-18 | 红云红河烟草(集团)有限责任公司 | Quick box-changing device for filter stick |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB694334A (en) † | 1950-12-14 | 1953-07-15 | James Ernest Morris | Improvements in or relating to receptacles |

| DE1882950U (en) | 1962-10-04 | 1963-11-14 | Hauni Werke Koerber & Co Kg | CIGARETTE SLOPE. |

| US3406126A (en) † | 1966-12-07 | 1968-10-15 | Avco Corp | Conductive synthetic resin composition containing carbon filaments |

| US4228194A (en) † | 1979-05-14 | 1980-10-14 | Meeder Ernest P | Electrically conductive article and method of making the same |

| DE3001204A1 (en) † | 1980-01-15 | 1981-07-30 | Bayer Ag, 5090 Leverkusen | ELECTRICALLY CONDUCTIVE POLYCARBONATE |

| NL193609C (en) † | 1981-12-30 | 2000-04-04 | Bekaert Sa Nv | Composite strand for processing as granulate in plastic products and method for manufacturing a plastic mixing granulate. |

| DE3543301A1 (en) † | 1985-12-07 | 1987-06-11 | Roehm Gmbh | ELECTRICALLY CONDUCTIVE SOLID PLASTICS |

| JP2552625B2 (en) * | 1993-11-09 | 1996-11-13 | 淀川化成株式会社 | Box for transporting glass substrates |

| EP0780594A1 (en) † | 1995-12-21 | 1997-06-25 | Elf Atochem S.A. | Antistatic belts |

| US6702091B2 (en) † | 1998-09-15 | 2004-03-09 | Rolcon, Inc. | Conveyor roller assembly |

| US20020099119A1 (en) † | 1999-05-27 | 2002-07-25 | Bradley D. Craig | Water-borne ceramer compositions and antistatic abrasion resistant ceramers made therefrom |

| IT1309297B1 (en) * | 1999-06-22 | 2002-01-22 | Gd Spa | POCKET CONVEYOR. |

| DE10007479A1 (en) * | 2000-02-18 | 2001-08-23 | Hauni Maschinenbau Ag | Device for conveying a fiber strand of the tobacco processing industry |

| WO2005022603A2 (en) † | 2003-09-02 | 2005-03-10 | Integral Technologies, Inc. | Low cost conductive containers manufactured from conductive loaded resin-based materials |

| DE102004055629A1 (en) * | 2004-11-12 | 2006-05-24 | Hauni Maschinenbau Ag | Apparatus and method for successively emptying containers filled with articles |

| DE102007013548A1 (en) † | 2007-03-17 | 2008-09-18 | Hauni Maschinenbau Ag | Modular shaft trays |

| DE102007022868A1 (en) * | 2007-05-12 | 2008-11-13 | Hauni Maschinenbau Ag | Emptying magazine and transfer device for a tray emptying, a tray emptying and a method for emptying filled with rod-shaped products Schragen and forwarding the products to downstream devices |

| PL212815B1 (en) † | 2008-05-29 | 2012-11-30 | Int Tobacco Machinery Poland | Equipment for unloading the multisegmented cassetes filled up with rod-like elements, used in the tobacco industry |

| DE102008027636A1 (en) | 2008-06-07 | 2009-12-10 | Hauni Maschinenbau Ag | Device and method for the successive emptying of containers filled with rod-shaped products |

| DE102009025568A1 (en) * | 2009-06-13 | 2010-12-16 | Hauni Maschinenbau Ag | Device and method for the successive emptying of containers filled with rod-shaped products |

| PL221883B1 (en) | 2010-01-21 | 2016-06-30 | Int Tobacco Machinery Poland Spółka Z Ograniczoną Odpowiedzialnością | Method for removing electrostatic charges from the cases used for transportation of rod-like elements, a case protected against negative impact of electrostatic field and the device for unloading the cases filled with the rod-like elements with simultaneous removal of electrostatic charges |

| CN201634598U (en) * | 2010-03-25 | 2010-11-17 | 龙建萍 | Bamboo and plastic plate for baking firework powder particles |