EP2783178B1 - Lichtbogenofen mit einem ofendeckeltragarmsystem - Google Patents

Lichtbogenofen mit einem ofendeckeltragarmsystem Download PDFInfo

- Publication number

- EP2783178B1 EP2783178B1 EP12784203.7A EP12784203A EP2783178B1 EP 2783178 B1 EP2783178 B1 EP 2783178B1 EP 12784203 A EP12784203 A EP 12784203A EP 2783178 B1 EP2783178 B1 EP 2783178B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- furnace

- cover

- furnace cover

- rotary

- hydraulic cylinder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D1/00—Casings; Linings; Walls; Roofs

- F27D1/18—Door frames; Doors, lids or removable covers

- F27D1/1808—Removable covers

- F27D1/1816—Removable covers specially adapted for arc furnaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B3/00—Hearth-type furnaces, e.g. of reverberatory type; Electric arc furnaces ; Tank furnaces

- F27B3/08—Hearth-type furnaces, e.g. of reverberatory type; Electric arc furnaces ; Tank furnaces heated electrically, with or without any other source of heat

- F27B3/085—Arc furnaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D1/00—Casings; Linings; Walls; Roofs

- F27D1/18—Door frames; Doors, lids or removable covers

- F27D1/1808—Removable covers

- F27D2001/1825—Means for moving the cover

- F27D2001/185—Means for moving the cover comprising means for tilting the cover

Definitions

- the present invention relates to an electric arc furnace, with at least one furnace vessel, a furnace lid and with a furnace lid associated Tragarmsystem with which the furnace lid on the furnace vessel via a connected to the Tragarmsystem pivoting and / or lifting portal is formed and lowered and at least one Electrode support over which an electrode is raised and lowered formed by at least one passage opening in the furnace lid.

- arc furnaces From the state of the art arc furnaces, so-called. EAF ovens, with Tragarmsystemen for the furnace lid known in which water-cooled boom are provided which hold the furnace lid in a 3-point suspension - in a V-arrangement. Furthermore, self-supporting Einarmige furnace cover systems are known, which is associated with its own Deckelhub- and slewing gear. Such generic arc furnaces are for example from the DE 1 940 740 and the DE 3 522 559 known. Furthermore, the DE 1 216 900 a device for coupling the lift-off furnace lid to the electrode lifting device of an electric arc furnace.

- This Tragarmsysteme have proven useful, but are associated with the disadvantage that, for example, in the 3-point suspension of the furnace lid three annular space used, double-acting lift cylinders in the immediate vicinity of the current-carrying components, such as the electrode support arms are arranged. This often leads to damage caused by current flow due to induction and / or arcing on the cylinders themselves. Furthermore, with such a configuration, additional cooling of the lifting systems of the support arms is essential. This results in the disadvantage of a costly cooling water supply with very long cooling water pipes, from a Transformatorenhauswand to the furnace cover.

- a piston side used, single-acting hydraulic cylinder which is hinged to the base of the rotary and / or lifting portal at a first receiving point, and at a second receiving point .der in alignment aligned to the first pick-up point and arranged on a recording facial expressions and is rotatably mounted, wherein the recording facial features is designed as a lever and rotatably mounted on the rotary and / or lifting portal on a recording associated with this, and the recording facial expressions with the Tragarmsystem the furnace cover is connected, and the furnace lid can be raised / lowered and folded over the receptacle mimics that can be connected to the support arm system.

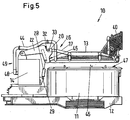

- the self-supporting Tragarmsystem the furnace lid is formed from spokes pairs crossing at right angles, wherein the pair of spokes, which is formed parallel to the transverse axis of the furnace vessel (bend plane) extended over the edge of the lid.

- the conventional support arms for a cover can be omitted in favor of a self-supporting furnace cover.

- a shortening of the coolant connections through the rotary and / or lifting tower and below a tilting stage associated with the furnace is possible. Due to the simplified coolant supply, the cover replacement time can be shortened considerably.

- the radial spokes have free ends, wherein the free ends are associated with pin joints.

- the recording facial expressions can be lowered by the hydraulic cylinder to the extent that the pin joints are posted at the free ends of the Tragarmsystems from the storage cavities of the recording facial expressions and the furnace cover is mechanically and electrically decoupled from the rotary and / or lifting portal.

- the geometry between the hydraulic cylinder, and the receiving points for the Tragarmsystem is selected on the recording facial that horizontal displacements are generated when lifting the furnace cover, which negligible in the region of the openings of the electrodes through the furnace lid are formed in the interface plane of the opening of the furnace vessel so that adhesions of the furnace lid with the edge of the furnace vessel over shear stresses generated by the cover movement are solvable.

- Negligibly small in this context means that the relative movement between the guided through the passage opening electrode and the furnace lid is so small that it leads to no contact between the electrode and the furnace lid, which would damage one or the other component.

- the recording facial expression is formed as a lever and rotatably mounted on the rotary and / or lifting portal on one of these associated recording and connected to the second pick-up point of the recording mimic with the hydraulic cylinder.

- the coolant lines of the coolant supply system guided in installation position from below through the rotary portal exit on the side facing away from the hydraulic cylinder from the rotary portal, extending over the top parallel to the recording facial and connected to a furnace cover associated with the flange connection.

- the coolant lines can be shortened and the installation can be carried out more efficiently, since the rotary and / or lifting portal is now an integral part of the coolant supply system.

- the previously provided lid support arms can be omitted. This leads to a reduction in construction height of at least 2 meters and the associated need to cool these components. Savings result not only in the area of significant weight reduction of the lid construction and the elimination of the cost of producing elaborate welded structures, but also in the assembly of these brackets, since the overhead for aligning and welding the brackets omitted on the rotary portal. With regard to the guidance and arrangement of the electrode guide columns, nothing changes in the structure of the rotary and / or lifting portal.

- the cooling water supply to the furnace lid is no longer as usual over long, coming from the transformer house wall hose lines, but lead directly from below through the rotary portal.

- hose lines are also provided here, but they are relatively short and less prone to tearing and thus less dangerous for the oven operation, as in a damage to the hoses no cooling water with the liquid Steel can come into contact.

- the cooling water is led via short hoses flexible and electrically non-conductive to the furnace lid.

- On and / or on the furnace cover flange connections are provided, which are easy and comfortable to reach.

- the furnace cover segments are still supported by a cooling frame with a pipe frame (cooling water distributor and collector). Radial spokes are replaced by pairs of spokes crossing at right angles. The pair of spokes, which runs parallel to the furnace transverse axis (bend plane), is extended beyond the edge of the cover. At the free ends of these spokes is a pin joint for receiving by the receiving facial expressions (designed as Deckelhubwerkarme). Parallel thereto, brackets are provided on the lower cover ring, each with a pressure plate as counterparts to those of the Deckelhubwerkes (as forces).

- the furnace cover can be reached via a fixed staircase on the tilting platform. A stage level on the furnace lid provides direct access to the electrode fixtures, as well as direct and easy access to the flange connections and shut-off fittings of the furnace cover cooling water supply.

- stage level In order to allow access to the flange connections of the coolant guide system and the cover passages, as well as to the electrodes holding electrode clamping devices, is assigned to the furnace cover a stage level, which is accessible via a staircase. This creates the most level work surface that can be safely and comfortably committed.

- the flange of the coolant guide system on the furnace lid are formed in a further advantageous embodiment of the present invention as quick couplings.

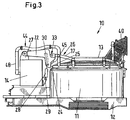

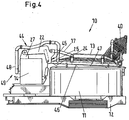

- the electric arc furnace 10 essentially consists of a furnace vessel 11 which is tiltably mounted on a tilting platform 12.

- the furnace vessel 11 can be covered with a furnace lid 13.

- the furnace cover 13 is a self-supporting structure and forms a support arm system 26.

- radial spokes 15, 16 and 17, 18 interconnected at right angles crossing to the supporting skeleton.

- the pair of spokes 17, 18, which runs parallel to the furnace transverse axis (bend plane), is formed extended beyond the lid edge 19 of the furnace lid 13.

- the spokes 17, 18 have free ends 20, 21, which pin joints 33, 34 are assigned.

- a receiving mimic 22 designed as a lever arm is assigned to the rotary and / or lifting portal 14.

- the recording facial expressions 22 is articulated via a receptacle 27 on the rotary and / or lifting portal 14.

- the recording facial expression 22 is raised by a hydraulic cylinder 28, which is articulated to the base of the rotary and / or lifting portal 14 at a first receiving point 29.

- the hydraulic cylinder With a second pick-up point 30, the hydraulic cylinder is operatively connected to the pick-up mimic 22 in alignment with the first pick-up point 29.

- the recording facial expressions 22 are associated with bearing cavities 31, 32.

- the receiving mimic 22 is now raised via the hydraulic cylinder 28, so that in this way the bearing recesses 31, 32 in the pin joints 33, 34 of the free ends 20, 21 of the radial spokes 17, 18 of the furnace lid 13 can engage frictionally; as this particular in Fig. 3 is shown.

- brackets 24 are provided on the lower cover ring; each having a pressure plate 25 and this as a force-pair counterpart with a receiving mimic 22 associated support region 45 lie flat.

- the furnace cover 13 on its upper side 41 openings 35, 36, can be guided by the electrodes 37, 38 in the furnace vessel 11.

- the electrodes 37, 38 are clamped to an electrode support arm 39. It is intended to decouple the electrodes 37, 38 both mechanically and electrically from the rotary and / or lifting portal 14.

- the furnace cover 13 is still associated with a flue gas vent 40 through which the gassing gases produced during the melting process are derived.

- the furnace cover 13 is accessible via a permanently installed on the tilting platform 12 stairs 42.

- a provided on the furnace cover 13 stage level 43 allows direct and easy access to the electrodes 37, 38 and their fixtures and flange connections and shut-off valves (both not shown) of a coolant guide system only partially shown 44, via which the electric arc furnace 10 are subjected to a coolant can.

- the lever arm of the receiving mimic 22 is designed so that when lifting the furnace cover 13 horizontal displacements are generated, which in the region of the passage openings 35, 36 for the electrodes 37, 38 in the furnace lid 13 negligible, in the interface plane of the furnace vessel opening 46 of the furnace vessel 11 but are formed so that adhesions of the furnace lid 13 are solved with the edge 47 of the furnace vessel 11 generated by the cover movement shear stresses.

- the coolant guide system 44 is envisaged to form the coolant guide system 44 from a combination of rigid tubing and flexible tube sections.

- the coolant supply system 44 is guided directly through the rotary and / or lifting portal 14.

- a line 48 emerges from a side facing away from the hydraulic cylinder 28 on the rotating and / or lifting portal 14 again and is passed over the Consimik 22 to the furnace lid 13, where it is connected for example via a flange.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Vertical, Hearth, Or Arc Furnaces (AREA)

- Furnace Housings, Linings, Walls, And Ceilings (AREA)

- Furnace Details (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE201110119797 DE102011119797A1 (de) | 2011-11-23 | 2011-11-23 | Lichtbogenofen mit einem Ofendeckeltragarmsystem |

| PCT/DE2012/000992 WO2013075682A1 (de) | 2011-11-23 | 2012-09-27 | Lichtbogenofen mit einem ofendeckeltragarmsystem |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2783178A1 EP2783178A1 (de) | 2014-10-01 |

| EP2783178B1 true EP2783178B1 (de) | 2016-11-09 |

Family

ID=47172189

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12784203.7A Active EP2783178B1 (de) | 2011-11-23 | 2012-09-27 | Lichtbogenofen mit einem ofendeckeltragarmsystem |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2783178B1 (enExample) |

| DE (1) | DE102011119797A1 (enExample) |

| IN (1) | IN2014CN04442A (enExample) |

| WO (1) | WO2013075682A1 (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109612263A (zh) * | 2019-01-28 | 2019-04-12 | 徐州金虹钢铁集团有限公司 | 一种电弧炉 |

| CN110108129A (zh) * | 2019-06-10 | 2019-08-09 | 河南天利热工装备股份有限公司 | 一种井式炉提升装置 |

| CN115682736B (zh) * | 2022-10-31 | 2025-05-23 | 安徽玉龙电力科技有限公司 | 一种炉顶磁性拉杆装置 |

| CN119040555B (zh) * | 2024-09-10 | 2025-05-30 | 济宁金宇特钢有限公司 | 一种自动开盖式立式炼钢炉 |

| CN119372477A (zh) * | 2024-12-27 | 2025-01-28 | 河南瑞德克气力输送设备有限公司 | 一种红土镍矿煤粉喷吹装置及工艺方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1216900B (de) | 1965-06-19 | 1966-05-18 | Demag Elektrometallurgie Gmbh | Vorrichtung zum Ankuppeln des abhebbaren Ofendeckels an die Elektroden-Hubvorrichtung eines Lichtbogenofens |

| DE1940740A1 (de) | 1968-08-14 | 1970-02-19 | Solis Srl | Schneidevorrichtung zur Herstellung eines Laengsschnitts waehrend der Bildung des Warenstuecks auf Rundstrickmaschinen fuer Struempfe u.dgl. |

| DE3522559C1 (de) | 1985-06-24 | 1987-01-22 | Fuchs Systemtechnik Gmbh | Lichtbogenofen |

| JP2596826Y2 (ja) * | 1993-10-15 | 1999-06-21 | 株式会社ショーワ | 鋳造炉用炉蓋 |

| AT401304B (de) * | 1993-11-04 | 1996-08-26 | Voest Alpine Ind Anlagen | Deckelhubwerk für einen auf ein metallurgisches gefäss aufsetzbaren deckel |

-

2011

- 2011-11-23 DE DE201110119797 patent/DE102011119797A1/de not_active Withdrawn

-

2012

- 2012-09-27 EP EP12784203.7A patent/EP2783178B1/de active Active

- 2012-09-27 IN IN4442CHN2014 patent/IN2014CN04442A/en unknown

- 2012-09-27 WO PCT/DE2012/000992 patent/WO2013075682A1/de not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| IN2014CN04442A (enExample) | 2015-09-04 |

| WO2013075682A1 (de) | 2013-05-30 |

| DE102011119797A1 (de) | 2013-05-23 |

| EP2783178A1 (de) | 2014-10-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2783178B1 (de) | Lichtbogenofen mit einem ofendeckeltragarmsystem | |

| DE2128245A1 (de) | Maschine mit einem Rotor | |

| EP3201440B1 (de) | Gasturbine mit hebevorrichtung | |

| DE102016008822B4 (de) | Mobilkran mit verstellbarer Ballastaufnahmevorrichtung | |

| EP2992287B1 (de) | Umschmelzofen und kardangelenk für die elektrodenstangenhalterung eines umschmelzofens | |

| EP3564182B1 (de) | Autobetonpumpe | |

| EP1905527A1 (de) | Strangbrennschneidmaschine für gegossene Werkstücke, insbesondere Knüppel und Blöcke aus Stahl | |

| DE2412240C2 (de) | Anhebevorrichtung für die obere Gießband-Tragvorrichtung einer Stranggießmaschine | |

| DE2430786C2 (de) | Drehturm für Stahlgießpfannen | |

| DE102011120408A1 (de) | Lastaufnahmeeinrichtung zum Anheben von schweren Anlagenteilen, insbesondere von Offshore-Anlagen | |

| DE102015006480A1 (de) | Hebeeinheit für Inspektionsarbeiten | |

| DE102014014407A1 (de) | Umschmelzofen mit einer Wägezelle | |

| EP2947037B1 (de) | Kran | |

| DE202018006613U1 (de) | Vorrichtung zur Montage von Teilen hoher und extra hoher Türme | |

| DE102014224649B3 (de) | Hubsystem für eine metallurgische Anlage, metallurgische Anlage und Verfahren zum vertikalen Versetzen einer Komponente einer Gefäßeinheit | |

| WO2009153026A1 (de) | Drehportal für einen ofen | |

| WO2000022178A1 (de) | Haubenofenanlage | |

| DE2133781C3 (de) | Tiegelwechselwage | |

| EP2921563A1 (de) | Vorrichtung zum vertikalen Anheben und/oder Absenken eines metallurgischen Gefäßes, Anlage mit einer solchen Vorrichtung und Verfahren | |

| EP1913796B1 (de) | Kühlvorrichtung aus einzelsegmenten für elektroden eines metallurgischen ofens | |

| EP2360282A1 (de) | Elektrolichtbogenofen | |

| DE102011083822B3 (de) | Lichtbogenofen mit auf Schienen verfahrbarem Wiegerahmen | |

| DE102008038889B4 (de) | Vorrichtung zum Aushalsen dickwandiger Rohre | |

| DE102016014659A1 (de) | Arbeitsmaschine mit einer Ballasteinrichtung | |

| DE2917674A1 (de) | Begehbare hebevorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140623 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SMS GROUP GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20151116 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160616 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 844329 Country of ref document: AT Kind code of ref document: T Effective date: 20161115 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502012008760 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20161109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170209 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170210 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170309 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170309 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502012008760 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170209 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170810 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170927 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170927 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171002 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20180822 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120927 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161109 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190927 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190927 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230707 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250919 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250923 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20250919 Year of fee payment: 14 |