EP2691701B1 - Procédé d'optimisation de la combustion totale des gaz d'échappement d'une installation de combustion - Google Patents

Procédé d'optimisation de la combustion totale des gaz d'échappement d'une installation de combustion Download PDFInfo

- Publication number

- EP2691701B1 EP2691701B1 EP12712955.9A EP12712955A EP2691701B1 EP 2691701 B1 EP2691701 B1 EP 2691701B1 EP 12712955 A EP12712955 A EP 12712955A EP 2691701 B1 EP2691701 B1 EP 2691701B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- combustion

- nozzle

- fluid

- primary

- combustion chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000007789 gas Substances 0.000 title claims description 44

- 238000000034 method Methods 0.000 title claims description 27

- 238000002485 combustion reaction Methods 0.000 claims description 106

- 239000012530 fluid Substances 0.000 claims description 25

- 238000002156 mixing Methods 0.000 claims description 15

- 239000000567 combustion gas Substances 0.000 claims description 11

- 239000003546 flue gas Substances 0.000 claims description 11

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 claims description 9

- 239000011343 solid material Substances 0.000 claims 4

- 239000007787 solid Substances 0.000 description 20

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 15

- 238000000265 homogenisation Methods 0.000 description 10

- 239000000203 mixture Substances 0.000 description 9

- 230000002093 peripheral effect Effects 0.000 description 9

- 239000000446 fuel Substances 0.000 description 8

- 238000001035 drying Methods 0.000 description 7

- 238000002347 injection Methods 0.000 description 7

- 239000007924 injection Substances 0.000 description 7

- 229910052760 oxygen Inorganic materials 0.000 description 5

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 4

- 239000001301 oxygen Substances 0.000 description 4

- 238000011084 recovery Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000002028 Biomass Substances 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 238000004939 coking Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 238000005243 fluidization Methods 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 229910017464 nitrogen compound Inorganic materials 0.000 description 1

- 150000002830 nitrogen compounds Chemical class 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 239000002243 precursor Substances 0.000 description 1

- 238000000197 pyrolysis Methods 0.000 description 1

- 239000003473 refuse derived fuel Substances 0.000 description 1

- 239000002893 slag Substances 0.000 description 1

- 239000004449 solid propellant Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000004056 waste incineration Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/08—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating

- F23G5/14—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion

- F23G5/16—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion in a separate combustion chamber

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/08—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating

- F23G5/14—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion

- F23G5/16—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion in a separate combustion chamber

- F23G5/165—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating including secondary combustion in a separate combustion chamber arranged at a different level

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L7/00—Supplying non-combustible liquids or gases, other than air, to the fire, e.g. oxygen, steam

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L9/00—Passages or apertures for delivering secondary air for completing combustion of fuel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L9/00—Passages or apertures for delivering secondary air for completing combustion of fuel

- F23L9/02—Passages or apertures for delivering secondary air for completing combustion of fuel by discharging the air above the fire

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23L—SUPPLYING AIR OR NON-COMBUSTIBLE LIQUIDS OR GASES TO COMBUSTION APPARATUS IN GENERAL ; VALVES OR DAMPERS SPECIALLY ADAPTED FOR CONTROLLING AIR SUPPLY OR DRAUGHT IN COMBUSTION APPARATUS; INDUCING DRAUGHT IN COMBUSTION APPARATUS; TOPS FOR CHIMNEYS OR VENTILATING SHAFTS; TERMINALS FOR FLUES

- F23L2900/00—Special arrangements for supplying or treating air or oxidant for combustion; Injecting inert gas, water or steam into the combustion chamber

- F23L2900/07002—Injecting inert gas, other than steam or evaporated water, into the combustion chambers

Definitions

- the present invention relates to a method for optimizing the combustion of exhaust gases of a combustion plant according to the preamble of claim 1.

- a method for optimizing the combustion of exhaust gases of a combustion plant is described for example in the EP-A-1508745 described.

- Incinerators for burning solid fuels such as municipal waste, refuse derived fuels, biomass and other materials are well known to those skilled in the art.

- Such plants include a combustion chamber in which the solid is burned with supply of primary air, which is referred to as primary combustion.

- the solid from the inlet into the combustion chamber to the outlet through various sub-processes, which can be roughly subdivided into drying, ignition, combustion and ash burning. In each of these sub-processes, exhaust gases of different composition are generated.

- the primary air While in the drying phase, the primary air only absorbs moisture from the solid to be burned, can be found in the ignition phase pyrolytic decomposition products.

- the oxygen supplied in the ignition phase is often completely converted, so that the exhaust gas flow generated in this phase has very little or no oxygen.

- exhaust gases are formed with typical compositions of CO, CO 2 , O 2 , H 2 O and N 2 , while finally over the ash ash practically unused air is present.

- these different exhaust gas streams pass into a secondary combustion chamber arranged downstream in the direction of flow, where they are burnt out with the supply of secondary air, which is referred to as secondary combustion.

- a method comprising a combustion of the solid and an afterburning of the incompletely combusted exhaust gas constituents is known, for example, from US Pat WO 2007/090510

- the aim of this invention is to reduce the primary nitrogen compounds NH 3 and HCN in order to minimize the formation of nitrogen oxides (NO x ) in the post-combustion chamber.

- EP-A-1077077 relates to a similar process as that of WO 2007/090510 , wherein the denitrification of the flue gases, the SNCR method is used in which no catalyst is used, but a reducing agent is injected into the flue gases.

- Such SNCR processes operate at temperatures of 850 to 1000 ° C and require sophisticated control.

- the reduction of nitrogen oxides is also in WO 99/58902 addressed.

- the gases emerging from the combustion chamber are homogenized with the addition of an oxygen-free or oxygen-poor medium in a mixing stage, after which the homogenized exhaust gas flow passes through a steady zone in which the nitrogen oxides already formed are to be reduced.

- the amount of accumulating pyrolysis gas is so large that the locally available secondary air quantity is insufficient for complete burnout. This causes unburned gases to escape from the post-combustion chamber, resulting in, for example, CO peaks in the chimney.

- the peripheral wall surrounding the combustion chamber or the afterburning chamber can be damaged on the one hand by the prevailing high temperatures.

- caking or coking may occur in this area, which must be removed in time-consuming maintenance work.

- EP-A-1081434 The problem of reducing the amount of unburned substances and in particular CO, try about in EP-A-1081434 .

- EP-A-1382906 and US-B-5313895 approached procedures. So is about according to US-B-5313895 a mixed fluid is introduced, the gases leaving the combustion chamber in a Eddy current offset.

- a special nozzle arrangement is described, by means of which a rotating flow in the flow channel is produced in a plane of injection of the flame in the region of the flame ceiling.

- US-B-5313895 described method the problem of present in the combustion chamber temperature imbalance only unsatisfactory way.

- the temperature in the inlet-side region should be reduced by means of injection of water droplets or water vapor.

- this is disadvantageous in terms of the energy recovery balance.

- the aim of the present invention is thus to provide a method for optimizing the burnout of exhaust gases of a combustion plant, which on the one hand ensures a high degree of operational reliability and which, on the other hand, allows a high energy recovery from the combustion to be obtained.

- the method according to the invention comprises the steps of introducing the solid to be combusted via an inlet into a combustion chamber defining a primary combustion chamber, combusting the solid in the primary combustion chamber in the form of a combustion bed conveyed via a combustion grate by supplying primary air and the combusted solid via a combustion chamber in the conveying direction the inlet opposite outlet is discharged from the primary combustion chamber.

- the primary combustion gases liberated upon combustion of the solid become downstream in the flow direction, i. usually arranged above the combustion chamber, a secondary combustion chamber defining afterburner chamber burned under supply of secondary air.

- the exhaust gases containing the primary combustion gases are homogenized in a mixing zone. This is done by means of a fluid introduced via a nozzle.

- nozzle is to be understood as an indefinite article; Thus, the term includes both a single and multiple nozzles.

- Homogenization is understood in this context to mean that the exhaust gases or the individual exhaust gas streams of different composition are mixed in such a way that the most homogeneous possible gas mixture is obtained.

- the mixing zone now at least approximately immediately adjoins the combustion bed in the flow direction of the exhaust gases. As a rule, it is thus arranged in other words at least approximately directly above the combustion bed. This allows very hot exhaust gas streams, such as may occur in the ignition or combustion zone, practically immediately above the combustion bed with the cooler exhaust gas streams from the drying and ash combustion zone to mix and thus compensate for temperature peaks early or lower.

- the method allows the energy recovery balance to be unaffected, as would be the case with cooling by means of a cooling medium.

- the homogenization of the exhaust gas streams generated in the individual combustion zones results in a gas mixture which is optimally preconditioned for afterburning in the secondary combustion chamber.

- the present invention thus allows to ensure an optimal combustion of the exhaust gases even at low (secondary) excess air; the emission of pollutants, such as CO or unburned hydrocarbons, can thus be kept very low even with small amounts of supplied secondary air.

- the fluid is introduced via one or more nozzles.

- the exit velocity of the fluid from the nozzle is about 40 to about 120 m / s, wherein the nozzle is aligned in the sense of the present invention at an angle of -10 ° to + 10 ° relative to the inclination of the combustion grate.

- nozzles In addition to the nozzles defined above, there may be other nozzles that are not oriented at the angle defined above relative to the inclination of the combustion grate.

- Inclination of the combustion grate in this context is understood to mean the total inclination of the grate (and not the orientation of possibly existing individual grate steps).

- the inventive alignment of the nozzle ensures that even with the inventive arrangement of the mixing zone immediately above the fuel bed excessive swirling of solids is avoided by the rust.

- the inventive injection rate of the fluid also contributes from about 40 to about 120 m / s.

- the found combination of nozzle arrangement according to the invention and injection rate thus makes it possible in total to connect the mixing zone in the direction of flow of the exhaust gases at least approximately directly to the combustion bed, without resulting in excessive unwanted swirling of the solids from the combustion grid.

- the mixing zone is appropriately spaced from the combustion grate. Furthermore, the mixing zone may extend at most to a distance of 2 meters measured from the fuel bed. When considered in the flow direction of the exhaust gases, the mixing zone thus ends after a maximum of 2 meters and thus still at a sufficient distance before the secondary air injection. In the invention At least approximately immediately adjacent to the combustion bed subsequent mixing zone, said upper limit is sufficient to obtain the desired homogenization of the exhaust gases.

- the exit velocity of the fluid from the nozzle is about 90 m / s.

- the exit velocity refers to the velocity that the fluid has on exit from the nozzle opening.

- the nozzles used as standard usually have a circular nozzle cross-section of 60 mm to 200 mm. It is conceivable that the nozzle cross-section continuously tapers in the direction of the nozzle orifice so that the diameter of the outlet opening of the nozzle is 60 mm to 90 mm.

- the respective nozzle is preferably oriented at an angle of -10 ° to + 5 °, more preferably -5 ° to + 5 °, relative to the inclination of the combustion grate.

- the respective nozzle may be oriented at an angle of -10 ° to 0 ° relative to the inclination of the combustion grate.

- the fluid comprises a flue gas returned from a downstream zone of the secondary combustion chamber.

- the recirculation preferably takes place from one zone between the steam generator and the fireplace.

- the amount of introduced flue gas is about 5 to 35% of the amount of primary air supplied, preferably about 20%.

- any other conceivable fluid can be used, in particular air, an inert gas, such as nitrogen, water vapor or mixtures thereof.

- the injection of the fluid takes place via a nozzle or nozzle row arranged in this region.

- a very pronounced temperature imbalance and thus damage or contamination of the peripheral wall surrounding the combustion chamber can be effectively prevented.

- the respective nozzle when a recirculated flue gas is used as the fluid, preferably has an outer tube and an inner tube extending in the axial direction of the outer tube and enclosed by the inner tube, wherein the inner tube is intended for guiding the flue gas and the outer tube for guiding air ,

- the inner diameter of the inner tube is about 70 mm, while the inner diameter of the outer tube, i. the outer diameter of the present between inner tube and outer tube annular gap, about 110 mm.

- the air flow in this embodiment serves as a shield which protects the nozzle from the accumulation of contaminants entrained in the flue gas. Especially in the inlet side area Temperatures such deposits could easily lead to caking, which can lead to failure of the nozzle in extreme cases; This is effectively prevented according to the described embodiment. It has proven to be advantageous if at least 1 nozzle per meter of the combustion chamber width is provided. Preferably, the introduction of the fluid via at least two nozzles, more preferably at least six nozzles. This ensures as complete as possible homogenization with a relatively small amount of injected fluid.

- a combustor of an incinerator for carrying out the method may include a peripheral wall enclosing a primary combustion chamber, an inlet for introducing the solid to be combusted into the primary combustion chamber, a combustion grate for combustion of the solid, an outlet disposed opposite the inlet in the conveying direction of the solid for discharging the combusted solid from the primary combustion chamber and a nozzle for homogenizing the exhaust gases released during the combustion of primary combustion gases include.

- the nozzle is arranged in a range of at most 3 meters, preferably 0.5 meters to 3 meters, most preferably 0.5 to 2 meters above the combustion grate. In general, the nozzle is arranged in the peripheral wall of the combustion chamber, preferably in the region of the inlet or the outlet.

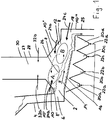

- the solid to be burned 2 is filled in a hopper 4 and of this usually introduced by means of a Dosierstössels via an inlet 6 into the combustion chamber 8.

- the combustion chamber 8 comprises a peripheral wall 10, which encloses an upwardly tapering, primary combustion chamber 12.

- the solid 2 is conveyed in the form of a fuel bed 14 via a (advancing) combustion grate 16 through which primary air flows and thereby burned.

- a drying zone In the conveying direction F, there are successively a drying zone, an ignition zone, a combustion zone and an ash combustion zone, before the burnt solid is discharged via an outlet 18 arranged opposite the inlet 6 and subsequently fed to a slag conveyor via a purifier.

- the distribution of the primary air takes place in the embodiment shown via individual sub-wind chambers 20a, 20b, 20c, 20d, which are fed via separate primary air lines 22a, 22b, 22c, 22d.

- nozzles 24a, 24b, 24c via which a fluid is introduced into the combustion chamber 8.

- the nozzles are designed such that the exit velocity of the fluid from the nozzles is 40 to 120 m / s.

- a nozzle 24a is disposed in the inlet side region 8 'of the combustion chamber 8, specifically in an inlet facing, obliquely upwardly extending portion 10' of the peripheral wall 10.

- Two nozzles 24b, 24c are shown in FIG outlet side region 8 "is arranged, wherein a nozzle 24b in the obliquely upwardly extending portion 10" and in which the end face 25 defining, perpendicular part 10 '''of the peripheral wall is arranged.

- any other number and arrangement of nozzles suitable for the purposes of the present invention is also conceivable.

- the exhaust gases which contain the combustion gases liberated during the combustion, are homogenized in a mixing zone 26 which adjoins the combustion bed 14 at least approximately directly in the flow direction thereof.

- This homogenization is indicated in the figure by dashed arrows, where A schematically denotes the region of relatively high temperature and relatively high concentration of primary combustion gases, and B denotes the region of lower temperature and lower concentration of primary combustion gases.

- an afterburner chamber 28 which is connected downstream of the combustion chamber 8 and defines a secondary combustion chamber 27, in which the exhaust gases are burned with the supply of secondary air.

- an afterburner chamber 28 in which the exhaust gases are burned with the supply of secondary air.

- nozzles 32a, 32b are provided for introducing the secondary air.

- Fig. 2 illustrated introduces the fluid with actuated nozzle in position to the fact that the O 2 concentration measured locally in the exhaust gas flow generated in the combustion zone (shown in bold solid lines) approximately corresponds to the global O 2 concentration (shown in thin dashed lines) in the exhaust gas generated in the combustion chamber , In contrast, when the nozzle is not actuated in the OFF position, the locally measured O 2 concentration is much lower than that measured globally.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Incineration Of Waste (AREA)

- Air Supply (AREA)

- Combustion Of Fluid Fuel (AREA)

Claims (8)

- Procédé pour l'optimisation de la combustion de gaz d'échappement d'un incinérateur comprenant les étapes suivantes:la matière solide (2) à incinérer est introduite par une entrée (6) dans une chambre de combustion (8) définissant un espace de combustion primaire (12),la matière solide (2) dans l'espace de combustion primaire (12), sous la forme d'un lit de combustion (14) acheminé sur une grille de combustion (16), est incinérée avec admission d'air primaire et la matière solide incinérée est déchargée de l'espace de combustion primaire (12) par une sortie (18) disposée à l'opposé par rapport à la direction d'acheminement (F) de l'entrée (6), etles gaz de combustion primaires dégagés pendant la combustion de la matière solide (2) sont incinérés avec admission d'air secondaire dans une chambre de combustion secondaire (28) définissant un espace de combustion secondaire (27) et disposée en aval de la chambre de combustion (8) par rapport à la direction d'écoulement desdits gaz de combustion primaires,les gaz d'échappement contenant les gaz de combustion primaires étant homogénéisés dans une zone de mélange (26) à l'aide d'un fluide introduit au moyen d'une buse (24a, 24b, 24c) avant d'entrer dans l'espace de combustion secondaire (27),la zone de mélange (26) étant reliée au moins approximativement directement dans la direction d'écoulement des gaz d'échappement au lit de combustion (14),caractérisé en ce que la vitesse de sortie du fluide de la buse (24a, 24b, 24c) est de 40 à 120 m/s, et en ce que la buse (24a, 24b, 24c) est orientée avec un angle de -10° à +10° par rapport à l'inclinaison de la grille de combustion (16).

- Procédé selon l'une des revendications précédentes, caractérisé en ce que la vitesse de sortie du fluide de la buse (24a, 24b, 24c) est de 90 m/s.

- Procédé selon l'une des revendications précédentes, caractérisé en ce que la buse (24a, 24b, 24c) est orientée avec un angle de -5° à +5° par rapport à l'inclinaison de la grille de combustion (16).

- Procédé selon l'une des revendications précédentes, caractérisé en ce que le fluide comprend un gaz de fumée retourné d'une zone raccordée en aval de l'espace de combustion secondaire (27).

- Procédé selon la revendication 4, caractérisé en ce que la quantité de gaz de fumée introduite est 5% à 35%, préférablement approximativement 20%, de la quantité d'air primaire admise.

- Procédé selon l'une des revendications précédentes, caractérisé en ce que l'injection du fluide est réalisée au moyen d'une buse (24a) disposée dans une région de la chambre de combustion (8) du côté de l'entrée.

- Procédé selon la revendication 4 ou 5, caractérisé en ce que la buse (24a, 24b, 24c) présente un tube extérieur et un tube intérieur qui s'étend dans la direction axiale du tube extérieur et qui est entouré par celui-ci, le tube intérieur étant conçu pour la conduite du gaz de fumée et le tube extérieur étant conçu pour la conduite d'air.

- Procédé selon l'une des revendications précédentes, caractérisé en ce que le fluide est introduit au moyen d'au moins deux buses (24a, 24b, 24c), préférablement d'au moins six buses.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL12712955.9T PL2691701T5 (pl) | 2011-03-29 | 2012-03-28 | Sposób optymalizacji wypalania gazów odpadowych spalarni |

| NO12712955A NO2691701T3 (fr) | 2011-03-29 | 2012-03-28 | |

| RS20171117A RS56483B2 (sr) | 2011-03-29 | 2012-03-28 | Postupak optimizacije naknadnog sagorevanja gasova postrojenja za sagorevanje |

| EP12712955.9A EP2691701B2 (fr) | 2011-03-29 | 2012-03-28 | Procédé d'optimisation de la combustion totale des gaz d'échappement d'une installation de combustion |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11002575A EP2505919A1 (fr) | 2011-03-29 | 2011-03-29 | Procédé d'optimisation de la combustion des gaz d'échappement d'une installation de combustion par homogénéisation des gaz de fumée dessus du lit de combustion réalisée par injection des gaz de fumée |

| PCT/EP2012/001361 WO2012130446A1 (fr) | 2011-03-29 | 2012-03-28 | Procédé d'optimisation de la combustion totale des gaz d'échappement d'une installation de combustion |

| EP12712955.9A EP2691701B2 (fr) | 2011-03-29 | 2012-03-28 | Procédé d'optimisation de la combustion totale des gaz d'échappement d'une installation de combustion |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2691701A1 EP2691701A1 (fr) | 2014-02-05 |

| EP2691701B1 true EP2691701B1 (fr) | 2017-08-23 |

| EP2691701B2 EP2691701B2 (fr) | 2024-03-20 |

Family

ID=44501668

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11002575A Withdrawn EP2505919A1 (fr) | 2011-03-29 | 2011-03-29 | Procédé d'optimisation de la combustion des gaz d'échappement d'une installation de combustion par homogénéisation des gaz de fumée dessus du lit de combustion réalisée par injection des gaz de fumée |

| EP12712955.9A Active EP2691701B2 (fr) | 2011-03-29 | 2012-03-28 | Procédé d'optimisation de la combustion totale des gaz d'échappement d'une installation de combustion |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11002575A Withdrawn EP2505919A1 (fr) | 2011-03-29 | 2011-03-29 | Procédé d'optimisation de la combustion des gaz d'échappement d'une installation de combustion par homogénéisation des gaz de fumée dessus du lit de combustion réalisée par injection des gaz de fumée |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US20140182492A1 (fr) |

| EP (2) | EP2505919A1 (fr) |

| JP (1) | JP2014513786A (fr) |

| ES (1) | ES2647667T5 (fr) |

| FI (1) | FI2691701T4 (fr) |

| NO (1) | NO2691701T3 (fr) |

| PL (1) | PL2691701T5 (fr) |

| RS (1) | RS56483B2 (fr) |

| WO (1) | WO2012130446A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015068517A (ja) * | 2013-09-27 | 2015-04-13 | 日立造船株式会社 | 焼却炉における燃焼運転方法および焼却炉 |

| JP6260058B2 (ja) * | 2014-09-12 | 2018-01-17 | 三菱重工環境・化学エンジニアリング株式会社 | ストーカ式焼却炉 |

| JP6992194B2 (ja) * | 2018-10-05 | 2022-01-13 | 三菱重工業株式会社 | ストーカ式焼却設備及び被焼却物の焼却方法 |

| US10816197B2 (en) * | 2018-12-07 | 2020-10-27 | Eco Burn Inc. | System for the dynamic movement of waste in an incinerator |

| CN113574320B (zh) * | 2019-03-15 | 2024-03-08 | 日立造船株式会社 | 焚烧炉 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5313895A (en) | 1990-11-22 | 1994-05-24 | Hitachi Zosen Corporation | Method of inhibiting formation of unburned substances in refuse incinerator, and refuse incinerator |

| EP1077077A2 (fr) | 1999-08-12 | 2001-02-21 | ABB (Schweiz) AG | Procédé de traitement thermique de matières solides |

| EP1081434A1 (fr) | 1999-08-30 | 2001-03-07 | Von Roll Umwelttechnik AG | Dispositif pour générer un flux gazeux rotatif |

| EP1508745A2 (fr) | 2003-08-22 | 2005-02-23 | Fisia Babcock Environment GmbH | Méthode pour réduire la production de NOx dans les chambres de combustion et équipement pour la mise en oeuvre de la méthode |

| DE102004037442A1 (de) | 2004-08-02 | 2006-03-16 | Alstom Technology Ltd | Verfahren zur thermischen Behandlung von Abfall in einer thermischen Abfallbehandlungsanlage sowie thermische Abfallbehandlungsanlage |

| JP2009121747A (ja) * | 2007-11-15 | 2009-06-04 | Hitachi Zosen Corp | 二次燃焼室における二次燃焼空気の吹き込み方法 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3716088A1 (de) * | 1987-04-09 | 1989-02-02 | Muellverbrennungsanlage Wupper | Verfahren zum verbrennen insbesondere von muell |

| JPH04350411A (ja) * | 1990-11-22 | 1992-12-04 | Hitachi Zosen Corp | ごみ焼却炉における未燃分発生抑制方法 |

| JP2662746B2 (ja) * | 1991-04-04 | 1997-10-15 | 日立造船株式会社 | 火格子型ごみ焼却炉 |

| JP2758090B2 (ja) * | 1991-10-21 | 1998-05-25 | 株式会社クボタ | 焼却炉におけるco制御方法 |

| JP3596690B2 (ja) * | 1995-06-15 | 2004-12-02 | 石川島播磨重工業株式会社 | 電気炉におけるNOxの発生低減方法およびその装置 |

| JP3210859B2 (ja) * | 1996-05-01 | 2001-09-25 | 株式会社クボタ | ゴミ焼却炉の二次燃焼ガス供給機構 |

| JPH10110926A (ja) * | 1996-08-14 | 1998-04-28 | Nippon Sanso Kk | 燃焼式除害装置 |

| JPH10205734A (ja) * | 1997-01-14 | 1998-08-04 | Takuma Co Ltd | ストーカ式燃焼炉における2次空気の供給方法 |

| JP3319327B2 (ja) | 1997-03-26 | 2002-08-26 | 日本鋼管株式会社 | ごみ焼却炉の燃焼制御方法およびその装置 |

| JPH10288325A (ja) * | 1997-04-16 | 1998-10-27 | N K K Plant Kensetsu Kk | ごみ焼却炉燃焼排ガス中のダイオキシン類発生抑制方法 |

| US6336415B1 (en) * | 1998-05-11 | 2002-01-08 | Alstom (Switzerland) Ltd | Method for the heat treatment of solids |

| NL1015519C2 (nl) * | 2000-06-14 | 2001-12-28 | Amsterdam Gem Dienst Afvalverw | Rookgasrecirculatie bij een afvalverbrandingsinstallatie. |

| DE10051733B4 (de) * | 2000-10-18 | 2005-08-04 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zur gestuften Verbrennung von Brennstoffen |

| JP3661662B2 (ja) * | 2002-03-28 | 2005-06-15 | Jfeエンジニアリング株式会社 | 廃棄物焼却灰中の金属回収方法および廃棄物焼却炉 |

| KR100705204B1 (ko) * | 2003-04-18 | 2007-04-06 | 제이에프이 엔지니어링 가부시키가이샤 | 화격자식(火格子式) 폐기물 소각로 및 그 연소 제어방법 |

| JP5345386B2 (ja) * | 2005-04-29 | 2013-11-20 | ダブリュー・アール・グレイス・アンド・カンパニー−コネチカット | 部分燃焼FCC法で使用するNOx低減用組成物 |

| EP1726876B1 (fr) * | 2005-05-27 | 2015-05-06 | Takuma Co., Ltd. | Méthode améliorée pour la combustion des déchets solides |

| DE102006005464B3 (de) | 2006-02-07 | 2007-07-05 | Forschungszentrum Karlsruhe Gmbh | Verfahren zur primärseitigen Stickoxidminderung in einem zweistufigen Verbrennungsprozess |

| US7975628B2 (en) * | 2006-09-13 | 2011-07-12 | Martin GmbH für Umwelt- und Energietechnik | Method for supplying combustion gas in incineration systems |

-

2011

- 2011-03-29 EP EP11002575A patent/EP2505919A1/fr not_active Withdrawn

-

2012

- 2012-03-28 US US14/008,798 patent/US20140182492A1/en not_active Abandoned

- 2012-03-28 NO NO12712955A patent/NO2691701T3/no unknown

- 2012-03-28 JP JP2014501477A patent/JP2014513786A/ja active Pending

- 2012-03-28 EP EP12712955.9A patent/EP2691701B2/fr active Active

- 2012-03-28 WO PCT/EP2012/001361 patent/WO2012130446A1/fr active Application Filing

- 2012-03-28 ES ES12712955T patent/ES2647667T5/es active Active

- 2012-03-28 FI FIEP12712955.9T patent/FI2691701T4/en active

- 2012-03-28 PL PL12712955.9T patent/PL2691701T5/pl unknown

- 2012-03-28 RS RS20171117A patent/RS56483B2/sr unknown

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5313895A (en) | 1990-11-22 | 1994-05-24 | Hitachi Zosen Corporation | Method of inhibiting formation of unburned substances in refuse incinerator, and refuse incinerator |

| EP1077077A2 (fr) | 1999-08-12 | 2001-02-21 | ABB (Schweiz) AG | Procédé de traitement thermique de matières solides |

| EP1081434A1 (fr) | 1999-08-30 | 2001-03-07 | Von Roll Umwelttechnik AG | Dispositif pour générer un flux gazeux rotatif |

| EP1508745A2 (fr) | 2003-08-22 | 2005-02-23 | Fisia Babcock Environment GmbH | Méthode pour réduire la production de NOx dans les chambres de combustion et équipement pour la mise en oeuvre de la méthode |

| DE102004037442A1 (de) | 2004-08-02 | 2006-03-16 | Alstom Technology Ltd | Verfahren zur thermischen Behandlung von Abfall in einer thermischen Abfallbehandlungsanlage sowie thermische Abfallbehandlungsanlage |

| JP2009121747A (ja) * | 2007-11-15 | 2009-06-04 | Hitachi Zosen Corp | 二次燃焼室における二次燃焼空気の吹き込み方法 |

Non-Patent Citations (5)

| Title |

|---|

| DD, MASSNAHMEN ZUR MINDERUNG FEUERRAUMSEITIGER KORROSIONEN, no. hh |

| F. KRÜL L: "Verfahren zur nummerischen Simulation von Müllrostfeuerung", DISSERTATION, 2001, pages 1 - 237, XP055491976 |

| KRULL: "Die Auswirkung unterschiedlicher Sekundärluftverteilungen auf den Verbrennungsablauf in einer Müllrostfeuerung", pages 1 - 6 |

| OBERNBERGER: "Abbrand- und NOx-Simulation für Biomassefeuerung", BMVIT, September 2003 (2003-09-01), pages 1 - 155, XP002407054 |

| REIMANN D.O.: "Rostfeuerung zur Abfallverbrennung", article FERDINAND KRULL, WALTER BIENERT: "Von der konventionellen W alzenrostfeuerung zurfreiprogrammierbaren Feuerleistungsregelung mitOptimierung der Feuerraumgeometriein der MV A Diisseldorf", pages: 519 - 546 |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2647667T5 (es) | 2024-09-19 |

| EP2691701B2 (fr) | 2024-03-20 |

| FI2691701T4 (en) | 2024-04-04 |

| PL2691701T3 (pl) | 2018-01-31 |

| JP2014513786A (ja) | 2014-06-05 |

| EP2505919A1 (fr) | 2012-10-03 |

| WO2012130446A1 (fr) | 2012-10-04 |

| EP2691701A1 (fr) | 2014-02-05 |

| PL2691701T5 (pl) | 2024-07-15 |

| RS56483B2 (sr) | 2024-04-30 |

| ES2647667T3 (es) | 2017-12-26 |

| US20140182492A1 (en) | 2014-07-03 |

| NO2691701T3 (fr) | 2018-01-20 |

| RS56483B1 (sr) | 2018-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1698827B1 (fr) | Procédé pour brûler des combustibles et plus particulièrement des déchets | |

| DE102006005464B3 (de) | Verfahren zur primärseitigen Stickoxidminderung in einem zweistufigen Verbrennungsprozess | |

| EP2691701B1 (fr) | Procédé d'optimisation de la combustion totale des gaz d'échappement d'une installation de combustion | |

| DE2461078A1 (de) | Verfahren zur verminderung von schadstoffen bei verbrennungsvorgaengen und vorrichtung zur durchfuehrung desselben | |

| DE2300522A1 (de) | Vorrichtung zum verbrennen von brennbzw. treibstoffen | |

| DE3716088A1 (de) | Verfahren zum verbrennen insbesondere von muell | |

| EP0498014A1 (fr) | Procédé pour l'admission d'air de combustion et installation de chauffage | |

| EP0111874A1 (fr) | Installation pour brûler la poussière de charbon | |

| DE3915992A1 (de) | Verfahren zur reduktion von stickstoffoxiden | |

| EP3076076A1 (fr) | Procede de commande de combustion pour foyer a grille et foyer a grille | |

| EP1078203A1 (fr) | Procede de traitement thermique de matieres solides | |

| EP1754937B1 (fr) | Tête de brûleur et procédé pour brûler du combustible | |

| DE4230311C1 (de) | Verfahren und Verbrennungsofen zum Verbrennen von Abfällen | |

| DE4402172C2 (de) | Verfahren zur Verbrennung von Brennstoff und Anlage zur Durchführung des Verfahrens | |

| EP1281026B1 (fr) | Procede et dispositif pour incinerer des sous-produits organiques | |

| DE102006034032B4 (de) | Thermische Abgasreinigungsvorrichtung und Verfahren zur thermischen Abgasreinigung | |

| DE4401821C2 (de) | Verfahren zum Verbrennen von Stoffen, insbesondere von Müll und Biomassen, und Vorrichtung zur Durchführung des Verfahrens | |

| EP4155643A1 (fr) | Dispositif et procédé de séchage de matériau, ainsi qu'installation de mélange d'asphalte doté d'un tel dispositif | |

| EP0611919A1 (fr) | Procédé d'alimentation de gaz de comburant à un incinérateur avec un foyer avec grille et dispositif pour la mise en oeuvre du procédé | |

| DE102004037442B4 (de) | Verfahren zur thermischen Behandlung von Abfall in einer thermischen Abfallbehandlungsanlage sowie thermische Abfallbehandlungsanlage | |

| WO2007028711A1 (fr) | Ensemble de bruleurs pour une chambre de combustion, chambre de combustion correspondante et procede pour bruler un combustible | |

| DE3524962C2 (fr) | ||

| DE3625397C2 (fr) | ||

| EP3260776B1 (fr) | Système de lance, citerne comprenant un système de lance et procédé de réduction de nox | |

| DE2816282C2 (de) | Müllverbrennungsofen mit einem Wirbelbett |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130923 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: WALDNER, MAURICE, HENRI |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20160303 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F23G 5/16 20060101AFI20170208BHEP Ipc: F23L 7/00 20060101ALI20170208BHEP Ipc: F23L 9/02 20060101ALI20170208BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20170322 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: PATENTANWAELTE SCHAAD, BALASS, MENZL AND PARTN, CH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 921750 Country of ref document: AT Kind code of ref document: T Effective date: 20170915 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502012011081 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2647667 Country of ref document: ES Kind code of ref document: T3 Effective date: 20171226 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20170823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171223 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171123 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171124 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502012011081 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: DOOSAN LENTJES GMBH Effective date: 20180517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180328 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 921750 Country of ref document: AT Kind code of ref document: T Effective date: 20180328 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180328 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120328 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170823 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230506 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20240320 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502012011081 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20240321 Year of fee payment: 13 Ref country code: NL Payment date: 20240320 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20240320 Year of fee payment: 13 Ref country code: DE Payment date: 20240320 Year of fee payment: 13 Ref country code: GB Payment date: 20240320 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20240315 Year of fee payment: 13 Ref country code: SE Payment date: 20240320 Year of fee payment: 13 Ref country code: RS Payment date: 20240315 Year of fee payment: 13 Ref country code: PL Payment date: 20240220 Year of fee payment: 13 Ref country code: NO Payment date: 20240322 Year of fee payment: 13 Ref country code: IT Payment date: 20240329 Year of fee payment: 13 Ref country code: FR Payment date: 20240327 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: RPEO |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20240401 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20240426 Year of fee payment: 13 |